Electrical Plug Lockouts

Lock out a plug that powers machinery so no one starts it up during maintenance. Place a plug into the cylinder of these lockouts and secure with a padlock. All can fit a standard electrical plug that has a single cord. Made of plastic, they resist corrosion and are nonconductive for use with electronics. These lockouts help you comply with OSHA 29 CFR 1910.147, which requires electrical circuits to be locked out to prevent injury.

Lockouts for 2 or more padlocks let multiple people add their own padlock. This keeps everyone safe until all of the maintenance work is done and all padlocks are removed.

Lockouts with 2 holes for electrical plugs let you insert a cord from either end. That means you can lock out two devices at once, or lock out both the plug and socket of the same cord.

Lockouts with 5 holes for electrical plugs have a variety of hole sizes to handle different cord diameters. They’ll fit dual-cord battery plugs for forklifts, as well as standard single-cord plugs. Use them with gas-powered equipment, too—the largest hole on these lockouts fits a gas cylinder valve.

Lockouts with adjustable-fit closure let you secure any cord diameter up to 1 1/4”. Slide the two top lids against each other to change the hole size.

Lockouts with a message alert passersby that a plug has been locked out for safety.

Lockouts that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet ongoing purchasing requirements for LEED-certified facilities.

For Plug | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | No. of Holes for Electrical Plugs | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Dia. | Temp. Range, ° F | Message | Features | Specifications Met | Each | |

Yellow Plastic | |||||||||||||||

| 1 | 5/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2"-3" | 6 1/4" | __ | __ | 3 1/2" | 32° to 275° | __ | Adjustable-Fit Closure | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| 4 | 3/8" | 1 1/8" | 2 | 4 3/4" | 1 1/2"-2 3/4" | 7 1/4" | __ | __ | 4 1/4" | -20° to 140° | __ | __ | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 4 | 3/8" | 1 7/16" | 2 | 10 1/4" | 1/2"-4 1/2" | 12 1/2" | __ | __ | 5" | 0° to 175° | __ | __ | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

Yellow Plastic (English/Spanish Message) | |||||||||||||||

| 3 | 9/16" | 1 1/4" | 1 | 5 1/2" | 1 1/2"-3" | 7" | __ | __ | 3 3/4" | -25° to 200° | Danger—Do Not Plug In/No Conectar | Adjustable-Fit Closure | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

Red Plastic (English Message) | |||||||||||||||

| 2 | 11/32" | 1/2" | 2 | 3 1/8" | 1/2"-1 5/8" | 3 1/2" | 3 1/8" | 2" | __ | 0° to 175° | Danger—Locked Out—Do Not Remove | __ | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

| 3 | 9/16" | 1/2" | 2 | 3" | 3/4"-2" | 3 1/2" | __ | __ | 2 1/2" | -25° to 200° | Danger—Do Not Operate—Equipment Locked Out | __ | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| 6 | 9/32" | 1 1/8", 1", 1" | 5 | 6 3/4" | 1/2"-2 1/2" | 7 1/4" | 4 1/4" | 3" | __ | -40° to 300° | Danger—Do Not Operate—Equipment Locked Out | __ | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 00000 |

Plug-In Electrical Plug Lockouts

These lockouts plug into standard two- and three-prong plugs and lock with keys so the plug can't be used. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers.

Keyed-alike lockout includes keys with a specific key number. Keyed-differently lockout includes keys with a random key number.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Keying | Key No. | No. of Keys Included | Lg. | Wd. | Dp. | For Plug Type | Temp. Range, ° F | Color | Specifications Met | Each | |

Plastic-Coated Steel | |||||||||||

| Keyed Alike | 4001 | 2 | 1 3/4" | 1 1/4" | 3/4" | Two Prong, Three Prong | -40° to 194° | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| Keyed Differently | __ | 2 | 1 3/4" | 1 1/4" | 3/4" | Two Prong, Three Prong | -40° to 194° | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Electrical Socket Lockouts

Make sure no one inserts a plug into an IEC socket on your equipment during maintenance. Fit these lockouts in your socket and twist the key end to clamp them onto the prongs. Then secure with a padlock and lockout tag. Made of plastic, they’re durable and resist wear. They’re also nonconductive for safe use with electronics. They help you comply with OSHA 29 CFR 1910.147, which requires controls to be locked out during maintenance to prevent injuries.

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| IEC Style | Lg. | Wd. | Ht. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Specifications Met | Each | |

Plastic | ||||||||||

| C13 | 3 1/2" | 1 1/8" | 7/8" | 1 | 1/4" | 0° to 245° | Orange | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Lockout Bags

Lock out hoist controls, large electrical connectors, spouts, and other odd-sized controls. These bags cinch onto your equipment and secure with a padlock to prevent accidental start-ups. All have a warning label to alert others that equipment has been locked out for maintenance. They help you comply with OSHA 29 CFR 1910.147, which requires power sources and supply lines to be locked out to prevent injuries.

