About Load Center

More

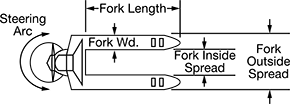

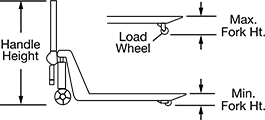

Battery-Operated Lift Trucks with Forks

A hydraulic pump powered by a rechargeable battery raises and lowers loads with the push of a button. A charge indicator lets you know how much battery life is left. The push-button control has a self-retracting cord. Two swivel casters at the rear of the lift truck make steering and pivoting easy. Once the truck is in place, engage the floor lock to lift and lower loads.

Counterbalanced bases have shorter legs for closer access to the load. A counterweight set (sold separately) is required.

Straddle bases have a greater distance between the legs for easier access to loads on pallets.

Polyurethane wheels are nonmarking, abrasion-resistant, and shock absorbing. Use them on all floor types, including areas with debris. Phenolic wheels are nonmarking and roll best on smooth surfaces, but can be noisy.

Warning: Never use to lift people.

Fork | O'all | Base Leg | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Cap., lbs. | Lg. | Wd. | Min. Ht. | Max. Ht. | Outside Spread | Inside Spread | Load Center | Lg. | Ht. | For Pallet Wd. | Handle Ht. | Inside Spread | Outside Spread | Wheel Configuration | Wheel Material | Each | |

Steel Body | |||||||||||||||||

Counterbalanced Base | |||||||||||||||||

| 1,000 | 25" | 3" | 1" | 5'4" | 6 1/2"-24 1/2" | 1/2"-18 1/2" | 13" | 5'1" | 6'11" | 26"-32" | 38" | 20 1/4" | 26 1/4" | Two Swivel Casters and Two Axle-Mounted Wheels | Phenolic Plastic | 0000000 | 000000000 |

| 1,000 | 25" | 3" | 1" | 6'4" | 6 1/2"-24 1/2" | 1/2"-18 1/2" | 13" | 5'1" | 7'8" | 26"-32" | 38" | 20 1/4" | 26 1/4" | Two Swivel Casters and Two Axle-Mounted Wheels | Phenolic Plastic | 0000000 | 00000000 |

Straddle Base | |||||||||||||||||

| 2,000 | 42" | 3" | 1 1/2" | 5'4" | 6"-29" | 0"-23" | 24" | 4'1" | 6'11" | 26"-40" | 51" | 42" | 48" | Two Swivel Casters and Two Axle-Mounted Wheels | Polyurethane Rubber | 0000000 | 00000000 |

Battery-Operated Lift Trucks with Platform

Platforms support material directly without an additional pallet. A hydraulic pump powered by a rechargeable battery raises and lowers loads with the push of a button. A charge indicator lets you know how much battery life is left. The push-button control has a self-retracting cord. Two swivel casters at the rear of the lift truck makes steering and pivoting easy. Once the truck is in place, engage the floor lock to lift and lower loads. They have nonmarking phenolic wheels that roll best on smooth surfaces.

Warning: Never use to lift people.

Platform | O'all | Base Leg | Wheel | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Cap., lbs. | Ht. | Lg. | Wd. | Load Center | Lg. | Ht. | For Pallet Wd. | Handle Ht. | Inside Spread | Outside Spread | Wheel Configuration | Dia. | Material | Type | Specifications Met | Each | |

Steel Body | |||||||||||||||||

| 2,000 | 6"-5'8" | 24" | 27" | 15" | 3'2" | 6'11" | 26"-40" | 52" | 20" | 26" | Two Swivel Casters and Two Axle-Mounted Wheels | 5" | Phenolic Plastic | Solid | ASME B56.10 | 0000000 | 000000000 |

Battery-Powered Pallet Trucks

|  |

|

Let these trucks do the lifting for you. A hydraulic pump raises and lowers loads at the touch of a button while a throttle controls forward and reverse speed. An automatic brake stops the truck when the handle is released. The truck also has a safety button that automatically reverses the direction of travel if the truck comes in contact with an obstacle. Operates for eight hours on a full charge when used intermittently. A discharge indicator lets you know when batteries need charging. The polyurethane wheels absorb shock to roll over rough floors and areas with debris.

Warning: Never use to lift people.

Fork | Wheel | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pallet Wd. | O'all Cap., lbs. | Lg. | Wd. | Outside Spread | Inside Spread | Min. Ht. | Max. Ht. | Steering Arc | O'all Lg. | Handle Ht. | Wheel Configuration | Dia. | Type | Power Source | Each | |

Yellow Steel Body | ||||||||||||||||

Polyurethane Rubber Wheels | ||||||||||||||||

| 28"-40" | 4,500 | 48" | 6 3/4" | 26 3/4" | 13" | 3 1/4" | 8" | 180° | 73 1/4" | 48" | Six Axle-Mounted Wheels | 10" (Steer) 3" (Load) | Tread on Core (Load) Tread on Core (Steer) | Battery | 0000000 | 000000000 |

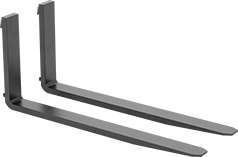

Forklift Forks

Replace worn or damaged forks, or switch to a different length. These forklift forks meet Industrial Truck Association (ITA) standards for mounting to Class II or Class III forklifts. Slide each fork onto your carriage and lock in place with a pin. Once installed, the pin keeps them from moving side to side. These forks have tapered tips, so they’re easy to guide into pallet slots.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

| Lg. | Wd. | Thick. | Capacity per Pair, lbs. | Material | Includes | Pair | |

Class II—16" Between Carriage Hooks | |||||||

|---|---|---|---|---|---|---|---|

| 42" | 4" | 1 1/2" | 4,000 | Steel | Carriage Locking Pin | 0000000 | 0000000 |

| 42" | 4" | 1 3/4" | 5,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 48" | 4" | 1 1/2" | 4,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 48" | 4" | 1 3/4" | 5,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 60" | 4" | 1 3/4" | 5,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

Class III—20" Between Carriage Hooks | |||||||

| 48" | 5" | 1 3/4" | 6,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 48" | 5" | 2" | 8,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 60" | 5" | 1 3/4" | 6,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 60" | 5" | 2" | 8,000 | Steel | Carriage Locking Pin | 0000000 | 000000 |

| 72" | 5" | 1 3/4" | 6,000 | Steel | Carriage Locking Pin | 0000000 | 00000000 |

| 72" | 5" | 2" | 8,000 | Steel | Carriage Locking Pin | 0000000 | 00000000 |

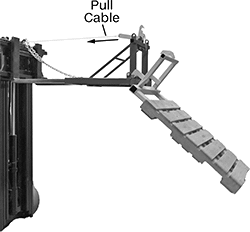

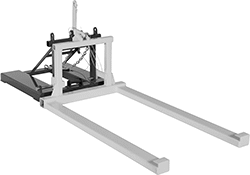

Fork-Mount Pallet Dumpers

Shift loads off pallets and into containers from the safety of your forklift. A long cable extends from the top of these dumpers to your seat—pull it to release a latch and tip the front of the dumper. A hook at the end of each arm keeps the pallet from sliding off. Once you’ve dumped the load, lower your forks to the ground to straighten the pallet and latch the dumper back together.

Note: Capacities are approximate and depend on the type and load capabilities of the forklift used. Check with the manufacturer of your forklift for load capabilities before using.

Warning: Never use to lift people or items over people.

Fork Pockets | For Max. Fork | Fork | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Usable Fork Lg. | Capacity, lbs. | No. of | Spacing Ctr.-to-Ctr. | For Min. Fork Lg. | Wd. | Ht. | Material | Color | Lg. | Wd. | Ht. | Forklift Attachment Type | Material | Color | Features | Each | |

| 52" | 2,000 | 2 | 20 1/2" | 32" | 7 1/2" | 2" | Powder-Coated Steel | Yellow | 91" | 32" | 32 1/2" | Hook and Chain | Powder-Coated Steel | Blue | Pull Cable | 0000000 | 0000000 |