About Exhaust Fans

More

About Choosing a Heater

More

About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

About Sound Levels

Measured in decibels (dB), volume ratings indicate how much noise equipment makes. Some common volume levels include a whisper @ 20 dB, a refrigerator @ 40 dB, a conversation @ 60 dB, and a light machine shop @ 90 dB. OSHA recommends hearing protection for exposure to 80 dB and greater.

About Calculating the Airflow Required for Air Cleaning

More

Forced-Air Ventilating Wall-Mount Fans

Improve air quality and manage temperature and moisture levels by forcing fresh air into your space instead of exhausting air out. These fans create positive pressure to push air into an enclosed space, helping create static pressure to quickly ventilate smoke, gas, and other fumes. They’re direct-drive fans, so they have fewer moving parts than belt-drive fans for less maintenance.

For technical drawings and 3-D models, click on a part number.

For Opening | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage (Current) | Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Power, hp | Ht. | Wd. | Ht. | Wd. | Dp. | Frame Material | Blade Material | Guard Material | Environmental Rating | Each | |

Three Phase—Hardwire | ||||||||||||||||

Non-Oscillating | ||||||||||||||||

| 190V AC (10.9 A) 208V AC (11.7 A) 240V AC (1.9 A) | 58" | 34,000 | 600 | 1 | 3 | 65 1/2" | 65 1/2" | 65" | 65" | 34" | Polypropylene Plastic | Plastic | 304 Stainless Steel | IP65 | 0000000 | 000000000 |

Destratification Fans for Areas with High Ceilings

Continuously mix and circulate air to balance room temperature in spaces where there is a large difference in temperature between the floor and ceiling. They prevent you from over cooling or heating a space to maintain your desired temperature. All have a polyethylene plastic housing that is durable and resists rust. The motor is rated IP66 for protection against dust and washdowns.

| Voltage | Current, A | Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Power, hp | Cord Lg., ft. | Housing Material | Blade Material | Guard Material | For Min. Ceiling Ht., ft. | Mounting Fasteners Included | Mounting Hole Diameter | Each | |

Single Phase—Three Prong Plug | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Non-Oscillating | |||||||||||||||

| 120V AC 240V AC | 3.9 1.9 | 18" | 1,700 | 1,000 | 1 | 1/3 | 8 | Polyethylene Plastic | Plastic | Powder-Coated Steel | 7 | No | 1/4" | 0000000 | 0000000 |

Low-Profile Direct-Drive Ceiling-Mount Fans

Ideal for low-clearance applications where you need headroom, these direct-drive fans are compact and have fewer moving parts than belt-drive fans for less maintenance. The louvers adjust so you can direct airflow in two directions at the same time. They have a polyethylene housing, so they’re durable and resist corrosion.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | Current, A | Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Power, hp | Ht. | Wd. | Dp. | Housing Material | Blade Material | Environmental Rating | Includes | Each | |

Three Phase—Hardwire | |||||||||||||||

Non-Oscillating | |||||||||||||||

| 190V AC 208V AC 240V AC | 10.9 11.7 10.1 | 58" | 40,100 | 600 | 1 | 3 | 65 1/4" | 65 1/4" | 31" | Polyethylene Plastic | Plastic | IP65 | Mounting Chain Kit | 0000000 | 000000000 |

Corrosion-Resistant Belt-Drive Ceiling-Mount Fans

For rust resistance and durability, these fans have a polyethylene housing. They’re belt-drive fans, so they’re quieter and will last longer than direct-drive fans because their parts can be replaced if worn or damaged.

Fans with an open-dripproof motor enclosure are for indoor locations that are relatively clean and dry.

