Carbide Square End Mills

For longer tool life and a better finish in general purpose milling applications, these solid carbide end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel end mills. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

Center-cutting end mills allow plunge cuts into a surface.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Nitride (TiN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 0000000 |

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 000000 | 000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Fast-Cutting Carbide Square End Mills

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square-bottomed slots, pockets, and edges.

A titanium-aluminum-nitride (TiAlN) or aluminum-titanium-nitride (AlTiN) coating allows them to dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication. Aluminum-titanium-nitride (AlTiN) has a higher percentage of aluminum than titanium-aluminum-nitride (TiAlN).

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Center-cutting end mills allow plunge cuts into a surface.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

End Mills | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Aluminum Titanium Nitride (AlTiN) Coated—4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/8" | 3 1/2" | Variable | 35°-38° | Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

High-Speed Steel Square End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

Center-cutting end mills allow plunge cuts into a surface.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 1/2" | 1 1/8" | 3 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

| 9/16" | 1/2" | 2 1/2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

3 Flute | |||||||||

| 9/16" | 1/2" | 1 3/8" | 3 3/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 000000 | 00000 |

4 Flute | |||||||||

| 9/16" | 1/2" | 1 3/8" | 3 3/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

| 9/16" | 1/2" | 2 1/2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

| 9/16" | 1/2" | 4" | 6" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 9/16" | 1/2" | 1 1/8" | 3 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 9/16" | 1/2" | 2 1/2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 00000000 | 00000 |

4 Flute | |||||||||

| 9/16" | 1/2" | 1 3/8" | 3 3/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 9/16" | 1/2" | 2 1/2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 9/16" | 1/2" | 4" | 6" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 00000000 | 00000 |

High-Speed Steel Square End Mills with Two Milling Ends

When one end wears out, switch to the opposite end for two times the life of a standard high-speed steel end mill. Made of high-speed steel, these end mills are for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. Their square ends make them good for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 5/8" | 1 1/8" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

4 Flute | |||||||||

| 9/16" | 5/8" | 1 3/8" | 5" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 9/16" | 5/8" | 1 1/8" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

4 Flute | |||||||||

| 9/16" | 5/8" | 1 3/8" | 5" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

Cobalt Steel Square End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs.

Center-cutting end mills allow plunge cuts into a surface.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 1/2" | 1 1/8" | 3 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

4 Flute | |||||||||

| 9/16" | 1/2" | 1 3/8" | 3 3/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

Carbide Ball End Mills

For longer tool life and a better finish in general purpose milling applications, these solid carbide end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel end mills. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Nitride (TiN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Nitride (TiN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Nitride (TiN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

3 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 9/16" | 9/16" | 1 1/4" | 3 1/2" | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 0000000 |

High-Speed Steel Ball End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 1/2" | 1" | 3 1/16" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 9/16" | 1/2" | 1" | 3 1/16" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

Cobalt Steel Ball End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 9/16" | 1/2" | 1 1/8" | 3 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Copper, Hardened Steel, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Cobalt Steel Drill/Mill End Mills

Made of cobalt steel, these end mills have good heat and wear resistance, so they can run at high speeds in hard material. A 90° pointed tip allows them to be used for drilling as well as for slotting, profiling, and chamfering cuts. All are center cutting, allowing plunge cuts into a surface.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Point Angle | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

2 Flute | ||||||||||

| 9/16" | 1/2" | 1 13/32" | 3 13/32" | Equal | 90° | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | ||||||||||

2 Flute | ||||||||||

| 9/16" | 1/2" | 1 13/32" | 3 13/32" | Equal | 90° | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

High-Speed Steel T-Slot End Mills

Use these versatile end mills for milling in most material, including aluminum, brass, bronze, iron, and steel. They're often used to create slots in machine tool tables, indexing tables, and other workholding surfaces.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills.

Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

For technical drawings and 3-D models, click on a part number.

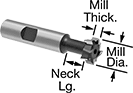

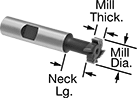

Mill | Neck | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For T-Slot Bolt Size | Dia. | Thick. | Shank Dia. | Dia. | Lg. | Overall Lg. | For Use On | Each | |

Uncoated | |||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 2 19/32" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 2 19/32" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

Titanium Carbonitride (TiCN) Coated | |||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 2 19/32" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

Aluminum Titanium Nitride (AlTiN) Coated | |||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 2 19/32" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

Carbide-Tipped T-Slot End Mills

Made of carbide-tipped high-speed steel, these end mills provide a sharper, harder edge at high temperatures than plain high-speed steel. Because they aren’t as brittle as solid carbide, they can be used in less rigid setups, such as manual milling machines. They're often used to create slots in machine tool tables, indexing tables, and other workholding surfaces.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

For technical drawings and 3-D models, click on a part number.

Mill | Neck | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For T-Slot Bolt Size | Dia. | Thick. | Shank Dia. | Dia. | Lg. | Lg. of Cut | Overall Lg. | For Use On | Each | |

Uncoated | ||||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 15/64" | 2 19/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 0000000 |

Titanium Nitride (TiN) Coated | ||||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 15/64" | 2 19/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | ||||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 15/64" | 2 19/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Aluminum Titanium Nitride (AlTiN) Coated | ||||||||||

| 1/4" | 9/16" | 15/64" | 1/2" | 0.266" | 35/64" | 15/64" | 2 19/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |