Selecting and Measuring Expansion Joints

For information about selecting pipe size, see Selecting and Measuring Pipe & Fittings.

More

Expansion Joints with Flanged Ends

These joints reduce stress, vibration, and noise in piping systems by providing a point of flexibility to absorb movement. The flanged ends rotate for easy bolt hole alignment during installation. They mate with a same-size flat-surface Class 150 flange without the need for a gasket. Joints have a flexible body that is reinforced with nylon for added strength.

Position the expansion joints as close as possible to anchor points. Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Nonabrasive Slurry, Water

- Temperature Range: -10° to 220° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

- For Use With: Alcohol, Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

High-Temperature All-Metal Expansion Joints with Flanged Ends

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Temperature Range: -20° to 800° F

- Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

These all-metal expansion joints can handle higher temperatures than rubber expansion joints. They reduce stress, vibration, and noise in piping systems by providing a point of flexibility to absorb movement. Joints are made of 304 stainless steel for very good corrosion resistance. The flanged ends rotate for easy bolt hole alignment during installation. Flanges mate with a same-size flat-surface Class 150 flange with a gasket (sold separately).

Liners (sold separately) slide into the expansion joint to provide a smooth interior for unrestricted flow.

For technical drawings and 3-D models, click on a part number.

Expansion Joints with Sealing Flanged Ends for Metal Pipe

Because the flanges are molded into the body for a wide sealing surface, these joints provide a tighter seal than other expansion joints. Each flange is supported by a zinc-plated steel plate. Flanges mate with a same-size flat-surface Class 150 flange without the need for a gasket. Joints reduce stress, vibration, and noise in metal piping systems by providing a point of flexibility to absorb movement. They have a flexible body that is reinforced with cord for added strength.

Mount these expansion joints as close as possible to anchor points. Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Coolant, Grease, Hydraulic Fluid, Water

- Temperature Range: -65° to 220° F

- Maximum Pressure: 210 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

- For Use With: Grain Alcohol, Nonabrasive Slurry, Water

- Temperature Range: -20° to 220° F

- Maximum Pressure: 190 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

Expansion Joints with Sealing Flanged Ends for Plastic Pipe

These joints reduce stress, vibration, and noise in plastic piping systems by providing a point of flexibility to absorb movement. Joints provide a tighter seal than other expansion joints because the flanges are molded into the body for a wide sealing surface. Each flange is supported by a zinc-plated steel plate. Flanges mate with a same-size flat-surface Class 150 flange without the need for a gasket.

Neoprene joints resist abrasion better than EPDM joints.

Position the expansion joints as close as possible to anchor points. Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Natural Gas, Oil, Water

- Temperature Range: -10° to 220° F

- Maximum Pressure: See table

- Maximum Vacuum: 24 in. of Hg @ 72° F

- For Use With: Alcohol, Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 24 in. of Hg @ 72° F

Chemical-Resistant Expansion Joints with Flanged Ends

- For Use With: Coolant, Hydrochloric Acid, Water

- Temperature Range: -0° to 400° F

- Maximum Pressure: See table

- Maximum Vacuum: 29 in. of Hg @ 72° F

The PTFE body on these expansion joints has a super-smooth surface that stands up to corrosive chemicals. Joints have a triple-bulb design that provides excellent vibration absorption, reducing stress on your piping system. The flanges mate with a same-size flat-surface Class 150 flange without the need for a gasket. Limit rods are attached to the flanges to prevent overextension.

For technical drawings and 3-D models, click on a part number.

Distance | Threaded Bolt Holes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | Pipe Size | Lg. | No. of Bolt Holes | Compression | Expansion | Offset | Max. Pressure | Expansion Joint Type | Flange Material | Bolt Hole Thread Size | Each | |

Ultra-Corrosion-Resistant Coated PTFE Plastic | ||||||||||||

| 11" | 6 | 4" | 8 | 1 1/8" | 1 1/8" | 9/16" | 130 psi @ 72° F | Triple Bulb | Iron | 3/4"-10 | 0000000 | 000000000 |

Expansion Joints with Flanged Ends for High Vibration

These expansion joints have a double-bulb design for extra movement and vibration absorption. The flanged ends rotate for easy bolt hole alignment during installation. They mate with a same-size flat-surface Class 150 flange without the need for a gasket. Joints have a flexible body that is reinforced with nylon for added strength.

Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

- For Use With: Grain Alcohol, Nonabrasive Slurry, Water

- Temperature Range: -10° to 220° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

- For Use With: Alcohol, Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: 220 psi @ 72° F

- Maximum Vacuum: 26 in. of Hg @ 72° F

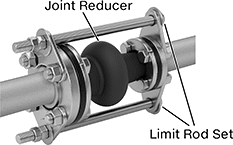

Expansion Joint Reducers with Flanged Ends

Connect different pipe sizes in your line while adding a point of flexibility between them. These expansion joints absorb movement between two connected pipes to reduce stress, vibration, and noise. Their flanged ends mate with same-size Class 150 flanges without the need for a gasket. Each flange is supported by a zinc-plated steel plate. The body of these expansion joints is reinforced with cord for added strength.

