About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

Programmable Base/Face-Mount Speed-Control Motors

These speed-control motors combine a variable-frequency drive and motor into one, saving space in your control panel and reducing the amount of wiring required. Bolt them directly to gearboxes, pumps, and other machinery, or use the welded base to mount them to a surface. You can program the drive to start, stop, change speed, and reverse direction based on inputs from a PLC or sensor. These motors are often used to start or stop a conveyor based on PLC commands or vary the speed of a fan to maintain a room’s temperature.

The shaft is keyed and comes with key stock. These motors are rated for continuous duty, so they'll run equipment that never turns off. All have automatic overload protection, which turns motors off if they become overheated and restarts them once they’ve cooled. A TEFC (totally enclosed fan cooled) motor enclosure protects these motors better than ODP (open dripproof) enclosures in damp and dusty environments. The external fan keeps the motor cool.

An IE5 efficiency rating means these motors and drives are rated for the highest efficiency available. From partial to full output, they'll use less electricity than motors with other ratings.

Program these motors in a number of ways. You can download the free manufacturer software to your computer and connect to the motor via Bluetooth, or you can use a PC Connection Cord (sold separately) to connect your motor directly to your computer's USB port. The software allows you to control or monitor the motor in real time. To integrate them into larger control systems, these motors can be programmed using Modbus-RTU and BACnet protocols. Use a keypad (sold separately) to start or stop motors or to increase or decrease speed in real time. Its digital display also shows real-time motor information and allows you to edit control parameters. The keypad can be mounted up to 10 ft. away into a panel with the included cord to create a control station.

For technical drawings and 3-D models, click on a part number.

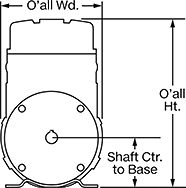

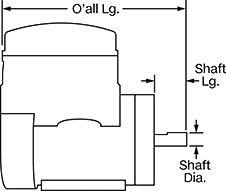

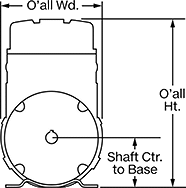

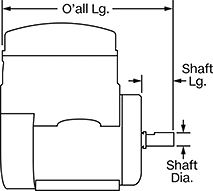

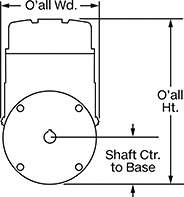

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Environmental Rating | Each | |

240 Volts AC, Single Phase | ||||||||||||||

NEMA 143TC | ||||||||||||||

| 1 | 3,450 | 2.4 | Totally Enclosed Fan Cooled (TEFC) | 13 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | IP54 | 0000000 | 000000000 |

NEMA 145TC | ||||||||||||||

| 2 | 3,450 | 4.4 | Totally Enclosed Fan Cooled (TEFC) | 13 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

240 Volts AC, Three Phase | ||||||||||||||

NEMA 143TC | ||||||||||||||

| 1 | 3,450 | 2.4 | Totally Enclosed Fan Cooled (TEFC) | 13 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

NEMA 145TC | ||||||||||||||

| 2 | 3,450 | 4.3 | Totally Enclosed Fan Cooled (TEFC) | 13 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

NEMA 182TC | ||||||||||||||

| 3 | 3,450 | 7.3 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 14" | 1 1/8" | 2 3/4" | 4 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

NEMA 184TC | ||||||||||||||

| 5 | 3,450 | 10.5 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 14" | 1 1/8" | 2 3/4" | 4 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

USB Connection | RJ45 Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| End Type | End Shape | Gender | End Type | End Shape | Gender | Serial Port Interface | Each | |

| Plug | Straight | Male | Plug | Straight | Male | RS-485 | 0000000 | 0000000 |

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage Range | Current, mA | Ht. | Wd. | Dp. | Serial Port Interface | Reversing Capability | Environmental Rating | Specifications Met | Each | |

| 10V DC-36V DC | 30 | 3.19" | 2.6" | 0.95" | RS-485 | Reversing | IP54 | CE Marked | 0000000 | 0000000 |

Programmable Base-Mount Speed-Control Motors

Save space in your control panel with a variable-frequency drive and motor in one unit. These motors require less wiring than motors that need to be attached to a separate drive. They have a base mount that’s welded to the enclosure, so you can secure them to a flat surface. Program the drive to start, stop, change speed, and reverse direction based on inputs from a PLC or sensor. These motors are often used to start or stop a conveyor based on PLC commands or vary the speed of a fan to maintain a room’s temperature.

