About Structural Adhesives

More

About Paint and Protective Coatings

More

Quick-Set Epoxy Structural Adhesives

For quick repairs, these epoxies begin to harden in 6 minutes or less. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives.

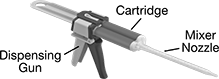

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP100NS is nonsagging, so it won't drip from vertical or overhead surfaces.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| DP100 | 1.64 | Cartridge | 5 min. | 48 hrs. | 750 | 2 | 1:1 | Thick Liquid (12,000 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 000000 |

| DP100 | 6.76 | Cartridge | 5 min. | 48 hrs. | 750 | 2 | 1:1 | Thick Liquid (12,000 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 00000 |

| DP100NS | 1.64 | Cartridge | 5 min. | 48 hrs. | 840 | 2 | 1:1 | Paste (93,750 cP) | -65° to 320° | Clear | Metal, Plastic, Rubber | 0000000 | 00000 |

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| 0.84 | Syringe | 5 min. | 24 hrs. | 3,300 | Not Rated | 1:1 | Thick Liquid (10,000 cP) | -10° to 200° | Clear | Metal, Plastic, Rubber, Glass, Wood | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 6.76 fl. oz. 3M Cartridges | 0000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 6.76 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

Epoxy Structural Adhesives

Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. They work especially well on metals. The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP110, 14310, 14260, and 305-1/2 bond dissimilar materials.

DP125, 14255, and 14251 form flexible bonds.

Epoxy in 5-oz. tubes is solvent-free. It can be softened in warm water if the contents of the tube have hardened.

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| 1838L | 64 | Can | 60 min. | 7 days | 2,000 | 4 | 1:1 | Thick Liquid (11,000 cP) | -65° to 350° | Clear | Metal, Plastic, Rubber, Composites, Glass, Masonry, Wood | 00000000 | 0000000 |

| DP110 | 1.64 | Cartridge | 8 min. | 48 hrs. | 1,500 | 20 | 1:1 | Thick Liquid (50,000 cP) | -65° to 350° | Clear | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| DP125 | 1.64 | Cartridge | 20 min. | 7 days | 1,500 | 35 | 1:1 | Thick Liquid (16,250 cP) | -65° to 300° | Clear | Metal, Plastic, Rubber | 0000000 | 00000 |

| DP190 | 1.64 | Cartridge | 60 min. | 14 days | 850 | 20 | 1:1 | Thick Liquid (8,000 cP) | -65° to 350° | Clear | Metal, Plastic, Rubber, Masonry | 0000000 | 00000 |

| DP190 | 6.76 | Cartridge | 60 min. | 14 days | 850 | 20 | 1:1 | Thick Liquid (8,000 cP) | -65° to 350° | Clear | Metal, Plastic, Rubber, Masonry | 00000000 | 00000 |

Mfr. Model | Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| 10 Minute Epoxy | 14251 | 1.69 | Cartridge | 10 min. | 90 min. | 2,400 | 20 | 1:1 | Thick Liquid (80,000 cP) | -65° to 200° | Clear | Metal, Plastic, Masonry, Wood | 00000000 | 000000 |

| 2 Ton Epoxy | 14260 | 1.69 | Cartridge | 8 min. | 16 hrs. | 2,250 | 2 | 1:1 | Thick Liquid (8,000 cP) | -40° to 200° | Clear | Metal, Metal to Plastic, Metal to Composites, Plastic, Plastic to Composites, Composites | 00000000 | 00000 |

| 2 Ton Epoxy | 14310 | 0.84 | Syringe | 8 min. | 16 hrs. | 2,250 | 2 | 1:1 | Thick Liquid (8,000 cP) | -40° to 200° | Clear | Metal, Metal to Plastic, Metal to Composites, Plastic, Plastic to Composites, Composites | 0000000 | 00000 |

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | For Joining | Each | |

| 5 | Tube | 20 min. | 24 hrs. | 2,500 | Not Rated | 2:1 | Paste (Not Rated) | -65° to 260° | Clear | Metal, Plastic, Rubber | 0000000 | 000000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 6.76 fl. oz. 3M Cartridges | 0000000 | 0000 |

| Mixer Nozzle for 1.69 fl. oz. Cartridges | 00000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 6.76 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz. Cartridges | 00000000 | 00000 |

Waterproof Epoxy Structural Adhesives

Even when used under water, these adhesives maintain their strength. The most weather- and chemical-resistant structural adhesives, epoxies tend to work especially well on metals.

