Flat-Surface Brackets

For technical drawings and 3-D models, click on a part number.

Lg. | Mounting | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Appearance | (A) | (B) | (C) | Thick. | Capacity | Fasteners Included | Number of Holes | Hole Style | For Screw Size | 1-49 | 50-Up | ||

| 1 | Zinc-Plated Steel | Dull | 1 1/2" | 3/8" | 1 1/2" | 0.06" | Not Rated | No | 4 | Countersunk | No. 5 | 0000000 | 00000 | 00000 |

| 1 | Zinc-Plated Steel | Dull | 2" | 3/8" | 2" | 0.07" | Not Rated | No | 4 | Countersunk | No. 5 | 0000000 | 0000 | 0000 |

| 1 | Zinc-Plated Steel | Dull | 2 1/2" | 1/2" | 2 1/2" | 0.06" | Not Rated | No | 4 | Countersunk | No. 6 | 0000000 | 0000 | 0000 |

| 1 | Zinc-Plated Steel | Dull | 3 1/2" | 5/8" | 3 1/2" | 0.07" | Not Rated | No | 4 | Countersunk | No. 8 | 0000000 | 0000 | 0000 |

| 1 | Zinc-Plated Steel | Dull | 6" | 1" | 6" | 0.08" | Not Rated | No | 6 | Countersunk | No. 9 | 0000000 | 0000 | 0000 |

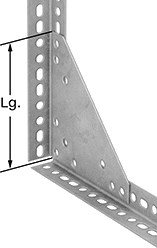

Flat and Angled Bolt-Together Framing and Fittings

Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

For technical drawings and 3-D models, click on a part number.

Surface brackets connect rails.

Galvanized steel brackets have better corrosion resistance in wet environments than zinc-plated steel brackets, and they can be used outdoors.

| Lg. | Thick. | Material | Mounting Hole Shape | For Screw Size | Mounting Fasteners Included | Each | |

| 6" | 0.08" | Galvanized Steel | Round | 5/16" | No | 0000000 | 00000 |

Easy-to-Machine 6005 Aluminum

- Yield Strength: 35,000 psi

- Hardness: Brinell 85 (Soft)

- Temper: T61

- Fabrication: Extruded

- Specifications Met: ASTM B221

Often used in structural applications to reinforce joints, these 6005 aluminum triangular tubes are lightweight, corrosion resistant, and easier to machine and form than 6061 aluminum. You can fabricate them into a custom bracket, also called a gusset, by drilling mounting holes on the sides that form the 90° angle. To access the mounting holes, you'll also need to drill holes or a slot on the angled side. These triangular tubes can also be welded into place.

For technical drawings and 3-D models, click on a part number.