How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Clamps for Claw-Clamp High-Vacuum Fittings for Stainless Steel Tubing

Connect claw-clamp high-vacuum fittings for an airtight seal. For a complete connection, you'll need four clamps and a ring (sold separately).

Double-claw clamps attach to the grooves on the fittings.

Single-claw clamps have a clamp on one end and an exposed bolt on the other. Thread the bolt-end directly into the body of pumps, valves, or other high-vacuum components.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Material | Max. Vacuum | Each | |

Double Claw | |||||||

|---|---|---|---|---|---|---|---|

Aluminum | |||||||

| 2 1/2", 3", 4" | 3.74", 4.33", 5.12" | 63, 80, 100 | ISO-K | 18-8 Stainless Steel | 1 × 10 -9 torr @ 72° F | 0000000 | 00000 |

| 6" | 7.09" | 160 | ISO-K | 18-8 Stainless Steel | 1 × 10 -9 torr @ 72° F | 0000000 | 0000 |

Single Claw | |||||||

Aluminum | |||||||

| 2 1/2", 3", 4" | 3.74", 4.33", 5.12" | 63, 80, 100 | ISO-K | 18-8 Stainless Steel | 1 × 10 -9 torr @ 72° F | 0000000 | 0000 |

| 6" | 7.09" | 160 | ISO-K | 18-8 Stainless Steel | 1 × 10 -9 torr @ 72° F | 0000000 | 0000 |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Max. Temp., °F | Each | |

| 2 1/2" | 3.74" | 63 | ISO-K | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 1 × 10 -9 torr @ 72° F | 400° | 0000000 | 000000 |

| 3" | 4.33" | 80 | ISO-K | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 1 × 10 -9 torr @ 72° F | 400° | 000000 | 00000 |

| 4" | 5.12" | 100 | ISO-K | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 1 × 10 -9 torr @ 72° F | 400° | 0000000 | 00000 |

| 6" | 7.09" | 160 | ISO-K | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 1 × 10 -9 torr @ 72° F | 400° | 0000000 | 00000 |

Quick-Clamp High-Vacuum Fittings for Aluminum Tubing

- For Use With: Air

- Specifications Met: ISO 2861

For use in high-vacuum systems, these fittings use a metal reinforced O-ring to create an airtight seal. To form a complete connection, pair two adapters with a clamp and a ring (all sold separately). Made of aluminum, these fittings are lightweight and resist corrosion. This and the airtight seal make them a good choice for vacuum coating, heat treating, or leak testing. Also known as KF, QF, and NW fittings.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: 0° to 300° F

- Tubing: Use with aluminum

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Wall Thick. | Material | Max. Vacuum | Lg. | Each | |

| 3/4" | 1.18" | 16 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 1 9/16" | 0000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 1/2" | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 1 9/16" | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 3/4" | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 1 9/16" | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 3/4" | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 0.065" | Aluminum | 1 × 10 -7 torr @ 72° F | 1 9/16" | 0000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Connect quick-clamp fittings in high-vacuum applications. Clamps tighten by hand. They are aluminum, which is lightweight with good corrosion resistance.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever | ||||||||

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range: 0° to 350° F

- Tubing: Use with aluminum

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | O-Ring Material | Max. Vacuum | Each | |

| 3/4" | 1.18" | 16 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 0000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | Viton® Fluoroelastomer Rubber | 1 × 10 -7 torr @ 72° F | 0000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

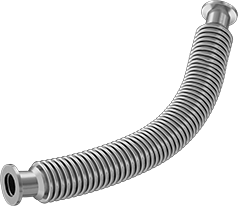

Hose absorbs moderate vibration.

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

3 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

4 3/16" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 3/4" | 1 3/16" | 16 | 10 -7 torr @ 72° F | 304 Stainless Steel | 4 1/8" | 2 1/4" | 00000000 | 0000000 |

| Manual | 1" | 1 9/16" | 25 | 10 -7 torr @ 72° F | 304 Stainless Steel | 5 5/8" | 3" | 00000000 | 000000 |

| Manual | 1 1/2" | 2 1/8" | 40 | 10 -7 torr @ 72° F | 304 Stainless Steel | 6 3/8" | 3 7/8" | 00000000 | 000000 |

| Manual | 2" | 2 15/16" | 50 | 10 -7 torr @ 72° F | 304 Stainless Steel | 8" | 4 1/2" | 00000000 | 000000 |

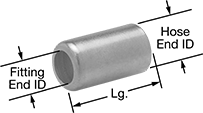

Crimp-On Ferrules for Air and Water Hose

Use ferrules to create a permanent connection between your air- and water-hose and barbed hose fittings. You will need a hose crimper (sold separately) for installation.

Brass and aluminum ferrules have good corrosion resistance. Choose a ferrule with an ID no more than 0.025" larger than your hose OD (measured with the fitting installed); also make sure the ferrule is at least as long as the barbed end of your fitting.

For technical drawings and 3-D models, click on a part number.

Wire Rope Compression Sleeves—Not for Lifting

An economical option for light-duty tethering, securing, and suspending. Compression sleeves are also known as ferrules, crimps, swaging, and splicing sleeves. They're compatible with Nicopress compression tools.

Warning: Fittings must match rope diameter and be installed correctly to obtain maximum holding power. Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

Sleeves | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | Compression Tools | |||||||||

| Dia. | Construction | Sleeve Lg. | Required Number of Compressions | Capacity | Pkg. Qty. | Pkg. | Compression Tool Type | Each | ||

Aluminum | ||||||||||

For Steel Rope | ||||||||||

| 3/64" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 IWRC 3 × 7 Hollow Core 7 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core | 3/8" | 4 | 95% of the Rope's Capacity | 50 | 0000000 | 00000 | Multidiameter | 000000 | 0000000 |

| 1/16" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 3/8" | 1 | 100% of the Rope's Capacity | 50 | 0000000 | 0000 | Multidiameter | 000000 | 000000 |

| 3/32" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1/2" | 2 | 100% of the Rope's Capacity | 50 | 0000000 | 0000 | Multidiameter | 000000 | 000000 |

| 1/8" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 5/8" | 3 | 100% of the Rope's Capacity | 50 | 000000 | 00000 | Multidiameter | 000000 | 000000 |

| 5/32" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 3/4" | 3 | 100% of the Rope's Capacity | 10 | 000000 | 0000 | Multidiameter | 000000 | 000000 |

| 3/16" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 7/8" | 4 | 100% of the Rope's Capacity | 10 | 000000 | 0000 | Multidiameter | 000000 | 000000 |

| 1/4" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1" | 3 | 100% of the Rope's Capacity | 10 | 000000 | 0000 | Single Diameter | 0000000 | 000000 |

| 9/32" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1 3/16" | 4 | 100% of the Rope's Capacity | 10 | 0000000 | 0000 | Single Diameter | 0000000 | 000000 |

| 5/16" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1 3/8" | 4 | 100% of the Rope's Capacity | 5 | 000000 | 0000 | Single Diameter | 00000000 | 000000 |

| 3/8" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1 7/16" | 5 | 100% of the Rope's Capacity | 5 | 000000 | 0000 | Hydraulic | 00000000 | 00000000 |

| 7/16" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 1 7/8" | 6 | 100% of the Rope's Capacity | 5 | 0000000 | 00000 | Hydraulic | 00000000 | 00000000 |

| 1/2" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 7 × 7 Strand Core 6 × 7 Fiber Core | 2 1/8" | 4 | 100% of the Rope's Capacity | 5 | 0000000 | 00000 | Hydraulic | 00000000 | 00000000 |

Wire Rope Stops—Not for Lifting

Aluminum stops are an economical alternative to copper.

Warning: Fittings must match rope diameter and be installed correctly to obtain maximum holding power. Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

Stops | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | Compression Tools | |||||||||||

| Dia. | Construction | OD | Compressed OD | Sleeve Lg. | Required Number of Compressions | Capacity | Pkg. Qty. | Pkg. | Compression Tool Type | Each | ||

Aluminum | ||||||||||||

For Steel Rope | ||||||||||||

| 1/16" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 7/32" | 3/16" | 3/16" | 1 | 30% of the Rope's Capacity | 50 | 0000000 | 00000 | Multidiameter | 000000 | 0000000 |

| 3/32" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 11/32" | 9/32" | 5/16" | 1 | 30% of the Rope's Capacity | 50 | 000000 | 0000 | Multidiameter | 0000000 | 000000 |

| 1/8" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 11/32" | 9/32" | 5/16" | 1 | 30% of the Rope's Capacity | 50 | 000000 | 0000 | Multidiameter | 0000000 | 000000 |

| 5/32" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 13/32" | 11/32" | 5/16" | 1 | 30% of the Rope's Capacity | 50 | 000000 | 00000 | Multidiameter | 0000000 | 000000 |

| 3/16" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 7/16" | 11/32" | 5/16" | 1 | 30% of the Rope's Capacity | 50 | 000000 | 00000 | Multidiameter | 0000000 | 000000 |

| 1/4" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 21/32" | 37/64" | 11/16" | 2 | 30% of the Rope's Capacity | 10 | 000000 | 0000 | Single Diameter | 0000000 | 000000 |

| 5/16" | 1 × 7 Strand Core 1 × 19 Strand Core 3 × 7 Hollow Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 11/16" | 37/64" | 11/16" | 2 | 30% of the Rope's Capacity | 10 | 000000 | 0000 | Single Diameter | 0000000 | 000000 |

Rope Compression Sleeves—Not for Lifting

Install with a compression tool to create a strong, permanent loop. They're also known as swaging and splicing sleeves, crimps, and ferrules. They're compatible with Nicopress compression tools.

Warning: Fittings must match rope diameter and be installed correctly to obtain maximum holding power. Test all assemblies for required strength before use.

Sleeves | Single-Diameter Compression Tools | Multidiameter Compression Tools | Hydraulic Bench Compression Tools | Hydraulic Compression Tools | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rope Dia. | Sleeve Lg. | Required No. of Compressions | Pkg. Qty. | Pkg. | Each | Each | Each | Each | |||||

Aluminum | |||||||||||||

| 3/64" | 3/8" | 1 | 25 | 0000000 | 00000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | 00 | 000000 | 00 |

| 1/16" | 3/8" | 1 | 25 | 000000 | 0000 | 0000000 | 000000 | 000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 3/32", 7/64" | 9/16" | 2 | 25 | 0000000 | 0000 | 000000 | 00 | 000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 1/8", 9/64" | 11/16" | 3 | 25 | 000000 | 00000 | 00000000 | 000000 | 000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 5/32" | 3/4" | 3 | 10 | 0000000 | 0000 | 000000 | 00 | 000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 3/16" | 1" | 4 | 25 | 000000 | 00000 | 00000000 | 000000 | 000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 7/32", 1/4" | 1 1/4" | 5 | 10 | 000000 | 0000 | 00000000 | 000000 | 000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 9/32" | 3/4" | 3 | 5 | 0000000 | 0000 | 0000000 | 000000 | 000000 | 00 | 000000 | 00 | 000000 | 00 |

| 5/16" | 1 1/8" | 4 | 10 | 000000 | 00000 | 000000 | 00 | 000000 | 00 | 000000 | 00 | 0000000 | 000000000 |

| 3/8" | 1 9/16" | 2 | 10 | 000000 | 00000 | 000000 | 00 | 000000 | 00 | 0000000 | 000000000 | 000000 | 00 |

| 7/16" | 1 7/8" | 6 | 5 | 0000000 | 00000 | 000000 | 00 | 000000 | 00 | 000000 | 00 | 00000000 | 00000000 |

| 1/2" | 2" | 2 | 5 | 000000 | 00000 | 000000 | 00 | 000000 | 00 | 0000000 | 00000000 | 000000 | 00 |