The size listed is the combined total of the two parts.

ClearWeld and Plastic Bonder can be applied to wet surfaces.

Mfr. Model | Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | Color | Environment | For Joining | Each | |

| ClearWeld | 50114 | 0.5 | Syringe | 5 min. | 1 hrs. | 1,500 | 1:1 | Paste | Not Rated to 300° | Clear | Submersible | Metal, Plastic, Rubber, Composites | 0000000 | 00000 |

| ClearWeld | 50240H | 8 | Tube | 5 min. | 1 hrs. | 1,500 | 1:1 | Paste | Not Rated to 300° | Clear | Submersible | Metal, Plastic, Rubber, Composites | 0000000 | 00000 |

Epoxy Structural Adhesive Assortments

Easily handle a variety of small jobs. Assortments include eight different epoxies in 0.1-oz. packets. The strongest and most weather- and chemical-resistant structural adhesives, epoxies work especially well on metals.

| Epoxy Type (For Joining) | Each | |

| Easy Flowing (Composites, Metal) Fast Hardening (Masonry, Metal, Rubber) For Vertical Surfaces (Masonry, Metal, Wood) General Purpose (Masonry, Metal, Plastic, Rubber) High Strength (Metal, Rubber) Machinable Surface Filler (Composites, Metal) Optically Clear (Glass, Metal) Water Resistant (Composites, Masonry, Metal) | 0000000 | 000000 |

Optically Clear Epoxy Structural Adhesives

For invisible bond lines, these adhesives dry clear. Epoxies are the strongest and most weather- and chemical-resistant structural adhesives. Choose an epoxy that hardens quickly for fast repairs, or one that hardens slowly to allow more time for positioning.

The size listed is the combined total of the two parts. Use cartridges with a dispensing gun and mixer nozzle to simultaneously mix and dispense adhesives.

DP100 Plus, DP105, and epoxy in 4.5-oz. tubes bond dissimilar materials.

0151 and E-30CL are suitable for fiber-optic applications.

E-05CL is toughened to form resilient, impact-resistant bonds on dissimilar materials. It's suitable for use on fiber-optic components.

E-05MR has good moisture resistance. It's toughened to form resilient, impact-resistant bonds on dissimilar materials.

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| DP100 Plus | 1.64 | Cartridge | 3 min. | 48 hrs. | 1,700 | 13 | 1:1 | Thick Liquid (8,750 cP) | -65 to 300° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 000000 |

| DP105 | 1.64 | Cartridge | 4 min. | 48 hrs. | 1,300 | 35 | 1:1 | Thick Liquid (7,500 cP) | -65 to 300° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| 0151 | 1.69 | Cartridge | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 000000 |

| 0151 | 3.3 | Tube | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 00000 |

| 0151 | 41.6 | Can | 60 min. | 24 hrs. | 2,675 | Not Rated | 2.7:1 | Thick Liquid (60,000 cP) | -65 to 160° F | Metal, Plastic, Rubber, Glass | 00000000 | 000000 |

| 608 | 1.69 | Cartridge | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65 to 130° F | Metal, Plastic, Rubber | 0000000 | 00000 |

| 608 | 2.8 | Tube | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65 to 130° F | Metal, Plastic, Rubber | 00000000 | 00000 |

| D609 | 1.69 | Cartridge | 5 min. | 24 hrs. | 1,800 | Not Rated | 1:1 | Thick Liquid (15,000 cP) | -65 to 180° F | Metal, Plastic, Rubber | 00000000 | 00000 |

| E-05CL | 1.69 | Cartridge | 3 min. | 24 hrs. | 1,430 | Not Rated | 1:1 | Thick Liquid (2,500 cP) | -65 to 180° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| E-05MR | 1.69 | Cartridge | 5 min. | 24 hrs. | 3,380 | Not Rated | 1:1 | Thick Liquid (25,000 cP) | -65 to 250° F | Metal, Metal to Plastic, Metal to Rubber, Plastic, Plastic to Rubber, Rubber | 0000000 | 00000 |

| E-30CL | 1.69 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (10,000 cP) | -65 to 250° F | Metal, Plastic, Ceramic, Glass | 0000000 | 00000 |

| E-30CL | 6.76 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (10,000 cP) | -65 to 250° F | Metal, Plastic, Ceramic, Glass | 0000000 | 00000 |

| M-31CL | 1.69 | Cartridge | 30 min. | 24 hrs. | 3,100 | Not Rated | 2:1 | Thick Liquid (6,000 cP) | -65 to 300° F | Metal, Plastic, Rubber, Glass | 0000000 | 00000 |

Mfr. Model | Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | No. | Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| ClearWeld | 50112 | 0.85 | Syringe | 5 min. | 60 min. | 2,000 | Not Rated | 1:1 | Thick Liquid (10,000 cP) | Not Rated to 200° F | Metal, Plastic, Rubber, Wood | 0000000 | 00000 |

Container | Strength | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Each | |

| 4.5 | Tube | 60 min. | 36 hrs. | 2,450 | Not Rated | 2:1 | Paste (Not Rated) | -65 to 260° F | Metal, Metal to Plastic, Metal to Rubber, Metal to Glass, Plastic, Plastic to Rubber, Plastic to Glass, Rubber, Rubber to Glass, Glass | 0000000 | 000000 |

Container | Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Net Weight, oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel | Mix Ratio | Consistency (Viscosity) | Temp. Range, °F | For Joining | Pkg. Qty. | Pkg. | |

Loctite® Adhesives | |||||||||||||

| 608 | 0.14 | One-Time-Use Packet | 5 min. | 24 hrs. | 2,980 | Not Rated | 1:1 | Paste (100,000 cP) | -65° to 130° | Metal, Plastic, Rubber | 10 | 00000000 | 000000 |

Adhesives | |||||||||||||

| __ | 0.1 | One-Time-Use Packet | 60 min. | 7 days | 2,400 | Not Rated | 1.61:1 | Thick Liquid (14,000 cP) | 0° to 180° | Metal, Glass | 10 | 0000000 | 00000 |

| Each | ||

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Step Tip) | 0000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. 3M Cartridges (Taper Tip) | 0000000 | 0000 |

| Mixer Nozzle for 1.69 fl. oz. Loctite® Cartridges | 00000000 | 0000 |

| Mixer Nozzle for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 0000 |

| Replacement Plunger for 1.64 fl. oz. 3M Cartridges | 0000000 | 00000 |

| Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.64 fl. oz. 3M Cartridges | 0000000 | 000000 |

| Dispensing Gun for 1.69 fl. oz Loctite® Cartridges | 00000000 | 00000 |

| Dispensing Gun for 6.76 fl. oz. Loctite® Cartridges | 0000000 | 000000 |

| Air-Powered Dispensing Gun for 1.69 fl. oz. Loctite® Cartridges | 000000000 | 000000 |

Flexible Light-Activated Instant-Bond Adhesives

These adhesives stay pliable for flexible bonds that resist cracking. For easy positioning, they begin to harden only when exposed to light.

1700A257 and 2454N1 fluoresce under UV light for easy inspection.

Container | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Max. Gap Size Filled | Begins to Harden | Reaches Full Strength | Light Intensity Requirements to Reach Full Strength | Cure Type | Consistency (Viscosity) | Elongation | Temp. Range, °F | Color | For Joining | Each | |

Adhesives | |||||||||||||

| 1.69 | Bottle | 0.25" | 5 sec. | 30 min. | 5 sec. @ 100 mW/cm2 | UV Light | Thin Liquid (850 cP) | Not Rated | 45° to 80° | Clear | Ceramic, Composites, Glass, Metal, Plastic, Rubber | 000000 | 000000 |

Surface Fillers

These surface fillers can be used on vertical surfaces without sagging. They repair cracked, worn, and damaged surfaces. The size listed is the combined total of the two parts.

