About Nuts, Materials, and Finishes

More

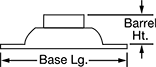

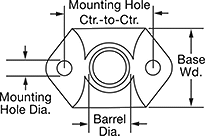

Mil. Spec. Rivet-Mount Nuts

Create threads in hard-to-work areas—where you can’t reach the back of a workpiece, or material is too thin to be tapped. For a strong grip, these nuts have distorted threads that increase friction with bolts. Because they mount with two rivets, they won’t spin when you’re tightening screws. However, these nuts do move inside their retainers, which lets you install bolts at a slight angle; use them to align with off-center parts. All meet military guidelines for dimensions and material.

Cadmium-plated nuts resist corrosion in industrial and saltwater environments, although will lose their corrosion resistance over 450° F. The cadmium plating also adds lubricity, making these nuts easy to install.

A286 stainless steel nuts are corrosion resistant. Silver-plated stainless steel nuts withstand temperatures up to 800° F. The silver plating also adds lubricity and prevents seizing caused by friction between nuts and bolts.

Lubricated nuts thread onto bolts smoothly.

For technical drawings and 3-D models, click on a part number.

Base | Barrel | Mounting | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Dia. | Ht. | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Specifications Met | Each | |

Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21075-04N | 000000000 | 00000 |

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21075-06N | 000000000 | 0000 |

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21075-08N | 000000000 | 0000 |

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21075-3N | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21075-4N | 000000000 | 0000 |

Cadmium-Plated Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21075L04N | 000000000 | 0000 |

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21075L06N | 000000000 | 0000 |

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21075L08N | 000000000 | 0000 |

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21075L3N | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21075L4N | 000000000 | 0000 |

Carbon Steel—Unlubricated | |||||||||||

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21059-06 | 000000000 | 0000 |

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21059-08 | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21059-3 | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21059-4 | 000000000 | 0000 |

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 0.375" | 9/32" | 2 | 0.13" | 1" | MS21059-5 | 000000000 | 00000 |

Cadmium-Plated Carbon Steel—Lubricated | |||||||||||

| 4-40 | 61/64" | 13/32" | 1/32" | 0.141" | 9/64" | 2 | 0.098" | 11/16" | MS21059L04 | 000000000 | 0000 |

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21059L06 | 000000000 | 0000 |

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21059L08 | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21059L3 | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21059L4 | 000000000 | 0000 |

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 0.375" | 9/32" | 2 | 0.13" | 1" | MS21059L5 | 000000000 | 00000 |

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21059L6 | 000000000 | 00000 |

A286 Stainless Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076L04N | 000000000 | 00000 |

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21076L06N | 000000000 | 00000 |

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21060L06 | 000000000 | 00000 |

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21076L08N | 000000000 | 0000 |

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21060L08 | 000000000 | 0000 |

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076L3N | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060L3 | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076L4N | 000000000 | 0000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060L4 | 000000000 | 00000 |

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076L5N | 000000000 | 00000 |

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 0.375" | 9/32" | 2 | 0.13" | 1" | MS21060L5 | 000000000 | 00000 |

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21060L6 | 000000000 | 00000 |

Silver-Plated A286 Stainless Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076-04N | 000000000 | 00000 |

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21060-06 | 000000000 | 0000 |

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21076-08N | 000000000 | 00000 |

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076-3N | 000000000 | 0000 |

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060-3 | 000000000 | 0000 |

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076-4N | 000000000 | 00000 |

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060-4 | 000000000 | 00000 |

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076-5N | 000000000 | 00000 |

Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong, permanent hold. They stand up to high torque and pulling force better than rivet nuts.

For the strongest threads, choose steel nuts. Nuts with a steel retainer should be welded to uncoated steel surfaces. Zinc-plated steel nuts resist corrosion in wet environments. Nuts with an aluminum retainer should be welded to aluminum surfaces.

For the most corrosion resistance, choose stainless steel nuts. They have a stainless steel retainer, so they should be welded to stainless steel surfaces.

For technical drawings and 3-D models, click on a part number.

Base | |||||||

|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Ht. | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 6-32 | 1 1/2" | 1/2" | 3/64" | 29/64" | 1 | 000000000 | 00000 |

| 8-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 10-24 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 10-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 1/4"-28 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 5/16"-24 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-16 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-24 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

| 7/16"-14 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 00000 |

| 1/2"-13 | 2 1/4" | 15/16" | 1/16" | 51/64" | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with 5052 Aluminum Retainer | |||||||

| 10-32 | 1 1/2" | 1/2" | 3/64" | 11/32" | 10 | 000000000 | 00000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 10 | 000000000 | 00000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 10 | 000000000 | 00000 |

| 3/8"-16 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with C1008/C1010 Steel Retainer | |||||||

| 10-24 | 1 1/2" | 1/2" | 3/64" | 11/32" | 5 | 000000000 | 0000 |

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 7/16" | 5 | 000000000 | 0000 |

| 5/16"-18 | 2" | 25/32" | 1/16" | 33/64" | 5 | 000000000 | 00000 |

Stainless Steel Nut with Stainless Steel Retainer | |||||||

| 1/4"-20 | 1 3/4" | 9/16" | 1/16" | 11/32" | 1 | 000000000 | 00000 |

Metric Aligning Weld Nuts

Threads float inside the retainer so you can install a bolt at a slight angle to align with off-center parts. Weld these nuts to metal surfaces for a strong permanent hold. They stand up to high torque and pulling force better than rivet nuts.