Canvas bags allow air to circulate so condensation doesn’t build up. They’re also flexible and durable.

Nylon bags are wear resistant and strong. With holes for multiple padlocks and lockout tags, each person can add their own as they start a job. Each padlock adds another layer of security, and until the last is removed, these bags won’t open.

Polyester bags are the best choice for waterspouts because they won’t swell from water exposure.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Color | Language | Message | Specifications Met | Each | |

Canvas | |||||||||

| 18" | 9 3/4" | 1 | 9/32" | Yellow | English | Lock Out For Safety | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

Nylon | |||||||||

| 17" | 7" | 6 | 9/32" | Red | English, Spanish, French | Locked Out—Do Not Remove, Cerrado—No Lo Quite, Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

| 26" | 10" | 6 | 9/32" | Red | English, Spanish, French | Locked Out—Do Not Remove, Cerrado—No Lo Quite, Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Polyester | |||||||||

| 5" | 5" | 1 | 5/16" | Red | English | Locked Out—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Battery Cable Connector Lockouts

Padlock these lockouts over the ends of battery cables to keep forklifts, pallet jacks, and other machinery powered off during maintenance. They signal that equipment is being serviced, preventing accidental startups. These lockouts have space for two padlocks, so teams can safely perform two maintenance tasks at once.

Made from nonconductive plastic, they insulate battery terminals and protect workers from accidental shocks, helping you comply with OSHA 29 CFR 1910.147 requirements for the control of electricity. These lockouts are also rated UL 94 HB, which means they have been tested in a horizontal position for flame resistance; the slow-burning plastic keeps flames from spreading.

Hinged lockouts fully enclose battery cable ends and inline connections. Fit battery connectors, such as lugs and terminal clamps, over the internal post to hold cables in place.

Slide-on lockouts are best for large battery connectors.

For Max. Connector | Cable Opening | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | For No. of Battery Cables | Wd. | Ht. | Post Dia. | Lg. | Wd. | Ht. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Specifications Met | Each | |

Hinged | ||||||||||||||||

Plastic | ||||||||||||||||

| 2 5/8" | 1 1/2" | 1 1/4" | 1 | 1" | 1" | 1/4" | 3 3/4" | 2 7/8" | 1 3/8" | 2 | 5/16" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147, UL 94 HB | 0000000 | 000000 |

| 2 5/8" | 2 3/4" | 1 5/8" | 2 | 2" | 1 3/8" | 1/4" | 5 3/4" | 4 1/8" | 1 3/4" | 2 | 5/16" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147, UL 94 HB | 0000000 | 00000 |

Slide On | ||||||||||||||||

Plastic | ||||||||||||||||

| 4 1/2" | 2 7/8" | 1 3/8" | __ | __ | __ | __ | 5 1/4" | 3 1/8" | 2 1/2" | 2 | 5/16" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147, UL 94 HB | 0000000 | 00000 |

Pendant Switch Lockouts

Prevent cranes, hoists, and other machinery controlled by pendant switches from starting up during maintenance. Unlike soft lockout bags, these lockouts have rigid sides that keep control buttons from being pressed while work is underway. With space for four padlocks, multiple people can safely work on the same equipment. These lockouts expand to fit over most switch sizes, and collapse flat for storage. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers.

For Switch | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Max. Wd. | Lg. | Wd. | Dp. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Specifications Met | Each | |

Plastic/Fabric | |||||||||||

| 4"-18" | 5" | 11"-20" | 5 1/4" | 5 1/4" | 4 | 3/8" | -40° to 212° | Red | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

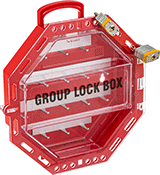

Portable Group Lockout Boxes

Lock out a machine with fewer padlocks when a team is working. After locking one padlock to each electrical control and placing the keys in the box, each person can attach a padlock to the outside of the box before starting their work. The keys are only accessible once all padlocks have been removed, keeping everyone safe while maintenance is completed. Once these boxes are locked, you can still add keys through a slot. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could cause injuries.

These lockout boxes resist corrosion. Plastic boxes are nonconductive. Stainless steel boxes have drain holes to keep moisture from building up inside. They're stackable for easy storage.

Styles A and C have a window, so you can view the keys inside. Made of polycarbonate plastic, the window protects your keys from water exposure and resists impact to prevent break-ins.

