How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

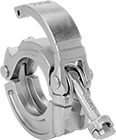

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

316 stainless steel fittings have excellent corrosion resistance.

3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

For technical drawings and 3-D models, click on a part number.

- For Use With:

316/316L Stainless Steel: Air, Beverage, Water

316 Stainless Steel: Air, Beverage, Dairy, Food, Water - Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: See Table

Fittings with bolt-on flange end connect to a same-size bolt-on flange with a gasket (sold separately) to create an access point within a line.

Bolt Hole | 316/316L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Tube Flange OD | Pipe Size | Pipe Flange OD | Bolt Circle Dia. | Dia. | No. of | Bolts Included | Specifications Met | Each | |

| 1" | 1.984" | 1 | 4 1/4" | 3 1/8" | 5/8" | 4 | No | 3-A Certified 63-04 | 000000000 | 0000000 |

| 1 1/2" | 1.984" | 1 1/2 | 5" | 3 7/8" | 5/8" | 4 | No | 3-A Certified 63-04 | 000000000 | 000000 |

| 2" | 2.516" | 2 | 6" | 4 3/4" | 3/4" | 4 | No | 3-A Certified 63-04 | 000000000 | 000000 |

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2" | 1.900" | 2.520" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

EPDM Rubber | ||||||||

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

For Tube OD | |||||||

|---|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Includes | Each | |

| 1" | 1" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 0000000 |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

| 2" | 2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.64" | 2.516" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.64" | 2.516" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Sanitary Sampling Stainless Steel Tube Fittings

- For Use With: Dairy, Beverage, Water, Air, Food

- Tubing: Use with welded 316/316L stainless steel

- Specifications Met: 3-A Certified 63-03

Take samples in sanitary environments—these tube fittings won’t contaminate your lines or force you to pause them. Made of 316L stainless steel, they’ll stand up to harsh cleaners and sanitizers without corroding. They also have polished internal surfaces, minimizing the space where bacteria could grow. With quick-clamp connections, they are easy to take apart for cleaning or reconfiguring your line. All are 3-A certified to meet sanitary design standards, so they’re often used in food and beverage, pharmaceutical, and biotech applications.

All fittings require pierceable lids (sold separately) to draw samples through a hypodermic needle. Each lid is good for seven samples, and each sample leaves a hole mark, so you know when it’s time to unscrew the nut on the tube fitting and swap in a new lid. To help prevent dust and moisture from accumulating on the lid, all tube fittings have a dust cover. These lids are FDA compliant, so they keep contaminants from entering your line and also are approved for direct contact with food if they break off and fall in. Manufactured free of contaminants and allergens, all are BPA-, latex-, and phthalate-free. They’re also TSE/BSE compliant, meaning they’ve never come into contact with any animal products.

Pair these tube fittings with liquid samplers for a sample. They use gravity to draw out liquid through the needle directly into the bag.

For technical drawings and 3-D models, click on a part number.

Bag | Needle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, ml | Ht. | Wd. | Thick., mil | Gauge | Lg. | ID | OD | Material | Connection Type | Color | Specifications Met | Each | |

PVC Plastic | |||||||||||||

| 250 | 8" | 5" | 14 | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | ISO 10993, USP Class VI | 0000000 | 00000 |

| 2,000 | 14" | 7" | 14 | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | ISO 10993, USP Class VI | 0000000 | 0000 |

Clamps for Quick-Clamp Fittings for Dairy

- Temperature Range: 0° to 140° F

- Tubing: Use with soft (Durometer 50A-65A) silicone rubber

- Specifications Met: FDA Compliant 21 CFR 177.1500, USP Class VI

Use these clamps with quick-clamp fittings to quickly connect and disconnect your line as needed.

For technical drawings and 3-D models, click on a part number.

Ultra-Chemical-Resistant Food Industry

Compressible PTFE Pipe Gaskets with Bolt Holes

Made of FDA-listed material for use with food and beverage, these soft expanded PTFE gaskets compress to ensure a tight seal. They are chemically inert (except to molten alkali metal and fluorine compounds). Commonly called full-face gaskets, they cover the entire face of flat-surface pipe flanges and align with the bolt holes. All gasket specifications are sized to meet ANSI standards. Gaskets for ANSI Class 150 flanges are compatible with low-pressure pipe flanges. Gaskets for ANSI Class 300 flanges are compatible with medium-pressure pipe flanges.

For technical drawings and 3-D models, click on a part number.

| For Pipe Size | ID | OD | No. of Bolt Holes | Temperature Range, °F | Color | Specifications Met | Each | |

1/16" Thick. | ||||||||

|---|---|---|---|---|---|---|---|---|

For ANSI Class 150 | ||||||||

| 1/2 | 27/32" | 3 1/2" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3/4 | 1 1/16" | 3 7/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 | 1 5/16" | 4 1/4" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/4 | 1 21/32" | 4 5/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/2 | 1 29/32" | 5" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 | 2 3/8" | 6" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 1/2 | 2 7/8" | 7" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 | 3 1/2" | 7 1/2" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 1/2 | 4" | 8 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 4 | 4 1/2" | 9" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 5 | 5 9/16" | 10" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 6 | 6 5/8" | 11" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 8 | 8 5/8" | 13 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

