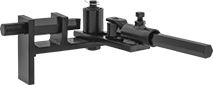

Wire, Rod, and Flat Stock Benders

Bend wire and rod up to 1/2" diameter and flat stock up to 1/4"×1" with this rugged steel bender. Use it to create hooks, brackets, and pipe hangers. It can be clamped in a vise.

For technical drawings and 3-D models, click on a part number.

For Max. Flat Stock | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Die Dia. | For Max. Wire Dia. | Thick. | Wd. | For Max. Rod Dia. | Material | Lg. | Wd. | Ht. | Each | |

For Brass, Copper, Stainless Steel, Steel | ||||||||||

| 3/4", 1 1/4", 1 5/8" | 1/2" | 1/4" | 1" | 1/2" | Steel | 20" | 2" | 5" | 0000000 | 000000 |

Economy Wire, Rod, and Flat Stock Benders

Bend wire and rod up to 3/8" diameter and flat stock up to 1/2"×3/16" to create hooks, brackets, and pipe hangers. They can be clamped in a vise.

For technical drawings and 3-D models, click on a part number.

Wire, Rod, and Flat Stock Curvers

Also known as ring rollers, these curvers shape wire, rods, and flat stock into curves and circles. Turn the handle to drive material through the steel rollers. With each pass through the rollers, tighten the tensioner knob in small increments to gradually increase the curve.

Curvers with stand come with three sets of rollers—one for flat stock and two for wire and rods. They can apply pressure from either side of the bottom roller, creating more curve options.

For Max. Flat Stock | Stand | Mounting Holes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Wire Dia. | Thick. | Wd. | For Rod Dia. | Min. Bending Radius | Material | Ht. | Wd. | Dp. | Handle Lg. | Roller Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Copper, Stainless Steel, Steel | ||||||||||||||||||

| 1/4" | 3/16" | 1" | 1/4" | 1 1/2" | Steel | 5 1/2" | 6 1/2" | 5 1/2" | 13 1/2" | 1 1/4" | __ | __ | __ | No | 2 | 3/8" | 0000000 | 0000000 |

| 1/4", 1/2" | 3/16" | 1" | 1/4", 1/2" | 1 3/8" | Steel | 6 3/4" | 5 1/2" | 9 3/4" | 9" | 1 13/16" | 39" | 21" | 21" | Yes | 2 | 5/16" | 0000000 | 000000 |

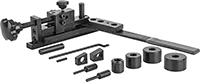

Wire, Rod, and Flat Stock Benders for Complex Shapes

Create squares, coils, and S-shapes. This bender can be mounted to your bench top or clamped in a vise. Circle pins make additional sizes of bends and coils.

For Max. Flat Stock | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. Wire Dia. | Thick. | Wd. | For Max. Rod Dia. | Pin Dia. | Material | Lg. | Wd. | Ht. | Mounting Fasteners Included | No. of | Dia. | Handle Lg. | Includes | Each | |

For Brass, Copper, Stainless Steel, Steel | |||||||||||||||

| 5/16" | 1/8" | 1" | 5/16" | 3/16", 1/4", 1/2", 1", 1 1/4", 1 1/2", 1 3/4" | Steel | 9 1/2" | 2 1/2" | 3 1/2" | No | 2 | 5/16" | 12" | Forming Pin, Seven Circle Pins, Stop Pin, Two Sharp-Angle Dies | 0000000 | 0000000 |

Benchtop Rolling Mills

With hardened rollers and precision-machined gears, these rolling mills stand up to heavy use. They’re often used to compress sheets to an uncommon gauge size, convert scrap metal into sheets or wire, or create different thicknesses in a single piece of metal without welding multiple pieces together. After several passes through the mill, you may need to anneal your metal to soften it and prevent cracking.

Manual mills are gear driven, making them easier to turn than direct-drive rolling mills. Their rollers have grooves so you can form square and half-round wire in addition to sheets.

Electric mills do not require hand cranking, so they provide the power you need to complete high volumes of work. They have flat rollers for creating uniform sheets.

Gear speed ratio indicates the force it takes to turn the output gear. For instance, the manual rolling mill has a 4:1 gear ratio, meaning that you rotate the handle four times to turn the gear powering the rollers once.

For Max. Steel | Roller | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Thick. | Square Wire Size | Half-Round Wire Size | Gear Speed Ratio | Ht. | Wd. | Dp. | Handle Lg. | Dia. | No. of | Material | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||

| 2 9/16" | 3/16" | 3/64", 5/64", 1/8", 5/32", 3/16", 13/64", 7/32", 15/64", 1/4" | 0.098", 0.118", 0.157" | 4:1 | 14" | 12" | 8" | 12" | 2 1/2" | 2 | Steel | Cast Iron | No | 6 | 3/8" | 0000000 | 0000000 |

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Thick. | Gear Speed Ratio | Ht. | Wd. | Dp. | Dia. | No. of | Material | Frame Material | Horsepower, hp | Max. rpm | Current, A | Voltage | Cord Lg., ft. | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||

| 6 1/4" | 3/16" | 100:1 | 19" | 22" | 15" | 2 1/2" | 2 | Steel | Cast Iron | 1/2 | 13 | 1.7 | 120V AC | 5 | No | 4 | 1/2" | 0000000 | 000000000 |