How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Wire Ferrule Assortments

Keep a variety of ferrule sizes on hand. These ferrules add strength and stability to stranded wire, protecting it from damage. They also make it faster to insert the wire into terminal blocks. Use a crimper (not included) to install wire.

Barrel-insulated ferrules have a plastic cover to prevent short-circuiting with nearby wire. Nylon-insulated ferrules are more durable and resist chemicals better than polypropylene.

Noninsulated ferrules allow you to easily inspect the wire connection.

Use ferrules for two wires to insert two wires into one terminal block.

| For Number of Wires | Number of Pieces | Includes | Pin Lg. | Wire Connection Type | Terminal Material | Specifications Met | Max. Temp., °F | Max. Voltage | Each | |

Barrel Insulated—Polypropylene Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | Wire Ferrules (12-6 AWG) Compartmented Plastic Case | 0.39"- 0.47" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 000000 |

| 1 | 150 | Wire Ferrules (26-18 AWG) Compartmented Plastic Case | 0.24"- 0.31" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

| 1 | 400 | Wire Ferrules (22-14 AWG) Compartmented Plastic Case | 0.31" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

| 2 | 200 | Wire Ferrules (20-14 AWG) Compartmented Plastic Case | 0.31"- 0.39" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

| 2 | 225 | Wire Ferrules (22-14 AWG) Compartmented Plastic Case | 0.31"- 0.39" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

Barrel Insulated—Nylon Plastic | ||||||||||

| 1 | 600 | Wire Ferrules (22-12 AWG) Compartmented Plastic Case | 0.31"- 0.39" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CSA Certified, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

Noninsulated | ||||||||||

| 1 | 370 | Wire Ferrules (16-10 AWG) Compartmented Plastic Case | 0.35"- 0.47" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

| 1 | 1,800 | Wire Ferrules (22-14 AWG) Compartmented Plastic Case | 0.24"- 0.28" | Crimp On | Tin-Plated Copper | UL Classified, UL Listed, CE Marked, DIN 46228-4 | 220° | 600V AC 600V DC | 0000000 | 00000 |

Wire Rope Compression Sleeve Assortments—Not for Lifting

Aluminum sleeves are an economical alternative to copper.

Copper sleeves are stronger than aluminum.

Tin-plated copper sleeves have mild corrosion resistance.

Zinc-plated copper sleeves are more corrosion resistant than tin-plated copper.

Warning: Fittings must match rope diameter and be installed correctly to obtain maximum holding power. Test all assemblies for required strength before use. Do not use with coated rope unless the coating is removed.

For Wire Rope | |||||||

|---|---|---|---|---|---|---|---|

| Number of Sleeves | Dia. | Construction | Compression Sleeve Material | Stop Sleeve Material | Specifications Met | Each | |

| 270 | 3/64" (35 Compression Sleeves) 1/16" (50 Compression Sleeves, 50 Stop Sleeves) 3/32" (30 Compression Sleeves, 30 Stop Sleeves) 5/32" (8 Compression Sleeves, 8 Stop Sleeves) 1/8" (20 Compression Sleeves, 20 Stop Sleeves) 3/16" (6 Compression Sleeves, 8 Stop Sleeves) 1/4" (3 Compression Sleeves, 2 Stop Sleeves) | 1 × 19 Strand Core 1 × 7 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Aluminum | Aluminum | MS51844 | 0000000 | 0000000 |

| 305 | 3/64" (35 Compression Sleeves, 35 Stop Sleeves) 1/16" (50 Compression Sleeves, 50 Stop Sleeves) 3/32" (30 Compression Sleeves, 30 Stop Sleeves) 5/32" (8 Compression Sleeves, 8 Stop Sleeves) 1/8" (20 Compression Sleeves, 20 Stop Sleeves) 3/16" (6 Compression Sleeves, 8 Stop Sleeves) 1/4" (3 Compression Sleeves, 2 Stop Sleeves) | 1 × 19 Strand Core 1 × 7 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Tin-Plated Copper | Zinc-Plated Copper | MS51844 | 0000000 | 000000 |

| 385 | 1/32" (40 Compression Sleeves, 40 Stop Sleeves) 3/64" (35 Compression Sleeves, 35 Stop Sleeves) 1/16" (50 Compression Sleeves, 50 Stop Sleeves) 3/32" (30 Compression Sleeves, 30 Stop Sleeves) 5/32" (8 Compression Sleeves, 8 Stop Sleeves) 1/8" (20 Compression Sleeves, 20 Stop Sleeves) 3/16" (6 Compression Sleeves, 8 Stop Sleeves) 1/4" (3 Compression Sleeves, 2 Stop Sleeves) | 1 × 19 Strand Core 1 × 7 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Copper | Copper | MS51844 | 0000000 | 000000 |

| 385 | 1/32" (40 Compression Sleeves, 40 Stop Sleeves) 3/64" (35 Compression Sleeves, 35 Stop Sleeves) 1/16" (50 Compression Sleeves, 50 Stop Sleeves) 3/32" (30 Compression Sleeves, 30 Stop Sleeves) 5/32" (8 Compression Sleeves, 8 Stop Sleeves) 1/8" (20 Compression Sleeves, 20 Stop Sleeves) 3/16" (6 Compression Sleeves, 8 Stop Sleeves) 1/4" (3 Compression Sleeves, 2 Stop Sleeves) | 1 × 19 Strand Core 1 × 7 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Zinc-Plated Copper | Zinc-Plated Copper | MS51844 | 0000000 | 000000 |

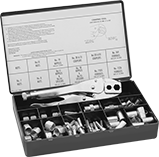

Hose Crimping Tool and Fitting Sets for Compressed Gas

Sets contain a crimping tool and a variety of fittings, nuts, and ferrules so you can connect pressure regulators, torches, and other components of your welding system. Fittings are also known as CGA (Compressed Gas Association) fittings. They are brass for good corrosion resistance.

Barbed adapters let you adapt to a threaded end so you can connect welding hose to pressure regulators or torches. They consist of a barbed shaft with a rounded end that sits inside a threaded nut so you can make a threaded hose connection.

Barbed connectors are also known as hose menders and splicers. Use them to connect lengths of hose or to repair damaged hose. Slide the barbed end into welding hose and use a hose ferrule and the crimping tool to secure the fitting to hose.

Threaded connectors let you attach threaded welding hose to pressure regulators and torches.

Fittings with left-hand threads are identified with a notch in the nut.

Note: Fittings have a CGA number that corresponds to a specific type of gas. Choose a fitting with the same CGA number as your tank and other system components.

| For Hose ID | No. of Pieces | Includes | Max. Pressure | For Use With | Each | |

Brass | ||||||

|---|---|---|---|---|---|---|

| 3/16", 1/4" | 93 | Crimping Tool Eight barbed hose adapters for 3/16" hose ID (use with A-size nuts) Six barbed hose adapters for 3/16" hose ID (use with B-size nuts) Ten barbed hose adapters for 1/4" hose ID (use with B-size nuts) Two barbed hose connectors for 3/16" hose ID Four barbed hose connectors for 1/4" hose ID One A-size 3/8"-24 male right-hand threaded connector (CGA-020) One A-size 3/8"-24 male left-hand threaded connector (CGA-021) One B-size 9/16"-18 male right-hand threaded connector (CGA-022) One B-size 9/16"-18 male left-hand threaded connector (CGA-023) Four A-size 3/8"-24 right-hand threaded nuts (CGA-020) Four A-size 3/8"-24 left-hand threaded nuts (CGA-021) Eight B-size 9/16"-18 female right-hand threaded nuts (CGA-022) Eight B-size 9/16"-18 female left-hand threaded nuts (CGA-023) Twelve ferrules with 0.45" hose end ID Ten ferrules with 0.562" hose end ID Twelve ferrules with 0.593" hose end ID | 200 psi @ 72° F | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 0000000 | 0000000 |

| 5/16", 3/8" | 71 | Crimping Tool Eight barbed hose adapters for 5/16" hose ID (use with B-size nuts) Eight barbed hose adapters for 3/8" hose ID (use with B-size nuts) Two barbed hose connectors for 5/16" hose ID Two barbed hose connectors for 3/8" hose ID One B-size 9/16"-18 male right-hand threaded connector (CGA-022) One B-size 9/16"-18 male left-hand threaded connector (CGA-023) Eight B-size 9/16"-18 female right-hand threaded nuts (CGA-022) Eight B-size 9/16"-18 female left-hand threaded nuts (CGA-023) Eight ferrules with 0.625" hose end ID Eight ferrules with 0.656" hose end ID Six ferrules with 0.687" hose end ID Eight ferrules with 0.718" hose end ID | 200 psi @ 72° F | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Oxygen, Propane | 0000000 | 000000 |

Front and Back Sleeves for Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on copper tubing. Sleeves are brass for good corrosion resistance. They are also known as ferrules.

Sleeves with a dispenser are easier to install than individual sleeves, and less likely to get lost. Front and back sleeves are paired together—slide them off the dispenser and directly onto a tube.

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/8" | Brass | 3/16" | 10 | 7/64" | 10 | 2,800 psi @ 72° F | 00000000 | 000000 |

| 3/16" | Brass | 3/16" | 10 | 7/64" | 10 | 1,800 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Brass | 3/16" | 10 | 7/64" | 10 | 1,300 psi @ 72° F | 00000000 | 00000 |

| 5/16" | Brass | 3/16" | 10 | 7/64" | 10 | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/8" | Brass | 3/16" | 10 | 7/64" | 10 | 1,100 psi @ 72° F | 00000000 | 00000 |

| 1/2" | Brass | 3/16" | 10 | 7/64" | 10 | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/8" | Brass | 3/16" | 10 | 7/64" | 10 | 1,250 psi @ 72° F | 00000000 | 00000 |

| 3/4" | Brass | 9/32" | 10 | 5/32" | 10 | 1,000 psi @ 72° F | 00000000 | 00000 |

| 7/8" | Brass | 9/32" | 10 | 5/32" | 10 | 1,100 psi @ 72° F | 00000000 | 00000 |

| 1" | Brass | 9/32" | 10 | 5/32" | 10 | 1,000 psi @ 72° F | 00000000 | 000000 |