About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

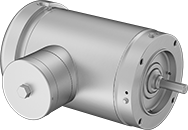

US-Made Base-Mount AC Motors

Wound, wired, and assembled in the U.S. These base-mount motors are manufactured for durability and include high-quality bearings, so they hold up to occasional overload conditions and spikes in torque. Rated for continuous duty, they’re often used with equipment that requires constant power, such as fans, pumps, and conveyors. Bolt the base of these motors to any flat surface and connect the shaft to your load.

When pairing with a variable frequency drive (AC motor speed control), choose a three-phase motor that’s inverter rated.

Enclosures that are open have vents that let air flow over the motor, which keeps it cool and helps it run efficiently. Use them in clean, dry environments—the enclosure blocks drips and debris that fall from above, but dust and moisture can pass through the vents. Open drip proof (ODP) and open slotted band (OPSB) enclosures only have vents.Enclosures that are totally enclosed don’t have vents, so they can be used in damp and dirty environments. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure. Totally enclosed fan cooled (TEFC) enclosures have an external fan that blows air over the outside of the enclosure to keep the motor cool. Motors with overload protection turn off in overload conditions to prevent motor damage. Automatic overload protection starts the motor automatically after it cools.

Optional drip covers are recommended when your motor will be mounted with the shaft facing down. They attach to the back side of the motor to prevent moisture from pooling on top.

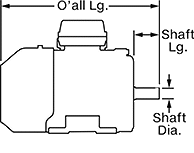

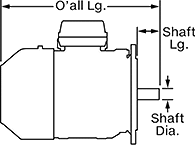

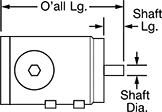

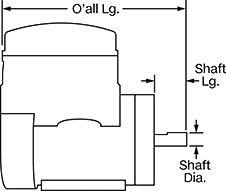

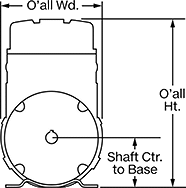

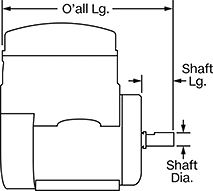

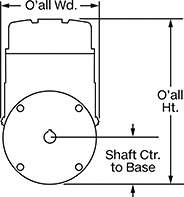

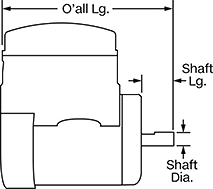

For technical drawings and 3-D models, click on a part number.

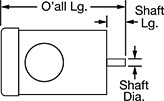

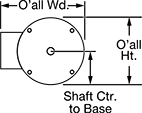

Motors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

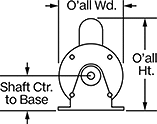

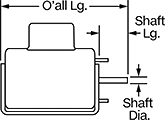

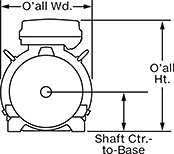

Overall | Shaft | Drip Covers | ||||||||||||||

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Overload Protection Type | Insulation Max. Temp., °F | Each | Each | ||

230 Volts AC, Single Phase | ||||||||||||||||

NEMA 184T—Welded Base | ||||||||||||||||

| 3 | 1,750 | 11.2 | No | Open Slotted Band (OPSB) | 16 1/2" | 11 1/4" | 11 1/4" | 1 1/8" | 2 3/4" | 4 1/2" | __ | 311° | 00000000 | 000000000 | 00000000 | 0000000 |

230/460 Volts AC, Three Phase | ||||||||||||||||

NEMA 145T—Welded Base | ||||||||||||||||

| 3 | 3,450 | 7.6/3.8 | Yes | Open Slotted Band (OPSB) | 13" | 9" | 7" | 7/8" | 2 1/4" | 3 1/2" | __ | 311° | 00000000 | 000000 | 00000000 | 000000 |

NEMA 182T—Welded Base | ||||||||||||||||

| 3 | 1,760 | 8.4/4.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 11 1/4" | 11" | 1 1/8" | 2 3/4" | 4 1/2" | __ | 311° | 00000000 | 00000000 | 00000000 | 000000 |

| 3 | 1,760 | 8.8/4.4 | Yes | Open Slotted Band (OPSB) | 15" | 11 1/4" | 8 1/2" | 1 1/8" | 2 3/4" | 4 1/2" | Automatic | 311° | 00000000 | 00000000 | 00000000 | 000000 |

Base-Mount AC Motors

To get equipment moving, bolt the base of these motors to any flat surface and connect the shaft to your load. They’re rated for continuous duty, so they’re often used with equipment that requires constant power, like fans, pumps, and conveyors.

