How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Sleeves for Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F

- Tubing: Use with copper

- Specifications Met: DIN 3861

Use these sleeves with compression nuts and fittings to create a strong seal on copper tubing. Made of brass, they gently bite into tubing as you tighten the nut, and have good corrosion resistance. All meet DIN 3861, which is an international standard for tube fitting dimensions.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Sleeve Material | Maximum Pressure | Each | |

| 4 | 1 | Brass | 1,800 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | Brass | 2,500 psi @ 72° F | 00000000 | 000 |

| 8 | 1 | Brass | 2,100 psi @ 72° F | 00000000 | 000 |

| 10 | 1 | Brass | 1,600 psi @ 72° F | 00000000 | 000 |

| 12 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 14 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 15 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

Nuts for Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F

- Tubing: Use with copper

- Specifications Met: DIN 3870

Create a strong seal on copper tubing when you couple these nuts with compression sleeves and fittings. Made of nickel-plated brass, they resist corrosion better than plain brass. All meet DIN 3870, which is an international standard for tube fitting dimensions.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Length, mm | Each | |

Short Nuts | ||||||

| 4 | 1 | Nickel-Plated Brass | 1,800 psi @ 72° F | 11 | 00000000 | 00000 |

| 6 | 1 | Nickel-Plated Brass | 2,500 psi @ 72° F | 12 | 00000000 | 000 |

| 8 | 1 | Nickel-Plated Brass | 2,100 psi @ 72° F | 12 | 00000000 | 000 |

| 10 | 1 | Nickel-Plated Brass | 1,600 psi @ 72° F | 16 | 00000000 | 0000 |

| 12 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 16 | 00000000 | 0000 |

| 14 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 19 | 00000000 | 0000 |

| 15 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 17 | 00000000 | 0000 |

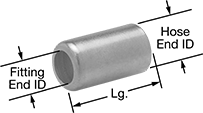

Crimp-On Ferrules for Air and Water Hose

Use ferrules to create a permanent connection between your air- and water-hose and barbed hose fittings. You will need a hose crimper (sold separately) for installation.

Brass and aluminum ferrules have good corrosion resistance. Choose a ferrule with an ID no more than 0.025" larger than your hose OD (measured with the fitting installed); also make sure the ferrule is at least as long as the barbed end of your fitting.

For technical drawings and 3-D models, click on a part number.

| Hose End ID | Lg. | Fitting End ID | Pkg. Qty. | Pkg. | |

Brass | |||||

|---|---|---|---|---|---|

| 0.275" | 0.5" | 0.217" | 50 | 0000000 | 000000 |

| 0.33" | 0.484" | 0.25" | 50 | 0000000 | 00000 |

| 0.358" | 0.5" | 0.266" | 50 | 0000000 | 00000 |

| 0.38" | 0.718" | 0.266" | 50 | 0000000 | 00000 |

| 0.41" | 0.5" | 0.266" | 50 | 0000000 | 00000 |

| 0.45" | 0.5" | 0.266" | 50 | 0000000 | 00000 |

| 0.478" | 0.688" | 0.328" | 50 | 0000000 | 00000 |

| 0.5" | 0.5" | 0.328" | 50 | 0000000 | 00000 |

| 0.5" | 1" | 0.344" | 25 | 0000000 | 00000 |

| 0.525" | 1" | 0.375" | 25 | 0000000 | 00000 |

| 0.548" | 0.484" | 0.375" | 50 | 0000000 | 00000 |

| 0.55" | 0.55" | 0.406" | 50 | 0000000 | 00000 |

| 0.562" | 1" | 0.438" | 25 | 0000000 | 00000 |

| 0.575" | 0.484" | 0.375" | 50 | 0000000 | 00000 |

| 0.593" | 1" | 0.438" | 25 | 0000000 | 00000 |

| 0.6" | 0.5" | 0.5" | 50 | 0000000 | 00000 |

| 0.625" | 0.55" | 0.453" | 25 | 0000000 | 00000 |

| 0.625" | 1" | 0.453" | 25 | 0000000 | 00000 |

| 0.65" | 0.5" | 0.5" | 50 | 0000000 | 00000 |

| 0.656" | 1" | 0.438" | 25 | 0000000 | 00000 |

| 0.675" | 0.516" | 0.5" | 25 | 0000000 | 00000 |

| 0.687" | 1" | 0.5" | 25 | 0000000 | 00000 |

| 0.7" | 0.516" | 0.5" | 50 | 0000000 | 00000 |

| 0.718" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.725" | 0.531" | 0.5" | 50 | 0000000 | 00000 |

| 0.75" | 0.531" | 0.5" | 50 | 0000000 | 00000 |

| 0.75" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.781" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.8" | 0.844" | 0.688" | 25 | 0000000 | 00000 |

| 0.812" | 1" | 0.625" | 25 | 0000000 | 00000 |

| 0.825" | 0.844" | 0.688" | 25 | 0000000 | 00000 |

| 0.85" | 0.563" | 0.688" | 25 | 0000000 | 00000 |

| 0.875" | 0.844" | 0.688" | 25 | 0000000 | 00000 |

| 0.9" | 0.844" | 0.688" | 25 | 0000000 | 00000 |

| 0.925" | 0.81" | 0.688" | 25 | 0000000 | 00000 |

| 0.975" | 0.844" | 0.688" | 10 | 0000000 | 00000 |

| 1" | 0.844" | 0.687" | 25 | 0000000 | 00000 |

| 1.05" | 0.844" | 0.693" | 25 | 0000000 | 00000 |

| 1.1" | 0.844" | 0.812" | 25 | 0000000 | 00000 |

| 1.15" | 0.844" | 0.875" | 25 | 0000000 | 00000 |

| 1.375" | 0.875" | 1.125" | 10 | 0000000 | 00000 |

Crimp-On Ferrules for Welding Hose

Use ferrules to create a permanent connection between your welding hose and barbed hose fittings. You will need a hose crimper (sold separately) for installation. Ferrules are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| Hose End ID | Lg. | Each | |

Brass | |||

|---|---|---|---|

| 0.45" | 9/16" | 000000000 | 00000 |

| 0.478" | 11/16" | 000000000 | 0000 |

| 1/2" | 1/2" | 000000000 | 000 |

| 1/2" | 1" | 000000000 | 0000 |

| 0.525" | 1/2" | 000000000 | 000 |

| 0.525" | 1" | 000000000 | 0000 |

| 0.548" | 31/64" | 000000000 | 000 |

| 0.562" | 1" | 000000000 | 0000 |

| 0.564" | 3/4" | 000000000 | 0000 |

| 0.575" | 31/64" | 000000000 | 000 |

| 0.593" | 1" | 000000000 | 0000 |

| 5/8" | 1/2" | 000000000 | 0000 |

| 5/8" | 1" | 000000000 | 0000 |

| 0.656" | 1" | 000000000 | 0000 |

| 0.687" | 1" | 000000000 | 0000 |

| 0.718" | 1" | 000000000 | 0000 |

| 3/4" | 1" | 000000000 | 0000 |

| 0.781" | 1" | 000000000 | 0000 |

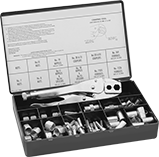

Hose Crimping Tool and Fitting Sets for Compressed Gas

Sets contain a crimping tool and a variety of fittings, nuts, and ferrules so you can connect pressure regulators, torches, and other components of your welding system. Fittings are also known as CGA (Compressed Gas Association) fittings. They are brass for good corrosion resistance.

Barbed adapters let you adapt to a threaded end so you can connect welding hose to pressure regulators or torches. They consist of a barbed shaft with a rounded end that sits inside a threaded nut so you can make a threaded hose connection.

Barbed connectors are also known as hose menders and splicers. Use them to connect lengths of hose or to repair damaged hose. Slide the barbed end into welding hose and use a hose ferrule and the crimping tool to secure the fitting to hose.

Threaded connectors let you attach threaded welding hose to pressure regulators and torches.

Fittings with left-hand threads are identified with a notch in the nut.

Note: Fittings have a CGA number that corresponds to a specific type of gas. Choose a fitting with the same CGA number as your tank and other system components.

| For Hose ID | No. of Pieces | Includes | Max. Pressure | For Use With | Each | |

Brass | ||||||

|---|---|---|---|---|---|---|

| 3/16", 1/4" | 93 | Crimping Tool Eight barbed hose adapters for 3/16" hose ID (use with A-size nuts) Six barbed hose adapters for 3/16" hose ID (use with B-size nuts) Ten barbed hose adapters for 1/4" hose ID (use with B-size nuts) Two barbed hose connectors for 3/16" hose ID Four barbed hose connectors for 1/4" hose ID One A-size 3/8"-24 male right-hand threaded connector (CGA-020) One A-size 3/8"-24 male left-hand threaded connector (CGA-021) One B-size 9/16"-18 male right-hand threaded connector (CGA-022) One B-size 9/16"-18 male left-hand threaded connector (CGA-023) Four A-size 3/8"-24 right-hand threaded nuts (CGA-020) Four A-size 3/8"-24 left-hand threaded nuts (CGA-021) Eight B-size 9/16"-18 female right-hand threaded nuts (CGA-022) Eight B-size 9/16"-18 female left-hand threaded nuts (CGA-023) Twelve ferrules with 0.45" hose end ID Ten ferrules with 0.562" hose end ID Twelve ferrules with 0.593" hose end ID | 200 psi @ 72° F | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 0000000 | 0000000 |

| 5/16", 3/8" | 71 | Crimping Tool Eight barbed hose adapters for 5/16" hose ID (use with B-size nuts) Eight barbed hose adapters for 3/8" hose ID (use with B-size nuts) Two barbed hose connectors for 5/16" hose ID Two barbed hose connectors for 3/8" hose ID One B-size 9/16"-18 male right-hand threaded connector (CGA-022) One B-size 9/16"-18 male left-hand threaded connector (CGA-023) Eight B-size 9/16"-18 female right-hand threaded nuts (CGA-022) Eight B-size 9/16"-18 female left-hand threaded nuts (CGA-023) Eight ferrules with 0.625" hose end ID Eight ferrules with 0.656" hose end ID Six ferrules with 0.687" hose end ID Eight ferrules with 0.718" hose end ID | 200 psi @ 72° F | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 0000000 | 000000 |

Screw-On Hose Fittings for Air and Water

The female connector screws directly onto rubber hose without the need for a separate adapter. You’ll need a female connector (ferrule) and a male adapter (stem) with the same hose ID to make a connection. Screw the female connector onto hose, then thread the male adapter into the female connector. When assembled, the fitting compresses against the hose, forming a strong seal. Also known as reusable fittings, they can be unscrewed from the hose end and used on a new hose.

Brass fittings are softer than 303 stainless steel fittings, so they’re easier to thread together. They have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 250 psi @ 72° F

- Temperature Range: -40° to 160° F