Horizontal-Force Bolt-Down Vibration-Damping Mounts with Unthreaded Hole

Isolate vibration and noise from oscillating equipment like fans and tumblers that create horizontal (shear) force. They can also be used in compression load applications. Made of stainless steel cable and aluminum, these mounts withstand temperatures up to 500° F and have excellent resistance to corrosion and oils. Use the holes in the base to bolt down these mounts to keep your equipment stationary.

For technical drawings and 3-D models, click on a part number.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity per Mount, lbs. | Deflection @ Capacity | Shear Capacity per Mount, lbs. | Deflection @ Shear Capacity | O'all Ht. | O'all Lg. | O'all Wd. | Bar Wd. | Temperature Range, °F | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | ||

Stainless Steel with Aluminum Bar | |||||||||||||||

| 1 | 9 | 0.13" | 2 | 0.13" | 1" | 3.1" | 1.2" | 0.4" | -150° to 500° | No | 4 | 0.18" | 2.7" | 0000000 | 000000 |

| 1 | 12 | 0.13" | 3 | 0.13" | 1.4" | 4.4" | 1.6" | 0.5" | -150° to 500° | No | 4 | 0.2" | 3.95" | 00000000 | 000000 |

| 1 | 17 | 0.13" | 4 | 0.13" | 1.3" | 4.4" | 1.5" | 0.5" | -150° to 500° | No | 4 | 0.2" | 3.95" | 0000000 | 000000 |

| 1 | 25 | 0.13" | 7 | 0.13" | 1.1" | 4.4" | 1.3" | 0.5" | -150° to 500° | No | 4 | 0.2" | 3.95" | 0000000 | 000000 |

| 1 | 40 | 0.13" | 12 | 0.13" | 1.5" | 5" | 1.8" | 0.6" | -150° to 500° | No | 4 | 0.26" | 4.5" | 0000000 | 000000 |

| 1 | 55 | 0.13" | 19 | 0.13" | 1.3" | 5" | 1.6" | 0.6" | -150° to 500° | No | 4 | 0.26" | 4.5" | 00000000 | 000000 |

| 1 | 75 | 0.13" | 20 | 0.13" | 1.3" | 5" | 1.7" | 0.6" | -150° to 500° | No | 4 | 0.26" | 4.5" | 0000000 | 000000 |

| 1 | 125 | 0.13" | 39 | 0.13" | 1.6" | 5" | 1.8" | 0.6" | -150° to 500° | No | 4 | 0.26" | 4.5" | 00000000 | 000000 |

| 1 | 175 | 0.13" | 53 | 0.13" | 1.4" | 5" | 1.6" | 0.6" | -150° to 500° | No | 4 | 0.26" | 4.5" | 0000000 | 000000 |

| 2 | 200 | 0.13" | 50 | 0.13" | 2.9" | 6.7" | 3.5" | 1" | -150° to 500° | No | 8 | 0.28" | 1.75", 2.63", 1.75" | 00000000 | 000000 |

| 2 | 300 | 0.13" | 60 | 0.13" | 2.8" | 8.5" | 3.3" | 1" | -150° to 500° | No | 8 | 0.28" | 1.75", 2.63", 1.75" | 0000000 | 000000 |

| 2 | 500 | 0.13" | 105 | 0.13" | 3.5" | 8.5" | 4.1" | 1" | -150° to 500° | No | 8 | 0.33" | 1.75", 2.63", 1.75" | 0000000 | 000000 |

| 3 | 900 | 0.13" | 200 | 0.13" | 3.9" | 10.5" | 4.4" | 1" | -150° to 500° | No | 8 | 0.41" | 2.15", 3.23", 2.15" | 0000000 | 000000 |

Screw-Mount Locating and Support Buttons

Mount through the counterbored hole with a socket head cap screw to support and position workpieces and fixtures from the bottom or side. They’re also known as rest buttons.

Stainless steel buttons are a good choice to avoid corrosion when working with stainless steel workpieces or fixtures.

For technical drawings and 3-D models, click on a part number.

| Dia. | Lg. | Lg. Tolerance | For Mounting Screw Size | Mounting Fasteners Included | Each | |

Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| 3/8" | 3/8" | -0.001" to 0.001" | No. 6 | No | 0000000 | 00000 |

| 1/2" | 1/2" | -0.001" to 0.001" | No. 8 | No | 0000000 | 0000 |

| 5/8" | 1/2" | -0.001" to 0.001" | No. 8 | No | 0000000 | 0000 |

| 3/4" | 1/2" | -0.001" to 0.001" | No. 10 | No | 0000000 | 0000 |

| 1" | 1/2" | -0.001" to 0.001" | 1/4" | No | 0000000 | 00000 |

Press-Fit Locating and Support Buttons

Support and position workpieces and fixtures from the bottom or side. These buttons press into a drilled hole for permanent installation. Also known as rest buttons.

Stainless steel buttons are a good choice to avoid corrosion when working with stainless steel workpieces or fixtures.

For technical drawings and 3-D models, click on a part number.

Stud | Tolerance | ||||||

|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Dia. | Lg. | Lg. | Stud Dia. | Each | |

Stainless Steel | |||||||

| 3/8" | 1/4" | 3/16" | 1/4" | 0" to 0.001" | -0.015" to 0" | 00000000 | 00000 |

| 3/8" | 3/8" | 3/16" | 1/4" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

| 3/8" | 1/2" | 3/16" | 1/4" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

| 1/2" | 1/4" | 1/4" | 5/16" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

| 1/2" | 3/8" | 1/4" | 5/16" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

| 1/2" | 1/2" | 5/16" | 5/16" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

| 1/2" | 3/4" | 5/16" | 5/16" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

| 1/2" | 1" | 5/16" | 5/16" | 0" to 0.001" | -0.015" to 0" | 00000000 | 0000 |

Domed-Head Locating and Support Buttons

Support rounded or irregularly shaped workpieces from the bottom or side with minimal contact. Press the stud into a drilled hole for permanent installation. Also known as rest buttons.

Stainless steel buttons resist corrosion. They’re a good choice when working with stainless steel workpieces or fixtures.

For technical drawings and 3-D models, click on a part number.

Swiveling Tips for Screws and Threaded Studs

Attach to the end of a screw or threaded stud to apply uniform pressure on uneven and angled surfaces. Also known as toggle and swivel-foot pads.

For technical drawings and 3-D models, click on a part number.

| Dia. | Ht. | Load Capacity, lbs. | Thread Size | Range of Motion | Each | |

Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| 5/8" | 5/8" | 3,900 | 1/4"-20 | 10° | 0000000 | 00000 |

| 11/16" | 3/4" | 5,900 | 5/16"-18 | 10° | 0000000 | 0000 |

| 3/4" | 13/16" | 6,400 | 3/8"-16 | 10° | 0000000 | 00000 |

| 7/8" | 15/16" | 7,000 | 1/2"-13 | 10° | 0000000 | 00000 |

| 1" | 1" | 10,000 | 5/8"-11 | 10° | 0000000 | 00000 |

| 1 1/4" | 1 3/8" | 13,500 | 3/4"-10 | 10° | 0000000 | 00000 |

| 1 5/8" | 1 13/16" | 18,750 | 1"-8 | 10° | 0000000 | 00000 |

Nonmarring Swiveling Tips for Screws and Threaded Studs

The contact area is covered in plastic to protect soft metal and polished surfaces. Attach these tips to the end of a screw or threaded stud to apply uniform pressure on uneven and angled surfaces. Also known as toggle and swivel-foot pads.

For technical drawings and 3-D models, click on a part number.

| Dia. | Ht. | Load Capacity, lbs. | Thread Size | Range of Motion | Tip Material | Each | |

Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

| 5/8" | 5/8" | 3,900 | 1/4"-20 | 10° | Acetal Plastic | 0000000 | 000000 |

| 11/16" | 3/4" | 5,900 | 5/16"-18 | 10° | Acetal Plastic | 0000000 | 00000 |

| 3/4" | 13/16" | 6,400 | 3/8"-16 | 10° | Acetal Plastic | 00000000 | 00000 |

| 7/8" | 15/16" | 7,000 | 1/2"-13 | 10° | Acetal Plastic | 00000000 | 00000 |

| 1" | 1" | 10,000 | 5/8"-11 | 10° | Acetal Plastic | 00000000 | 00000 |

| 1 1/4" | 1 3/8" | 13,500 | 3/4"-10 | 10° | Acetal Plastic | 00000000 | 00000 |

| 1 5/8" | 1 13/16" | 18,750 | 1"-8 | 10° | Acetal Plastic | 00000000 | 00000 |

Swiveling Gripper Tips for Screws and Threaded Studs

Attach to the end of a screw or threaded stud—the serrated face swivels to grip uneven and angled surfaces. Also known as toggle and swivel-foot pads.

For technical drawings and 3-D models, click on a part number.

| Dia. | Ht. | Load Capacity, lbs. | Range of Motion | Mounting Hole Thread Size | Each | |

Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| 5/8" | 5/8" | 5,000 | 10° | 1/4"-20 | 00000000 | 000000 |

| 11/16" | 3/4" | 7,600 | 10° | 5/16"-18 | 00000000 | 00000 |

| 3/4" | 13/16" | 8,250 | 10° | 3/8"-16 | 00000000 | 00000 |

| 7/8" | 15/16" | 9,000 | 10° | 1/2"-13 | 00000000 | 00000 |

| 1" | 1" | 12,900 | 10° | 5/8"-11 | 00000000 | 00000 |

| 1 1/4" | 1 3/8" | 17,400 | 10° | 3/4"-10 | 00000000 | 00000 |

| 1 5/8" | 1 13/16" | 24,200 | 10° | 1"-8 | 00000000 | 00000 |

Corrosion-Resistant Press-Fit Drill Bushings

These bushings are made of stainless steel for corrosion resistance. Mount flush with jig plates for precise drilling. Drill bushings can also be used as spacers, shims, and machinery bushings.

303 stainless steel provides excellent corrosion resistance.

440C stainless steel is harder than 303 to resist wear. It provides good corrosion resistance.

Also Available: Other sizes. Please select 8504A999 and specify ID, OD, and length.

For technical drawings and 3-D models, click on a part number.

Tolerance | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Lg. | For Drill Bit Size | ID | OD | Lg. | Drill Bushing Type | Hardness | Each | |

303 Stainless Steel | |||||||||

0.25" ID | |||||||||

| 3/8" | 1/4" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 000000 |

| 3/8" | 3/8" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/8" | 1/2" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/8" | 3/4" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 3/8" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 1/2" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 3/4" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 1" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

0.3125" ID | |||||||||

| 1/2" | 1/4" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 3/8" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 1/2" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 3/4" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

0.375" ID | |||||||||

| 1/2" | 3/8" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 1/2" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 3/4" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1/2" | 1" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 5/8" | 3/8" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 5/8" | 1/2" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 5/8" | 1" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

0.5" ID | |||||||||

| 5/8" | 3/8" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 5/8" | 1/2" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 5/8" | 3/4" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 5/8" | 1" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/4" | 3/8" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/4" | 1/2" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/4" | 5/8" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/4" | 3/4" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/4" | 1" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

0.625" ID | |||||||||

| 3/4" | 1/2" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 3/4" | 1" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 7/8" | 1/2" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 7/8" | 3/4" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 7/8" | 1" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

0.75" ID | |||||||||

| 7/8" | 1" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1" | 1" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1" | 1 1/4" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

1" ID | |||||||||

| 1 1/4" | 3/4" | 1" | 0.0002" to 0.0006" | 0.0017" to 0.002" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1 1/4" | 1" | 1" | 0.0002" to 0.0006" | 0.0017" to 0.002" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1 1/4" | 1 1/2" | 1" | 0.0002" to 0.0006" | 0.0017" to 0.002" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

| 1 3/8" | 1/2" | 1" | 0.0002" to 0.0006" | 0.0018" to 0.0022" | -0.01" to 0.01" | P | Rockwell C25 | 00000000 | 00000 |

440C Stainless Steel | |||||||||

0.25" ID | |||||||||

| 3/8" | 1/4" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/8" | 3/8" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/8" | 1/2" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/8" | 3/4" | 1/4", E | 0.0001" to 0.0004" | 0.0013" to 0.0016" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 1/2" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 3/4" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 1" | 1/4", E | 0.0001" to 0.0004" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