Boxes with a control-lock hole allow a supervisor to lock them with a control padlock. Boxes with a removable key cup make it easy to retrieve keys dropped in the key slot. Lift the cup out to access your keys.

| Style | Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks (Hole Location) | Min. Padlock Vertical Shackle Clearance | For Max. Padlock Shackle Dia. | No. of Windows | Window Material | Features | Stackable | Each | |

Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | Red | 7 3/4" | 4" | 7 3/4" | 17 (Outside of Box) | 1 1/2" | 1/4" | 1 | Polycarbonate Plastic | Handle, Key Slot | No | 00000000 | 000000 |

Powder-Coated Steel | |||||||||||||

| B | Blue | 9" | 3 1/2" | 6" | 13 (Outside of Box) | 5/8" | 9/32" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 00000000 | 00000 |

| B | Red | 4 1/4" | 4 1/4" | 6 1/4" | 7 (Outside of Box) | 1" | 5/16" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 00000000 | 00000 |

| B | Red | 9" | 3 1/2" | 6" | 13 (Outside of Box) | 5/8" | 9/32" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 00000000 | 00000 |

| B | Yellow | 10" | 4" | 6" | 13 (Outside of Box) | 3/4" | 5/16" | __ | __ | Control-Lock Hole, Handle, Key Slot | No | 000000000 | 00000 |

| C | Red | 8" | 4 1/2" | 4 3/4" | 20 (Outside of Box) | 3/4" | 1/4" | 2 | Polycarbonate Plastic | Handle, Key Slot | No | 00000000 | 000000 |

| C | Red | 12" | 8 1/4" | 9" | 21 (Outside of Box) | 1/2" | 5/16" | 1 | Polycarbonate Plastic | Control-Lock Hole, Handle, Key Slot, Removable Key Cup | Yes | 00000000 | 000000 |

Powder-Coated Stainless Steel | |||||||||||||

| C | Red | 12" | 6 1/2" | 5 3/4" | 19 (Outside of Box) | 3/4" | 3/8" | 1 | Polycarbonate Plastic | Control-Lock Hole, Drain Holes, Handle, Key Slot, Removable Key Cup | Yes | 00000000 | 00000 |

Wall-Mount Group Lockout Boxes

Lock out a machine with fewer padlocks when a team is working. After locking one padlock to each electrical control and placing the keys in the box, each person locks their own padlock to the outside of these boxes. The keys are only accessible once all the padlocks have been removed—keeping your group safe. Once these boxes are locked, you can still add keys through a slot. Made of plastic, they’re lightweight, durable, corrosion resistant, and nonconductive. A plastic window lets you view the keys inside while protecting them from water exposure. These boxes help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could cause injuries.

Boxes with a control-lock hole allow a supervisor to lock them with a control padlock.

Boxes with a wall-mount bracket make it easy to remove your box from a wall. After you mount the bracket, these boxes slide on and off of it.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks (Hole Location) | For Max. Padlock Shackle Dia. | No. of Key Hooks | Fasteners Included | No. | Screw Size | Number of Windows | Window Material | Features | Includes | Each | |

Plastic | |||||||||||||||

| Red | 2 3/4" | 4" | 5 3/4" | 12 (Outside of Box) | 9/32" | 3 | No | 3 | No. 4 | 1 | Polycarbonate Plastic | Key Slot | Wall-Mount Bracket | 00000000 | 000000 |

| Red | 4" | 13" | 11" | 26 (Outside of Box) | 15/32" | 11 | No | 2 | No. 10 | 1 | Polycarbonate Plastic | Control-Lock Hole, Key Slot | __ | 000000000 | 000000 |

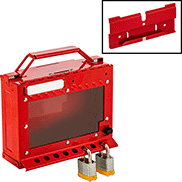

Portable/Wall-Mount Group Lockout Boxes

Carry these boxes from job to job and mount them near equipment to lock out valves, electrical controls, and other machines with fewer padlocks, saving your team time. With these lockout boxes, you only need one padlock to lock out a piece of equipment. When starting maintenance work, have each person lock their own padlock to the outside of the box and place their key inside. The keys are only accessible once everyone has removed their padlocks, keeping your team safe. Each box has hooks to keep your keys organized and easy to identify. Once these boxes are locked, you can still add keys through a slot. All boxes help you comply with OSHA 29 CFR 1910.147 procedures for controlling hazardous energy.

Plastic boxes are lightweight and corrosion resistant. They’re also nonconductive for use near electronics. While they’re a durable option, they aren’t as strong as steel and stainless steel boxes. Steel boxes are stronger than stainless steel boxes. They’re powder coated for corrosion protection. Stainless steel boxes resist corrosion better than steel boxes, and they’re powder coated for even more corrosion resistance. They’re stronger than plastic boxes, but weaker than steel boxes.

Boxes with a polycarbonate plastic window let you view the keys inside. Thanks to its material, the window protects your keys from water exposure and resists impact to prevent break-ins.

Boxes with a wall-mount bracket make it easy to secure your box to a wall and remove it. To secure and prevent unwanted removal, place the box against the mounted bracket and slide the locking mechanism inside of the box in place. To remove, unlock the cover of the box and slide the locking mechanism to the unlocked position.

Boxes with a document display let you view checklists and permits as you lock out equipment, reducing the risk of injury. Thanks to an IP-rated gasket, they’ll keep your documents protected in damp environments. The lock caddy is removable so it’s easy to transport your padlocks and keys during lockout. For easy retrieval of the keys you drop through the slot, the key cup that collects them is removable as well.

