Engraving End Mills

A fine-point tip cuts lettering, numbering, and designs in a variety of metals and composites, such as aluminum, fiberglass, and titanium. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. All are center cutting, allowing plunge cuts into a surface.

End mills with one flute are best where fine detail is required. They evacuate chips and dissipate heat better than end mills with more flutes, which extends tool life.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use end mills coated with titanium-aluminum-nitride (TiAlN) or aluminum-titanium-nitride (AlTiN) for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills. They dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Cutting Angle | Tip Dia. | Shank Dia. | O'all Lg. | For Use On | End Mill Type | Each | |

Uncoated | ||||||||

|---|---|---|---|---|---|---|---|---|

1 Flute | ||||||||

| 1/8" | 30° | 0.015" | 1/8" | 2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 1/8" | 60° | 0.015" | 1/8" | 2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/8" | 90° | 0.015" | 1/8" | 2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/8" | 120° | 0.015" | 1/8" | 2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/16" | 30° | 0.015" | 3/16" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/16" | 60° | 0.015" | 3/16" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/16" | 90° | 0.015" | 3/16" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/16" | 120° | 0.015" | 3/16" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 30° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 60° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 90° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 120° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/8" | 30° | 0.015" | 3/8" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/8" | 60° | 0.015" | 3/8" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/8" | 90° | 0.015" | 3/8" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/8" | 120° | 0.015" | 3/8" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/2" | 30° | 0.015" | 1/2" | 3" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/2" | 60° | 0.015" | 1/2" | 3" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/2" | 90° | 0.015" | 1/2" | 3" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/2" | 120° | 0.015" | 1/2" | 3" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

Titanium Aluminum Nitride (TiAlN) Coated | ||||||||

1 Flute | ||||||||

| 1/8" | 30° | 0.015" | 1/8" | 1 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/8" | 60° | 0.015" | 1/8" | 1 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/8" | 90° | 0.015" | 1/8" | 1 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/16" | 30° | 0.015" | 3/16" | 2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 3/16" | 60° | 0.015" | 3/16" | 2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 30° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 60° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 1/4" | 90° | 0.015" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

Straight and Spiral Router Bits for Wood, Particle Board, and Plywood

Create square slots, pockets, and edges in wood. These router bits are plunge cutting, letting you cut directly into the workpiece from above. They do not have a pilot, so guide your router along a straight edge when hand routing to make accurate cuts.

Bits with spiral flutes leave a smoother finish than straight-flute bits and make plunge cuts more easily. They're made of solid carbide for longer tool life and faster cutting speeds than high-speed steel.

Spiral-flute bits with upward and downward chip removal are also known as compression bits. Acting similar to scissors, they move chips away from the top and bottom edges of the cut for a smooth finish on both.

Choose a bit with one flute for a faster cut; bits with more flutes produce a smoother finish.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | Each | |

Uncoated Carbide | |||||||

|---|---|---|---|---|---|---|---|

Spiral Flutes with Upward and Downward Chip Removal | |||||||

| 1/8" | 3/8" | 1/4" | 2 1/2" | 1 | CNC Machine | 0000000 | 000000 |

Straight and Spiral Router Bits for Plastic

The smooth flutes and sharp cutting edges on these router bits cleanly cut square slots, pockets, and edges in most plastics, including polyethylene, polycarbonate, and vinyl. They do not have a pilot, so guide your router along a straight edge when hand routing to make accurate cuts.

High-speed steel bits are for general purpose use. They can be used with hand tools, router tables, and CNC machines.

Use carbide bits for longer tool life and faster cutting speeds than high-speed steel. Ceramic-coated carbide bits have a coating that increases the hardness of the bits and protects them from high heat, making them last about 2.5 times longer than uncoated bits.

Bits with straight flutes are for general purpose use. They quickly remove material, leaving a rough finish.

Bits with spiral flutes leave a smoother finish than straight-flute bits. Bits with upward chip removal lift chips up for applications that require a smooth finish on the bottom edge of the cut. Securely clamp the workpiece before routing to prevent lifting. Bits with downward chip removal push chips down for applications that require a smooth finish on the cut's top edge.

Bits with a plunge cut type let you cut directly into the workpiece from above. Other bits are best for operations where the peripheral teeth do most of the work such as trimming, contouring, and finishing.