When pairing with a variable frequency drive (AC motor speed control), choose a three-phase motor that’s inverter rated.

Motors with a NEMA frame size have an oversized shaft and high-quality bearings to stand up to heavy and side loads better than even our domestic motors. Densely packed windings and thin laminations ensure the motor stays cool and runs efficiently.

Motors with an IEC frame size meet international standards for electrical products. Their compact body fits in tight spaces.

Totally enclosed fan cooled (TEFC) enclosures don’t have vents, so they can be used in damp and dirty environments. They have an external fan that blows air over the outside of the enclosure to keep the motor cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

Open drip proof (ODP) enclosures have vents that let air flow over the motor, which keeps it cool and helps it run efficiently. Use them in clean, dry environments—the enclosure blocks drips and debris that fall from above, but dust and moisture can pass through the vents.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||

NEMA 143T/NEMA 145T | |||||||||||||||

| 3 | 3,505 | 7.6/3.8 | Yes | Open Dripproof (ODP) | 12 1/4" | 9 1/2" | 6 3/4" | 7/8" | 2 1/4" | 3 1/2" | F | 311° | __ | 0000000 | 0000000 |

NEMA 182T | |||||||||||||||

| 3 | 1,755 | 8.4/4.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 16 1/2" | 11 1/2" | 10 3/8" | 1 1/8" | 2 3/4" | 4 1/2" | F | 311° | __ | 0000000 | 000000 |

| 3 | 1,755 | 8.6/4.3 | Yes | Open Dripproof (ODP) | 14 3/8" | 11 1/4" | 10 3/8" | 1 1/8" | 2 3/4" | 4 1/2" | F | 311° | __ | 0000000 | 000000 |

| 3 | 3,490 | 7.0/3.5 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 3/4" | 12 1/8" | 10 1/2" | 1 1/8" | 2 3/4" | 4 1/2" | F | 311° | __ | 0000000 | 000000 |

NEMA 213T | |||||||||||||||

| 3 | 1,175 | 8.0/4.0 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 1/8" | 14 1/4" | 12 1/4" | 1 3/8" | 3 3/8" | 5 1/4" | F | 311° | __ | 0000000 | 00000000 |

IEC 100L | |||||||||||||||

| 3 | 4,000 | 7.8/3.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 9" | 11 1/8" | 28mm | 60mm | 100mm | F | 311° | IP55 | 0000000 | 000000 |

IEC 112M | |||||||||||||||

| 3 | 4,000 | 8.8/4.4 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 10" | 12" | 28mm | 60mm | 112mm | F | 311° | IP55 | 0000000 | 00000000 |

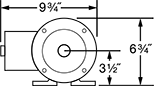

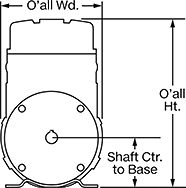

Face-Mount AC Motors

Bolt these motors directly to gearboxes, pumps, and other machinery. They’re more compact than base-mount motors and the direct, rigid connection to your equipment helps keep them aligned. Rated for continuous duty, they are often used with equipment that requires constant power, such as fans and conveyors. These motors are inverter-rated, so you can use them with a variable frequency drive (AC motor speed control).

A totally enclosed fan cooled (TEFC) enclosure means you can use them in damp and dirty environments since they don’t have vents. They have an external fan that blows air over the outside of the enclosure to keep the motor cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

Motors with an IEC frame size meet international standards for electrical products. Their compact body fits in tight spaces.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Mounting Flange Type | Dia. | Lg. | Center to Base | Insulation Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||

IEC 100L | |||||||||||||||

| 3 | 1,770 | 7.8/3.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 5/8" | 9 3/4" | 11 5/8" | B5 | 28mm | 60mm | 100mm | 311° | IP55 | 00000000 | 000000000 |

Sanitary Washdown Base/Face-Mount AC Motors

For versatility in food and sanitary lines, these motors mount by their feet or bolt directly to equipment to power pumps and other machines. Many features make them safe for sanitary and washdown environments: Smooth contours and a laser-marked nameplate limit where bacteria could grow. A stainless steel enclosure, epoxy resin lined interior, and IP69 rating mean they stand up to hot spraying water, chemicals, and harsh cleaners often used in food plants. A two-barrier seal on the shaft stops water from getting in. If water does seep in, drain plugs let it out.

Rated for continuous duty, these motors run equipment that never turns off. They’re also inverter rated, so they work with variable frequency drive (VFD) to run at different speeds. You can wire for clockwise or counterclockwise rotation; instructions are included. The conduit box also rotates, so there’s no need to reroute power when connecting conduit.

TEFC (totally enclosed fan cooled) motors have a fan that cools the housing.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | Torque @ 460V AC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Shaft Type | Class | Max. Temp., °F | Starting Torque, in.-lbs. | Continuous Operating Torque, in.-lbs. | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||||

NEMA 145TC—Totally Enclosed Fan Cooled (TEFC) | |||||||||||||||||

| 3 | 3,600 | 7.4/3.7 | Yes | 16 1/4" | 9 3/4" | 6 3/4" | 7/8" | 2 1/8" | 3 1/2" | Keyed | H | 356° | 204 | 54 | IP69 | 0000000 | 000000000 |

Sanitary Washdown Face-Mount AC Motors

Bolt these motors directly to conveyors and other machines to power equipment on food and sanitary lines. They help you meet Good Manufacturing Practices (GMP) since they have many features that make them safe for sanitary and washdown environments. Smooth contours and a laser-marked nameplate limit the space where bacteria could grow. They don’t have feet, so they’re easy to rinse down thoroughly. A stainless steel enclosure, epoxy resin lined interior, and IP69 rating mean they withstand hot spraying water, harsh cleaners, and sanitizers common to food plants. A two-barrier seal keeps water from getting in through the shaft. If water does seep in, drain plugs let it out.

These motors are also called C-face motors. They’re rated for continuous duty, so they’ll run equipment that never turns off. Inverter rated, they also work with variable frequency drive (VFD) to run at different speeds. You can wire for clockwise or counterclockwise rotation; instructions are included. Their conduit box also rotates to connect conduit from any side without needing to reroute power.

TEFC (totally enclosed fan cooled) motors have a fan that cools the housing.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | Torque @ 460V AC | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Shaft Type | Class | Max. Temp., °F | Starting Torque, in.-lbs. | Continuous Operating Torque, in.-lbs. | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||||

NEMA 145TC—Totally Enclosed Fan Cooled (TEFC) with Rotatable Conduit Box | |||||||||||||||||

| 3 | 3,600 | 7.4/3.7 | Yes | 16 1/4" | 9 7/8" | 6 1/2" | 7/8" | 2 1/8" | 3 1/4" | Keyed | H | 356° | 204 | 54 | IP69 | 0000000 | 000000000 |

Programmable Base/Face-Mount Speed-Control Motors

These speed-control motors combine a variable-frequency drive and motor into one, saving space in your control panel and reducing the amount of wiring required. Bolt them directly to gearboxes, pumps, and other machinery, or use the welded base to mount them to a surface. You can program the drive to start, stop, change speed, and reverse direction based on inputs from a PLC or sensor. These motors are often used to start or stop a conveyor based on PLC commands or vary the speed of a fan to maintain a room’s temperature.

The shaft is keyed and comes with key stock. These motors are rated for continuous duty, so they'll run equipment that never turns off. All have automatic overload protection, which turns motors off if they become overheated and restarts them once they’ve cooled. A TEFC (totally enclosed fan cooled) motor enclosure protects these motors better than ODP (open dripproof) enclosures in damp and dusty environments. The external fan keeps the motor cool.

An IE5 efficiency rating means these motors and drives are rated for the highest efficiency available. From partial to full output, they'll use less electricity than motors with other ratings.

Program these motors in a number of ways. You can download the free manufacturer software to your computer and connect to the motor via Bluetooth, or you can use a PC Connection Cord (sold separately) to connect your motor directly to your computer's USB port. The software allows you to control or monitor the motor in real time. To integrate them into larger control systems, these motors can be programmed using Modbus-RTU and BACnet protocols. Use a keypad (sold separately) to start or stop motors or to increase or decrease speed in real time. Its digital display also shows real-time motor information and allows you to edit control parameters. The keypad can be mounted up to 10 ft. away into a panel with the included cord to create a control station.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Environmental Rating | Each | |

240 Volts AC, Three Phase | ||||||||||||||

NEMA 182TC | ||||||||||||||

| 3 | 3,450 | 7.3 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 14" | 1 1/8" | 2 3/4" | 4 1/2" | F | 311° | IP54 | 0000000 | 000000000 |

USB Connection | RJ45 Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| End Type | End Shape | Gender | End Type | End Shape | Gender | Serial Port Interface | Each | |

| Plug | Straight | Male | Plug | Straight | Male | RS-485 | 0000000 | 0000000 |

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage Range | Current, mA | Ht. | Wd. | Dp. | Serial Port Interface | Reversing Capability | Environmental Rating | Specifications Met | Each | |

| 10V DC-36V DC | 30 | 3.19" | 2.6" | 0.95" | RS-485 | Reversing | IP54 | CE Marked | 0000000 | 0000000 |

Programmable Base-Mount Speed-Control Motors

Save space in your control panel with a variable-frequency drive and motor in one unit. These motors require less wiring than motors that need to be attached to a separate drive. They have a base mount that’s welded to the enclosure, so you can secure them to a flat surface. Program the drive to start, stop, change speed, and reverse direction based on inputs from a PLC or sensor. These motors are often used to start or stop a conveyor based on PLC commands or vary the speed of a fan to maintain a room’s temperature.