The shaft is keyed and comes with key stock. Rated for continuous duty, these motors can run machines that require constant power. All have automatic overload protection, which turns motors off if they become overheated and restarts them once they’ve cooled. They also have totally enclosed fan cooled (TEFC) enclosures, which don’t have vents, so you can install them in damp and dirty environments. An external fan blows air over the outside of the enclosure to keep these motors cool.

An IE5 efficiency rating means these motors and drives are rated for the highest efficiency available. From partial to full output, they'll use less electricity than motors with other ratings.

Download free software to control and monitor them in real time. Connect them to your computer via Bluetooth or use a PC connection cord (sold separately) to plug them into a USB port. To integrate them into larger control systems, these motors can be programmed using Modbus-RTU and BACnet protocols. Use a keypad (sold separately) to start or stop motors or to increase or decrease speed in real time. To create a control station, mount the keypad into a panel up to 10 ft. away from the motor with the included cord.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Environmental Rating | Each | |

240 Volts AC, Single Phase | ||||||||||||||

NEMA 143T | ||||||||||||||

| 1 | 3,450 | 2.3 | Totally Enclosed Fan Cooled (TEFC) | 12 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/2" | 3 1/2" | F | 311° | IP54 | 0000000 | 000000000 |

NEMA 145T | ||||||||||||||

| 2 | 3,450 | 4.4 | Totally Enclosed Fan Cooled (TEFC) | 13 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/2" | 3 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

240 Volts AC, Three Phase | ||||||||||||||

NEMA 143T | ||||||||||||||

| 1 | 3,450 | 2.3 | Totally Enclosed Fan Cooled (TEFC) | 12 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/2" | 3 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

NEMA 145T | ||||||||||||||

| 2 | 3,450 | 4.3 | Totally Enclosed Fan Cooled (TEFC) | 13 3/8" | 7 1/4" | 11 7/8" | 7/8" | 2 1/2" | 3 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

NEMA 182T | ||||||||||||||

| 3 | 3,450 | 7.3 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 14" | 1 1/4" | 3 1/2" | 4 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

NEMA 184T | ||||||||||||||

| 5 | 3,450 | 10.5 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 14" | 1 1/4" | 3 1/2" | 4 1/2" | F | 311° | IP54 | 0000000 | 00000000 |

USB Connection | RJ45 Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| End Type | End Shape | Gender | End Type | End Shape | Gender | Serial Port Interface | Each | |

| Plug | Straight | Male | Plug | Straight | Male | RS-485 | 0000000 | 0000000 |

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage Range | Current, mA | Ht. | Wd. | Dp. | Serial Port Interface | Reversing Capability | Environmental Rating | Specifications Met | Each | |

| 10V DC-36V DC | 30 | 3.19" | 2.6" | 0.95" | RS-485 | Reversing | IP54 | CE Marked | 0000000 | 0000000 |

Programmable Face-Mount Speed-Control Motors

A variable-frequency drive and motor in one unit, these motors save space in your control panel and require less wiring than separate drives and motors. They bolt directly to gearboxes, pumps, and other machinery. You can program the drive to start, stop, change speed, and reverse direction based on inputs from a PLC or sensor. These motors are often used to start or stop a conveyor based on PLC commands or vary the speed of a fan to maintain a room’s temperature.

Rated for continuous duty, these motors can run machines that require constant power. They have totally enclosed fan cooled (TEFC) enclosures, which don’t have vents, so you can install them in damp and dirty environments. An external fan blows air over the outside of the enclosure to keep these motors cool. All have automatic overload protection, which turns motors off if they become overheated and restarts them once they’ve cooled.

An IE5 efficiency rating means these motors and drives are rated for the highest efficiency available. From partial to full output, they'll use less electricity than motors with other ratings.