Container | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Size | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | Mix Ratio | Approx. Coverage @ Thick. | Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Loctite® Fixmaster Poxy Pak™ | |||||||||||||

| EA 9017 | 0.8 fl. oz. | Syringe | 5 | 60 min. | Thick Liquid | 1:1 | Not Rated | -65° to 300° | Clear | Sand | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, ABS Plastic, CPVC Plastic, PETG Plastic, Polycarbonate Plastic, Polyimide Plastic, Polystyrene Plastic, Polyurethane Rubber, PVC Plastic, PVDF Plastic, Concrete, Glass, Wood | 0000000 | 000000 |

Surface Filler Patches

Knead the epoxy-coated patch and resin together to make repairs to pipes, tanks, drums, and containers in the field.

| Lg. | Wd. | Begins to Harden, min. | Reaches Full Strength | Mix Ratio | For Use Outdoors | Temp. Range, ° F | Color | Finishing Method | For Use On | Each | |

Surface Fillers | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4" | 6" | 1 | 30 min. | 1:1 | Yes | Not Rated to 425° | Clear | Sand | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, Polystyrene Plastic, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, CPVC Plastic, PETG Plastic, PVDF Plastic, Polyimide Plastic, Vinyl Plastic, EPDM Rubber, SBR Rubber, Fiberglass, Wood | 00000000 | 000000 |

Epoxy Potting Compounds

Encase electronic assemblies in a layer of epoxy for protection from dust, chemicals, moisture, mechanical shock, and vibration. The strongest of the potting compounds, epoxies are rigid and wear resistant. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1001™, ES1902™, and ES2500™ come with a mixer nozzle.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch | Overall | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | Specifications Met | For Use On | Color | Each | |

| DP270 | 1.64 | Thick Liquid | 3 hrs. | 48 hrs. | 850 | 0.18 | -65° to 210° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | Clear | 00000000 | 000000 |

| DP270 | 6.8 | Thick Liquid | 3 hrs. | 48 hrs. | 850 | 0.18 | -65° to 210° | UL 94 HB | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Rubber, Glass | Clear | 00000000 | 00000 |

| Mixer Nozzle for 1.64 fl. oz. Cartridges | 0000000 | Each | 00000 |

| Dispensing Gun for 1.64 fl. oz. and 1.69 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Mixer Nozzle for 1.64 fl. oz. and 1.69 fl. oz. Cartridges (Mixing Elements: 16) | 0000000 | Each | 0000 |

| Dispensing Gun for 6.8 fl. oz. Cartridges | 0000000 | Each | 000000 |

| Mixer Nozzle for 6.8 fl. oz. Cartridges | 0000000 | Each | 0000 |

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

| ES1902 | 1.7 | Thin Liquid | 60 | 24 | 1,350 | Not Rated | -40° to 250° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic | Clear | 0000000 | 000000 |

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Optically Clear Epoxy Potting Compounds

Clear enough to read through, these UV-resistant potting compounds allow optimal light transmission for use with LEDs, solar cells, and fiber optics. Use them to encase electronic assemblies for protection from dust, chemicals, moisture, mechanical shock, and vibration. Rigid and wear resistant, epoxies are the strongest of the potting compounds. They have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. All require a mixer nozzle and gun to dispense.

Loctite® ES1901™ comes with a mixer nozzle.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Compounds—Extra Hard | |||||||||||

| ES1901 | 1.7 | Thick Liquid | 3 | 24 | 400 | Not Rated | -40° to 220° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Plastic, Ceramic, Glass | Clear | 0000000 | 000000 |

Two-Part Adhesive Dispensing Guns | |||

|---|---|---|---|

| Dispensing Gun for 1.7 fl. oz. Cartridges | 00000000 | Each | 000000 |

Heavy Duty Coatings for Electronics

Thinner than potting compounds, these coatings flow easily into small spaces between electrical components. Use them to secure and insulate hardware on printed circuit boards. Rigid and wear resistant, epoxies have excellent chemical and moisture resistance, withstand a wide range of temperatures, and provide excellent electrical insulation. Dispense with a mixer nozzle and a gun (each sold separately).

Dry Time | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mfr. Model No. | Container Size, fl. oz. | Consistency | Touch, min. | Overall, hrs. | Dielectric Strength, V/mil | Temp. Range, °F | For Use On | Color | Each | |

Loctite® Coatings—Extra Hard | ||||||||||

| E-00CL | 1.7 | Thick Liquid | 5 | 24 | 400 | -65° to 180° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Clear | 0000000 | 000000 |

| E-00CL | 6.8 | Thick Liquid | 5 | 24 | 400 | -65° to 180° | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Titanium, Silver, Plastic, Composites, Fiberglass | Clear | 0000000 | 00000 |

Harsh Environment Coatings for Electronics

High humidity, harsh chemicals, water submersions, and salt are no match for these electronic coatings. They also resist UV light, so they’ll work outdoors. Use them on circuit boards, sensors, and LED drivers in heavy machinery. Also known as conformal coatings, they’re thinner than potting compounds, so they flow into the smallest contours of your components to cover them completely.

Epoxy coatings resist impact and wear better than PVDF coatings, and they work in higher temperatures. You can also use them as an adhesive. For controlled pouring, they’re thickened with silicate. These coatings are autoclavable, and they’ll even cure underwater. Dispense them with a mixer nozzle and a gun (each sold separately).

Dry Time | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Consistency | Touch | Overall | Mixing Required | Mix Ratio | Mixer Nozzle Included | Dielectric Strength, V/mil | Thermal Conductivity, W/m-K | Temp. Range, °F | For Use On | Color | Autoclavable | Each | |

Epoxy Coatings—Extra Hard | ||||||||||||||

Cartridge | ||||||||||||||

| 1.69 | Thick Liquid | 12 hrs. | 24 hrs. | Yes | 2:1 | No | 500 | Not Rated | -50° to 350° | Aluminum, Brass, Bronze, Steel, Stainless Steel, Titanium, Cast Iron, Iron, Silver, Plastic, Rubber, Composites, Fiberglass | Clear | Yes | 0000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 oz. | 00000000 | 000000 |

| For Cartridge Size | Each | |

| 1.69 oz. | 00000000 | 00000 |

Antislip Coatings

Longer-lasting than antislip tape, these coatings contain grit to provide traction. They’re good for areas with pedestrian traffic.

Water-based epoxy coatings are clear and can be applied over nearly any surface, even old coatings, without altering their appearance. These two-part coatings come with a mixer that attaches to a hand-held drill and a roller cover to apply them once mixed. The size listed is the combined total of the two parts.

Apply gallon-sized water-based coatings with a roller. Coatings that comply with OSHA 29 CFR 1910.22 meet requirements for walking-working surfaces.

Container | Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, gal. | Net Weight, oz. | Composition | Touch | O'all | Approx. Coverage @ Thick. | Mix Ratio | Application Time After Mixing, min. | Specifications Met | For Use On | Includes | Color (Appearance) | Each | |

Epoxy—Aerosol Can | |||||||||||||

| __ | 12 | Solvent Based | 20 min. | 24 hrs. | 15 sq. ft. @ 1 mil | __ | __ | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Iron, Galvanized Iron, Galvanized Steel, Fiberglass, Masonry, Concrete, Stone, Asphalt, Wood | __ | Clear (Gloss) | 00000000 | 000000 |

Epoxy—Can | |||||||||||||

| 1 | __ | Water Based | 27 min. | 30 min. | 185 sq. ft. @ 38 mil | 4:1 | 25 | OSHA Compliant 29 CFR 1910.22 | Aluminum, Brass, Copper, Steel, Stainless Steel, Galvanized Iron, Galvanized Steel, Plastic, Rubber, Ceramic, Glass, Masonry, Concrete, Stone, Asphalt, Drywall | Mixer, Roller Cover | Clear (Gloss) | 0000000 | 000000 |

| Roller Cover for Solvent-Based Coatings | 0000000 | Each | 00000 |

Flame-Retardant Coatings

Use these coatings in kitchens, furnace areas, and ships on plastic, metal, wood, and masonry. Apply with a brush, roller, or sprayer. The size listed is the combined total of the two parts.