The shaft is keyed and comes with key stock. Rated for continuous duty, these motors can run machines that require constant power. All have automatic overload protection, which turns motors off if they become overheated and restarts them once they’ve cooled. They also have totally enclosed fan cooled (TEFC) enclosures, which don’t have vents, so you can install them in damp and dirty environments. An external fan blows air over the outside of the enclosure to keep these motors cool.

An IE5 efficiency rating means these motors and drives are rated for the highest efficiency available. From partial to full output, they'll use less electricity than motors with other ratings.

Download free software to control and monitor them in real time. Connect them to your computer via Bluetooth or use a PC connection cord (sold separately) to plug them into a USB port. To integrate them into larger control systems, these motors can be programmed using Modbus-RTU and BACnet protocols. Use a keypad (sold separately) to start or stop motors or to increase or decrease speed in real time. To create a control station, mount the keypad into a panel up to 10 ft. away from the motor with the included cord.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Environmental Rating | Each | |

240 Volts AC, Three Phase | ||||||||||||||

NEMA 182T | ||||||||||||||

| 3 | 3,450 | 7.3 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 14" | 1 1/4" | 3 1/2" | 4 1/2" | F | 311° | IP54 | 0000000 | 000000000 |

USB Connection | RJ45 Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| End Type | End Shape | Gender | End Type | End Shape | Gender | Serial Port Interface | Each | |

| Plug | Straight | Male | Plug | Straight | Male | RS-485 | 0000000 | 0000000 |

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage Range | Current, mA | Ht. | Wd. | Dp. | Serial Port Interface | Reversing Capability | Environmental Rating | Specifications Met | Each | |

| 10V DC-36V DC | 30 | 3.19" | 2.6" | 0.95" | RS-485 | Reversing | IP54 | CE Marked | 0000000 | 0000000 |

Programmable Face-Mount Speed-Control Motors

A variable-frequency drive and motor in one unit, these motors save space in your control panel and require less wiring than separate drives and motors. They bolt directly to gearboxes, pumps, and other machinery. You can program the drive to start, stop, change speed, and reverse direction based on inputs from a PLC or sensor. These motors are often used to start or stop a conveyor based on PLC commands or vary the speed of a fan to maintain a room’s temperature.

Rated for continuous duty, these motors can run machines that require constant power. They have totally enclosed fan cooled (TEFC) enclosures, which don’t have vents, so you can install them in damp and dirty environments. An external fan blows air over the outside of the enclosure to keep these motors cool. All have automatic overload protection, which turns motors off if they become overheated and restarts them once they’ve cooled.

An IE5 efficiency rating means these motors and drives are rated for the highest efficiency available. From partial to full output, they'll use less electricity than motors with other ratings.

Download free software to control and monitor them in real time. Connect them to your computer via Bluetooth or use a PC connection cord (sold separately) to plug them into a USB port. These motors also use Modbus-RTU and BACnet protocols, so you can integrate them into building and process control systems. You can also use a keypad (sold separately) to control these motors. It has a digital display that shows live motor information, such as output frequency and speed, and allows you to edit control parameters in real time. To create a control station, mount the keypad into a panel up to 10 ft. away from the motor with the included cord.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Environmental Rating | Each | |

240 Volts AC, Three Phase | ||||||||||||||

NEMA 182TC | ||||||||||||||

| 3 | 3,450 | 7.3 | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 10 5/8" | 13 3/4" | 1 1/8" | 2 3/4" | 4.37" | F | 311° | IP54 | 00000000 | 000000000 |

USB Connection | RJ45 Connection | |||||||

|---|---|---|---|---|---|---|---|---|

| End Type | End Shape | Gender | End Type | End Shape | Gender | Serial Port Interface | Each | |

| Plug | Straight | Male | Plug | Straight | Male | RS-485 | 0000000 | 0000000 |

Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage Range | Current, mA | Ht. | Wd. | Dp. | Serial Port Interface | Reversing Capability | Environmental Rating | Specifications Met | Each | |

| 10V DC-36V DC | 30 | 3.19" | 2.6" | 0.95" | RS-485 | Reversing | IP54 | CE Marked | 0000000 | 0000000 |