Push-On External Retaining Rings

No groove required—press these rings onto the end of a shaft. Use them on unhardened shafts that are softer than the push ring. The ring bites into the metal to form an interference grip. Styles A, B, and C have teeth that dig into the shaft material, so expect minor scratching. Use a push nut installation tool (sold separately) to install rings, or install them manually.

1050 spring steel and 1060-1090 spring steel rings are an economical choice with good strength. A black finish is the result of a heat treatment to darken them—making them ideal for blending into dark backgrounds. However, these rings will rust if exposed to moisture. Black-phosphate finish is mildly corrosion resistant in dry environments. In wet environments, a zinc yellow-chromate plated finish has some corrosion resistance, and a zinc chromate plated finish has good corrosion resistance.

18-8 stainless steel rings have good corrosion resistance. A passivated finish adds protection against corrosion.

15-7 PH stainless steel rings have high strength with good corrosion resistance. Rings are passivated for added protection against corrosion.

For technical drawings and 3-D models, click on a part number.

Ring | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

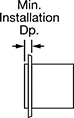

| Style | For OD | OD | Thick. | Ht. | Min. Installation Dp. | Passivation | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

Black-Phosphate 1060-1090 Spring Steel | |||||||||||

| A | 3/32" | 21/64" | 0.01" | 1/32" | 0.058" | __ | Not Rated | Magnetic | 100 | 000000000 | 00000 |

| A | 1/8" | 3/8" | 0.01" | 1/32" | 0.058" | __ | Not Rated | Magnetic | 100 | 000000000 | 0000 |

| A | 5/32" | 13/32" | 0.01" | 1/32" | 0.058" | __ | Not Rated | Magnetic | 100 | 000000000 | 0000 |

| A | 3/16" | 29/64" | 0.01" | 1/32" | 0.062" | __ | Not Rated | Magnetic | 100 | 000000000 | 0000 |

| A | 1/4" | 17/32" | 0.015" | 3/64" | 0.074" | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 0000 |

| A | 5/16" | 19/32" | 0.015" | 3/64" | 0.074" | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 0000 |

| A | 3/8" | 21/32" | 0.015" | 3/64" | 0.074" | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 0000 |

| A | 7/16" | 3/4" | 0.015" | 3/64" | 0.09" | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| A | 1/2" | 53/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| A | 9/16" | 57/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C47 | Magnetic | 50 | 000000000 | 0000 |

| A | 5/8" | 61/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C47 | Magnetic | 50 | 000000000 | 0000 |

| A | 3/4" | 1 5/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C47 | Magnetic | 50 | 000000000 | 00000 |

| A | 7/8" | 1 13/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C47 | Magnetic | 25 | 000000000 | 0000 |

| A | 1" | 1 21/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C47 | Magnetic | 25 | 000000000 | 0000 |

Black-Phosphate 1050 Spring Steel | |||||||||||

| B | 1/16" | 3/16" | __ | 1/32" | 0.25" | __ | Rockwell C38 | Magnetic | 200 | 000000000 | 00000 |

| B | 3/32" | 3/16" | __ | 1/32" | 0.25" | __ | Rockwell C38 | Magnetic | 200 | 000000000 | 00000 |

| B | 3/16" | 7/16" | __ | 1/16" | 0.25" | __ | Rockwell C30 | Magnetic | 100 | 000000000 | 0000 |

| B | 5/16" | 5/8" | __ | 1/16" | 0.25" | __ | Rockwell C30 | Magnetic | 100 | 000000000 | 00000 |

| B | 3/8" | 3/4" | __ | 3/32" | 0.25" | __ | Rockwell C38 | Magnetic | 50 | 000000000 | 00000 |

| B | 5/8" | 1" | __ | 5/64" | 0.25" | __ | Rockwell C38 | Magnetic | 50 | 000000000 | 00000 |