Clear coatings are frequently used on wood—use one coat on sealed wood and two on unsealed. They can be used outside without breaking down, but prolonged exposure to UV light may cause them to yellow.

Dry Time | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Composition | Touch, hrs. | O'all, hrs. | Approximate Coverage @ Thickness | Mix Ratio | Application Time After Mixing, hrs. | Max. Temp., °F | Application Temp. Range, °F | Flammability Rating | For Use On | Color (Appearance) | Each | |

Epoxy | |||||||||||||

| 1 | Water Based | 8 | 48 | 150 sq. ft. @ 10 mil | 100:26 | 2.5 | 250° | 40° to 100° | UL 94 V-0 | Aluminum, Copper, Steel, Stainless Steel, Galvanized Iron, Galvanized Steel, Plastic, Rubber, Composites, Fiberglass, Ceramic, Glass, Masonry, Concrete, Stone, Asphalt, Drywall, Wood | Clear (Gloss) | 000000 | 0000000 |

Heavy Duty Epoxy Coatings for Concrete Floors

These coatings are more durable than our standard coatings for concrete floors. They provide a stain-resistant finish that protects your floors from moisture, chemicals, foot traffic, and hand carts. Repair cracks and holes prior to application. Apply with a squeegee, roller, or sprayer. The size listed is the combined total of the two parts.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Composition | Touch, hrs. | Overall, hrs. | Approx. Coverage @ Thick. | Mix Ratio | Application Time After Mixing, hrs. | Max. Temp., °F | Application Temp. Range, °F | For Use On | Color (Appearance) | Each | |

| 1 | Water Based | 24 | 72 | 160 sq. ft. @ 5 mil | 2:1 | 2 | 250° | 50° to 90° | Concrete | Clear (Satin) | 000000 | 0000000 |

Low-Odor Heavy Duty Epoxy Coatings for Concrete Floors

Use these solvent-free, high-gloss coatings to protect concrete floors in enclosed areas. Durable enough for forklift traffic, they resist stains, moisture, and chemicals. Apply with a brush, roller, or sprayer. The size listed is the combined total of the two parts.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Touch, hrs. | Overall, hrs. | Approx. Coverage @ Thick. | Mix Ratio | Application Time After Mixing, min. | Max. Temp., °F | Application Temp. Range, °F | For Use On | Color (Appearance) | Each | |

| 3/4 | 24 | 72-96 | 90 sq. ft. @ 10 mil | 2:1 | 20-30 | 250° | 50° to 100° | Concrete | Clear (Gloss) | 0000000 | 0000000 |

Primers for Concrete Floors

These thin primers penetrate deeply into concrete floors to create a hard surface that can then be coated with any urethane or epoxy coating. Primers resist abrasion and chemicals, such as mild acids, alkalies, salt, and fuel. Apply with a roller. The size listed is the combined total of the two parts.

Mfr. Model | Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | No. | Container Size, gal. | Composition | Touch, hrs. | Overall, hrs. | Approx. Coverage @ Thick. | Max. Temp., °F | Application Temp. Range, °F | For Topcoat Composition | For Use On | Color | Each | |

Loctite® Primers | |||||||||||||

| Fixmaster Epoxy | PC 7641 | 1 | Water Based | 2 | 6 | 250 sq. ft. @ 2 mil | 180° | 50° to 120° | Solvent Based, Water Based | Ceramic, Concrete, Stone, Wood, Plaster | Clear | 0000000 | 0000000 |