Choose a bit with one flute for a faster cut; bits with more flutes produce a smoother finish.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | For Use On | Cut Type | Each | |

Uncoated High-Speed Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Straight Flutes | |||||||||

| 1/8" | 1/2" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 00000000 | 000000 |

Uncoated Carbide | |||||||||

Straight Flutes | |||||||||

| 1/4" | 3/4" | 1/4" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | __ | 00000000 | 00000 |

| 3/8" | 7/8" | 3/8" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | __ | 00000000 | 00000 |

| 1/2" | 1" | 1/2" | 3" | 1 | CNC Machine | Hard Plastic, Soft Plastic | __ | 00000000 | 00000 |

Spiral Flutes with Upward Chip Removal | |||||||||

| 1/16" | 1/4" | 1/4" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 3/32" | 1/4" | 1/8" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 1/8" | 1/2" | 1/8" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 5/32" | 9/16" | 1/4" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 3/16" | 5/8" | 1/4" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 7/32" | 3/4" | 1/4" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 3/8" | 5/8" | 3/8" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 1/2" | 1 1/4" | 1/2" | 3" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 000000 |

Spiral Flutes with Downward Chip Removal | |||||||||

| 1/16" | 1/4" | 1/8" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 1/8" | 1/2" | 1/8" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 5/32" | 9/16" | 1/4" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

| 3/16" | 5/8" | 1/4" | 2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | Plunge | 0000000 | 00000 |

Ceramic-Coated Carbide | |||||||||

Straight Flutes | |||||||||

| 1/8" | 1/2" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 3/16" | 5/8" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

Spiral Flutes with Upward Chip Removal | |||||||||

| 1/16" | 1/4" | 1/8" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 1/8" | 1/4" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 1/8" | 3/4" | 1/8" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 1/4" | 3/8" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

Spiral Flutes with Downward Chip Removal | |||||||||

| 1/16" | 1/4" | 1/8" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

| 1/8" | 1/2" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | Hard Plastic, Soft Plastic | __ | 0000000 | 00000 |

Straight and Spiral Router Bits for Aluminum

Also known as O-flute bits, the flutes on these bits are open and rounded for efficient chip removal when cutting aluminum. This also reduces heat to prevent melting or warping. Use these bits to create square slots, pockets, and edges. They are plunge cutting, letting you cut directly into the workpiece from above. They do not have a pilot, so guide your router along a straight edge when hand routing to make accurate cuts.

High-speed steel bits can be used with hand routers, router tables, and CNC machines.

Carbide bits have a longer life and faster cutting speeds than high-speed steel bits. Their extreme hardness makes them brittle, so they’re not recommended for use with hand tools. A highly rigid setup, such as a CNC machine, is necessary to keep bits from breaking.

Bits with straight flutes are for general purpose use. They quickly remove material, leaving a rough finish.

Bits with spiral flutes leave a smoother finish than straight-flute bits and make plunge cuts more easily. Bits with upward chip removal lift chips up for applications that require a smooth finish on the bottom edge of the cut. Securely clamp the workpiece before routing to prevent lifting. Bits with downward chip removal push chips down for applications that require a smooth finish on the cut's top edge.

Choose a bit with one flute for a faster cut; bits with two flutes produce a smoother finish.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | Each | |

Uncoated High-Speed Steel | |||||||

|---|---|---|---|---|---|---|---|

Straight Flutes with Upward Chip Removal | |||||||

| 1/8" | 1/2" | 1/4" | 2" | 1 | CNC Machine, Hand Router, Router Table | 0000000 | 000000 |

| 3/16" | 5/8" | 1/4" | 2 1/2" | 1 | CNC Machine, Hand Router, Router Table | 0000000 | 00000 |

| 1/4" | 3/4" | 1/4" | 2 1/2" | 1 | CNC Machine, Hand Router, Router Table | 0000000 | 00000 |

| 1/2" | 1" | 1/2" | 3" | 1 | CNC Machine, Hand Router, Router Table | 0000000 | 00000 |

Uncoated Carbide | |||||||

Straight Flutes with Upward Chip Removal | |||||||

| 1/8" | 1/2" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 3/16" | 5/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/4" | 3/4" | 1/4" | 2 1/2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/4" | 1" | 1/4" | 3" | 1 | CNC Machine | 0000000 | 00000 |

| 5/16" | 13/16" | 3/8" | 2 1/2" | 1 | CNC Machine | 0000000 | 00000 |

| 3/8" | 7/8" | 3/8" | 2 1/2" | 1 | CNC Machine | 0000000 | 00000 |

| 7/16" | 1" | 1/2" | 3" | 1 | CNC Machine | 0000000 | 000000 |

| 1/2" | 1" | 1/2" | 3" | 1 | CNC Machine | 0000000 | 000000 |

Spiral Flutes with Upward Chip Removal | |||||||

| 1/8" | 1/4" | 1/8" | 1 1/2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/8" | 1/2" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 3/16" | 3/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 3/16" | 5/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/4" | 3/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/4" | 1 1/4" | 1/4" | 3" | 1 | CNC Machine | 0000000 | 00000 |

| 3/8" | 3/4" | 3/8" | 3" | 1 | CNC Machine | 0000000 | 00000 |

| 3/8" | 1 1/8" | 3/8" | 3" | 1 | CNC Machine | 0000000 | 000000 |

Spiral Flutes with Downward Chip Removal | |||||||

| 1/8" | 1/4" | 1/8" | 1 1/2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/8" | 1/4" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 3/16" | 3/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 3/16" | 5/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/4" | 3/8" | 1/4" | 2" | 1 | CNC Machine | 0000000 | 00000 |

| 1/4" | 1 1/4" | 1/4" | 3" | 1 | CNC Machine | 0000000 | 00000 |

| 3/8" | 1/8" | 3/8" | 3" | 1 | CNC Machine | 0000000 | 000000 |

| 3/8" | 3/4" | 3/8" | 3" | 1 | CNC Machine | 0000000 | 000000 |

Trimming Router Bits

Cut layers of material flush to one another or make cuts along a template.

Use carbide bits for longer tool life and faster cutting speeds than high-speed steel. Micrograin carbide bits provide superior wear resistance, long tool life, and a cleaner finish than bits made of other materials.

Solid pilots guide the bit while routing. They are more durable than ball-bearing bits. Ball-bearing pilots guide the bit for accurate cuts and produce less friction than solid pilots for smoother operation.

Pilot location describes the position of the pilot when the bit is used for hand routing. The pilot location is reversed when using the bit with a router table. Bottom-pilot bits trim material from an upper layer of the workpiece so that it is flush with the layer below. In addition to flush trimming, they can be used to cut along a template placed below the workpiece.

Bits with straight flutes are for general purpose use. They quickly remove material, leaving a rough finish.

Choose a bit with one flute for a faster cut; bits with more flutes produce a smoother finish.

Bits with an overhang cutoff edge remove most of the excess material from the edge of workpieces such as countertops and sink cutouts, but they leave some material leftover for precise trimming after the installation. This process minimizes the risk of chipping laminate during installation and produces a clean, professional finish.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Pilot Type | Ball-Bearing Pilot Dia. | Number of Flutes | Flute Type | For Tool Type | For Use On | Features | Each | |

Bottom Pilot | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8" | 1/2" | 1/4" | 2 7/16" | Ball Bearing | 3/4" | 1 | Straight | Hand Router, Router Table, CNC Machine | Wood, Particleboard, Plywood, Plastic Laminate | Overhang Cutoff Edge | 0000000 | 000000 |

Panel Pilot Router Bits

Panel Pilot Cut Style | Spiral Flutes |

Straight Flutes |

The pointed tip creates starter holes for efficient plunge cutting in wood. For precise cutouts, use the tip as a pilot and guide the bit along a template placed below the workpiece.

Bits with spiral flutes leave a smoother finish than straight-flute bits and make plunge cuts more easily. They're made of high-speed steel and can be used with hand tools, router tables, and CNC machines.

Bits with straight flutes are for general purpose use. They quickly remove material, leaving a rough finish. Made of carbide-tipped high-speed steel, these bits provide a longer tool life and faster cutting speeds than standard high-speed steel bits.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Pilot Type | Number of Flutes | For Tool Type | For Use On | Each | |

Uncoated High-Speed Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Spiral Flutes | |||||||||

| 1/4" | 5/8" | 1/4" | 2 3/4" | Solid | 1 | Hand Router, Router Table, CNC Machine | Wood, Particleboard, Plywood | 00000000 | 000000 |

| 1/2" | 1 1/4" | 1/2" | 3 13/16" | Solid | 1 | Hand Router, Router Table, CNC Machine | Wood, Particleboard, Plywood | 00000000 | 00000 |

| 1/2" | 2 1/8" | 1/2" | 4 1/2" | Solid | 1 | Hand Router, Router Table, CNC Machine | Wood, Particleboard, Plywood | 00000000 | 00000 |

Uncoated Carbide-Tipped High-Speed Steel | |||||||||

Straight Flutes | |||||||||

| 1/4" | 3/4" | 1/4" | 2 9/16" | Solid | 1 | Hand Router | Wood, Particleboard, Plywood | 0000000 | 00000 |

| 3/8" | 1" | 3/8" | 3" | Solid | 1 | Hand Router | Wood, Particleboard, Plywood | 0000000 | 00000 |

| 1/2" | 1 3/16" | 1/2" | 3 1/2" | Solid | 1 | Hand Router | Wood, Particleboard, Plywood | 0000000 | 00000 |

Corner-Rounding Router Bits

Choose from bits that form a variety of shapes along the edges of your workpiece.

Use solid carbide bits to round off sharp edges on plastic sheets. Their extreme hardness makes them brittle, so they’re not recommended for use with hand tools. A highly rigid setup, such as a CNC machine, is necessary to prevent the bit from breaking.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Cut Radius | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | For Use On | Each | |

Uncoated Carbide | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Rounded Corner Style | |||||||||

| 1/4" | 1/8" | 3/8" | 1/4" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | 0000000 | 000000 |

| 1/4" | 3/16" | 3/8" | 1/4" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | 0000000 | 00000 |

| 1/4" | 1/4" | 3/8" | 1/4" | 2 1/2" | 1 | CNC Machine | Hard Plastic, Soft Plastic | 0000000 | 00000 |

Chamfer Router Bits

These bits make chamfer, bevel, and other angled cuts in wood.

Solid carbide bits offer the longest tool life and fastest cutting speeds, so they can be used on wood and plastic laminate. A solid pilot guides the bit while routing. The extreme hardness of these bits makes them brittle, so they're not recommended for use with hand tools. A highly rigid setup, such as a CNC machine, is necessary to prevent the bit from breaking.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Cut Angle | Shank Dia. | Overall Lg. | Pilot Type | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 1/4" | 7° | 1/4" | 1 1/2" | Solid | 1 | Straight | CNC Machine | Wood, Plastic Laminate | 00000000 | 000000 |

Router Bits for Wood Joining

Create shapes that fit together to form wood joints commonly used to build doors and frames.

Lock Miter—Create right-angle and glue joints. Using a router table, create this two-piece joint by first cutting along the short edge of one piece of wood, then along the long edge of the other piece of wood.

Keyhole—These joints are often used as wall-mounting slots.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide-Tipped Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 1/4" | 1 1/4" | 1/2" | 2 3/4" | 1 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 000000 |

| Cutter Thick. | Cutting Dia. | Shank Dia. | Overall Lg. | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide-Tipped Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1 1/4" | 1/2" | 2 3/4" | 1 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 000000 |

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide-Tipped Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 5/8" | 1 3/16" | 1/2" | 2 5/8" | 1 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 0000000 |

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide-Tipped Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1/2" | 1/4" | 2" | 1 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 000000 |

| 17/32" | 1/2" | 1/4" | 1 7/8" | 1 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 00000 |

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide-Tipped Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/8" | 7/16" | 1/4" | 1 9/16" | 1 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 000000 |

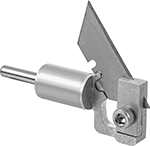

Router Bits for Thin Materials

Make shallow incisions in fabric, leather, and rubber. Unlike other router bits, these bits do not spin or rotate; instead, the blade follows the motion of the CNC machine, behaving like a rudder as it cuts through material. These bits are plunge cutting, letting you cut directly into the workpiece from above.

Carbide bits have a small, sharp point for cutting precise, thin lines. They’re spring loaded to apply constant pressure to the tip, making them good for cutting thinner materials than steel bits.

Steel bits use a utility-knife blade; the larger blade cuts through thicker materials than carbide bits.

| Cut Radius | Lg. of Cut | Cut Angle | Shank Dia. | Overall Lg. | Number of Flutes | Heat Treatment | For Tool Type | For Use On | Each | |

Uncoated Carbide | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Straight Flutes | ||||||||||

| 1/64" | 1/32" | 45°, 60° | 1/4" | 2 1/4" | 1 | __ | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl | 0000000 | 0000000 |

Uncoated Steel | ||||||||||

Straight Flutes | ||||||||||

| 1/16" | 1/16" | __ | 1/4" | 3 1/4" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl | 0000000 | 000000 |

| 1/16" | 1/16" | __ | 1/2" | 4 1/4" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl | 0000000 | 000000 |

| 1/8" | 1/4" | __ | 1/4" | 3 5/8" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl | 0000000 | 000000 |

| 1/8" | 1/4" | __ | 1/2" | 4 3/8" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl | 0000000 | 000000 |

| 1/8" | 1/2" | __ | 1/2" | 4 1/2" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl | 0000000 | 000000 |