Fast-Cutting Carbide Square End Mills with Chamfer Corner

A 45° corner chamfer improves cutting edge strength, so these end mills last longer than standard square end mills when milling hard material; however they do not create as sharp of a corner. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. They have a square end for milling square-bottomed slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Titanium-aluminum-nitride (TiAlN) and aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Chamfer Wd. | Corner Cutting Angle | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

End Mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Titanium Aluminum Nitride (TiAlN) Coated—8 Flute | |||||||||||

| 3/4" | 3/4" | 1 1/2" | 4" | 0.016" | 45° | Variable | 45° | Stainless Steel, Titanium | Center Cutting | 00000000 | 0000000 |

| 3/4" | 3/4" | 2 1/4" | 5" | 0.016" | 45° | Variable | 45° | Stainless Steel, Titanium | Center Cutting | 00000000 | 000000 |

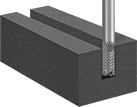

Carbide Square End Mills for Honeycomb Panels

Cut into the sides and make slots in honeycomb panels without damaging any layers. Honeycomb panels are commonly used in aerospace and automotive applications because they’re strong yet lightweight, but these same qualities make them difficult to machine. Unlike normal end mills, these have a left-hand helix and push material downward as they cut, preventing layers of the composite material from separating. The serrated edges break the honeycomb into small pieces, minimizing uncut fibers that can occur in composite material. A diamond coating on these end mills allows them to machine abrasive material, such as carbon fiber, fiberglass, and graphite.

They have a square end for milling square-bottomed slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface. They are good for long production runs. They run twice as fast as other carbide end mills and last up to 30 times longer.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia., mm | Shank Dia., mm | Lg. of Cut, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Diamond Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

8 Flute | |||||||||

| 10 | 10 | 30 | 90 | Equal | 15° | Carbon Fiber, Fiberglass, Graphite | Center Cutting | 0000000 | 0000000 |

High-Speed Steel Square End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs.

Noncenter-cutting end mills are for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

8 Flute | |||||||||

| 1 1/2" | 3/4" | 2" | 4 1/4" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 0000000 |

| 2" | 3/4" | 2" | 4 1/4" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 00000000 | 000000 |

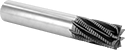

Roughing High-Speed Steel Square End Mills

Serrations along the cutting edge act as chip breakers, so these end mills can remove large amounts of material at high speeds. They are high-speed steel for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. Their square end makes them good for milling square slots and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Noncenter-cutting end mills are for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Pitch | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

8 Flute | ||||||||||

| 2" | 3/4" | 1 1/8" | 3 3/8" | Coarse | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 0000000 |

Cobalt Steel Square End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs.

Noncenter-cutting end mills are for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

8 Flute | |||||||||

| 1" | 1/2" | 3/4" | 2 3/4" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1" | 5/8" | 3/4" | 2 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1" | 3/4" | 3/4" | 3" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 5/8" | 3/4" | 2 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 3/4" | 3/4" | 3" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/4" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

Roughing Cobalt Steel Square End Mills

Serrations along the cutting edge act as chip breakers, so these end mills can remove large amounts of material at high speeds. With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. Their square end makes them good for milling square slots and edges. All are noncenter-cutting for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum.

Flute pitch indicates the size of the serrations on a roughing end mill. Coarse-pitch end mills create large chips for better performance on softer metal, such as aluminum, brass, bronze, and carbon steel.

For technical drawings and 3-D models, click on a part number.

Coarse Pitch | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

8 Flute | |||||||||

| 2" | 3/4" | 1 1/8" | 3 3/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 0000000 |

Titanium Carbonitride (TiCN) Coated | |||||||||

8 Flute | |||||||||

| 2" | 3/4" | 1 1/8" | 3 3/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 00000000 | 000000 |

Roughing Cobalt Steel Ball End Mills

Serrations along the cutting edge act as chip breakers, so these end mills can remove large amounts of material at high speeds without sacrificing tool life. With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as stainless steel, titanium, and tool steel. They have a coarse pitch and create large chips, so they’re also more efficient when working on soft metals such as aluminum, brass, and bronze. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Pitch | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

8 Flute | ||||||||||

| 2" | 2" | 4" | 7 3/4" | Coarse | Equal | 30° | Aluminum, Brass, Bronze, Copper, Stainless Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

| 2" | 2" | 6" | 9 3/4" | Coarse | Equal | 30° | Aluminum, Brass, Bronze, Copper, Stainless Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000000 |

Fast-Cutting Carbide Barrel End Mills

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. Also known as barrel cutters, these end mills create the smooth finish of a ball end mill, but with a tapered cutting surface that removes more material with each pass. They're ideal for 5-axis machining where you need to cut from many angles. Plus, compared to ball end mills, they move farther between overlapping passes (stepover), which decreases machining time and tool wear, so they’ll last longer. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. A titanium-aluminum-silicon-nitride (TiAlSiN) coating makes them extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia., mm | Max. Taper Dia., mm | Shank Dia., mm | Lg. of Cut, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

8 Flute | ||||||||||

| 2.5 | 6 | 12 | 14.4 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

| 3 | 5 | 16 | 18.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 5 | 16 | 27.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 3 | 6 | 12 | 13.5 | 100 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 21 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 24 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 5 | 16 | 28.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 4 | 8 | 16 | 18.5 | 109 | Variable | 10°-43° | Brass, Bronze, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Diamond-Coated Router Bits for Composites

With a diamond coating, these bits resist wear when used on abrasive materials, making them last about 50 times longer than uncoated bits. Their sharp cutting edges and flute shapes are specifically designed to cut through tough materials such as composites with minimal resistance. This means less strain on your router and more control when cutting, leading to a smooth cut. Bits are made of solid carbide for longer tool life and faster cutting speeds than high-speed steel.

Straight Flutes—For general purpose use. They quickly remove material, leaving a rough finish.

Spiral Flutes—Leave a smoother finish than straight-flute bits and make plunge cuts more easily (for plunge-cutting bits).

Roughed-Spiral Flutes—Nicks on the edges of the spirals reduce the amount of force required to cut through composites, giving you more control as you cut.

Diamond-Pattern Flutes—Small, staggered teeth aggressively cut, yet leave a smooth finish.

Use bits with a square cut style to cut slots, pockets, and edges. Bits with a drill/mill cut style have a pointed end for easier plunge cuts than square-cut bits.

Plunge-cutting bits let you cut directly into the workpiece from above. Other bits are best for operations where the peripheral teeth do most of the work such as trimming, contouring, and finishing.

Bits with upward chip removal lift chips up for applications that require a smooth finish on the bottom edge of the cut. Securely clamp the workpiece before routing to prevent lifting.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | Cut Type | For Tool Type | For Use On | Each | |

Diamond-Coated Carbide | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Straight Flutes with a Square Cut Style | |||||||||

| 6mm | 15mm | 6mm | 65mm | 8 | __ | CNC Machine | Fiber-Reinforced Plastic | 0000000 | 0000000 |

| 6mm | 15mm | 6mm | 65mm | 8 | Plunge | CNC Machine | Fiber-Reinforced Plastic | 0000000 | 000000 |

Straight Flutes with a Drill/Mill Cut Style | |||||||||

| 6mm | 18mm | 6mm | 65mm | 8 | Plunge | CNC Machine | Fiber-Reinforced Plastic | 0000000 | 000000 |

Spiral Flutes with a Square Cut Style—Upward Chip Removal | |||||||||

| 1/4" | 3/4" | 1/4" | 2 1/2" | 8 | __ | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/4" | 1" | 1/4" | 3" | 8 | __ | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

Roughed Spiral Flutes with a Square Cut Style—Upward Chip Removal | |||||||||

| 7/16" | 1 5/16" | 1/2" | 3" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 31/64" | 1 1/2" | 1/2" | 3" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/2" | 1" | 1/2" | 3" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/2" | 1 1/2" | 1/2" | 3" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

Diamond-Pattern Flutes with a Square Cut Style | |||||||||

| 1/8" | 1/2" | 1/8" | 1 1/2" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |

| 3/16" | 3/4" | 3/16" | 2" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |

| 1/4" | 1/2" | 1/4" | 2 1/2" | 8 | __ | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |

| 1/4" | 3/4" | 1/4" | 2 1/2" | 8 | __ | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |

| 1/4" | 1" | 1/4" | 3" | 8 | __ | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |

| 1/4" | 1 1/4" | 1/4" | 4" | 8 | __ | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |

Diamond-Pattern Flutes with a Drill/Mill Cut Style | |||||||||

| 1/4" | 1" | 1/4" | 3" | 8 | Plunge | CNC Machine, Router Table | Carbon Fiber | 0000000 | 000000 |