Weld steel nuts with a steel retainer to uncoated steel surfaces.

Weld zinc-plated steel nuts with an aluminum retainer to aluminum surfaces. They resist corrosion in wet environments.

For technical drawings and 3-D models, click on a part number.

Thread | Base | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Lg., mm | Wd., mm | Thick., mm | Ht., mm | Pkg. Qty. | Pkg. | |

Steel Nut with C1008/C1010 Steel Retainer | ||||||||

| M5 | 0.8 | 38.1 | 12.7 | 1.06 | 8.6 | 5 | 000000000 | 000000 |

| M6 | 1 | 38.1 | 12.7 | 1.06 | 8.6 | 10 | 000000000 | 00000 |

| M8 | 1.25 | 50.8 | 19.8 | 1.27 | 13.7 | 5 | 000000000 | 00000 |

| M10 | 1.5 | 50.8 | 19.8 | 1.27 | 13 | 5 | 000000000 | 00000 |

| M12 | 1.75 | 58.7 | 23.8 | 1.27 | 20.2 | 5 | 000000000 | 00000 |

Zinc-Plated Steel Nut with 5052 Aluminum Retainer | ||||||||

| M10 | 1.5 | 50.8 | 19.8 | 1.27 | 13 | 5 | 000000000 | 00000 |

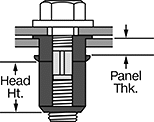

Steel Snap-In Nuts

Snap these nuts—also known as cage nuts—into square holes in thin material. They’re often used to mount servers and other equipment in electronics racks. Threads float inside the cage, so you can fasten a bolt at a slight angle to align off-center parts. Mounting legs expand to lock these nuts in place.

Install these nuts by hand, with pliers, or with a snap-in nut installation and removal tool.

Black-phosphate steel nuts are mildly corrosion resistant in dry environments.

Zinc-plated steel nuts resist corrosion in wet environments.

| Thread Size | Thread Pitch | For Panel Thick. | Square Hole Size | Wd. | Head Ht. | Pkg. Qty. | Pkg. | |

Black-Phosphate Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10-24 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 000000 |

| 10-24 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 15 | 000000000 | 0000 |

| 10-32 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 10 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.52" | 0.25" | 10 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.023" to 0.063" | 0.503" to 0.508" | 0.65" | 0.33" | 10 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.057" to 0.092" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 3/8"-16 | __ | 0.093" to 0.126" | 0.588" to 0.593" | 0.87" | 0.41" | 5 | 000000000 | 0000 |

Zinc-Plated Steel | ||||||||

| 6-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 8-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 8-32 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 8-32 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 10 | 000000000 | 0000 |

| 10-24 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-24 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-24 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 10-32 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| 12-24 | __ | 0.063" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.53" | 0.25" | 25 | 000000000 | 00000 |

| 5/16"-18 | __ | 0.028" to 0.056" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.057" to 0.092" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.127" to 0.162" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.028" to 0.056" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.057" to 0.092" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

| 3/8"-16 | __ | 0.127" to 0.162" | 0.503" to 0.508" | 0.7" | 0.3" | 15 | 000000000 | 00000 |

| 3/8"-16 | __ | 0.162" to 0.21" | 0.573" to 0.578" | 0.87" | 0.41" | 1 | 000000000 | 0000 |

| 3/8"-16 | __ | 0.24" to 0.26" | 0.588" to 0.593" | 0.87" | 0.41" | 1 | 000000000 | 0000 |

| 1/2"-13 | __ | 0.093" to 0.126" | 0.588" to 0.593" | 0.87" | 0.41" | 5 | 000000000 | 00000 |

Metric Black-Phosphate Steel | ||||||||

| M8 | 1.25mm | 6.1mm to 6.6mm | 0.503" to 0.508" | 0.66" | 0.3" | 10 | 000000000 | 0000 |