Download free software to control and monitor them in real time. Connect them to your computer via Bluetooth or use a PC connection cord (sold separately) to plug them into a USB port. These motors also use Modbus-RTU and BACnet protocols, so you can integrate them into building and process control systems. You can also use a keypad (sold separately) to control these motors. It has a digital display that shows live motor information, such as output frequency and speed, and allows you to edit control parameters in real time. To create a control station, mount the keypad into a panel up to 10 ft. away from the motor with the included cord.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Environmental Rating | Each | |

240 Volts AC, Single Phase | ||||||||||||||

NEMA 143TC | ||||||||||||||

| 1 | 3,450 | 2.4 | Totally Enclosed Fan Cooled (TEFC) | 12 3/8" | 7 1/4" | 11 5/8" | 7/8" | 2 1/4" | 3.14" | F | 311° | IP54 | 00000000 | 000000000 |

NEMA 145TC | ||||||||||||||

| 2 | 3,450 | 4.4 | Totally Enclosed Fan Cooled (TEFC) | 13 5/8" | 7 1/4" | 11 5/8" | 7/8" | 2 1/4" | 3.14" | F | 311° | IP54 | 00000000 | 00000000 |

240 Volts AC, Three Phase | ||||||||||||||

NEMA 143TC | ||||||||||||||

| 1 | 3,450 | 2.4 | Totally Enclosed Fan Cooled (TEFC) | 12 3/8" | 7 1/4" | 11 5/8" | 7/8" | 2 1/4" | 3.14" | F | 311° | IP54 | 00000000 | 00000000 |

NEMA 145TC | ||||||||||||||

| 2 | 3,450 | 4.3 | Totally Enclosed Fan Cooled (TEFC) | 13 5/8" | 7 1/4" | 11 5/8" | 7/8" | 2 1/4" | 3.14" | F | 311° | IP54 | 00000000 | 00000000 |

NEMA 182TC | ||||||||||||||

| 3 | 3,450 | 7.3 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 13 3/4" | 1 1/8" | 2 3/4" | 4.37" | F | 311° | IP54 | 00000000 | 00000000 |

NEMA 184TC | ||||||||||||||

| 5 | 3,450 | 10.5 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 13 3/4" | 1 1/8" | 2 3/4" | 4.37" | F | 311° | IP54 | 00000000 | 00000000 |

USB Connection | RJ45 Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| End Type | End Shape | Gender | End Type | End Shape | Gender | Serial Port Interface | Each | |

| Plug | Straight | Male | Plug | Straight | Male | RS-485 | 0000000 | 0000000 |

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage Range | Current, mA | Ht. | Wd. | Dp. | Serial Port Interface | Reversing Capability | Environmental Rating | Specifications Met | Each | |

| 10V DC-36V DC | 30 | 3.19" | 2.6" | 0.95" | RS-485 | Reversing | IP54 | CE Marked | 0000000 | 0000000 |

Speed-Control AC Gearmotors

Start, stop, reverse direction, and control the speed of these gearmotors from the mounted keypad. Because you can fine tune output speed and direction, these gearmotors are often used in material processing and handling applications, such as controlling the speed of a mixer or conveyor. These gearmotors are both a motor and speed reducer in one to lower speed while increasing torque. All transmit motion inline with the motor. Secure them to flat surfaces with the base mount. These gearmotors have a TEFC (totally enclosed fan cooled) enclosure that protects better than ODP (open drip proof) enclosures. They are not airtight but can be used in dirty, dusty, and damp environments. To keep the motor cool, they have an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

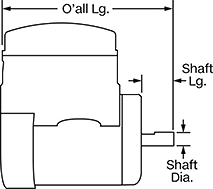

Overall | Shaft | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed Range @ Continuous Operating Torque | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Environmental Rating | Each | |