For ANSI Class 300 | ||||||||

| 1/2 | 27/32" | 3 3/4" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 3/4 | 1 1/16" | 4 5/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 1 | 1 5/16" | 4 7/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 1 1/4 | 1 21/32" | 5 1/4" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 1 1/2 | 1 29/32" | 6 1/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 2 | 2 3/8" | 6 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 2 1/2 | 2 7/8" | 7 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 3 | 3 1/2" | 8 1/4" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 4 | 4 1/2" | 10" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

1/8" Thick. | ||||||||

For ANSI Class 150 | ||||||||

| 1/2 | 27/32" | 3 1/2" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 3/4 | 1 1/16" | 3 7/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 1 | 1 5/16" | 4 1/4" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 1 1/4 | 1 21/32" | 4 5/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 1 1/2 | 1 29/32" | 5" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 | 2 3/8" | 6" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 1/2 | 2 7/8" | 7" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 | 3 1/2" | 7 1/2" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 1/2 | 4" | 8 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 4 | 4 1/2" | 9" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 5 | 5 9/16" | 10" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 6 | 6 5/8" | 11" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 8 | 8 5/8" | 13 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 000000 |

For ANSI Class 300 | ||||||||

| 1/2 | 27/32" | 3 3/4" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3/4 | 1 1/16" | 4 5/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 1 | 1 5/16" | 4 7/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 1 1/4 | 1 21/32" | 5 1/4" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 1 1/2 | 1 29/32" | 6 1/8" | 4 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 | 2 3/8" | 6 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 1/2 | 2 7/8" | 7 1/2" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 | 3 1/2" | 8 1/4" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 4 | 4 1/2" | 10" | 8 | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

Ultra-Chemical-Resistant Food Industry Compressible PTFE Pipe Gaskets

These soft expanded PTFE gaskets are made of FDA-listed material for use with food and beverage. They are chemically inert (except to molten alkali metal and fluorine compounds) and are compressible to ensure a tight seal. Also known as ring gaskets, use them with raised-surface pipe flanges; they fit the surface inside the bolt holes and do not interfere with the bolt connection. All gasket specifications are sized to meet ANSI standards. Gaskets for ANSI Class 150 flanges are compatible with low-pressure pipe flanges. Gaskets for ANSI Class 300 flanges are compatible with medium-pressure pipe flanges.

For technical drawings and 3-D models, click on a part number.

| For Pipe Size | ID | OD | Temperature Range, °F | Color | Specifications Met | Each | |

1/16" Thick. | |||||||

|---|---|---|---|---|---|---|---|

For ANSI Class 150 | |||||||

| 1/2 | 27/32" | 1 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3/4 | 1 1/16" | 2 1/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 | 1 5/16" | 2 5/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/4 | 1 21/32" | 3" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/2 | 1 29/32" | 3 3/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 2 | 2 3/8" | 4 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 2 1/2 | 2 7/8" | 4 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 | 3 1/2" | 5 3/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 4 | 4 1/2" | 6 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 000000 | 00000 |

| 5 | 5 9/16" | 7 3/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 6 | 6 5/8" | 8 3/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 8 | 8 5/8" | 11" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

For ANSI Class 300 | |||||||

| 1/2 | 27/32" | 2 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 3/4 | 1 1/16" | 2 5/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 1 | 1 5/16" | 2 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 1 1/4 | 1 21/32" | 3 1/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 1 1/2 | 1 29/32" | 3 3/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 2 | 2 3/8" | 4 3/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 0000 |

| 2 1/2 | 2 7/8" | 5 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 3 | 3 1/2" | 5 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 3 1/2 | 4" | 6 1/2" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 4 | 4 1/2" | 7 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 5 | 5 9/16" | 8 1/2" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 6 | 6 5/8" | 9 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

| 8 | 8 5/8" | 12 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 00000000 | 00000 |

1/8" Thick. | |||||||

For ANSI Class 150 | |||||||

| 1/2 | 27/32" | 1 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 3/4 | 1 1/16" | 2 1/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 | 1 5/16" | 2 5/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/4 | 1 21/32" | 3" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/2 | 1 29/32" | 3 3/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 2 | 2 3/8" | 4 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 1/2 | 2 7/8" | 4 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 | 3 1/2" | 5 3/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 4 | 4 1/2" | 6 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 5 | 5 9/16" | 7 3/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 6 | 6 5/8" | 8 3/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 8 | 8 5/8" | 11" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

For ANSI Class 300 | |||||||

| 1/2 | 27/32" | 2 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 3/4 | 1 1/16" | 2 5/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 | 1 5/16" | 2 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/4 | 1 21/32" | 3 1/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 0000 |

| 1 1/2 | 1 29/32" | 3 3/4" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 | 2 3/8" | 4 3/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 2 1/2 | 2 7/8" | 5 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 | 3 1/2" | 5 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 3 1/2 | 4" | 6 1/2" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 4 | 4 1/2" | 7 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 5 | 5 9/16" | 8 1/2" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 6 | 6 5/8" | 9 7/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |

| 8 | 8 5/8" | 12 1/8" | -450° to 350° | White | FDA Compliant 21 CFR 177.1550, USP Class VI | 0000000 | 00000 |