Fans with a totally enclosed motor enclosure can be used in dirty, dusty, and damp environments.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | Current, A | Blade Dia. | Airflow, cfm | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Ht. | Wd. | Dp. | Blade Material | Guard Material | Specifications Met | Each | |

Open Dripproof Motor Enclosure—Polyethylene Plastic Housing | |||||||||||||||

Three Phase—Hardwire | |||||||||||||||

| 240V AC 460V AC | 2.3 1.1 | 34" | 6,900 | 69 dB @ 15 ft. | 500 | 2 | 1/2 | 37 5/8" | 36 1/4" | 17 5/8" | Aluminum | Steel | ETL Listed, C-ETL Listed | 0000000 | 000000000 |

| 240V AC 460V AC | 3.3 1.5 | 40" | 10,600 | 70 dB @ 15 ft. | 425 | 1 | 3/4 | 43 5/8" | 42 1/4" | 20 5/8" | Aluminum | Steel | ETL Listed, C-ETL Listed | 0000000 | 00000000 |

| 240V AC 460V AC | 3.8 1.9 | 46" | 14,400 | 69 dB @ 15 ft. | 375 | 1 | 1 | 49 5/8" | 48 1/4" | 20 5/8" | Aluminum | Steel | ETL Listed, C-ETL Listed | 0000000 | 00000000 |

Totally Enclosed Motor Enclosure—Polyethylene Plastic Housing | |||||||||||||||

Single Phase—Hardwire | |||||||||||||||

| 120V AC 240V AC | 7.8 3.9 | 34" | 6,900 | 67 dB @ 15 ft. | 500 | 2 | 1/2 | 37 5/8" | 36 1/4" | 23" | Aluminum | Steel | ETL Listed, C-ETL Listed | 0000000 | 00000000 |

| 120V AC 240V AC | 10.8 5.4 | 40" | 10,600 | 70 dB @ 15 ft. | 425 | 1 | 3/4 | 43 5/8" | 42 1/4" | 23" | Aluminum | Steel | ETL Listed, C-ETL Listed | 0000000 | 00000000 |

| 120V AC 240V AC | 13.2 6.6 | 46" | 14,400 | 73 dB @ 15 ft. | 375 | 1 | 1 | 49 5/8" | 48 1/4" | 23" | Aluminum | Steel | ETL Listed, C-ETL Listed | 0000000 | 00000000 |

Rack-Mount Fans

Mount these fans directly to a rack. They have a pivoting extension arm and tilting fan head, so you can direct air where it’s needed and move them out of the way when not in use.

For technical drawings and 3-D models, click on a part number.

| Blade Dia. | Arm Reach | Airflow, cfm | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Voltage (Current) | Cord Lg., ft. | Housing Material | Blade Material | Guard Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

120V AC/240V AC, Single Phase—Three Prong Plug | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Non-Oscillating, Tilting | |||||||||||||||

| 14" | 15" | 2,600 | 66 dBA @ 15 ft. | 1,725 | 1 | 1/4 | 120V AC (2.8 A) 240V AC (1.4 A) | 12 | Powder-Coated Polypropylene Plastic | Galvanized Aluminum | Powder-Coated Steel | Yes | 9/16" | 0000000 | 0000000 |

| 18" | 17" | 3,800 | 68 dBA @ 15 ft. | 1,725 | 1 | 1/2 | 120V AC (6 A) 240V AC (3 A) | 12 | Powder-Coated Polypropylene Plastic | Galvanized Aluminum | Powder-Coated Steel | Yes | 9/16" | 0000000 | 00000000 |

| 22" | 19" | 5,500 | 69 dBA @ 15 ft. | 1,725 | 1 | 1/2 | 120V AC (6 A) 240V AC (3 A) | 12 | Powder-Coated Polypropylene Plastic | Galvanized Aluminum | Powder-Coated Steel | Yes | 9/16" | 0000000 | 00000000 |

| 26" | 21" | 7,600 | 84 dBA @ 15 ft. | 1,800 | 1 | 1 | 120V AC (13.4 A) 240V AC (6.8 A) | 12 | Powder-Coated Steel | Galvanized Aluminum | Powder-Coated Steel | Yes | 5/8" | 0000000 | 00000000 |

| 30" | 21" | 12,000 | 85 dBA @ 15 ft. | 1,800 | 1 | 1 | 120V AC (13.4 A) 240V AC (6.8 A) | 12 | Powder-Coated Polypropylene Plastic | Galvanized Aluminum | Powder-Coated Steel | Yes | 5/8" | 0000000 | 00000000 |