240 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.6 rpm to 9.9 rpm @ 3,190 in.-lbs. | 1.9 | 19 1/4" | 9 1/4" | 11 1/2" | 1 3/8" | 2 3/4" | 4 1/2" | IP54 | 0000000 | 000000000 |

| 1/2 | 5 rpm to 30 rpm @ 1,030 in.-lbs. | 1.9 | 17 1/4" | 8 1/2" | 10 1/2" | 1" | 2" | 3 1/2" | IP54 | 0000000 | 00000000 |

| 1/2 | 8.8 rpm to 53 rpm @ 585 in.-lbs. | 1.9 | 15 3/4" | 8" | 10 1/4" | 3/4" | 1 1/2" | 3" | IP54 | 0000000 | 00000000 |

| 1/2 | 24 rpm to 148 rpm @ 210 in.-lbs. | 1.9 | 15 3/4" | 8" | 10 1/4" | 3/4" | 1 1/2" | 3" | IP54 | 0000000 | 00000000 |

| 1/2 | 49 rpm to 295 rpm @ 106 in.-lbs. | 1.9 | 15 3/4" | 8" | 10 1/4" | 3/4" | 1 1/2" | 3" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,440 in.-lbs. | 3.5 | 22 1/2" | 9 3/4" | 12 1/2" | 1 5/8" | 3 1/8" | 5 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 4.9 rpm to 30 rpm @ 2,120 in.-lbs. | 3.5 | 20 1/4" | 8 3/4" | 11 1/2" | 1 1/4" | 2 3/8" | 4 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 8.6 rpm to 52 rpm @ 1,210 in.-lbs. | 3.5 | 19 1/4" | 8 1/2" | 10 3/4" | 1" | 2" | 3 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 24 rpm to 148 rpm @ 425 in.-lbs. | 3.5 | 17 3/4" | 8 1/4" | 10 1/2" | 3/4" | 1 1/2" | 3" | IP54 | 0000000 | 00000000 |

| 1 | 49 rpm to 295 rpm @ 210 in.-lbs. | 3.5 | 17 3/4" | 8 1/4" | 10 1/2" | 3/4" | 1 1/2" | 3" | IP54 | 0000000 | 00000000 |

Speed-Control Right-Angle AC Gearmotors

A good solution for tight spaces, these gearmotors let you control the start, stop, rotation direction, and speed while transmitting motion at a 90° angle from the motor, so you can mount them alongside your application. They combine a motor with a speed reducer to lower speed while increasing torque. All have a mounted keypad to make changes to the integrated speed control. Mount them to flat surfaces using their base. These gearmotors have a TEFC (totally enclosed fan cooled) enclosure that protects better than an ODP (open dripproof) enclosure. They aren’t airtight, but they can be used in dirty, dusty, and damp environments. To keep the motor cool, the enclosure has an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed Range @ Continuous Operating Torque | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Environmental Rating | Each | |

Left-Hand Output Shaft | |||||||||||

240 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.9 rpm to 12 rpm @ 2,660 in.-lbs. | 1.9 | 19" | 11 1/4" | 12" | 2 7/8" | 2 7/8" | 5.2" | IP54 | 0000000 | 000000000 |

| 1/2 | 4.8 rpm to 29 rpm @ 1,080 in.-lbs. | 1.9 | 17 1/4" | 9 1/2" | 11" | 1" | 2 1/8" | 3.94" | IP54 | 0000000 | 00000000 |

| 1/2 | 7.6 rpm to 46 rpm @ 680 in.-lbs. | 1.9 | 17 1/4" | 9 1/2" | 10 3/4" | 1" | 2 1/8" | 2.48" | IP54 | 0000000 | 00000000 |

| 1/2 | 24 rpm to 144 rpm @ 220 in.-lbs. | 1.9 | 16" | 9" | 10" | 3/4" | 1 5/8" | 1.97" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,750 in.-lbs. | 3.5 | 23 1/4" | 13 1/2" | 13 1/2" | 2" | 4 1/8" | 7.09" | IP54 | 0000000 | 00000000 |

| 1 | 4.8 rpm to 29 rpm @ 2,120 in.-lbs. | 3.5 | 20 1/2" | 11" | 11 3/4" | 1 3/8" | 2 7/8" | 4.41" | IP54 | 0000000 | 00000000 |

| 1 | 7.6 rpm to 46 rpm @ 1,350 in.-lbs. | 3.5 | 21" | 10 1/2" | 12 1/2" | 1 1/4" | 2 1/2" | 3.15" | IP54 | 0000000 | 00000000 |

| 1 | 24 rpm to 144 rpm @ 445 in.-lbs. | 3.5 | 18" | 9" | 10 1/2" | 3/4" | 1 5/8" | 1.97" | IP54 | 0000000 | 00000000 |