Zinc Yellow-Chromate-Plated 1060-1090 Spring Steel | |||||||||||

| A | 3/32" | 21/64" | 0.01" | 1/32" | 0.058" | __ | Rockwell C48 | Magnetic | 100 | 000000000 | 00000 |

| A | 1/8" | 3/8" | 0.01" | 1/32" | 0.058" | __ | Rockwell C48 | Magnetic | 100 | 000000000 | 00000 |

| A | 5/32" | 13/32" | 0.01" | 1/32" | 0.058" | __ | Rockwell C48 | Magnetic | 100 | 000000000 | 00000 |

| A | 3/16" | 29/64" | 0.01" | 1/32" | 0.062" | __ | Rockwell C48 | Magnetic | 100 | 000000000 | 00000 |

| A | 1/4" | 17/32" | 0.015" | 3/64" | 0.074" | __ | Rockwell C48 | Magnetic | 100 | 000000000 | 00000 |

| A | 5/16" | 19/32" | 0.015" | 3/64" | 0.074" | __ | Rockwell C48 | Magnetic | 50 | 000000000 | 00000 |

| A | 3/8" | 21/32" | 0.015" | 3/64" | 0.074" | __ | Rockwell C48 | Magnetic | 50 | 000000000 | 00000 |

| A | 7/16" | 3/4" | 0.015" | 3/64" | 0.09" | __ | Rockwell C48 | Magnetic | 50 | 000000000 | 00000 |

| A | 1/2" | 53/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C48 | Magnetic | 50 | 000000000 | 00000 |

| A | 9/16" | 57/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C48 | Magnetic | 50 | 000000000 | 00000 |

| A | 5/8" | 61/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C48 | Magnetic | 25 | 000000000 | 00000 |

| A | 3/4" | 1 5/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C48 | Magnetic | 25 | 000000000 | 00000 |

| A | 7/8" | 1 13/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C48 | Magnetic | 25 | 000000000 | 00000 |

| A | 1" | 1 21/64" | 0.015" | 3/64" | 0.108" | __ | Rockwell C48 | Magnetic | 25 | 000000000 | 00000 |

Zinc-Plated 1050 Spring Steel | |||||||||||

| B | 1/8" | 3/8" | __ | 3/64" | 0.25" | __ | Rockwell C38 | Magnetic | 200 | 000000000 | 00000 |

| B | 5/32" | 7/16" | __ | 3/64" | 0.25" | __ | Rockwell C38 | Magnetic | 25 | 000000000 | 00000 |

| B | 3/16" | 7/16" | __ | 1/16" | 0.25" | __ | Rockwell C38 | Magnetic | 200 | 000000000 | 00000 |

| B | 7/32" | 17/32" | __ | 5/64" | 0.25" | __ | Rockwell C38 | Magnetic | 200 | 000000000 | 00000 |

| B | 1/4" | 17/32" | __ | 1/16" | 0.25" | __ | Rockwell C38 | Magnetic | 200 | 000000000 | 00000 |

| B | 5/16" | 5/8" | __ | 1/16" | 0.25" | __ | Rockwell C38 | Magnetic | 100 | 000000000 | 00000 |

| B | 3/8" | 3/4" | __ | 3/32" | 0.25" | __ | Rockwell C30 | Magnetic | 50 | 000000000 | 00000 |

| B | 7/16" | 7/8" | __ | 3/32" | 0.25" | __ | Rockwell C38 | Magnetic | 50 | 000000000 | 00000 |

| B | 1/2" | 1" | __ | 7/64" | 0.25" | __ | Rockwell C38 | Magnetic | 25 | 000000000 | 00000 |

| C | 1/4" | 15/16" | __ | 3/32" | __ | __ | Rockwell C13 | Magnetic | 50 | 000000000 | 0000 |

| C | 5/16" | 15/16" | __ | 7/64" | __ | __ | Rockwell C13 | Magnetic | 50 | 000000000 | 00000 |

| C | 3/8" | 15/16" | __ | 3/32" | __ | __ | Rockwell C13 | Magnetic | 50 | 000000000 | 0000 |

18-8 Stainless Steel | |||||||||||

| D | 3/32" | 7/32" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 0000 |

| D | 1/8" | 7/32" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 1/8" | 1/4" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 1/8" | 21/64" | __ | 1/32" | __ | Passivated | Rockwell C27 | May Be Mildly Magnetic | 50 | 000000000 | 0000 |

| D | 5/32" | 17/64" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 0000 |

| D | 3/16" | 5/16" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 0000 |

| D | 3/16" | 3/8" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 1/4" | 5/16" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 1/4" | 7/16" | __ | 1/16" | __ | Not Passivated | Rockwell C27 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 5/16" | 7/16" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 3/8" | 5/8" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 7/16" | 37/64" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

| D | 1/2" | 3/4" | __ | 1/32" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

15-7 PH Stainless Steel | |||||||||||

| A | 3/32" | 21/64" | 0.01" | 1/32" | 0.058" | Passivated | Not Rated | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 1/8" | 3/8" | 0.01" | 1/32" | 0.058" | Passivated | Not Rated | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 5/32" | 13/32" | 0.01" | 1/32" | 0.058" | Passivated | Not Rated | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 3/16" | 29/64" | 0.01" | 1/32" | 0.062" | Passivated | Not Rated | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 1/4" | 17/32" | 0.01" | 1/32" | 0.074" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 5/16" | 19/32" | 0.01" | 1/32" | 0.074" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 3/8" | 21/32" | 0.01" | 1/32" | 0.074" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 7/16" | 3/4" | 0.015" | 3/64" | 0.09" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 1/2" | 53/64" | 0.015" | 3/64" | 0.108" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 9/16" | 57/64" | 0.015" | 3/64" | 0.108" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 5/8" | 61/64" | 0.015" | 3/64" | 0.108" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| A | 3/4" | 1 5/64" | 0.015" | 3/64" | 0.108" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| A | 7/8" | 1 13/64" | 0.015" | 3/64" | 0.108" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| A | 1" | 1 21/64" | 0.015" | 3/64" | 0.108" | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

302 Stainless Steel | |||||||||||

| B | 1/4" | 17/32" | __ | 5/64" | 0.25" | Not Passivated | Rockwell C30 | May Be Mildly Magnetic | 50 | 000000000 | 00000 |

Ring | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | For OD, mm | OD, mm | Thick., mm | Ht., mm | Min. Installation Dp., mm | Passivation | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

Black-Phosphate 1060-1090 Spring Steel | |||||||||||

| A | 3 | 8 | 0.25 | __ | 1.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 4 | 9 | 0.25 | __ | 2 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 0000 |

| A | 5 | 10 | 0.25 | __ | 2 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 0000 |

| A | 6 | 11 | 0.25 | __ | 2.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 0000 |

| A | 7 | 12 | 0.25 | __ | 2.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 0000 |

| A | 8 | 13 | 0.25 | __ | 2.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 0000 |

| A | 9 | 14 | 0.3 | __ | 2.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 10 | 16 | 0.3 | __ | 3 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 12 | 18 | 0.3 | __ | 3 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 14 | 20.5 | 0.3 | __ | 3 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 15 | 23 | 0.5 | __ | 3 | __ | Rockwell C45 | Magnetic | 25 | 000000000 | 0000 |

| A | 16 | 24.5 | 0.4 | __ | 3 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 17 | 26 | 0.5 | __ | 3.5 | __ | Rockwell C45 | Magnetic | 25 | 000000000 | 0000 |

| A | 18 | 27 | 0.4 | __ | 3.5 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 20 | 29 | 0.5 | __ | 3.5 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 22 | 31 | 0.5 | __ | 3.5 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 25 | 34 | 0.5 | __ | 4 | __ | Rockwell C45 | Magnetic | 25 | 000000000 | 00000 |

Black-Phosphate 1050 Spring Steel | |||||||||||

| B | 4 | 11.1 | __ | 1.5 | 6.5 | __ | Rockwell C38 | Magnetic | 100 | 000000000 | 00000 |

| B | 5 | 11.1 | __ | 1.5 | 6.5 | __ | Rockwell C38 | Magnetic | 100 | 000000000 | 00000 |

Zinc-Chromate-Plated 1060-1090 Spring Steel | |||||||||||

| A | 3 | 8 | 0.25 | __ | 1.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 4 | 9 | 0.25 | __ | 2 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 5 | 10 | 0.25 | __ | 2 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 6 | 11 | 0.25 | __ | 2.5 | __ | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| A | 7 | 12 | 0.25 | __ | 2.5 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 10 | 16 | 0.3 | __ | 3 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 12 | 18 | 0.3 | __ | 3 | __ | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| A | 16 | 24.5 | 0.4 | __ | 3 | __ | Rockwell C45 | Magnetic | 10 | 000000000 | 0000 |

| A | 20 | 29 | 0.5 | __ | 3.5 | __ | Rockwell C45 | Magnetic | 10 | 000000000 | 00000 |

| A | 22 | 31 | 0.5 | __ | 3.5 | __ | Rockwell C45 | Magnetic | 10 | 000000000 | 00000 |

Zinc-Plated 1050 Spring Steel | |||||||||||

| B | 6 | 13.5 | __ | 1.8 | 6.5 | __ | Rockwell C38 | Magnetic | 100 | 000000000 | 00000 |