Boxes with a control-lock hole have a dedicated spot for supervisors to lock the box closed.

Boxes with a dry erase label are helpful to write down permit and work order numbers.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Lg. | Wd. | Ht. | For Max. No. of Padlocks (Hole Location) | For Max. Padlock Shackle Dia. | No. of Key Hooks | Fasteners Included | No. | Screw Size | Mounting Location | No. of Windows | Features | Environmental Rating | Each | |

(A) Plastic Box with Polycarbonate Plastic Window | |||||||||||||||

| Red | 13" | 3 1/2" | 13" | 44 (Outside of Box) | 5/16" | 16 | No | 2 | 1/4" | Freestanding, Wall | 1 | Control-Lock Hole, Handle, Key Slot | __ | 0000000 | 000000 |

(B) Powder-Coated Steel Box | |||||||||||||||

| Red | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Freestanding, Wall | __ | Handle, Key Slot | __ | 00000000 | 00000 |

| Yellow | 6 3/8" | 3 1/2" | 12 3/4" | 14 (Outside of Box) | 9/32" | 12 | No | 4 | No. 8 | Freestanding, Wall | __ | Handle, Key Slot | __ | 00000000 | 00000 |

(C) Powder-Coated Steel Box with Polycarbonate Plastic Window | |||||||||||||||

| Red | 10 1/2" | 3 1/2" | 6 1/8" | 12 (Outside of Box) | 5/16" | 6 | No | 2 | No. 8 | Freestanding, Wall | 1 | Handle, Key Slot | __ | 0000000 | 00000 |

(D) Powder-Coated 430 Stainless Steel Box with Wall-Mount Bracket, Polycarbonate Plastic Window | |||||||||||||||

| Red | 8 3/8" | 4" | 6 7/8" | 8 (Outside of Box) | 3/8" | 4 | No | 3 | No. 10 | Freestanding, Wall | 1 | Dry Erase Label, Handle, Key Slot | __ | 0000000 | 00000 |

(E) Powder-Coated 430 Stainless Steel Box with Document Display, Polycarbonate Plastic Window | |||||||||||||||

| Red | 12 1/8" | 4 3/4" | 31" | 12 (Outside of Box); 12 (Removable Lock Caddy) | 9/32" | 12 | No | 8 | No. 8 | Wall | 2 | Control-Lock Hole, Dry Erase Label, Handle, Key Slot, Removable Key Cup | IP03 | 000000000 | 000000 |

Air Hose Lockouts

Block air hoses from connecting to compressed air. These lockouts secure with a padlock and lockout tag so your equipment doesn't start up during repairs. They also help you comply with OSHA 29 CFR 1910.147 requirements for locking out controls to prevent injuries.

Style D can lock out an air hose and electrical plug at the same time. Stash them in your tool bag so you don’t have to carry two separate types of lockouts when completing maintenance work.

Lockouts for more than one padlock let multiple people add their own padlock as they start a job. Until the last padlock is removed, these lockouts won’t open.

For Plug | Overall | Temp. Range, °F | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | For Coupling Size | For Hose Connection Type | For Quick Disconnect Component | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | For Max. Cord Dia. | Max. Lg. | Wd. | Lg. | Wd. | Ht. | Min. | Max. | Color | Label Included | Message | Each | |

Cover | ||||||||||||||||||

Plastic | ||||||||||||||||||

| D | 1/8 | Quick Disconnect | Plug | 4 | 1/4" | 1/4" | 5" | 2"-3 1/2" | 6 1/4" | 4 1/2" | 3 3/4" | 0° | 175° | Red | Yes | Lockout Device—Do Not Plug In | 0000000 | 000000 |

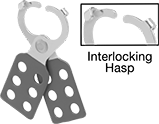

Pry-Resistant Lockout Hasps with Padlock Slot

A fold-over closing design hinders prying, while a slot instead of holes makes it easy to install multiple padlocks. Use these lockouts to lock out a single valve, switch, or other control on machinery and electrical equipment so it can't be used. Have each person attach a padlock before starting their work—the power can’t restart until all the locks are removed and maintenance is complete. When used with labeled or tagged padlocks, these lockouts help you comply with OSHA 29 CFR 1910.147 requirements to prevent injuries from controls being accidentally used during maintenance. Made of steel, these hasps are strong. They’re zinc plated to resist corrosion.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Body Ht. | Lg. | Wd. | Specifications Met | Each | |

Zinc-Plated Steel | ||||||||||

| 1" | 1" | 1/8" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 1" | 1" | 1/4" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 |

| 1 1/2" | 1" | 3/8" | 6 | 7/16" | 3 1/2" | 5 3/8" | 2 1/2" | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

| 3" | 1" | 1/8" | 9 | 5/16" | 3 1/2" | 6 5/8" | 2 1/4" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 3" | 1" | 1/4" | 9 | 5/16" | 3 1/2" | 6 3/4" | 2 1/4" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 4 3/4" | 1 1/2" | 1/4" | 3 | 3/8" | 2" | 7" | 3" | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

Pry-Resistant Lockout Hasps

With a fold-over clasp design, these hasps shut tight enough that picks and other tools can't pry them open. Use them to lock out controls so machinery stays off during repairs. With holes for multiple padlocks, each person can add their own as they start a job. Each padlock adds another layer of security, and until the last is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147 safety procedures.