0.3125" ID | |||||||||

| 1/2" | 1/4" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 1/2" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 3/4" | 5/16" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

0.375" ID | |||||||||

| 1/2" | 3/8" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 1/2" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 3/4" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1/2" | 1" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 5/8" | 3/8" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 5/8" | 1/2" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 5/8" | 1" | 3/8" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

0.5" ID | |||||||||

| 5/8" | 1/2" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 5/8" | 3/4" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 5/8" | 1" | 1/2" | 0.0001" to 0.0005" | 0.0014" to 0.0017" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/4" | 3/8" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/4" | 1/2" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/4" | 3/4" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/4" | 1" | 1/2" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

0.625" ID | |||||||||

| 3/4" | 1/2" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 3/4" | 1" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 7/8" | 1/2" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 7/8" | 3/4" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 7/8" | 1" | 5/8" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

0.75" ID | |||||||||

| 7/8" | 1" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1" | 1/2" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1" | 3/4" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1" | 1" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1" | 1 1/4" | 3/4" | 0.0001" to 0.0005" | 0.0015" to 0.0018" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

1" ID | |||||||||

| 1 1/4" | 3/4" | 1" | 0.0002" to 0.0006" | 0.0017" to 0.002" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1 1/4" | 1" | 1" | 0.0002" to 0.0006" | 0.0017" to 0.002" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1 1/4" | 1 1/2" | 1" | 0.0002" to 0.0006" | 0.0017" to 0.002" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1 3/8" | 1/2" | 1" | 0.0002" to 0.0006" | 0.0018" to 0.0022" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

| 1 3/8" | 1" | 1" | 0.0002" to 0.0006" | 0.0018" to 0.0022" | -0.01" to 0.01" | P | Rockwell C58 | 0000000 | 00000 |

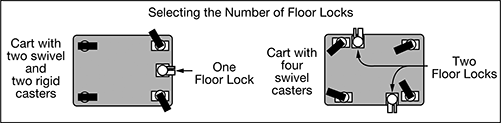

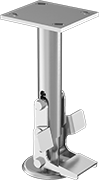

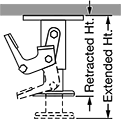

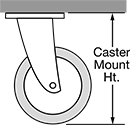

Floor Locks

Stabilize carts, trucks, workbenches, and other mobile equipment during loading and unloading. Floor locks bolt or weld to the underside of your equipment and have a spring-loaded base with a nonskid floor pad to keep equipment stationary.

Note: Floor locks are not load rated. They are designed to brake your equipment in place, not lift it off the floor.

For technical drawings and 3-D models, click on a part number.

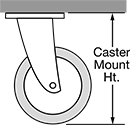

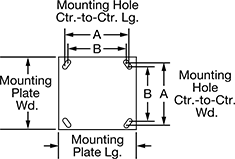

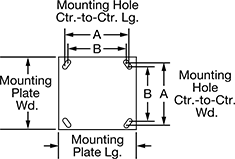

Ht. | Mounting Plate | Mounting Hole Ctr.-to-Ctr. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Caster Mount Ht. | Extended | Retracted | Clearance | Style | Lg. | Wd. | Lg. (A) | Lg. (B) | Wd. (A) | Wd. (B) | Mounting Fasteners Included | For Screw Size | Each | |

304 Stainless Steel | ||||||||||||||

| 5 5/8" | 5 5/8" | 4 1/2" | 1 1/8" | 1 | 4 1/2" | 4" | 3 5/8" | 3" | 3" | 2 5/8" | No | 3/8" | 0000000 | 0000000 |

| 6 1/2" | 6 1/2" | 5 3/8" | 1 1/8" | 1 | 4 1/2" | 4" | 3 5/8" | 3" | 3" | 2 5/8" | No | 3/8" | 0000000 | 000000 |

| 7 1/2" | 7 1/2" | 6 1/2" | 1" | 1 | 4 1/2" | 4" | 3 5/8" | 3" | 3" | 2 5/8" | No | 3/8" | 0000000 | 000000 |