About Sealant Flexibility

More

Adhesive-Back Frame-Mount Weatherstripping

No need to drill mounting holes, this weatherstripping has a peel-and-stick adhesive backing. Mount it to the sides and top of a door or window frame to seal gaps. The adhesive is made of acrylic for a waterproof and weatherproof bond.

Bulb seals conform to doors, compensating for irregular surfaces. They restrict airflow better than flat seals. Made of silicone, they withstand high temperatures and UV rays.

Finned seals have two flat fins that create multiple sealing points against a door. They compensate for uneven surfaces better, insulate better, and last longer than flat seals. Made of TPE, they resist UV rays like silicone bulb seals and withstand abrasion, tears, and solvents better. However, TPE will deteriorate and crack at temperatures above 250° F.

Flat seals are made of a graphite/rubber blend, which expands by as much as 10 times their original thickness in extreme heat to completely seal out flames. Also known as intumescent seals, they’re commonly used in fire doors, which often have a built-in groove shaped to fit them.

V-strip seals are made of stiff, folded material. One arm mounts to your door frame while the other presses firmly against the door to block airflow. They’re also known as tension seals. Bronze seals are durable and corrosion resistant, and often used on historical buildings to match the existing design. Stainless steel seals are stronger than rubber ones and more corrosion resistant than bronze ones. Often used in marine environments and food plants, they won’t degrade from contact with mild chemicals or detergents.

Seals that meet UL 1784 are rated for use as smoke and draft control gaskets.

For technical drawings and 3-D models, click on a part number.

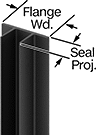

| Seal Material | For Max. Door Gap | Seal Projection | Flange Wd. | Fire Safety Rating | Specifications Met | Lengths, ft. | Per Ft. | |

Bulb Seal | ||||||||

|---|---|---|---|---|---|---|---|---|

| Silicone Rubber | 1/4" | 1/4" | 1/2" | UL 10B, UL 10C: 1 1/2 hr. for wood fire doors, 3 hr. for metal fire doors | UL 1784 | 0000000 | 00000 | |

Flat Seal | ||||||||

| Graphite/Rubber Blend | 1/16" | 1/16" | 1/2" | UL 10B, UL 10C: 1 1/2 hr. for wood fire doors, 3 hr. for metal fire doors | __ | 0000000 | 0000 | |

| Seal Material | Seal Color | For Max. Door Gap | Seal Projection | Flange Wd. | No. of Fins | Fire Safety Rating | Lg., ft. | Each | |

Finned Seal | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| TPE Rubber | Brown | 1/4" | 1/4" | 1/2" | 2 | UL 10B, UL 10C: 1 1/2 hr. for wood fire doors, 3 hr. for metal fire doors | 9 | 00000000 | 000000 |

V-Strip Seal | |||||||||

| Bronze | __ | 3/16" | 3/16" | 1" | __ | UL 10B, UL 10C: 1 1/2 hr. for wood fire doors, 3 hr. for metal fire doors | 7 | 000000 | 00000 |

| Stainless Steel | __ | 3/16" | 3/16" | 1" | __ | UL 10B, UL 10C: 1 1/2 hr. for wood fire doors, 3 hr. for metal fire doors | 7 | 000000 | 00000 |

Wraparound Top-Mount Weatherstripping

Close gaps between the top of a fire-rated door and its frame to comply with NFPA safety regulations. This UL-certified weatherstripping is often used to modify existing fire doors that no longer meet fire codes, so they don’t need to be replaced. Weatherstripping consists of a bulb seal, a fire-stop strip, a flange, and two end plates.

When the door is closed, the bulb seal compresses against the door frame, forming a tight barrier. This seal blocks air and compensates for uneven surfaces better than flat seals. Made from silicone, it’s durable enough to hold up to daily wear and tear. It’s also UV-resistant, and it withstands temperatures up to 450° F. A fire-stop strip lines the opposite side to completely seal gaps during a fire. When temperatures rise above 375° F, the strip expands to eight times its original size.

The stainless steel flange resists corrosion from water and chemicals. Stronger than aluminum flanges, it holds its shape even when fire is present. End plates are used to cover gaps on the sides of the doors for a finished look from every angle.

For technical drawings and 3-D models, click on a part number.

| Seal Material | Flange Material | Seal Projection | Flange Ht. | For Door Thick. | Fire Safety Rating | Includes | Features | Mounting Fasteners Included | Lengths, ft. | Per Ft. | |

Bulb Seal | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Silicone Rubber | Stainless Steel | 3/16" | 1 3/4" | 1 3/4" | UL 10C: 1 1/2 hr. for hollow metal and composite-core wood doors | End Plates | Fire-Stop Strips | Yes | 0000000 | 000000 | |

Wraparound Bottom-Mount Weatherstripping

Seal drafts, dust, and insects out of your space—this weatherstripping hugs the bottom of your door. Also known as door sweeps.

Flat seals press tight against smooth surfaces to form a solid barrier. However, they don’t compensate for uneven surfaces as well as bulb seals. Behind the seal, there’s a fire-stop strip that expands to eight times its original size in temperatures above 375° F. During a fire, it completely fills any gaps. This weatherstripping is often added to existing fire doors to help them meet NFPA safety regulations without replacing the entire door. Use end plates to cover the sides of the doors for a finished look from every angle.

Neoprene is more weather resistant than vinyl. It stands up to abrasion, water, oil, and detergents.

Stainless steel is stronger than aluminum, so it holds its shape better if exposed to fire. It’s also more chemical and corrosion resistant.

For technical drawings and 3-D models, click on a part number.

Weatherstripping | Replacement 4-Ft. Lg. Seals | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seal Material | Flange Material | Seal Projection | Flange Ht. | For Door Thick. | Fire Safety Rating | Mounting Fasteners Included | Includes | Features | Lengths, ft. | Per Ft. | Each | ||

Flat Seal | |||||||||||||

| Neoprene Rubber | Stainless Steel | 1 1/2" | 1" | 1 3/4" | UL 10B, UL 10C: 1 1/2 hr. for wood fire doors, 3 hr. for metal fire doors | Yes | End Plates | Fire-Stop Strips | 0000000 | 0000000 | 00000000 | 000000 | |

High-Temperature Fire-Rated Hollow Rubber Surface-Mount Seals

Tested in accordance with NFPA standards 80, 105, and 252, these silicone rubber seals are for use on fire-rated doors. They meet UL 10B, UL 10C, and UL 1784. Hollow construction provides compressibility. Attach these seals directly to a door’s surface to shield against dust, noise, and vibration.

For technical drawings and 3-D models, click on a part number.

High-Temperature Fire-Rated Rubber Surface-Mount Seals with Wiper

Made of solid silicone rubber and tested to meet strict NFPA fire standards, these seals can be used on fire-rated doors in environments that reach up to 600° F. They also stand up to water and salts. They’re firmer and more durable than silicone foam rubber seals. Install them on the inside of a door frame.

For technical drawings and 3-D models, click on a part number.

Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Hardness | Hardness Rating | Adhesive Type | Temp. Range, °F | Adhesive Temp. Range, °F | For Use Outdoors | Specifications Met | Color | Lengths, ft. | 1-99 | 100-Up | |

Silicone Rubber—Adhesive Back | |||||||||||||

| 1/2" | 3/8" | Durometer 65A | Medium Hard | Acrylic | -80° to 600° | -30° to 250° | Yes | ANSI/BHMA A156.22, NFPA 105, NFPA 252, UL 10C, UL 1784, NFPA 80 | Gray | 0000000 | 00000 | 00000 | |

Water- and Weather-Resistant Flame-Retardant

Push-On Seals with Bulb on Top

Made of EPDM foam, these seals resist water, sunlight, and ozone while also meeting transportation industry standards for flames, smoke, and toxicity. Softer and more flexible than EPDM rubber seals, they conform to uneven surfaces to guard against dust, noise, and vibration. The foam has a closed-cell construction, which resists absorption.

For technical drawings and 3-D models, click on a part number.

Fire-Rated Glass Sealing Tape

Seal glass windows in metal and wood fire-rated doors. Also known as glazing tape, it has an adhesive back with a peel-off liner.

Fire Safety | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rating, min. | Standard | Wd. | Lg., ft. | Tensile Strength, psi | Hardness | Application Temp. Range, °F | Max. Temp., °F | For Joining | Color | Each | |

Aluminum | |||||||||||

3/64" Thick. | |||||||||||

| 45 | UL 10C | 7/16" | 8 | 230 | Not Rated | 65° to 80° | 1800° | Metal Metal to Glass Glass Wood | White | 0000000 | 000000 |

| 45 | UL 10C | 7/16" | 14 | 230 | Not Rated | 65° to 80° | 1800° | Metal Metal to Glass Glass Wood | White | 0000000 | 00000 |

5/64" Thick. | |||||||||||

| 90 | UL 10C | 7/16" | 16 | 230 | Not Rated | 65° to 80° | 1800° | Metal Metal to Glass Glass | White | 000000000 | 00000 |