Plastic hasps resist corrosion and won’t scuff up surfaces.

Steel hasps are strong and zinc plated for corrosion resistance. Those with a vinyl coating won’t leave scratches on surfaces.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Plastic | ||||||||||

| 1 1/8" | 1" | 1/8" | 2 | 9/32" | 3 1/8" | 2 3/16" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

Zinc-Plated Steel | ||||||||||

| 3" | 1" | 1/4" | 6 | 3/8" | 6 3/4" | 2 1/4" | __ | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Vinyl-Coated Zinc-Plated Steel | ||||||||||

| 1 1/4" | 1" | 1/4" | 6 | 3/8" | 5" | 2 5/16" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

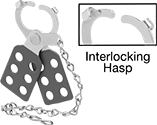

Pry-Resistant Interlocking-Hasp Lockouts with Chain

In addition to an overlapping hasp that interlocks when closed, lockouts have a chain that attaches to equipment so they won't get lost. Use these lockouts to lock out a single energy control on machinery and electrical equipment so it can't be used. All are vinyl coated so they won't mar surfaces. They help meet OSHA Compliant 29 CFR 1910.147 procedures for the control of energy sources that could cause injuries.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Mounting Chain Lg. | Specifications Met | Each | |

Vinyl-Coated Steel | ||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | 8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | 8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

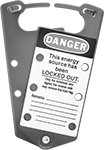

Pry-Resistant Interlocking-Hasp Lockouts

Clasps interlock when you close these lockouts to protect against prying. Use them to lock out controls so machinery stays off during repairs. They have multiple holes for multiple padlocks and lockout tags, so each person can add their own as they start the job. Each padlock adds another layer of security, and until the last is removed, these lockouts won’t open. They help you comply with OSHA 29 CFR 1910.147, which requires controls to be locked out during maintenance to prevent injuries.

Vinyl-coated lockouts protect surfaces from getting scuffed up.

Lockouts that meet UL-2809-2 are made of 100% recycled materials and are sustainably sourced to meet ongoing purchasing requirements for LEED-certified facilities.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Powder-Coated Steel | ||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 0000 |

Vinyl-Coated Steel | ||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 |

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Choose-a-Color Lockout Hasps with Label

Lockouts come in different colors for easy identification and to help meet OSHA standards. The label is permanently attached to record employee name and department. Use these lockouts to lock out a single energy control on machinery and electrical equipment so it can't be used.

For technical drawings and 3-D models, click on a part number.

Lockout Hasps

Lock out electrical panels, switches, and other power sources to keep machinery off during repairs. These hasps have multiple holes for multiple padlocks and tags, so each person can add their own as they start the job. Until the last padlock is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

Aluminum hasps resist corrosion better than steel hasps, so they won’t wear as easily. Steel hasps are stronger than aluminum and stainless steel hasps. Stainless steel hasps are both strong and corrosion resistant. While not as strong as steel hasps, they resist corrosion much better. They’re also stronger and more corrosion resistant than aluminum hasps.

Vinyl- and epoxy-coated hasps won’t scuff the surfaces they touch. Epoxy-coated hasps resist corrosion.

Hasps that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Aluminum | ||||||||||

Powder Coated | ||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 000000 |

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 2 1/16" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

Vinyl Coated | ||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Steel | ||||||||||

Powder Coated | ||||||||||

| 1" | 1" | 1/4" | 12 | 3/8" | 6 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

| 1" | 1" | 1/4" | 24 | 1/4" | 10 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

Vinyl Coated | ||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 4 1/2" | 1 3/4" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 |

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5" | 2 3/8" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 |

Epoxy Coated | ||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 5 1/16" | 1 3/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 |

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5 1/16" | 2 1/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

304 Stainless Steel | ||||||||||

Vinyl Coated | ||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| 1 1/4" | 1 1/4" | 1/4" | 6 | 5/16" | 4 9/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Low-Profile Lockout Hasps with Label

Same as our other low-profile lockout hasps, but with an attached label to record employee name and department. Use this lockout hasp to lock out a single energy control on machinery and electrical equipment so it can't be used. It helps you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers. Hasps that meet OSHA 29 CFR 1910.145 adhere to safety color standards for indicating hazards.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Message | Specifications Met | Each | |

Nickel-Plated Steel | ||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.145, OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

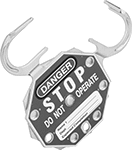

Lockout Hasps with Label

A Danger label on these hasps alerts passersby that an energy control is locked out. Use them to make sure machinery doesn’t get powered up during repairs. They have multiple holes for multiple padlocks and tags—mark them with names or maintenance tasks and remove them individually as work is completed. Until the last padlock is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

Steel hasps are stronger than aluminum hasps. Aluminum hasps resist corrosion better than steel hasps.

Style A have a stop sign design. Write on them with a dry erase marker so they can be reused without changing the label. Style B have a warning label on the front and space for 6 names and dates on the back.

Hasp Clearance | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Message | Color | Specifications Met | Each | |

Vinyl-Coated Steel | ||||||||||||

| A | 1 1/8" | 2 1/16" | 3/16" | 6 | 5/16" | 5 7/16" | 3 7/16" | Danger—Do Not Operate | Red | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Anodized Aluminum | ||||||||||||

| B | 1 1/2" | 1 1/2" | 3/16" | 6 | 9/32" | 7" | 2 3/4" | Danger—Do Not Operate | Red | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

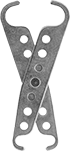

Dual-Jaw Lockout Hasps

Like two lockout hasps in one, there's a jaw at each end with different clearances for added versatility. Use these lockout hasps to lock out a single energy control on machinery and electrical equipment so it can't be used. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Specifications Met | Each | |

Zinc-Plated Steel | |||||||||

| 1/2" × 1" | 1/2" × 1" | 5/16" × 5/16" | 6 | 5/16" | 7 3/4" | 1 3/8" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

Aluminum | |||||||||

| 1" × 1 1/2" | 1" × 1 1/2" | 1/4" × 1/4" | 8 | 9/32" | 5 7/8" | 2" | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Lockout Hasps with Chain

These have a chain to attach to equipment so they won't get lost. Use them to lock out a single energy control on machinery and electrical equipment so it can't be used. Lockouts are vinyl coated so they won't mar surfaces. They help you comply with OSHA 1910.147 procedures for the control of energy sources that could injure workers.

For technical drawings and 3-D models, click on a part number.

Hasp Clearance | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Vinyl-Coated Aluminum | ||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

Low-Profile Lockout Hasps

With a smaller overall length, these lockout hasps fit in tighter spaces than other lockout hasps yet still hold a similar number of locks. Use them to lock out a single energy control on machinery and electrical equipment so it can't be used. They help you comply with OSHA 29 CFR 1910.147 procedures for the control of energy sources that could injure workers.

For technical drawings and 3-D models, click on a part number.

Nonconductive Lockout Hasps

Ideal for circuit breakers and other electrical equipment, these hasps are made of nonconductive plastic to prevent shocks. They also resist corrosion better than hasps with a metal body. Use them to lock out controls to keep machinery off while completing repairs. They have multiple holes for multiple padlocks and tags, so each person can add their own as they start the job. Until the last padlock is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147, which requires electrical controls to be locked out during maintenance to prevent injuries.

Style B have a slot instead of multiple holes, so it’s easier to install multiple padlocks.

Style C have a flexible clasp that you can bend to fit around irregular shapes. They also have a prominent warning label on the body.

Style D are good for tight-clearance applications, such as on circuit breakers. They have a thin, lightweight design.

Style E are bright red and shaped like a stop sign to remind you to be cautious near locked out equipment.

Hasps that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

Hasp Clearance | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specifications Met | Each | |

Plastic | |||||||||||

| A | 1" | 1" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 000000 |

| A | 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| B | 1 3/4" | 3/4" | 1" | 2 | 1 1/2" | 4 3/4" | 2 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

| C | 1 15/16" | 1" | 1/4" | 3 | 1/4" | 8" | 1 3/4" | Red | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 000000000 | 00000 |

| D | 3 1/2" | 1 1/4" | 3/8" | 6 | 3/8" | 7" | 1 3/4" | Orange | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

| E | 3 1/2" | 1 1/4" | 1/2" | 12 | 1/4" | 7 1/4" | 3 1/4" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 |

Nonconductive Lockout Hasps with Tag Holder

Made of plastic, these hasps limit the risk of shock when you’re locking out electrical equipment. Plus, they resist corrosion better than metal hasps. They have a holder for a disposable lockout tag (sold separately) to alert others to repairs. The holder secures the tag flush with the hasp, so it doesn’t get damaged or ripped off. Use these hasps to lock out controls to keep machinery off while completing repairs. They have holes for up to three padlocks, so each person can add their own as they start a job. Until the last padlock is removed, these hasps won’t open. They help you comply with OSHA 29 CFR 1910.147 requirements for locking out electrical controls to prevent injuries.