Hanging Box Fans

Easily hang these fans from your ceiling using the attached bracket and a mounting chain kit (sold separately). They're more powerful than our standard box fans. Made with a heavy duty 12-gauge welded wire mesh guard, these fans will stand up to tough environments. Plastic guard clips help reduce vibration between the housing and the guard, making these fans quieter. They require little maintenance thanks to their totally enclosed, high-efficiency motor and sealed ball bearings.

Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Voltage (Current) | Power, hp | Ht. | Wd. | Dp. | Drive Type | Housing Material | Blade Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

Single Phase—Hardwire | |||||||||||||||

Non-Oscillating | |||||||||||||||

| 24" | 5,100 | 1,650 | 1 | 120V AC (4.8 A) 240V AC (2.4 A) | 1/2 | 30 1/2" | 30 1/2" | 16 1/4" | Direct | Galvanized Steel | Aluminum | No | 3/8" | 0000000 | 0000000 |

| 36" | 9,600 | 850 | 1 | 120V AC (6.1 A) 240V AC (3 A) | 1/2 | 40 5/8" | 40 5/8" | 14 1/8" | Direct | Galvanized Steel | Steel | No | 3/8" | 0000000 | 000000 |

| 50" | 17,000 | 825 | 1 | 240V AC (5 A) | 1 | 54 1/2" | 54 1/2" | 18 3/8" | Direct | Galvanized Steel | Steel | No | 3/8" | 0000000 | 00000000 |

Three Phase—Hardwire | |||||||||||||||

Non-Oscillating | |||||||||||||||

| 24" | 5,000 | 850 | 1 | 240V AC (2.6 A) 460V AC (1.3 A) | 1/2 | 30 1/2" | 30 1/2" | 16 1/4" | Direct | Galvanized Steel | Steel | No | 3/8" | 0000000 | 000000 |

| 36" | 9,800 | 850 | 1 | 240V AC (2.6 A) 460V AC (1.3 A) | 1/2 | 40 5/8" | 40 5/8" | 14 1/8" | Direct | Galvanized Steel | Steel | No | 3/8" | 0000000 | 000000 |

| 50" | 17,400 | 825 | 1 | 240V AC (5.6 A) 460V AC (2.3 A) | 1 | 54 1/2" | 54 1/2" | 18 3/8" | Direct | Galvanized Steel | Steel | No | 3/8" | 0000000 | 00000000 |

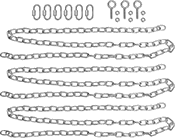

Chains | ||||

|---|---|---|---|---|

| No. of | Lg. | Includes | Each | |

| 3 | 72" | Six Threaded Connecting Links, Three Eyebolts, Six Nuts for Eyebolts | 0000000 | 000000 |

Direct-Drive Fan Motors

Since they have fewer moving parts, you can use these direct-drive motors to build fans that require less maintenance than fans with belt-drive motors. Mount them directly to a fan column.

For technical drawings and 3-D models, click on a part number.

Shaft | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Speed, rpm | Power, hp | Dia. | Lg. | Direction of Operation | Current, A | Voltage | Lg. | Wd. | Ht. | Insulation Class | Overload Protection Type | Each | |

NEMA 48Z—Welded (D-Profile Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 1,100 | 1/4 | 1/2" | 3 1/4" | Clockwise or Counterclockwise | 4.0 2.0 | 120V AC 240V AC | 9 3/4" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 0000000 |

| 1,100 | 1/3 | 1/2" | 3 1/4" | Clockwise or Counterclockwise | 4.5 2.3 | 120V AC 240V AC | 10" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,100 | 1/2 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 6.5 3.3 | 120V AC 240V AC | 11" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,700 | 1/4 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 3.4 1.7 | 120V AC 240V AC | 10 1/8" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,725 | 1/3 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 3.6 1.8 | 120V AC 240V AC | 10 1/8" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