Your pipe system must be rigidly anchored on both sides of the expansion joint to control expansion or contraction of the line. When proper anchoring cannot be provided, limit rods (sold separately) are required.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Alcohol, Calcium Chloride, Coolant, Grain Alcohol, Grease, Hydraulic Fluid, Sodium Carbonate (20% in Water), Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: See Table

- Maximum Vacuum: 26 in. of Hg @ 72° F

Unthreaded Bolt Holes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flange OD | Pipe Size | No. of Bolt Holes | Distance | Bolt Hole Size | ||||||||||||

(A) | (B) | (A) | (B) | Lg. | (A) | (B) | Compression | Expansion | Offset | Max. Pressure | Expansion Joint Type | Flange Material | (A) | (B) | Each | |

EPDM Rubber | ||||||||||||||||

| 11" | 9" | 6 | 4 | 8" | 8 | 8 | 1 9/16" | 3/4" | 1/2" | 190 psi @ 72° F | Single Bulb | EPDM Rubber | 7/8" | 3/4" | 0000000 | 000000000 |

| 13 1/2" | 11" | 8 | 6 | 8" | 8 | 8 | 1 9/16" | 3/4" | 1/2" | 190 psi @ 72° F | Single Bulb | EPDM Rubber | 7/8" | 7/8" | 0000000 | 00000000 |

Expansion Joints with Flanged Ends for Drinking Water

- For Use With: Drinking Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: See table

- Maximum Vacuum: 26in. of Hg @ 72° F

- Specifications Met: NSF/ANSI 61

The EPDM lining in these joints meets NSF/ANSI 61 standard for use with drinking water. To reduce stress, vibration, and noise in piping systems, they provide a point of flexibility to absorb movement. These joints have a flexible body reinforced with polyester cord for added strength. A zinc-plated steel plate supports each flange. The flanges mate with the same-size flat-surface Class 150 flange without the need for a gasket.

Position the expansion joints as close as possible to anchor points. Attach limit rod sets (sold separately) to the flanges to prevent overextension where anchoring is insufficient. To accommodate the thickness of the limit rod mounting plate, use bolts that are 7/8" longer than the bolts connecting the expansion joint to the pipe flange. Each set of limit rods requires eight bolts (not included).

For technical drawings and 3-D models, click on a part number.

Expansion Joints | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Distance | Limit Rod Sets | |||||||||||||

| Flange OD | Pipe Size | Lg. | No. of Bolt Holes | Compression | Expansion | Offset | Max. Pressure | Expansion Joint Type | Flange Material | Bolt Hole Size | Each | Pair | ||

EPDM Rubber with EPDM Rubber Liner | ||||||||||||||

| 11" | 6 | 6" | 8 | 1 5/8" | 3/4" | 3/4" | 190 psi @ 72° F | Single Bulb | Zinc-Plated Steel | 7/8" | 0000000 | 000000000 | 0000000 | 0000000 |

Clamp-On Expansion Joints

- For Use With: Calcium Chloride, Oil, Petroleum, Sewage, Sludge, Sodium Carbonate (20% in Water), Water

- Temperature Range:

Neoprene Rubber: -20° to 220° F

Silicone Rubber: -75° to 500° F - Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 20 in. of Hg @ 72° F

Slip these joints over your pipe ends and tighten the band clamps for a secure hold. Joints have a triple-bulb design that provides excellent vibration absorption to reduce stress on your piping system. They also have reinforcing rings for extra support during pressure surges and in vacuum applications.

Neoprene rubber joints are more abrasion resistant than silicone rubber joints.

For technical drawings and 3-D models, click on a part number.

Distance | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Pipe Size | Lg. | Compression | Expansion | Offset | Expansion Joint Type | Reinforcement Material | Band Clamp Material | Each | |

Neoprene Rubber | ||||||||||

| 6 5/8" | 6 | 7" | 1" | 1/2" | 1 1/8" | Triple Bulb | Nylon Plastic | 300 Series Stainless Steel | 0000000 | 0000000 |

Silicone Rubber | ||||||||||

| 6 5/8" | 6 | 7" | 1" | 1/2" | 1 1/8" | Triple Bulb | Fiberglass | 300 Series Stainless Steel | 00000000 | 000000 |

Expansion Joints with Butt-Weld Ends

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Temperature Range: -20° to 800° F

- Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

These joints weld to unthreaded pipe or another butt-weld fitting for a leak-resistant, permanent connection. They reduce stress, vibration, and noise in metal piping systems by providing a point of flexibility to absorb movement.

For technical drawings and 3-D models, click on a part number.

Distance | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Pipe Size | Lg. | Compression | Expansion | Offset | Expansion Joint Type | Butt Weld End Material | Each | |

321 Stainless Steel | |||||||||

| 6 5/8" | 6 | 9" | 13/16" | 3/8" | 1/16" | Bellow | Steel | 0000000 | 0000000 |