Metric Zinc-Plated Steel | ||||||||

| M5 | 0.8mm | 0.7mm to 1.6mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M5 | 0.8mm | 1.7mm to 2.6mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M5 | 0.8mm | 2.4mm to 3.2mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M5 | 0.8mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 0.7mm to 1.6mm | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 1.7mm to 2.6mm | 0.375" to 0.38" | 0.52" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 2.4mm to 3.2mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M6 | 1mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.54" | 0.25" | 25 | 000000000 | 00000 |

| M8 | 1.25mm | 0.7mm to 1.4mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

| M8 | 1.25mm | 1.5mm to 2.3mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M8 | 1.25mm | 2.4mm to 3.2mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M8 | 1.25mm | 3.2mm to 4.1mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

| M10 | 1.5mm | 1.5mm to 2.3mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M10 | 1.5mm | 2.4mm to 3.2mm | 0.503" to 0.508" | 0.7" | 0.3" | 10 | 000000000 | 00000 |

| M10 | 1.5mm | 3.2mm to 4.1mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

| M10 | 1.5mm | 4.1mm to 5mm | 0.503" to 0.508" | 0.66" | 0.3" | 1 | 000000000 | 0000 |

Stainless Steel Snap-In Nuts

For excellent corrosion resistance in most environments, these nuts are made of 18-8 stainless steel. Snap them into square holes in thin material, and the mounting legs expand to lock them in place. Also known as cage nuts, the threads float inside the cage, so you can fasten a bolt at a slight angle to align off-center parts. These nuts are often used to mount servers and other equipment in electronics racks. They may be mildly magnetic.

Install these nuts by hand, with pliers, or with a snap-in nut installation and removal tool.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Thread Pitch | For Panel Thick. | Square Hole Size | Wd. | Head Ht. | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10-24 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 000000 |

| 10-24 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-24 | __ | 0.093" to 0.126" | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-24 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-32 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 10-32 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.49" | 0.25" | 5 | 000000000 | 0000 |

| 10-32 | __ | 0.093" to 0.126" | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 10-32 | __ | 0.125" to 0.156" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| 1/4"-20 | __ | 0.025" to 0.063" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.064" to 0.105" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.093" to 0.126" | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 1/4"-20 | __ | 0.125" to 0.156" | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| 5/16"-18 | __ | 0.093" to 0.126" | 0.503" to 0.508" | 0.66" | 0.29" | 1 | 000000000 | 0000 |

Metric 18-8 Stainless Steel | ||||||||

| M5 | 0.8mm | 0.7mm to 1.6mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M5 | 0.8mm | 1.7mm to 2.6mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M5 | 0.8mm | 2.4mm to 3.2mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 00000 |

| M5 | 0.8mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 0.7mm to 1.6mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 1.7mm to 2.6mm | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 2.4mm to 3.2mm | 0.343" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

| M6 | 1mm | 3.2mm to 3.9mm | 0.375" to 0.38" | 0.52" | 0.25" | 5 | 000000000 | 0000 |

Easy-to-Install Snap-In Nuts

Pinch the flexible plastic casing of these nuts to add threads to thin metal. Unlike typical rigid snap-in nuts, these squeeze into a square hole from the front or back of your material. Once installed, they stay put. They meet DIN EN 61373, so they’re certified for use in environments with heavy vibration—think a bumpy railcar. GR-63-CORE tested, they’ve also passed earthquake simulations. In your facility, this means you can trust them to hold tight to sensitive equipment, like the servers suspended on your electrical racks.

Also known as cage nuts, they come in two parts—the cage and the nut—that you combine before installation. Threads float inside the cage, so you can fasten a bolt at a slight angle to align with off-center parts.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Thread Pitch, mm | For Panel Thick., mm | Square Hole Size | Wd. | Head Ht. | Case Material | Specifications Met | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M6 | 1 | 1 to 4 | 0.362" to 0.375" | 0.5" | 0.41" | Plastic | DIN EN 61373; GR-63-CORE, Issue 4 | 10 | 000000000 | 000000 |

Clip-On Nuts for Flanged Edges

--11177024b411582304949-p9@halfx_637181330299885752.png?ver=imagenotfound)

Slide these nuts on the edge of a panel and position them by hand. Also known as G-style clip-on nuts, they have threads that float inside the retainer so you can install a bolt at a slight angle to align off-center parts.

Zinc-plated steel clip-on nuts are corrosion resistant in wet environments.

Black-phosphate steel clip-on nuts are mildly corrosion resistant in dry environments.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Thread Pitch | For Panel Thick. | Distance from Ctr. of Hole to Edge (A) | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | ||||||

|---|---|---|---|---|---|---|

| 10-32 | __ | 0.069" to 0.079" | 0.285" | 10 | 000000000 | 00000 |

| 12-24 | __ | 0.069" to 0.079" | 0.285" | 5 | 000000000 | 0000 |

| M5 | 0.8 mm | 1.75mm to 2mm | 7.23mm | 10 | 000000000 | 0000 |

| M6 | 1 mm | 1.75mm to 2mm | 8mm | 10 | 000000000 | 00000 |

Black-Phosphate Steel | ||||||

| 10-32 | __ | 0.069" to 0.079" | 0.26" | 10 | 000000000 | 0000 |

| 12-24 | __ | 0.069" to 0.079" | 0.285" | 5 | 000000000 | 0000 |