NEMA F48Z—Welded (D-Profile Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 825 | 1/2 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 7.1 3.6 | 120V AC 240V AC | 11" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,700 | 1/2 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 5.5 2.8 | 120V AC 240V AC | 11" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

NEMA K56Z—Welded (Keyed Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 850 | 1/2 | 5/8" | 2 5/8" | Clockwise or Counterclockwise | 6.6 3.3 | 120V AC 240V AC | 12" | 6 1/2" | 8 3/4" | B | Thermal | 0000000 | 000000 |

NEMA P56CZ—Welded (Keyed Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 850 | 1 | 5/8" | 3 1/4" | Counterclockwise | 5.1 | 240V AC | 14 1/4" | 6 1/2" | 8 3/4" | B | Thermal | 0000000 | 000000 |

Hazardous Location Upblast Roof-Mount Exhaust Fans

With a UL-listed motor, these fans can be used in hazardous environments with combustible gases and dust to draw stagnant and humid air out through your roof, forcing it up and away from its surface.

Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance.

Belt-drive fans are quieter and last longer than direct-drive fans because their components can be replaced if they’re worn or damaged.

For technical drawings and 3-D models, click on a part number.

Fans | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting Bases | ||||||||||||||

| Blade Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Base Wd. | Wt., lbs. | Max. Ambient Temp., °F | Housing Material | Environmental Rating | Each | Each | ||

Totally Enclosed Motor Enclosure | |||||||||||||||

120/240V AC, Single Phase—Hardwire | |||||||||||||||

| 24" | 3,900 cfm @ 1/2 in. of H₂O 6,900 cfm @ 0 in. of H₂O | 75 dBA @ 5 ft. | 1,150 | 3/4 | 33" | 25" | 36" | 340 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 000000000 | 0000000 | 0000000 |

| 30" | 5,900 cfm @ 1/2 in. of H₂O 9,350 cfm @ 0 in. of H₂O | 72 dBA @ 5 ft. | 1,150 | 1 | 39" | 28" | 42" | 370 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

240/460V AC, Three Phase—Hardwire | |||||||||||||||

| 36" | 15,700 cfm @ 1/2 in. of H₂O 21,000 cfm @ 0 in. of H₂O | 79 dBA @ 5 ft. | 1,150 | 3 | 45" | 31" | 48" | 480 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

| 42" | 19,400 cfm @ 1/2 in. of H₂O 25,300 cfm @ 0 in. of H₂O | 80 dBA @ 5 ft. | 1,150 | 3 | 51" | 34" | 54" | 520 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

| 48" | 31,600 cfm @ 1/2 in. of H₂O 36,200 cfm @ 0 in. of H₂O | 89 dBA @ 5 ft. | 1,150 | 7 1/2 | 57" | 37" | 60" | 670 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

Fans | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting Bases | ||||||||||||||

| Blade Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Base Wd. | Wt., lbs. | Max. Ambient Temp., °F | Housing Material | Environmental Rating | Each | Each | ||

Totally Enclosed Motor Enclosure | |||||||||||||||

120/240V AC, Single Phase—Hardwire | |||||||||||||||

| 24" | 3,530 cfm @ 1/2 in. of H₂O 6,150 cfm @ 0 in. of H₂O | 71 dBA @ 5 ft. | 1,750 | 3/4 | 33" | 25" | 36" | 340 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 000000000 | 0000000 | 0000000 |

| 30" | 2,950 cfm @ 1/2 in. of H₂O 9,800 cfm @ 0 in. of H₂O | 68 dBA @ 5 ft. | 1,750 | 3/4 | 39" | 28" | 42" | 410 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

