How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

For technical drawings and 3-D models, click on a part number.

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with butt-weld end weld to tubing for a permanent connection. Fittings with butt-weld end are also known as ferrules.

| For Tube OD (Quick Clamp) | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD (Butt Weld) | Material | Max. Vacuum | Lg. | Each | |

| 1/2" | 1.18" | 10 | ISO-KF | 1/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 000000 |

| 1/2" | 1.18" | 10 | ISO-KF | 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 1/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 3/8" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 3/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 1/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 3/8" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 3/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 1" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 3/8" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 3/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 1/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 3/8" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 3/4" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 1" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 1 1/2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 2" | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 13/64" | 00000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever | ||||||||

| 1/2", 3/4" | 1.18" | 10, 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 1 × 10 -7 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Fluoroelastomer O-Ring: 0° to 300° F

Fittings with Silicone O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

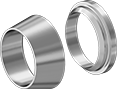

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 1/2" | 1.18" | 10 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 0000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 0000000 | 00000 |

Rings with Stainless Steel Screen | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 75 psi @ 72° F | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 50 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 1/2" | 1.18" | 10 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | Not Rated | 00000000 | 00000 |

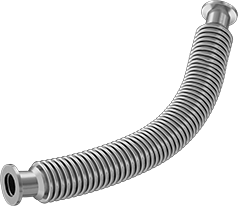

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

3 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

4 3/16" Lg. | |||||||||

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 3/4" | 1.18" | 16 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 5/8" | Flexible | 00000000 | 000000 |

| 1" | 1.57" | 25 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 1 3/8" | Flexible | 00000000 | 000000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 1 × 10 -7 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 1/2" | 1 3/16" | 10 | 10 -7 torr @ 72° F | 304 Stainless Steel | 4 1/8" | 2 1/4" | 00000000 | 0000000 |

| Manual | 3/4" | 1 3/16" | 16 | 10 -7 torr @ 72° F | 304 Stainless Steel | 4 1/8" | 2 1/4" | 00000000 | 000000 |

| Manual | 1" | 1 9/16" | 25 | 10 -7 torr @ 72° F | 304 Stainless Steel | 5 5/8" | 3" | 00000000 | 000000 |

| Manual | 1 1/2" | 2 1/8" | 40 | 10 -7 torr @ 72° F | 304 Stainless Steel | 6 3/8" | 3 7/8" | 00000000 | 000000 |

| Manual | 2" | 2 15/16" | 50 | 10 -7 torr @ 72° F | 304 Stainless Steel | 8" | 4 1/2" | 00000000 | 000000 |

Front and Back Sleeves for Yor-Lok Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | 00000000 | 000000 |

Sleeves for Vibration-Resistant Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Lubricants, Mineral Oil, Water

- Temperature Range: -30° to 270° F, except fluoroelastomer rubber sleeves are -15° to 450° F

- Tubing: Use with copper

Use these sleeves with vibration-resistant compression nuts and fittings. They are rubber instead of metal, so they cushion the tubing and absorb vibration while creating a tight seal. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Sleeve Color | Max. Pressure | Each | |

Buna-N Rubber | ||||

|---|---|---|---|---|

| 1/8" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 00000 |

| 3/16" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 0000 |

Fluoroelastomer Rubber | ||||

| 3/16" | Black with Red Stripe | 300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Black with Red Stripe | 300 psi @ 72° F | 00000000 | 0000 |

Front and Back Sleeves for Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Mineral Oil, Fuel Oil, Gasoline, Diesel Fuel, Cutting Oil, Hydraulic Fluid

- Temperature Range: -20° to 800° F

- Tubing: Use with seamless steel

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on steel tubing. They are also known as ferrules.

Zinc-plated steel sleeves have fair corrosion resistance. 316 stainless steel sleeves have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Each | |

| 1" | 0.065" | Zinc-Plated Steel | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 000000 |

Front and Back Sleeves for Ultra-Corrosion-Resistant

Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Acetic Acid, Air, Bleach, Cutting Oil, Diesel Fuel, Formic Acid, Fuel Oil, Gasoline, Hydraulic Fluid, Iron Chlorides, Mineral Oil, Salt Water, Steam, Water

- Temperature Range: 0° to 1,000° F

- Tubing: Use with seamless soft C276 nickel

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these C276 nickel Hastelloy sleeves with Yor-Lok nuts and fittings to create a strong, leak-resistant seal. With the best corrosion resistance of any Yor-Lok sleeves we offer, they stand up to aggressive chemicals and resist pitting and cracking from stress. They are also known as ferrules.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Sleeve Material | Max. Pressure | Each | |

| 1/2" | C276 Nickel | 2,600 psi @ 72° F | 00000000 | 000000 |