Wing Nut Expansion Plugs

Twist the wing nut on these plugs to expand the seal and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Style A aren’t recommended for pressure testing, so they’re often used as a dust cover. Plugs with a stainless steel plate have excellent corrosion resistance.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal Material | Each | |

Style A | ||||||||

Stainless Steel Plate | ||||||||

| 2 1/2 | 2.44"-2.60" | 5 | 12 | 2 13/16" | 0° to 175° | Neoprene Rubber | 0000000 | 000000 |

Hex-Nut Expansion Plugs

Tighten the nut on these plugs to expand the seal and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Style D have an eyebolt that allows you to tether or hang the plug for convenient storage.

Plugs with a stainless steel plate have excellent corrosion resistance.

Plugs with a zinc-plated steel plate have fair corrosion resistance.

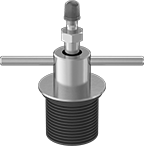

T-Handle Expansion Plugs

Twist the easy-grip T-handle on these plugs to expand the seal and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Plugs with a zinc-plated steel plate have fair corrosion resistance.

Plugs with a stainless steel plate have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal Material | Each | |

Brass Handle | ||||||||

Zinc-Plated Steel Plate | ||||||||

| 2 1/2 | 2.44"-2.60" | 5 | 12 | 3 7/8" | -40° to 250° | Neoprene Rubber | 0000000 | 000000 |

Stainless Steel Handle | ||||||||

Stainless Steel Plate | ||||||||

| 2 1/2 | 2.44"-2.60" | 5 | 12 | 3 7/8" | -40° to 250° | Neoprene Rubber | 0000000 | 00000 |

Quick-Snap Expansion Plugs

Turn the cam handle to expand the seal, then snap the handle down to hold it in place and close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Plugs with a zinc-plated steel plate have fair corrosion resistance.

Plugs with a stainless steel plate have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

For Pipe | Max. Back Pressure | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal Material | Each | |

Brass Handle | ||||||||

Zinc-Plated Steel Plate | ||||||||

| 2 1/2 | 2.47"-2.55" | 5 | 12 | 2 5/16" | -40° to 250° | Neoprene Rubber | 0000000 | 000000 |

Stainless Steel Handle | ||||||||

Stainless Steel Plate | ||||||||

| 2 1/2 | 2.47"-2.55" | 5 | 12 | 2 5/16" | -40° to 250° | Neoprene Rubber | 0000000 | 00000 |

Expansion Plugs with Bypass

Use the bypass tube on these plugs to add air, water, and other fluid to your pipeline or to relieve pressure while testing. The seal expands to temporarily close off pipe openings. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

For Styles A-E and H-L, twist the wing nut to expand the seal.

Styles C and D have an NPT threaded bypass for making leak-tight connections.

For Styles F and G, twist the easy-grip T-handle to expand the seal.

Styles G, J, and K have a Schrader valve bypass. An internal spring holds the valve shut until you depress the pin, giving you control over air flow.

For technical drawings and 3-D models, click on a part number.

For Pipe | Max. Back Pressure | Material | Bypass | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | ID | Air, psi | Water, ft. of head | O'all Ht. | Temp. Range, °F | Seal | Bypass Cap | Pipe Size | Thread Type | Thread Size | Gender | Each | |

Style D | |||||||||||||

Plastic Stem | |||||||||||||

| 2 1/2 | 2.40"-2.76" | 30 | 69 | 4 1/2" | -40° to 180° | Natural Rubber | Plastic | 1/2 | NPT | __ | Male | 0000000 | 000000 |

Style G | |||||||||||||

Steel Stem | |||||||||||||

| 2 1/2 | 2.44"-2.71" | 5 | 12 | 4 15/16" | -40° to 210° | Neoprene Rubber | Plastic | __ | Schrader | 0.305"-32 | __ | 00000000 | 000000 |

Air-Inflatable Plugs

Conform to wide and out-of-round pipes with these inflatable plugs. Also known as pneumatic plugs, they're designed for temporary seals since they can lose pressure over time. Inflate with a hand pump (sold separately); an air compressor may overinflate the plug and cause damage. Tether the plugs using either the eyebolt or chain/ring so they don't get lost or stuck in your pipes. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

For Pipe | Deflated | Max. Back Pressure | Material | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | ID | Dia. | Ht. | Air, psi | Water, ft. of head | Required Inflation Pressure, psi | Temp. Range, °F | Seal | Chain/Ring | Each | |

| 2 1/2 | 2.34"-2.75" | 2 5/16" | 4 1/2" | 13 | 30 | 35 | -20° to 125° | Natural Rubber | Zinc-Plated Steel | 000000 | 000000 |

Deep-Reach Wing Nut Expansion Plugs

Plate With

Brass Stem

Insert these plugs deep within your pipe to temporarily block off a line. Twist their wing nut to expand the seal. Maximum air back pressure is the amount of pressure a plug can withstand without moving. Maximum water back pressure refers to the pressure resulting from the height of the water above the plug.

Plugs with a stainless steel plate have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.