240/460V AC, Three Phase—Hardwire | |||||||||||||||

| 36" | 20,200 cfm @ 1/2 in. of H₂O 24,100 cfm @ 0 in. of H₂O | 82 dBA @ 5 ft. | 1,750 | 5 | 45" | 31" | 48" | 590 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

| 42" | 22,400 cfm @ 1/2 in. of H₂O 27,800 cfm @ 0 in. of H₂O | 78 dBA @ 5 ft. | 1,750 | 5 | 51" | 34" | 54" | 720 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

| 48" | 28,600 cfm @ 1/2 in. of H₂O 36,700 cfm @ 0 in. of H₂O | 80 dBA @ 5 ft. | 1,750 | 5 | 57" | 37" | 60" | 840 | 100° | Steel | NEC Class I Divisions 1, 2 Groups C, D; NEC Class II Divisions 1, 2 Groups E, F, G | 0000000 | 00000000 | 0000000 | 000000 |

Electric Blowguns for Large Areas

Clear dust and debris, test air ducts for leaks, and dry large surfaces without needing a compressed air line. Volume (dBA) is measured 3 ft. from the blowgun at 100 psi.

Attach the optional vacuum kit (sold separately) to convert the blowgun to a handheld vacuum.

High-Volume Hot Air Blowers

Blast your heating, drying, and shrinking projects with hot air to get the job done quickly. These blowers tilt 90° for directing airflow.

Use the optional curved-tip nozzle for installing heat-shrink tubing.

Hot Air Blowers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Replacement Heating Elements | |||||||||||||||

| Temp. Setting, °F | Airflow, cfm | Tip Dia. | Nozzle Lg. | Lg. | Wd. | Ht. | Wattage, W | Heating Element Material | Housing Material | Plug Type | NEMA Style | Specifications Met | Each | Each | ||

240V AC | ||||||||||||||||

| 300° | 47 | 1 7/8" | 6 1/4" | 12" | 6" | 9" | 1,200 | Mica | Steel | Three Prong | 6-15 | C-UL Listed, UL Listed | 0000000 | 0000000 | 00000000 | 000000 |

| 500° | 47 | 1 7/8" | 6 1/4" | 12" | 6" | 9" | 1,680 | Mica | Steel | Three Prong | 6-15 | C-UL Listed, UL Listed | 0000000 | 000000 | 00000000 | 00000 |

| 750° | 47 | 1 7/8" | 6 1/4" | 12" | 6" | 9" | 2,160 | Mica | Steel | Three Prong | 6-15 | C-UL Listed, UL Listed | 0000000 | 000000 | 00000000 | 00000 |

| For Max. Tube OD | Lg. | Tip Wd. | Each | |

| 2" | 4" | 3 1/4" | 0000000 | 000000 |

Heaters for Equipment-Cooling Fans

Heat the airflow from equipment-cooling fans to warm equipment and reduce humidity. Use with square equipment-cooling fans. Install in place of a fan guard using the mounting holes. Components are UL recognized.

For technical drawings and 3-D models, click on a part number.

For Overall Fan | Housing | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Wattage, W | Current, A | Material | Color | Mounting Hole Dia. | Mounting Fasteners Included | Each | |

240V AC, Single Phase—Wire Leads | ||||||||||

| 3.15" (80 mm) | 3.15" (80 mm) | 1.25" (31.75 mm) | 200 | 0.9 | Painted Aluminum | Black | 3/16" | No | 000000000 | 0000000 |

| 3.15" (80 mm) | 3.15" (80 mm) | 1.25" (31.75 mm) | 400 | 1.7 | Painted Aluminum | Black | 3/16" | No | 000000000 | 000000 |

| 4.69" (119 mm) | 4.69" (119 mm) | 1.25" (31.75 mm) | 200 | 0.9 | Painted Aluminum | Black | 3/16" | No | 00000000 | 000000 |

| 4.69" (119 mm) | 4.69" (119 mm) | 1.25" (31.75 mm) | 400 | 1.7 | Painted Aluminum | Black | 3/16" | No | 00000000 | 000000 |

| 4.69" (119 mm) | 4.69" (119 mm) | 1.25" (31.75 mm) | 600 | 2.6 | Painted Aluminum | Black | 3/16" | No | 00000000 | 000000 |

| 4.69" (119 mm) | 4.69" (119 mm) | 1.25" (31.75 mm) | 800 | 3.5 | Painted Aluminum | Black | 3/16" | No | 00000000 | 000000 |

Static-Eliminating Bars

Also known as ionizing bars, these bars remove static from moving materials on conveyors and assembly lines where there is little or no air movement. Mount bars 1" to 7" from the material. Do not mount directly over metal parts or rollers; the metal will absorb the ion charge and reduce the effectiveness of the bar.

Power supplies are required and can operate up to two static-eliminating bars.

Optional bar tester indicates whether your static eliminator is operating.

For technical drawings and 3-D models, click on a part number.

Static Control | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wd. | Dp. | Ht. | Wd. | Dp. | Voltage | Power Cord Lg., ft. | Features | Each | |

| 6" | 7" | 1 3/8" | 6" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 0000000 |

| 9" | 7" | 1 3/8" | 9" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 12" | 7" | 1 3/8" | 12" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 15" | 7" | 1 3/8" | 15" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 18" | 7" | 1 3/8" | 18" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 20" | 7" | 1 3/8" | 20" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 24" | 7" | 1 3/8" | 24" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 30" | 7" | 1 3/8" | 30" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 33" | 7" | 1 3/8" | 33" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 36" | 7" | 1 3/8" | 36" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 42" | 7" | 1 3/8" | 42" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 48" | 7" | 1 3/8" | 48" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 60" | 7" | 1 3/8" | 60" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 66" | 7" | 1 3/8" | 66" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 72" | 7" | 1 3/8" | 72" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 000000 |

| 96" | 7" | 1 3/8" | 96" | 3/4" | 120V AC/240V AC | 6 1/2 | Grounding Cord with Ring Terminal | 0000000 | 00000000 |

Ceiling Fan Speed Controls

Convert one or more single-speed ceiling fans to variable speed.

Controls with a switch can be turned on and off without adjusting the speed, reducing wear on the motor. Unlike knob-only controls, you can use use the switch to quickly start and stop fans without changing your settings.

Controls with a knob/switch have a rugged, sealed case that stands up to damp, rough, and other demanding environments.

Connect knob-only and slide bar/switch controls in a single-gang switch box.

For technical drawings and 3-D models, click on a part number.

Oil- and Coolant-Collecting Air Cleaners

Often used in machine shops, these cleaners remove oil and coolant mist from the air. Air passes through a spinning drum.

Cleaners that cannot be sold to California are restricted due to energy efficiency requirements.

For technical drawings and 3-D models, click on a part number.

Cleaners | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Replacement Filters | |||||||||||||||

| Airflow, cfm | Volume | Power, hp | Voltage | Current | For Inlet Duct Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | Mounting Hole Dia. | Includes | Cannot Be Sold To | Each | Each | ||

| 165 | 56 dB @ 15 ft. | 1/2 | 208V AC 240V AC 460V AC | 1.1A 2.2A 2.4A | 4" | 19" | 15" | 15" | No | 9/16" | Disposable Filter (Captures 98% of mist particles down to 1 micron) | __ | 000000 | 000000000 | 0000000 | 000000 |

| 380 | 58 dB @ 15 ft. | 1 | 208V AC 240V AC 460V AC | 2.1A 4.2A 4.6A | 4" | 21" | 17" | 22" | No | 9/16" | Disposable Filter (Captures 98% of mist particles down to 1 micron) | CA | 000000 | 00000000 | 0000000 | 00000 |

| 1,000 | 60 dB @ 15 ft. | 3 | 208V AC 240V AC 460V AC | 10.6A 4.8A 9.6A | 6" | 23" | 21" | 22" | No | 9/16" | Disposable Filter (Captures 98% of mist particles down to 1 micron) | CA | 000000 | 00000000 | 0000000 | 00000 |