Fast-Cutting Carbide Barrel End Mills for Aluminum, Brass, and Bronze

Barrel Cut Style | 3 Flute |

4 Flute |

A titanium-diboride (TiB2) coating reduces friction when working with nonferrous metals, so you can use these end mills to cut soft metals like aluminum, brass, and bronze. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life. Also known as barrel cutters, these end mills create the smooth finish of a ball end mill, but with a tapered cutting surface that removes more material with each pass. They're ideal for 5-axis machining where you need to cut from many angles. Plus, compared to ball end mills, they move farther between overlapping passes (stepover), which decreases machining time and tool wear, so they’ll last longer. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

End mills with three flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

For technical drawings and 3-D models, click on a part number.

| Mill Dia., mm | Max. Taper Dia., mm | Shank Dia., mm | Lg. of Cut , mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Diboride (TiB2) Coated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

3 Flute | ||||||||||

| 1 | 3 | 6 | 9 | 58 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 0000000 |

| 1.5 | 3 | 6 | 8 | 58 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 1.5 | 4 | 8 | 10 | 80 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 4 | 8 | 9 | 80 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 5 | 10 | 12 | 89 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2.5 | 5 | 10 | 11 | 89 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

4 Flute | ||||||||||

| 2 | 3 | 16 | 15 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 5 | 16 | 31 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2 | 6 | 12 | 20 | 100 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 2.5 | 6 | 12 | 14 | 100 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 5 | 16 | 18 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 5 | 16 | 19 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 5 | 16 | 27 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 3 | 6 | 12 | 13 | 100 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 5 | 16 | 21 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 5 | 16 | 24 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 5 | 16 | 28 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

| 4 | 8 | 16 | 18 | 109 | Variable | 15°-55° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

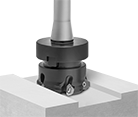

Replaceable Carbide-Insert Face Milling Cutters

Titanium-diboride (TiB2) coated inserts reduce friction in nonferrous metals and composites, so you can use them without lubrication in material like aluminum, fiberglass, and plastic.

Use octagon inserts for general face milling. With eight cutting edges, they generate smooth cuts. Use round inserts for roughing and heavy cuts. Their shape makes them stronger than octagon and square inserts. Use square inserts to create a 90° corner when shoulder milling.

For technical drawings and 3-D models, click on a part number.