Right-Hand Output Shaft | |||||||||||

240 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.9 rpm to 12 rpm @ 2,660 in.-lbs. | 1.9 | 19" | 12" | 12" | 1 3/8" | 2 7/8" | 5.2" | IP54 | 0000000 | 00000000 |

| 1/2 | 4.8 rpm to 29 rpm @ 1,080 in.-lbs. | 1.9 | 17 1/4" | 8 1/2" | 11" | 1" | 2 1/8" | 3.94" | IP54 | 0000000 | 00000000 |

| 1/2 | 7.6 rpm to 46 rpm @ 680 in.-lbs. | 1.9 | 17 1/4" | 8 1/2" | 10 3/4" | 1" | 2 1/8" | 2.48" | IP54 | 0000000 | 00000000 |

| 1/2 | 24 rpm to 144 rpm @ 220 in.-lbs. | 1.9 | 16" | 8 1/2" | 10" | 3/4" | 1 5/8" | 1.97" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,750 in.-lbs. | 3.5 | 23 1/4" | 12" | 13 1/2" | 2" | 4 1/8" | 7.09" | IP54 | 0000000 | 00000000 |

| 1 | 4.8 rpm to 29 rpm @ 2,120 in.-lbs. | 3.5 | 20 1/2" | 9" | 11 3/4" | 1 3/8" | 2 7/8" | 4.41" | IP54 | 0000000 | 00000000 |

| 1 | 7.6 rpm to 46 rpm @ 1,350 in.-lbs. | 3.5 | 21" | 8 1/2" | 12 1/2" | 1 1/4" | 2 1/2" | 3.15" | IP54 | 0000000 | 00000000 |

| 1 | 24 rpm to 144 rpm @ 445 in.-lbs. | 3.5 | 18" | 8 1/2" | 10 1/2" | 3/4" | 1 5/8" | 1.97" | IP54 | 0000000 | 00000000 |

Direct-Drive Fan Motors

Since they have fewer moving parts, you can use these direct-drive motors to build fans that require less maintenance than fans with belt-drive motors. Mount them directly to a fan column.

For technical drawings and 3-D models, click on a part number.

Shaft | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Speed, rpm | Power, hp | Dia. | Lg. | Direction of Operation | Current, A | Voltage | Lg. | Wd. | Ht. | Insulation Class | Overload Protection Type | Each | |

NEMA 48Z—Welded (D-Profile Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 1,100 | 1/4 | 1/2" | 3 1/4" | Clockwise or Counterclockwise | 4.0 2.0 | 120V AC 240V AC | 9 3/4" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 0000000 |

| 1,100 | 1/3 | 1/2" | 3 1/4" | Clockwise or Counterclockwise | 4.5 2.3 | 120V AC 240V AC | 10" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,100 | 1/2 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 6.5 3.3 | 120V AC 240V AC | 11" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,700 | 1/4 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 3.4 1.7 | 120V AC 240V AC | 10 1/8" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,725 | 1/3 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 3.6 1.8 | 120V AC 240V AC | 10 1/8" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

NEMA F48Z—Welded (D-Profile Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 825 | 1/2 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 7.1 3.6 | 120V AC 240V AC | 11" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

| 1,700 | 1/2 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 5.5 2.8 | 120V AC 240V AC | 11" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

NEMA K56Z—Welded (Keyed Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 850 | 1/2 | 5/8" | 2 5/8" | Clockwise or Counterclockwise | 6.6 3.3 | 120V AC 240V AC | 12" | 6 1/2" | 8 3/4" | B | Thermal | 0000000 | 000000 |

NEMA P56CZ—Welded (Keyed Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 850 | 1 | 5/8" | 3 1/4" | Counterclockwise | 5.1 | 240V AC | 14 1/4" | 6 1/2" | 8 3/4" | B | Thermal | 0000000 | 000000 |