High-Speed Steel Square End Mill Sets

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have square ends for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use on aluminum. Titanium-aluminum-nitride (TiAIN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 0000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 3/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 7/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3 1/4" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 3/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 7/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3 1/4" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 00000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 3/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 7/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3 1/4" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Iron, Nickel, Stainless Steel, Titanium | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 3/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 7/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3 1/4" O'all Lg. End Mill | Equal | 30° | Iron, Nickel, Stainless Steel, Titanium | Center Cutting | 00000000 | 000000 |

High-Speed Steel Square End Mill Sets with Two Milling Ends

Offering two times the life of a standard end mill, these have two milling ends so you can switch to the opposite end when one end wears out. Use them for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. Their square ends make them good for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 3 1/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3 3/4" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 0000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 3 1/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 3 1/4" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 3 3/8" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 3 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 3 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 4 1/8" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 3 1/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 3 1/8" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3 3/4" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 3 1/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 3 1/4" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 3 3/8" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 3 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 3 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 4 1/8" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 00000000 | 000000 |

Carbide Square End Mill Sets

Made of solid carbide, the end mills in these sets are harder, stronger, and more wear resistant than high-speed steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1/2" Lg. of Cut × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 5/8" Lg. of Cut × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 3/4" Lg. of Cut × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 13/16" Lg. of Cut × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 1" Lg. of Cut × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 1" Lg. of Cut × 3" O'all Lg. End Mill | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Carbide Square End Mill Sets with Two Milling Ends

Offering two times the life of a standard carbide end mill, the end mills in these sets have two milling ends so you can switch to the opposite end when one end wears out. Made of solid carbide, they're harder, stronger, and more wear resistant than high-speed steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have square ends for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

Titanium Nitride (TiN) Coated | |||||||

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

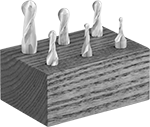

Drill/Mill End Mill Sets

These multifunction tools have a 90° pointed tip that allows them to be used for drilling as well as for slotting, profiling, and chamfering cuts. Made of solid carbide, they're harder, stronger, and more wear resistant than high-speed steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. All are center cutting, allowing plunge cuts into a surface.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | Point Angle | For Use On | End Mill Type | Each | |

Uncoated | ||||||||

|---|---|---|---|---|---|---|---|---|

2 Flute | ||||||||

| 3 | 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | 90° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

4 Flute | ||||||||

| 3 | 6 mm Mill Dia. × 6 mm Shank Dia. × 50 mm O'all Lg. End Mill 10 mm Mill Dia. × 10 mm Shank Dia. × 70 mm O'all Lg. End Mill 12 mm Mill Dia. × 12 mm Shank Dia. × 74 mm O'all Lg. End Mill | Equal | 30° | 90° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Carbide Ball End Mill Sets

For longer tool life and a better finish in general purpose milling applications, these solid carbide end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel end mills. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | |||||||

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Carbide Ball End Mill Sets with Two Milling Ends

Offering two times the life of a standard carbide end mill, the end mills in these sets have two milling ends so you can switch to the opposite end when one end wears out. Made of solid carbide, they're harder, stronger, and more wear resistant than high-speed steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

4 Flute | |||||||

| 6 | 1/8" Mill Dia. × 1/8" Shank Dia. × 1 1/2" O'all Lg. End Mill 3/16" Mill Dia. × 3/16" Shank Dia. × 2" O'all Lg. End Mill 1/4" Mill Dia. × 1/4" Shank Dia. × 2 1/2" O'all Lg. End Mill 5/16" Mill Dia. × 5/16" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

High-Speed Steel Ball End Mill Sets

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

| Number of Pieces | Includes | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||

|---|---|---|---|---|---|---|---|

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 3/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 7/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 0000000 |

Titanium Nitride (TiN) Coated | |||||||

2 Flute | |||||||

| 6 | 1/8" Mill Dia. × 3/8" Shank Dia. × 2 5/16" O'all Lg. End Mill 3/16" Mill Dia. × 3/8" Shank Dia. × 2 3/8" O'all Lg. End Mill 1/4" Mill Dia. × 3/8" Shank Dia. × 2 7/16" O'all Lg. End Mill 5/16" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 3/8" Mill Dia. × 3/8" Shank Dia. × 2 1/2" O'all Lg. End Mill 1/2" Mill Dia. × 1/2" Shank Dia. × 3" O'all Lg. End Mill | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

Fly Cutter Sets

Keep a variety of fly cutters on hand to tackle different sized workpieces. The fly cutters in these sets hold a lathe tool (sold separately) to shave a layer off your workpiece with each pass, creating a smooth, even finish. Use them with milling machines. Compared to end mills, these make a wider cut per pass. They also generate less heat, so you can run them at higher speeds. In the long run, these cutters will save you the expense of replacing entire end mills once they dull—you can either sharpen your worn lathe tool or just replace that one part.

| Number of Pieces | Material | Heat Treatment | Includes | Shank Dia. | Cut Style | Each | |

Straight Shank | |||||||

|---|---|---|---|---|---|---|---|

| 3 | Black-Oxide Steel | Hardened | 3/4" Head Dia. Cutter for 3/16" Square Tool Bit 1 1/8" Head Dia. Cutter for 1/4" Square Tool Bit 1 3/8" Head Dia. Cutter for 5/16" Square Tool Bit | 1/2" | Flat Surface | 0000000 | 000000 |

| 3 | Black-Oxide Steel | Hardened | 1 3/8" Head Dia. Cutter for 5/16" Square Tool Bit 2" Head Dia. Cutter for 5/16" Square Tool Bit 2 1/2" Head Dia. Cutter for 5/16" Square Tool Bit | 3/4" | Flat Surface | 0000000 | 000000 |

Replaceable Carbide-Insert Milling Cutter Kits

Create your own versatile milling cutters. These kits include a cutter body, inserts, wrenches, and screws. Also known as indexable end mills, replaceable insert milling cutters remove metal at least two times faster than comparable high-speed steel milling cutters. When the cutting edges dull, replace the carbide inserts instead of the entire tool. The inserts come factory sealed from the manufacturer for maximum traceability.

Use with an R8 shank arbor (sold separately).

Titanium-diboride (TiB2) coated inserts reduce friction in nonferrous metals and composites, so you can use them without lubrication in material like aluminum, fiberglass, and plastic. Titanium-aluminum-nitride (TiAlN) coated inserts dissipate heat better than other inserts, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the inserts cool, even when used without lubrication.

Kits come with either octagon or square inserts. Use octagon inserts for general face milling. With eight cutting edges, they generate smooth cuts. Use square inserts to create a 90° corner when shoulder milling.

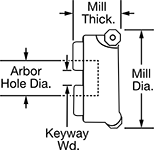

Mill | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Dia. | Arbor Hole Dia. | Keyway Wd. | For Use On | Includes | Container Type | Each | |

Titanium Diboride (TiB2) Coated | ||||||||

Octagon | ||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 0000000 |

| 1 7/8" | 3" | 1 1/4" | 0.5" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 4" | 1 1/2" | 0.625" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

Square | ||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 3" | 1 1/4" | 0.5" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 4" | 1 1/2" | 0.625" | Aluminum, Copper | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated | ||||||||

Octagon | ||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Hardened Steel, Tool Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 23/32" | 2" | 3/4" | 0.313" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 3" | 1 1/4" | 0.5" | Hardened Steel, Tool Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 3" | 1 1/4" | 0.5" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 4" | 1 1/2" | 0.625" | Hardened Steel, Tool Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 4" | 1 1/2" | 0.625" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

Square | ||||||||

| 1 23/32" | 2" | 3/4" | 0.313" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 3" | 1 1/4" | 0.5" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |

| 1 7/8" | 4" | 1 1/2" | 0.625" | Steel | 10 Inserts, Cutter Body, Extra Screws, Two Wrenches | Plastic Case | 0000000 | 000000 |