How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

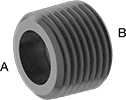

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line.

Fittings that meet ANSI/MSS SP-114 adhere to high-quality standards for heat treating, material thickness, and marking. 304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Locknuts thread onto the male end of a fitting to provide extra holding power so the fitting won’t loosen from vibration.

NPTF (Dryseal) threads and NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class:

NPSL: 150 - Fabrication:

NPSL: Heat Treated - Specifications Met:

NPSL: ANSI/MSS SP-114, ASTM A351

BSPP: DIN 431 - Pipe Nipples and Pipe:

NPSL: Use Schedule 40 stainless steel - Flanges:

NPSL: Use Class 150 stainless steel

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Adapters for tanks create an inlet or outlet connection on the surface of any tank, pressure vessel, or drum. Adapters with weld end allow for a permanent connection. Adapters with extension fit tightly into the hole, which keeps the fitting steady during welding.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: See table

- Specifications Met: ASME B16.14

- Pipe Nipples and Pipe: Use Schedule 40 steel

Pipe Size | |||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | Pressure Class | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male × NPT Female | |||||||

| 1/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 00000 |

| 3/8 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1/2 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 3/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

Extreme-Pressure Steel Threaded Pipe Fittings

The strongest steel fittings we offer, these can withstand extreme-pressure applications.

Galvanized and zinc-plated steel fittings have better corrosion resistance than plain steel fittings. PTFE-coated steel fittings have better corrosion resistance than galvanized and zinc-plated steel fittings.

Locknuts thread onto the male end of a fitting to provide extra holding power so the fitting won’t loosen from vibration.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Temperature Range: -100° to 500° F

- Pipe Nipples and Pipe: Use Schedule XXH steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | ||||||

|---|---|---|---|---|---|---|

| 1/8 | 02 | 10,000 psi @ 72° F | 5,000 psi @ 500° F | Galvanized Steel | 0000000 | 000000 |

Low-Pressure Aluminum Threaded Pipe Fittings

In addition to being lightweight, these aluminum fittings offer good corrosion resistance. Use them in low-pressure flow applications. To prevent cracking, do not tighten more than a 1/4-turn past hand tight.

Adapters for tanks weld onto the surface of any tank, pressure vessel, or drum to create a permanent inlet or outlet connection. Adapters with extended lip fit tightly into the hole, which keeps the fitting steady during welding.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water, Oil, Gasoline, Diesel Fuel

- Specifications Met: ASTM B221

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

| Pipe Size | For Hole Dia. | OD | Lg. | Each | |

NPT Female × Weld | |||||

|---|---|---|---|---|---|

| 1/8 | 7/8" | 1 5/16" | 1/4" | 0000000 | 00000 |

Medium-Pressure Aluminum Threaded Pipe Fittings

Designed for medium-pressure applications, these fittings have better strength than our low-pressure aluminum pipe fittings. They are lightweight with good corrosion resistance.

Fittings with blue anodized finish have better corrosion resistance and a harder surface than plain aluminum fittings.

BSPP male threads have a gasket to protect against leaks.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Oil, Water

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

| Pipe Size | Max. Pressure | Each | |

BSPT Female | |||

|---|---|---|---|

| 1/8 | 250 psi @ 72° F | 0000000 | 00000 |

- For Use With: Air, Oil, Water

| Pipe Size | Max. Pressure | Color | Finish | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/8 | 500 psi @ 72° F | Blue | Anodized | 0000000 | 00000 |

- For Use With: Air, Oil, Water

| Pipe Size | Max. Pressure | Color | Finish | Each | |

NPT Male | |||||

|---|---|---|---|---|---|

| 1/8 | 500 psi @ 72° F | Blue | Anodized | 0000000 | 00000 |

- For Use With: Air, Oil, Water

- Specifications Met: ASME B1.20.1, ASTM B241

- For Use With: Air, Oil, Water

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

Pipe Size | ||||

|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Each | |

BSPT Male × BSPT Female | ||||

| 1/4 | 1/8 | 250 psi @ 72° F | 0000000 | 000000 |

Low-Pressure Brass and Bronze Threaded Pipe Fittings

Use these fittings in low-pressure flow applications. They have good corrosion resistance. Fittings rated for use with drinking water meet NSF/ANSI 61 safety standards.

Locknuts thread onto the male end of a fitting to provide extra holding power so the fitting won’t loosen from vibration.

NPSL (National Pipe Straight Locknut) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Pressure Class: See table

- Specifications Met: See table

- Pipe Nipples and Pipe: See table

- Flanges: See table

For Pipe | For Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Pressure Class | Material | Schedule | Material | Class | Material | For Use With | Specifications Met | Each | |

NPSL Female | |||||||||||

| 1/8 | 200 psi @ 72° F | 125 | Brass | 40 | Brass | 150 | Brass | Air, Drinking Water, Natural Gas, Oil | ASME B1.20.1, ASME B16.15, ASTM A584, NSF/ANSI 61 | 00000000 | 00000 |

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

For technical drawings and 3-D models, click on a part number.

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with threaded pipe end require PTFE tape for sealing the threads.

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with threaded pipe end require PTFE tape for sealing the threads.

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Pipe Size | Material | Max. Vacuum | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.18" | 10 | ISO-KF | 1/8 | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 00000000 | 000000 |

| 3/4" | 1.18" | 16 | ISO-KF | 1/8 | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 1/8 | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1/8 | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 00000000 | 000000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever | ||||||||

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Fluoroelastomer O-Ring: 0° to 300° F

Fittings with Silicone O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 1/2" | 1.18" | 10 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 0000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 0000000 | 00000 |

Rings with Stainless Steel Screen | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 75 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 1/2" | 1.18" | 10 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

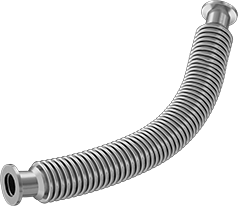

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

3 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

4 3/16" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 3/4" | 1 3/16" | 16 | 10 -7 torr @ 72° F | 304 Stainless Steel | 4 1/8" | 2 1/4" | 00000000 | 0000000 |

| Manual | 1" | 1 9/16" | 25 | 10 -7 torr @ 72° F | 304 Stainless Steel | 5 5/8" | 3" | 00000000 | 000000 |

| Manual | 1 1/2" | 2 1/8" | 40 | 10 -7 torr @ 72° F | 304 Stainless Steel | 6 3/8" | 3 7/8" | 00000000 | 000000 |

Quick-Clamp High-Vacuum Fittings for Aluminum Tubing

- For Use With: Air

- Specifications Met: ISO 2861

For use in high-vacuum systems, these fittings use a metal reinforced O-ring to create an airtight seal. To form a complete connection, pair two adapters with a clamp and a ring (all sold separately). Made of aluminum, these fittings are lightweight and resist corrosion. This and the airtight seal make them a good choice for vacuum coating, heat treating, or leak testing. Also known as KF, QF, and NW fittings.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: 0° to 300° F

- Tubing: Use with aluminum

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Pipe Size | Material | Max. Vacuum | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.18" | 10 | ISO-KF | 1/8 | Aluminum | 1 × 10 -7 torr @ 72° F | 0000000 | 000000 |

| 3/4" | 1.18" | 16 | ISO-KF | 1/8 | Aluminum | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 1/8 | Aluminum | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1/8 | Aluminum | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Connect quick-clamp fittings in high-vacuum applications. Clamps tighten by hand. They are aluminum, which is lightweight with good corrosion resistance.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever | ||||||||

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range: 0° to 350° F

- Tubing: Use with aluminum

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | O-Ring Material | Max. Vacuum | Each | |

| 1/2" | 1.18" | 10 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 0000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 0000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

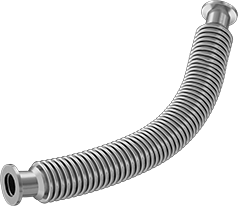

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Hose absorbs moderate vibration.

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

3 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

4 3/16" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 1/2" | 1 3/16" | 10 | 10 -7 torr @ 72° F | 304 Stainless Steel | 4 1/8" | 2 1/4" | 00000000 | 0000000 |

| Manual | 3/4" | 1 3/16" | 16 | 10 -7 torr @ 72° F | 304 Stainless Steel | 4 1/8" | 2 1/4" | 00000000 | 000000 |

| Manual | 1" | 1 9/16" | 25 | 10 -7 torr @ 72° F | 304 Stainless Steel | 5 5/8" | 3" | 00000000 | 000000 |

| Manual | 1 1/2" | 2 1/8" | 40 | 10 -7 torr @ 72° F | 304 Stainless Steel | 6 3/8" | 3 7/8" | 00000000 | 000000 |