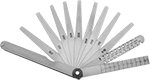

Combination Wire, Width, and Thickness Feeler Gauge Sets

These sets combine a wire gauge, a tapered-width feeler gauge, and a set of feeler gauges for tight spots in one tool. The tapered-width gauge is designed for measuring hole and slot widths and diameters. The feeler gauge leaves check the thickness of slots, gaps, and alignment; each leaf is marked with thickness. Leaves are riveted together in a fan design that folds up for portability.

Tapered Gauge Thick. Measuring | Closed | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Range | Increments | Wire Gauge Size | Leaf Lg. | Lg. | Wd. | Each | |

Steel | ||||||||

| 0.002", 0.003", 0.004", 0.006", 0.008", 0.01", 0.012", 0.015", 0.0625" | 1/64" to 3/16" | 1/64" | 1/16", 1/8", 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36 | 4 1/2" | 4 15/16" | 1/2" | 00000000 | 0000000 |

Ready-to-Use Feeler Gauges

Check gaps, alignment, and narrow slots. These feeler gauges have finished ends marked with thickness.

Steel gauges are polished.

Brass gauges have good corrosion resistance.

302/304 stainless steel gauges are more corrosion resistant than brass and steel.

316 stainless steel gauges have the best corrosion resistance.

Feeler Gauge Rolls

Cut to your desired length. These gauge rolls let you check gaps, alignment, and narrow slots. Thickness is marked every 6 inches.

Steel gauge rolls are polished.

Brass gauge rolls have good corrosion resistance.

302/304 stainless steel gauge rolls are more corrosion resistant than brass and steel.

316 stainless steel gauge rolls have the best corrosion resistance.

Color-Coded Feeler Gauges

Since each thickness is a different color, there’s no need to read the feeler gauge to tell your measurement. They are used to check gaps, alignment, and narrow slots. Gauges are nonmagnetic, nonmarring, noncorrosive, nonsparking, and resistant to oil.

| Thick. | Color | Lg. | Wd. | Pkg. Qty. | Pkg. | |

Plastic | ||||||

|---|---|---|---|---|---|---|

| 0.002" | Red | 12" | 1/2" | 5 | 00000000 | 00000 |