Hasp Clearance | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical | Horizontal | Hasp Thick. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Tag Included | Specifications Met | Each | |

Plastic | |||||||||||

| 2 3/4" | 1 3/8" | 1/2" | 3 | 5/16" | 5 1/4" | 3" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| Ht. | Wd. | Thick. | Message | Hole Dia. | Specifications Met | Pkg. Qty. | Pkg. | |

Polypropylene Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 4 1/2" | 2 1/8" | 0.01" | Danger—Locked Out—Do Not Operate Danger—This Energy Source Has Been Locked Out! | 13/32" | OSHA Compliant 29 CFR 1910.147 | 25 | 00000000 | 000000 |

Electrical and Valve Lockout Sets with Padlocks

Everything you need to lock out your electrical equipment or valves. These sets are your one stop shop for padlocks, hasps, and other lockout devices. Bright red, they alert others to service or repairs. Use them to comply with OSHA 29 CFR 1910.147 requirements to prevent injuries caused by accidental startups during maintenance.

Sets with a cable lockout can be used on panel boxes or handwheels. Thanks to their extra length, they weave between handles or wheels to prevent them from turning.

Sets in a carrying case store lockout components in a soft, portable bag.

Sets in a fanny pack are strapped around your waist to keep lockout devices within reach.

Sets in a plastic box are more weather resistant than sets in a carrying case or fanny pack.

Sets that meet UL 2809-2 are made of 100% recycled materials, so they meet purchasing requirements for LEED-certified facilities.

| Lockout Style | Includes | Specifications Met | Each | |

| Cover, Hasp | 1 Each: Plug Lockout 1 Each: Circuit Breaker Lockout 1 Valve Wheel Lockout (fits 2 1/2"-5" Diameter Wheels) 4 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 5 Each: Tags 5 Cable Ties Fanny Pack | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

| Bag, Cable, Cover, Hasp | 1 Each: Plug Lockout 1 Each: Plug Prong Lockout 5 Each: Circuit Breaker Lockouts 1 Each: Cable Lockout 3 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", and 4"-6 1/2" Diameter Wheels) 1 Each: Adjustable Ball Valve Lockout 1 Each: Hoist Cover 1 Each: Wall Switch Lockout 3 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Alike Padlocks with Labels 6 Each: Tags 6 Cable Ties Plastic Box | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| Bag, Cable, Cover, Hasp | 2 Each: Plug Lockouts 11 Each: Circuit Breaker Lockouts 1 Each: Cable Lockout 2 Each: Valve Lockouts 3 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", and 4"-6 1/2" Diameter Wheels) 1 Each: Wall Switch Lockout 6 Each: Lockout Hasps 6 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 12 Each: Tags 12 Cable Ties Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Forklift Lockout Sets with Padlock

Prevent injuries while servicing a forklift—these kits come with everything you need to perform lockout tagout procedures. They include a lockout device that fully covers a gas cylinder and connectors, preventing accidental startup. An eye-catching red padlock, hasp, lockout, and carrying bag alert others to the maintenance and signal they should proceed with caution. These kits help you comply with OSHA 29 CFR 1910.147, which requires the battery or gas cylinder to be locked out during maintenance.

| For Use With | Includes | Specifications Met | Each | |

| Battery Cable Connectors, Electrical Plugs, Gas Cylinders | 1 Each: 1/4" Shackle Diameter Keyed Differently Padlock with Label 1 Each: Lockout Hasp 1 Each: Plug Lockout 10 Each: Forklift Inspection Tags 10 Each: Lockout Tags 20 Each: Safety Labels 10 Each: Cable Ties Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Electrical Lockout Sets with Padlocks

Keep an assortment of padlocks, hasps, and other electrical lockouts on hand. Stored in a portable case, these sets have everything you need to lock out electrical equipment around your facility—just grab them and go. The lockouts are red or yellow to grab your attention and alert you to maintenance. Use them to help comply with OSHA 29 CFR 1910.147 requirements to prevent injuries caused by accidental startups during maintenance.

Sets in a carrying case store lockouts in a soft, portable bag.

Sets in a plastic box keep lockouts organized in a durable plastic container, like a toolbox. They’re more resistant to rain and snow than sets in a carrying case.

Sets that meet UL 2809-2 are made of 100% recycled materials, so they meet purchasing requirements for LEED-certified facilities.

| For Use With | Includes | Specifications Met | Each | |

| Circuit Breakers, Electrical Plugs | 3 Each: Cable Ties 4 Each: Circuit Breaker Lockouts 1 Each: Plug Lockout 2 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Alike Padlocks with Labels 3 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

| Circuit Breakers, Electrical Plugs | 3 Each: Cable Ties 2 Each: Plug Lockouts 2 Each: Lockout Hasps 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 2 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

| Circuit Breakers, Electrical Plugs, Wall Switches | 10 Each: Cable Ties 5 Each: Circuit Breaker Lockouts 1 Each: Plug Lockout 1 Each: Wall Switch Lockout 2 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags Plastic Box | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 |

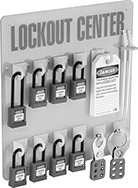

Wall-Mount Lockout Sets with Padlocks

Keep items for group lockouts organized and within reach with these sets. They mount to a wall and provide hangers for your lockout supplies. All padlocks and hasps are red, and the board or case is yellow plastic, so these sets are easy to see. They help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

Cases have a clear plastic cover to protect lockout items against water and dust.

Sets that meet UL 2809-2 are made of 100% recycled materials and are sustainably sourced to meet purchasing requirements for LEED-certified facilities.

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Includes | Ht. | Wd. | Dp. | Fasteners Included | No. | Screw Size | Specifications Met | Each | |

Boards | |||||||||

| 3 Each: Cable Ties 2 Each: Lockout Hasps 3 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 3 Each: Tags | 11" | 11" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

| 10 Each: Cable Ties 2 Each: Lockout Hasps 8 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 15" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

| 10 Each: Cable Ties 2 Each: Lockout Hasps 12 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 23" | 15" | 2 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 000000 |

| 2 Each: Lockout Hasps 16 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags | 13 1/2" | 14 1/2" | 3" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

Cases | |||||||||

| 12 Each: Cable Ties 2 Each: Lockout Hasps 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 12 Each: Tags | 12 1/4" | 16" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 24 Each: Cable Ties 2 Each: Lockout Hasps 10 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 24 Each: Tags | 15 1/2" | 22" | 1 3/4" | No | 4 | No. 6 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

Electrical, Valve, and Air Hose Lockout Sets with Padlocks

Lock out nearly any power source or supply line in your facility, from circuit breakers and valve handles to wall switches and air hose. These sets include padlocks, hasps, and other lockouts in a carrying case—just grab them and go. They also include a cable lockout for panel boxes, handwheels, and other devices that require extra length to secure. To alert others to maintenance and repair, the lockouts are red. The lockouts in these sets help you meet OSHA 29 CFR 1910.147 requirements to prevent injuries caused by accidental startups.

| For Use With | For Valve Control Type | Includes | Specifications Met | Each | |

| Air Hose, Circuit Breakers, Electrical Panels, Electrical Plugs, Push Buttons, Valves, Wall Switches | Hand Wheel, Handle | 1 Each: Air Hose Lockout 1 Each: Cable Lockout 1 Each: Push Button Lockout 1 Each: Valve Handle Lockout (Fits 3/8 to 1 Pipe Size) 1 Each: Wall Switch Lockout 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 2 Each: Lockout Hasps 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 5 Each: Cable Ties 5 Each: Tags Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Wall-Mount Electrical and Valve Lockout Sets with Padlocks

Keep everything you need to lock out most electrical equipment and valves around your facility in a single spot against the wall. These sets have supplies for locking out circuit breakers, valves, plugs, wall switches, and other controls. The supplies are red or yellow to alert people to maintenance. They help you comply with OSHA 29 CFR 1910.147, which requires power sources and supply lines to be locked out to prevent injuries.

Cabinets are made of stainless steel, so they resist damage better than our plastic cases. They meet UL 2809-2, so they’re made of at least 90% recycled materials to meet purchasing requirements for LEED-certified facilities.

Cases have a clear plastic cover to protect lockout items against water and dust while still letting you see inside. They have a larger set of supplies than our cabinets, including a cable lockout for weaving through and around panel boxes, valve wheels, and other hard-to-secure equipment.

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Includes | Ht. | Wd. | Dp. | Fasteners Included | No. | Screw Size | Specifications Met | Each | |

Cabinets | |||||||||

| 1 Each: Gas Cylinder Lockout 1 Each: Wall Switch Lockout 2 Each: Plug Lockouts 2 Valve Wheel Lockouts (1 Each that fits 1"-2 1/2" and 2 1/2"-5" Diameter Wheels) 3 Each: Circuit Breaker Lockouts 4 Each: Lockout Hasps 4 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 10 Each: Tags 10 Each: Cable Ties | 16" | 15 1/4" | 5 1/2" | No | 4 | No. 10 | OSHA Compliant 29 CFR 1910.147, UL 2809-2 | 00000000 | 0000000 |

Cases | |||||||||

| 1 Each: Cable Lockout 1 Each: Snap-On Lockout Hasp 2 Each: Plug Lockouts 2 Each: Lockout Hasps 2 Each: Valve Handle Lockouts (Fits 3/8 to 4 Pipe Size) 2 Each: Wall Switch Lockouts 4 Valve Wheel Lockouts (1 Each that fits 1"-3", 2"-5", 4"-6 1/2", and 6"-10" Diameter Wheels) 6 Each: 1/4" Shackle Diameter Keyed Differently Padlocks with Labels 8 Each: Circuit Breaker Lockouts 24 Each: Tags 24 Each: Cable Ties | 27" | 23 1/2" | 4 1/2" | No | 8 | No. 10 | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |