How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

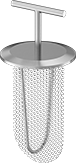

Stainless Steel Quick-Clamp T-Strainers

- Max. Pressure for Beverage, Dairy, Food, Pharmaceuticals, and Water: 150 psi @ 72° F

- Temp. Range: -50° to 275° F

Add these inline T-strainers to your sanitary process line to trap solid particles during clean-in-place (CIP) cycles. They have quick-clamp sanitary tube connections, also known as tri-clamp connections, for use in dairy, food, and other process lines that require frequent cleaning and disassembly. As the high-pressure cleaning fluid flows through your line, the strainer's screen catches particles larger than 1/8" to prevent damage to pumps, valves, and other downstream components. And because the total open area of the screen is larger than the area of the tube itself, the screen will not restrict flow.

Strainers come with a gasket and clamp to secure the screen inside the strainer. Gaskets and clamps for connecting the strainer to your line are sold separately. A handle lets you remove the screen to clean it between runs.

Strainers | Replacement Clamps | Replacement Screens | Replacement EPDM Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Lg. | Ht. | Screen Material | Screen Opening Size | Screen Lg. | Each | Each | Each | Each | ||||

316 Stainless Steel | ||||||||||||||

| 1 1/2" | 1.984" | 5 1/2" | 5 7/8" | 316 Stainless Steel | 1/8" | 3 1/2" | 0000000 | 0000000 | 00000000 | 000000 | 0000000 | 0000000 | 0000000 | 00000 |

| 2" | 2.516" | 7" | 6 7/8" | 316 Stainless Steel | 1/8" | 4 1/2" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 2 1/2" | 3.047" | 7" | 7 3/16" | 316 Stainless Steel | 1/8" | 4 3/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 3" | 3.579" | 7 1/2" | 7 11/16" | 316 Stainless Steel | 1/8" | 5 1/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

Screens for Stainless Steel Quick-Clamp T-Strainers

Use these replacement screens with our Stainless Steel Quick-Clamp T-Strainers. Designed for use in dairy, food, and other process lines that use clean-in-place (CIP) systems, they prevent damage to pumps, valves, and other downstream components. Insert the screen into the strainer, then add a gasket and clamp to seal. The screen catches particles larger than 1/8" without restricting flow.

| For Tube OD | For Flange OD | Screen Opening Size | Screen Lg. | Screen Material | For Use With | Each | |

| 1 1/2" | 1.984" | 1/8" | 3 1/2" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 0000000 |

| 2" | 2.516" | 1/8" | 4 1/2" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

| 2 1/2" | 3.047" | 1/8" | 4 3/4" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

| 3" | 3.579" | 1/8" | 5 1/4" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

Sanitary Metal Filter Housings

Along with a cartridge, these housings are used in liquid processing lines to filter contaminants and minimize bacteria growth in food and pharmaceutical plants, as well as other sanitary environments. Made of 316 stainless steel, they won’t corrode from frequent washdowns with harsh cleaners. With a self-draining design, rounded edges, and highly polished surfaces, they leave no space for liquids to linger or bacteria to grow. These housings connect to process lines with sanitary quick-clamp fittings that allow for fast disassembly and cleaning. An EPDM rubber gasket maintains a tight seal and resists water, detergents, chemicals, and steam. The gasket is FDA compliant for direct contact with food. Housings are 3-A certified for sanitary design standards and comply with FDA pharmaceutical equipment design standards.

Cartridges (sold separately) are pleated, creating a large surface area for trapping debris. They have one open end with an EPDM rubber O-ring and locking tabs—the O-ring creates a tight seal to ensure that liquids pass through the cartridge for filtration, while the locking tabs help align with cartridges for a secure fit. Cartridges are FDA compliant for direct contact with food.

Cartridges with a polypropylene filter are often used as pre-filters in liquid processing lines, capturing larger particles to prevent clogging.

Cartridges with a PES filter remove extremely small particles, so they’re commonly used as final filters in high-purity applications. They’re also known as absolute-rated cartridges.

For Cartridge | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Ht. | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Port-to-Port Length | Overall Height | Specifications Met | Each | |

| 1" | 1.984" | 21.9" | 2.2" | O-Ring End Caps | 1 | 15 | 150 | 300 | 9 13/16" | 32 1/4" | 3-A Certified 10-04, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 0000000 | 000000000 |

Removes Particle Size Down To, microns | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height | 80% Efficiency | 90% Efficiency | 98% Efficiency | 99.9% Efficiency | Max. Pressure, psi | Max. Temp., °F | Specifications Met | Each | |

Polypropylene Plastic | |||||||||

| 21.9" | 3 | 5 | 10 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000000 |

| 21.9" | 10 | 20 | 30 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

PES Plastic | |||||||||

| 21.9" | __ | __ | __ | 0.2 | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2240, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |