How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Hose

More

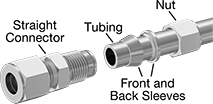

Yor-Lok Fittings for Stainless Steel Tubing

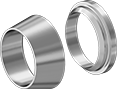

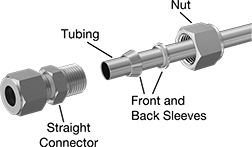

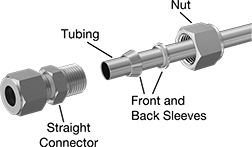

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

For Tubing | ||||||

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3mm | 0.5mm | 316 Stainless Steel | 9,700 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 8mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 12mm | 0.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 14mm | 1 to 2 mm | 316 Stainless Steel | 2,300 psi @ 72° F | -420° to 1200° | 0000000 | 00000 |

For Fitting | ||||||

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3mm | 0.5mm | 316 Stainless Steel | 9,700 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 8mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 12mm | 0.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3mm | 0.5mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 8mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 12mm | 0.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 14mm | 1.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3mm | 0.5mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 8mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 12mm | 0.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 14mm | 1.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 000000 |

| 1/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 5/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 1/2" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 5/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 3/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | |||||

|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Temp. Range, °F | Each | |

| 3/16" | 1/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 1/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 1/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 1/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 1/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 5/8" | 3/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 1/2" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 1" | 3/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | For Tubing | For Fitting | |||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Each | Each | ||

| 1/16" | 0.028" | Brass | 5,400 psi @ 72° F | 000000 | 00 | 00000000 | 00000 |

| 1/8" | 0.035" | Brass | 2,900 psi @ 72° F | 00000000 | 00000 | 00000000 | 0000 |

| 3/16" | 0.035" | Brass | 2,300 psi @ 72° F | 00000000 | 0000 | 00000000 | 0000 |

| 1/4" | 0.035" | Brass | 1,600 psi @ 72° F | 00000000 | 0000 | 00000000 | 0000 |

| 5/16" | 0.035" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 | 00000000 | 0000 |

| 3/8" | 0.035" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 | 00000000 | 0000 |

| 1/2" | 0.035" | Brass | 800 psi @ 72° F | 00000000 | 00000 | 00000000 | 0000 |

| 5/8" | 0.049" | Brass | 900 psi @ 72° F | 00000000 | 0000 | 00000000 | 0000 |

| 3/4" | 0.049" | Brass | 700 psi @ 72° F | 00000000 | 00000 | 00000000 | 0000 |

| 1" | 0.065" | Brass | 700 psi @ 72° F | 00000000 | 00000 | 00000000 | 00000 |

| 6mm | 1mm | Brass | 2,030 psi @ 72° F | 00000000 | 0000 | 00000000 | 0000 |

| 10mm | 1mm | Brass | 1,160 psi @ 72° F | 00000000 | 0000 | 000000 | 00 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/16" | Brass | 5,400 psi @ 72° F | 00000000 | 00000 |

| 1/8" | Brass | 2,900 psi @ 72° F | 00000000 | 0000 |

| 3/16" | Brass | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 800 psi @ 72° F | 00000000 | 0000 |

| 5/8" | Brass | 900 psi @ 72° F | 00000000 | 0000 |

| 3/4" | Brass | 700 psi @ 72° F | 00000000 | 0000 |

| 1" | Brass | 800 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Sleeve Material | Front Sleeve Lg. | Back Sleeve Lg. | Max. Pressure | Each | |

| 1/16" | Brass | 3/32" | 1/16" | 5,400 psi @ 72° F | 00000000 | 00000 |

| 1/8" | Brass | 3/16" | 3/32" | 2,900 psi @ 72° F | 00000000 | 0000 |

| 3/16" | Brass | 3/16" | 3/32" | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 3/16" | 3/32" | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 3/16" | 3/32" | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 3/16" | 3/32" | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 19/64" | 5/32" | 800 psi @ 72° F | 00000000 | 0000 |