Black Oxide 1060-1090 Spring Steel | |||||||||||

| C | 1.5 | 5 | __ | 1.3 | 1.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 2 | 7 | __ | 1.7 | 2 | __ | Rockwell C47 | Magnetic | 200 | 000000000 | 00000 |

| C | 3 | 10.5 | __ | 2.2 | 2.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 3.5 | 11 | __ | 2.2 | 2.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 4 | 12 | __ | 2.2 | 2.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 5 | 14 | __ | 2.5 | 3 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 6 | 16 | __ | 3 | 3.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 7 | 17 | __ | 3 | 3.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 8 | 18 | __ | 3 | 3.5 | __ | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| C | 10 | 20 | __ | 3 | 3.5 | __ | Rockwell C47 | Magnetic | 25 | 000000000 | 0000 |

Black Oxide 1050 Spring Steel | |||||||||||

| C | 1 | 4 | __ | 1.3 | 1.5 | __ | Rockwell C47 | Magnetic | 50 | 000000000 | 0000 |

| C | 2.5 | 8.5 | __ | 1.7 | 2 | __ | Rockwell C47 | Magnetic | 50 | 000000000 | 0000 |

| C | 4.5 | 13 | __ | 2.5 | 3 | __ | Rockwell C47 | Magnetic | 50 | 000000000 | 0000 |

| C | 5.5 | 14 | __ | 2.5 | 3 | __ | Rockwell C47 | Magnetic | 25 | 000000000 | 0000 |

15-7 PH Stainless Steel | |||||||||||

| A | 3 | 8 | 0.25 | __ | 1.5 | Passivated | Rockwell C44 | May Be Mildly Magnetic | 10 | 000000000 | 00000 |

| A | 5 | 10 | 0.25 | __ | 2 | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| A | 6 | 11 | 0.25 | __ | 2.5 | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| A | 9 | 14 | 0.3 | __ | 2.5 | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| A | 10 | 16 | 0.3 | __ | 3 | Passivated | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

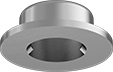

Push-On Retaining Caps

Use these caps to hold components in place and protect shaft ends. Install these caps with a hammer or push them into place by hand.

Corrosion-resistant-coated finish is more corrosion resistant in wet environments than zinc plated finish. Also known as black luster.

Nickel-plated finish has excellent corrosion resistance and a decorative appearance.

Zinc-plated finish is corrosion resistant in wet environments.

For technical drawings and 3-D models, click on a part number.

| For OD | OD | Ht. | Insert Material | Min. Hardness | Temperature Range, °F | Magnetic Properties | Pkg. Qty. | Pkg. | |

Black Corrosion-Resistant-Coated 1050 Spring Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 9/16" | 7/32" | Steel | Not Rated | __ | Magnetic | 5 | 000000000 | 00000 |

| 5/16" | 5/8" | 1/4" | Steel | Not Rated | __ | Magnetic | 5 | 000000000 | 0000 |

| 3/8" | 3/4" | 9/32" | Steel | Not Rated | __ | Magnetic | 5 | 000000000 | 00000 |

| 1/2" | 15/16" | 21/64" | Steel | Not Rated | __ | Magnetic | 5 | 000000000 | 00000 |

Nickel-Plated 1050 Spring Steel | |||||||||

| 1/4" | 1/2" | 7/32" | Steel | Rockwell C13 | __ | Magnetic | 25 | 000000000 | 0000 |

| 3/8" | 3/4" | 9/32" | Steel | Rockwell C13 | __ | Magnetic | 25 | 000000000 | 0000 |

Zinc-Plated 1050 Spring Steel | |||||||||

| 5/16" | 9/16" | 19/64" | Steel | Rockwell C44 | __ | Magnetic | 25 | 000000000 | 0000 |

| 1/2" | 15/16" | 21/64" | Steel | Rockwell C38 | __ | Magnetic | 10 | 000000000 | 0000 |

| 5/8" | 1 3/16" | 27/64" | Steel | Rockwell C38 | __ | Magnetic | 10 | 000000000 | 0000 |

400 Series Stainless Steel | |||||||||

| 1/8" | 27/64" | 1/8" | 18-8 Stainless Steel | Rockwell C49 | __ | May Be Mildly Magnetic | 10 | 000000000 | 0000 |

| 3/16" | 1/2" | 5/32" | 18-8 Stainless Steel | Rockwell C49 | __ | May Be Mildly Magnetic | 25 | 000000000 | 0000 |

| 1/4" | 41/64" | 13/64" | 18-8 Stainless Steel | Rockwell C49 | __ | May Be Mildly Magnetic | 10 | 000000000 | 0000 |

| 3/8" | 25/32" | 15/64" | 18-8 Stainless Steel | Rockwell C49 | __ | May Be Mildly Magnetic | 10 | 000000000 | 00000 |

Black Plastic | |||||||||

| 5/32" | 21/32" | 23/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 50 | 000000000 | 00000 |

| 3/16" | 21/32" | 23/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 50 | 000000000 | 00000 |

| 1/4" | 27/32" | 23/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 50 | 000000000 | 00000 |

| 5/16" | 27/32" | 29/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 25 | 000000000 | 00000 |

| 3/8" | 55/64" | 15/32" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 25 | 000000000 | 0000 |

| 7/16" | 53/64" | 7/16" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 10 | 000000000 | 0000 |

| 1/2" | 1 5/16" | 41/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 10 | 000000000 | 0000 |

| 5/8" | 1 5/16" | 41/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 10 | 000000000 | 0000 |

White Plastic | |||||||||

| 1/8" | 21/32" | 23/64" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 10 | 000000000 | 00000 |

| 3/16" | 21/32" | 11/32" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 25 | 000000000 | 0000 |

| 3/8" | 55/64" | 15/32" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 25 | 000000000 | 0000 |

Red Plastic | |||||||||

| 5/16" | 55/64" | 15/32" | Steel | Rockwell C45 | -90° to 150° | Magnetic | 25 | 000000000 | 0000 |

Flanged Push-On External Retaining Rings

The wide flange provides better load distribution than standard external push rings and can be used to cover oversized holes. Also known as thread cutting nuts. Use them on unhardened shafts that are softer than the push ring. The ring bites into the metal to form an interference grip.

For technical drawings and 3-D models, click on a part number.

| For OD | Flange Dia. | Hex Wd. | Ht. | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

Zinc-Plated 1050 Spring Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8" | 7/16" | 5/16" | 3/16" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 1/8" | 17/32" | 5/16" | 13/64" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 5/32" | 9/16" | 3/8" | 13/64" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 3/16" | 1/2" | 3/8" | 7/32" | Rockwell C41 | Magnetic | 100 | 000000000 | 0000 |

| 3/16" | 5/8" | 3/8" | 15/64" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 1/4" | 19/32" | 7/16" | 15/64" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 1/4" | 11/16" | 7/16" | 15/64" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 5/16" | 7/8" | 1/2" | 5/16" | Rockwell C41 | Magnetic | 50 | 000000000 | 00000 |

Rectangular Push-On External Retaining Rings

Also known as flat-style speed nuts, these have a large surface to distribute loads better than standard and flanged external push rings. Use them on unhardened shafts that are softer than the push ring. The ring bites into the metal to form an interference grip.

For technical drawings and 3-D models, click on a part number.

| For OD | Wd. | Lg. | Ht. | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

Black-Phosphate 1050 Spring Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/16" | 7/32" | 3/8" | 0.028" | Rockwell C41 | Magnetic | 100 | 000000000 | 000000 |

| 3/32" | 7/32" | 7/16" | 0.087" | Rockwell C41 | Magnetic | 50 | 000000000 | 00000 |

| 3/32" | 1/4" | 7/16" | 0.039" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 1/8" | 5/16" | 9/16" | 0.028" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 5/32" | 3/8" | 9/16" | 0.033" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 5/32" | 7/16" | 3/4" | 0.087" | Rockwell C41 | Magnetic | 50 | 000000000 | 00000 |

| 3/16" | 3/8" | 5/8" | 0.075" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 1/4" | 7/16" | 5/8" | 0.063" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

| 5/16" | 1/2" | 11/16" | 0.067" | Rockwell C41 | Magnetic | 100 | 000000000 | 00000 |

Push-On Internal Retaining Rings

No groove required—these rings have teeth that firmly grip the bore. Use them in unhardened shafts that are softer than the push ring. The metal must be soft enough for the ring to form an interference grip. Not recommended for use with nickel-, chrome-, or nitride-coated shafts.

1060-1090 spring steel rings are an economical choice with good strength. The black-phosphate finish is mildly corrosion resistant in dry environments.

15-7 PH stainless steel rings have high strength with good corrosion resistance. Rings are passivated for added protection against corrosion.

For technical drawings and 3-D models, click on a part number.

Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

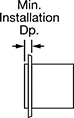

| For ID | ID | Thick. | Min. Installation Dp. | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

Black-Phosphate 1060-1090 Spring Steel | ||||||||

| 5/16" | 1/8" | 0.01" | 0.04" | Rockwell C47 | Magnetic | 100 | 000000000 | 000000 |

| 3/8" | 11/64" | 0.01" | 0.04" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 7/16" | 15/64" | 0.01" | 0.04" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 1/2" | 1/4" | 0.01" | 0.04" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 9/16" | 5/16" | 0.01" | 0.04" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 5/8" | 25/64" | 0.01" | 0.04" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 3/4" | 1/2" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 7/8" | 5/8" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 100 | 000000000 | 00000 |

| 15/16" | 11/16" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 50 | 000000000 | 00000 |

| 1" | 3/4" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 50 | 000000000 | 00000 |

| 1 1/8" | 13/16" | 0.015" | 0.06" | Rockwell C46 | Magnetic | 50 | 000000000 | 00000 |

| 1 1/4" | 15/16" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 50 | 000000000 | 00000 |

| 1 1/2" | 1 3/16" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 25 | 000000000 | 00000 |

| 1 3/4" | 1 7/16" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 10 | 000000000 | 0000 |

| 2" | 1 19/32" | 0.015" | 0.06" | Rockwell C47 | Magnetic | 10 | 000000000 | 0000 |

15-7 PH Stainless Steel | ||||||||

| 5/16" | 1/8" | 0.01" | 0.04" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 3/8" | 11/64" | 0.01" | 0.04" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 7/16" | 15/64" | 0.01" | 0.04" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 1/2" | 1/4" | 0.01" | 0.04" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 9/16" | 5/16" | 0.01" | 0.04" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 5/8" | 25/64" | 0.01" | 0.04" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 3/4" | 1/2" | 0.015" | 0.06" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 0000 |

| 7/8" | 5/8" | 0.015" | 0.06" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| 15/16" | 11/16" | 0.015" | 0.06" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| 1" | 3/4" | 0.015" | 0.06" | Rockwell C44 | May Be Mildly Magnetic | 5 | 000000000 | 00000 |

| 1 1/4" | 15/16" | 0.015" | 0.06" | Rockwell C44 | May Be Mildly Magnetic | 1 | 000000000 | 0000 |

| 1 1/2" | 1 3/16" | 0.015" | 0.06" | Rockwell C44 | May Be Mildly Magnetic | 1 | 000000000 | 0000 |

Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

| For ID, mm | ID, mm | Thick., mm | Min. Installation Dp., mm | Min. Hardness | Magnetic Properties | Pkg. Qty. | Pkg. | |

Black-Phosphate 1060-1090 Spring Steel | ||||||||

| 8 | 4 | 0.25 | 2 | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| 10 | 5 | 0.25 | 2 | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| 12 | 6 | 0.25 | 2.5 | Rockwell C45 | Magnetic | 100 | 000000000 | 0000 |

| 14 | 8 | 0.3 | 2.5 | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| 15 | 9 | 0.3 | 2.5 | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| 16 | 10 | 0.3 | 2.5 | Rockwell C45 | Magnetic | 100 | 000000000 | 00000 |

| 17 | 11 | 0.3 | 3 | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| 18 | 10.5 | 0.4 | 3 | Rockwell C45 | Magnetic | 50 | 000000000 | 0000 |

| 20 | 11 | 0.4 | 3.5 | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| 22 | 13 | 0.5 | 3.5 | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| 24 | 15 | 0.5 | 3.5 | Rockwell C45 | Magnetic | 50 | 000000000 | 00000 |

| 25 | 16 | 0.5 | 3.5 | Rockwell C45 | Magnetic | 25 | 000000000 | 0000 |

| 26 | 17 | 0.5 | 3.5 | Rockwell C45 | Magnetic | 25 | 000000000 | 00000 |

| 30 | 21 | 0.5 | 4 | Rockwell C45 | Magnetic | 25 | 000000000 | 00000 |

| 35 | 25 | 0.5 | 4 | Rockwell C45 | Magnetic | 10 | 000000000 | 0000 |

| 40 | 30 | 0.5 | 4 | Rockwell C45 | Magnetic | 10 | 000000000 | 0000 |

| 50 | 39 | 0.5 | 4 | Rockwell C45 | Magnetic | 10 | 000000000 | 0000 |