High-Speed Steel Square End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

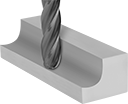

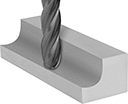

Center-cutting end mills allow plunge cuts into a surface. Noncenter-cutting end mills are for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 1 1/8" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

| 1 1/8" | 1" | 1 5/8" | 4 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

4 Flute | |||||||||

| 1 1/8" | 1" | 2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

6 Flute | |||||||||

| 1 1/8" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 00000000 | 000000 |

| 1 1/8" | 3/4" | 2" | 4 1/4" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 7/8" | 2" | 4 1/4" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 00000 |

| 1 1/8" | 1" | 2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 00000 |

| 1 1/8" | 1" | 4" | 6 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 00000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 1 1/8" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 1 1/8" | 1" | 1 5/8" | 4 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||||

| 1 1/8" | 1" | 2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

Roughing High-Speed Steel Square End Mills

Serrations along the cutting edge act as chip breakers, so these end mills can remove large amounts of material at high speeds. They are high-speed steel for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. Their square end makes them good for milling square slots and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Noncenter-cutting end mills are for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Pitch | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

6 Flute | ||||||||||

| 1 1/8" | 3/4" | 1 1/8" | 3 3/8" | Coarse | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 0000000 |

| 1 1/8" | 1" | 2" | 4 1/2" | Coarse | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Noncenter Cutting | 0000000 | 000000 |

Cobalt Steel Square End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs.

Center-cutting end mills allow plunge cuts into a surface. Noncenter-cutting end mills are for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 1 1/8" | 3/4" | 3/4" | 3" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

| 1 1/8" | 1" | 1 5/8" | 4 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

6 Flute | |||||||||

| 1 1/8" | 3/4" | 3/4" | 3" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

8 Flute | |||||||||

| 1 1/8" | 5/8" | 3/4" | 2 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 3/4" | 3/4" | 3" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

| 1 1/8" | 3/4" | 1 1/2" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 000000 |

Roughing Cobalt Steel Square End Mills

Serrations along the cutting edge act as chip breakers, so these end mills can remove large amounts of material at high speeds. With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. Their square end makes them good for milling square slots and edges. All are noncenter-cutting for operations where the peripheral teeth do most of the work, such as shoulder milling, contouring, and finishing. They cannot be used for plunge cuts.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum.

Flute pitch indicates the size of the serrations on a roughing end mill. Coarse-pitch end mills create large chips for better performance on softer metal, such as aluminum, brass, bronze, and carbon steel.

For technical drawings and 3-D models, click on a part number.

Coarse Pitch | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

6 Flute | |||||||||

| 1 1/8" | 1" | 2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 0000000 | 0000000 |

Titanium Carbonitride (TiCN) Coated | |||||||||

6 Flute | |||||||||

| 1 1/8" | 1" | 2" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Noncenter Cutting | 00000000 | 000000 |

High-Speed Steel Ball End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 1 1/8" | 3/4" | 1 5/8" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 0000000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 1 1/8" | 3/4" | 1 5/8" | 3 7/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

Cobalt Steel Ball End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts.

For technical drawings and 3-D models, click on a part number.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 1 1/8" | 1" | 2 1/4" | 4 3/4" | Equal | 30° | Aluminum, Brass, Bronze, Copper, Hardened Steel, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

High-Speed Steel Corner-Rounding End Mills

Use these versatile end mills for milling in most material, including aluminum, brass, bronze, iron, and steel. They have scooped corners for rounding the sharp edges of your workpiece.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills.

Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

For technical drawings and 3-D models, click on a part number.

| Cut Radius | Tip Dia. | Mill Dia. | Shank Dia. | Overall Lg. | Flute Spacing | For Use On | Each | |

Uncoated | ||||||||

|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||

| 5/16" | 3/8" | 1 1/8" | 1/2" | 3 1/4" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 0000000 |

| 5/16" | 3/8" | 1 1/8" | 3/4" | 3 1/2" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | ||||||||

4 Flute | ||||||||

| 5/16" | 3/8" | 1 1/8" | 1/2" | 3 1/4" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 5/16" | 3/8" | 1 1/8" | 3/4" | 3 1/2" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

Aluminum Titanium Nitride (AlTiN) Coated | ||||||||

4 Flute | ||||||||

| 5/16" | 3/8" | 1 1/8" | 1/2" | 3 1/4" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 5/16" | 3/8" | 1 1/8" | 3/4" | 3 1/2" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

Cobalt Steel Corner-Rounding End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills run at higher speeds and provide better performance on hard material. They have scooped corners for rounding the sharp edges of your workpiece.

For technical drawings and 3-D models, click on a part number.

| Cut Radius | Tip Dia. | Mill Dia. | Shank Dia. | Overall Lg. | Flute Spacing | For Use On | Each | |

Uncoated | ||||||||

|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||

| 5/16" | 3/8" | 1 1/8" | 7/8" | 3 1/2" | Equal | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 0000000 |

| 5/16" | 1/2" | 1 1/8" | 1/2" | 3 1/2" | Equal | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Outside Chamfer End Mills for Pipes, Tubes, and Rods

Mill an angled edge to the entire outside diameter of pipe, tubes, and rods in a single pass with more speed and precision than a handheld scraper. These end mills deburr pipe and tube for butt welds and shape rods for sliding into housings and holes. They attach to screw machines, lathes, and drill presses and can be set up to repeat cuts for multiple pipes. Staggered cutting edges reduce vibration, resulting in a smooth finish. They have teeth that distribute cutting force and extend the life of the tool. Made of high-speed steel, they work with a variety of metals. Attach to your machine with a shank (sold separately).

Mill | |||||||

|---|---|---|---|---|---|---|---|

| For OD | For Pipe Size | Dia. | Thick. | Thread Size | For Use On | Each | |

Uncoated—30° Cutting Angle | |||||||

| 1/4"-3/4" | 1/8, 1/4, 3/8 | 1 1/8" | 1 3/4" | 1/2"-20 | Aluminum, Brass, Bronze, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel | 0000000 | 0000000 |

Uncoated—45° Cutting Angle | |||||||

| 3/16"-3/4" | 1/8, 1/4, 3/8 | 1 1/8" | 1 5/16" | 1/2"-20 | Aluminum, Brass, Bronze, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

Carbide Dovetail End Mills for Dovetail Milling Vises

Cut dovetail notches into your workpiece for use with our Dovetail Milling-Machine Vises. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Mill | |||||||

|---|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | Overall Lg. | Flute Spacing | For Use On | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||

4 Flute—60° Chamfer Angle | |||||||

| 1 1/8" | 3/4" | 3/4" | 3 1/2" | Equal | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 000000 | 0000000 |

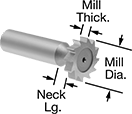

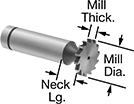

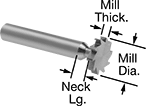

High-Speed Steel Keyseat End Mills

Use these end mills for general purpose keyseat cutting in a wide range of material, including aluminum, iron, and steel. They mill precise notches in rotary shafts to fit machine keys and can also be used for slot milling.

For technical drawings and 3-D models, click on a part number.

Mill | Neck | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | Dia. | Lg. | Overall Lg. | For Woodruff ANSI Key No. | For Use On | Each | |

| 1 1/8" | 1/16" | 1/2" | 0.31" | 3/8" | 2 1/16" | __ | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 1 1/8" | 3/32" | 1/2" | 0.31" | 3/8" | 2 3/32" | __ | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

| 1 1/8" | 1/8" | 1/2" | 0.31" | 3/8" | 2 1/8" | __ | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

| 1 1/8" | 3/16" | 1/2" | 0.31" | 3/8" | 2 3/16" | 609 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

| 1 1/8" | 7/32" | 1/2" | 0.31" | 3/8" | 2 7/32" | 709 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

| 1 1/8" | 1/4" | 1/2" | 0.38" | 3/8" | 2 1/4" | 809 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

| 1 1/8" | 5/16" | 1/2" | 0.44" | 3/8" | 2 5/16" | 1009 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 |

Carbide Keyseat End Mills

Made of solid carbide, these cutters are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. Use them to mill precise notches in rotary shafts to fit machine keys. They can also be used for slot milling.

For technical drawings and 3-D models, click on a part number.

Mill | Neck | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | Dia. | Lg. | Overall Lg. | For Woodruff ANSI Key No. | For Use On | Each | |

| 1 1/8" | 3/16" | 1/2" | 0.28" | 1/4" | 2 3/16" | 609 | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 0000000 |

| 1 1/8" | 1/4" | 1/2" | 0.28" | 1/4" | 2 1/4" | 809 | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1 1/8" | 5/16" | 1/2" | 0.44" | 3/8" | 2 5/16" | 1009 | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Cobalt Steel Keyseat End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel keyseat cutters can run at higher speeds and provide better performance on hard material. They mill precise notches in rotary shafts to fit machine keys and can also be used for slot milling.

Mill | Neck | |||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | Dia. | Lg. | Overall Lg. | For Use On | Each | |

| 1 1/8" | 1/16" | 1/2" | 0.31" | 3/8" | 2 1/16" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1 1/8" | 3/32" | 1/2" | 0.31" | 3/8" | 2 3/32" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

| 1 1/8" | 1/8" | 1/2" | 0.31" | 3/8" | 2 1/8" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 00000 |

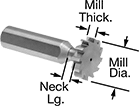

Fast-Cutting Carbide Keyseat End Mills

Get speed and longevity when cutting keyseats with these carbide end mills that have staggered teeth. The alternating right- and left-hand tooth style removes more material at high speeds than straight-tooth keyseat cutters. They mill precise notches in rotary shafts to fit machine keys and can also be used for slot milling. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Use uncoated end mills for general purpose milling and short production runs. They will stay sharper than coated end mills and leave a better finish on soft materials like aluminum. Use aluminum-titanium-nitride (AlTiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills. They dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

For technical drawings and 3-D models, click on a part number.

Mill | Neck | |||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | Dia. | Lg. | Overall Lg. | For Use On | Each | |

Uncoated | ||||||||

| 1 1/8" | 1/8" | 1/2" | 0.28" | 1/4" | 2 3/4" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 0000000 |

| 1 1/8" | 3/16" | 1/2" | 0.28" | 1/4" | 2 3/4" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

| 1 1/8" | 1/4" | 1/2" | 0.49" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

| 1 1/8" | 5/16" | 1/2" | 0.49" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

| 1 1/8" | 3/8" | 1/2" | 0.49" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Aluminum Titanium Nitride (AlTiN) Coated | ||||||||

| 1 1/8" | 1/8" | 1/2" | 0.28" | 1/4" | 2 3/4" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1 1/8" | 3/16" | 1/2" | 0.28" | 1/4" | 2 3/4" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1 1/8" | 1/4" | 1/2" | 0.49" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1 1/8" | 5/16" | 1/2" | 0.49" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

| 1 1/8" | 3/8" | 1/2" | 0.49" | 1/4" | 2 1/2" | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Fly Cutters

Shave shallow layers of material off your workpiece to create a smooth even finish. These fly cutters hold a lathe tool (sold separately) and run on your milling machine. Compared to end mills, these make a wider cut per pass. They also generate less heat, so you can run them at higher speeds. In the long run, these cutters will save you the cost of replacing entire end mills once they dull—you can either sharpen your worn lathe tool or just replace that one part.

For technical drawings and 3-D models, click on a part number.

For Tool Bit Shank | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Shank Dia. | Overall Lg. | Wd. | Shape | Ht. | Head Dia. | Material | Heat Treatment | Each | |

Straight Shank | ||||||||||

| 1 1/8" | 1/2" | 2 1/2" | 1/4" | Square | 1/4" | 1 1/8" | Black-Oxide Steel | Hardened | 0000000 | 000000 |