| 5/8" | Brass | 19/64" | 5/32" | 900 psi @ 72° F | 00000000 | 00000 |

| 3/4" | Brass | 19/64" | 5/32" | 700 psi @ 72° F | 00000000 | 0000 |

| 1" | Brass | 3/8" | 13/16" | 800 psi @ 72° F | 00000000 | 00000 |

| 6mm | Brass | 5mm | 3mm | 2,030 psi @ 72° F | 00000000 | 0000 |

| 10mm | Brass | 5mm | 3mm | 1,160 psi @ 72° F | 00000000 | 0000 |

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

Caps For Tubing | |||||||

| 1/8" | 0.035" | Zinc-Plated Steel | 6,800 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 8mm | 1mm | Zinc-Plated Steel | 4,200 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 3,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

Caps For Fitting | |||||||

| 1/8" | 0.035" | Zinc-Plated Steel | 6,800 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 3/4" | 0.049" | Zinc-Plated Steel | 2,200 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 1" | 0.065" | Zinc-Plated Steel | 2,100 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 00000 |

| 8mm | 1mm | Zinc-Plated Steel | 4,200 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 3,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/8" | 0.035" | Zinc-Plated Steel | 6,800 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 3/4" | 0.049" | Zinc-Plated Steel | 2,200 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 1" | 0.065" | Zinc-Plated Steel | 2,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 8mm | 1mm | Zinc-Plated Steel | 4,200 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 3,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 6,800 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 4,850 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 3,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 2,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 3/4" | 0.049" | Zinc-Plated Steel | 316 Stainless Steel | 2,150 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 1" | 0.065" | Zinc-Plated Steel | 316 Stainless Steel | 2,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 8mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 4,200 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 3,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

Liquid Nitrogen Hose with Tube Stem Fittings

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

The fittings are a short length of tubing that inserts into the end of another tube fitting. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Liquid Nitrogen Hose with Yor-Lok Tube Fittings

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

The fittings are also known as instrumentation fittings. They have two sleeves (double ferrules) that bite into metal tubing for a strong seal. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Liquid Nitrogen Hose with Yor-Lok Tube Fitting and Tube Stem Fitting

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

Also known as instrumentation fittings, the Yor-Lok fitting has two sleeves (double ferrules) that bite into metal tubing for a strong seal. The tube stem fitting is a short length of tubing that inserts into the end of another tube fitting. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Liquid Nitrogen Hose with Tube and Threaded Fittings

- Temperature Range: -325° to 1,250° F

- Maximum Vacuum: 29" of Hg @ 72° F

- Material: 316 Stainless Steel with 304 Stainless Steel Braid

The Yor-Lok tube fitting is also known as an instrumentation fitting. It has two sleeves (double ferrules) that bite into metal tubing for a strong seal. Use this air-cleaned hose to transfer liquid nitrogen across a wide temperature range.

Touch-Safe Insulated Cryogenic Hose with Tube Stem Fittings

- Temperature Range: -325° to 200° F

- Material: 321 Stainless Steel with 304 Stainless Steel Cover

Sealed vacuum insulation and a reflective barrier inside this hose maintains the temperature of liquids as cold as -325° F. Similar to a thermos, this prevents heat transfer, so the exterior of the hose won’t freeze or form condensation. This hose is safe to handle, even when used with liquid nitrogen, liquid argon, liquid carbon dioxide, and liquid methane. It meets strict ASME design and testing standards for process piping systems.

The tube stems on each end slide into tube fittings on a freezer or other equipment in your plant or laboratory. With ribbed insulation inside and spiral reinforcement outside, this hose won’t crack or leak when you bend and flex it around obstacles. The cover is 304 stainless steel, which stands up to wear and tear and won’t corrode from mild chemicals and water.

For technical drawings and 3-D models, click on a part number.

| Stem OD | ID | OD | Bend Radius | Max. Pressure | Specifications Met | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

316 Stainless Steel Tube Stem × 316 Stainless Steel Tube Stem | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4" × 1/4" | 1/4" | 1 1/8" | 6 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 3/8" × 3/8" | 3/8" | 1 3/8" | 7 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 1/2" × 1/2" | 1/2" | 1 11/16" | 8 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||