About Hazardous Location Environmental Ratings

More

About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

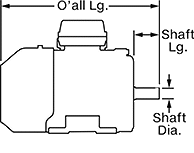

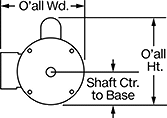

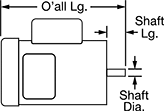

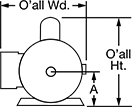

US-Made Base-Mount AC Motors

Wound, wired, and assembled in the U.S. These base-mount motors are manufactured for durability and include high-quality bearings, so they hold up to occasional overload conditions and spikes in torque. Rated for continuous duty, they’re often used with equipment that requires constant power, such as fans, pumps, and conveyors. Bolt the base of these motors to any flat surface and connect the shaft to your load.

When pairing with a variable frequency drive (AC motor speed control), choose a three-phase motor that’s inverter rated.

Motors with a vibration-damping base have rubber rings between the base and enclosure to minimize vibration.

Enclosures that are open have vents that let air flow over the motor, which keeps it cool and helps it run efficiently. Use them in clean, dry environments—the enclosure blocks drips and debris that fall from above, but dust and moisture can pass through the vents. Open drip proof (ODP) and open slotted band (OPSB) enclosures only have vents.Enclosures that are totally enclosed don’t have vents, so they can be used in damp and dirty environments. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure. Totally enclosed air-over (TEAO) enclosures don’t have their own fan. They need to be mounted in the airflow of an external fan or blower to keep the motor cool, so they’re often found in HVAC systems. Totally enclosed non-ventilated (TENV) enclosures are designed for use without a fan. They’re more compact than TEFC enclosures, and unlike TEAO enclosures, they can be installed in areas without airflow. However, motors with TENV enclosures are the least efficient because there is no active cooling.

Motors with overload protection turn off in overload conditions to prevent motor damage. Automatic overload protection starts the motor automatically after it cools.

Optional drip covers are recommended when your motor will be mounted with the shaft facing down. They attach to the back side of the motor to prevent moisture from pooling on top.

For technical drawings and 3-D models, click on a part number.

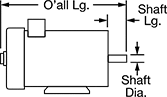

Motors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

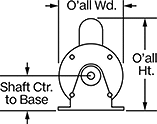

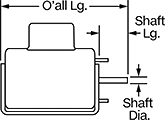

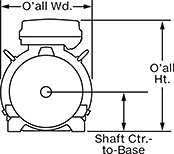

Overall | Shaft | Drip Covers | ||||||||||||||

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Overload Protection Type | Insulation Max. Temp., °F | Each | Each | ||

115/230 Volts AC, Single Phase | ||||||||||||||||

NEMA 48—Welded Base | ||||||||||||||||

| 1/4 | 1,725 | 2.6/1.3 | No | Open Dripproof (ODP) | 10" | 8" | 8 1/4" | 1/2" | 1 1/2" | 3" | __ | 311° | 00000000 | 0000000 | 00000000 | 0000000 |

NEMA 48Z—Vibration-Damping Base | ||||||||||||||||

| 1/4 | 1,700 | 4.8/2.4 | No | Totally Enclosed Air Over (TEAO) | 11 1/2" | 6 3/4" | 8 1/4" | 1/2" | 2 1/2" | 3" | Automatic | 266° | 00000000 | 000000 | 000000 | 00 |

230/460 Volts AC, Three Phase | ||||||||||||||||

NEMA 56—Welded Base | ||||||||||||||||

| 1/4 | 1,750 | 1.6/0.8 | Yes | Totally Enclosed Nonventilated (TENV) | 11 1/4" | 9 1/4" | 7" | 5/8" | 1 7/8" | 3 1/2" | __ | 311° | 00000000 | 000000 | 000000 | 00 |

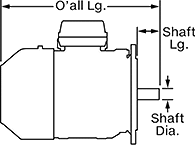

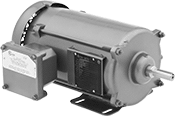

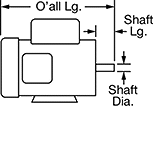

Base-Mount AC Motors

To get equipment moving, bolt the base of these motors to any flat surface and connect the shaft to your load. They’re rated for continuous duty, so they’re often used with equipment that requires constant power, like fans, pumps, and conveyors.

When pairing with a variable frequency drive (AC motor speed control), choose a three-phase motor that’s inverter rated.

Motors with a NEMA frame size have an oversized shaft and high-quality bearings to stand up to heavy and side loads better than even our domestic motors. Densely packed windings and thin laminations ensure the motor stays cool and runs efficiently.

Totally enclosed fan cooled (TEFC) enclosures don’t have vents, so they can be used in damp and dirty environments. They have an external fan that blows air over the outside of the enclosure to keep the motor cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

Open drip proof (ODP) enclosures have vents that let air flow over the motor, which keeps it cool and helps it run efficiently. Use them in clean, dry environments—the enclosure blocks drips and debris that fall from above, but dust and moisture can pass through the vents.

Motors with automatic overload protection turn off in overload conditions to prevent damage. Once they cool down, they start again automatically.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Overload Protection Type | Class | Max. Temp., °F | Each | |

115/230 Volts AC, Single Phase | |||||||||||||||

NEMA 56 | |||||||||||||||

| 1/4 | 1,735 | 2.7/1.4 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/4" | 8" | 7 7/8" | 5/8" | 1 7/8" | 3 1/2" | Automatic | F | 311° | 00000000 | 0000000 |

| 1/4 | 1,740 | 2.8/1.4 | No | Open Dripproof (ODP) | 11 1/8" | 8" | 7 7/8" | 5/8" | 1 7/8" | 3 1/2" | Automatic | F | 311° | 00000000 | 000000 |

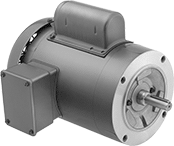

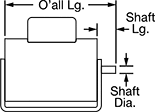

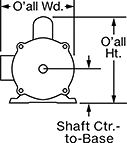

US-Made Face-Mount AC Motors

Wound, wired, and assembled in the U.S. These motors are manufactured for durability and include high-quality bearings, so they hold up to occasional overload conditions and spikes in torque. They bolt directly to gearboxes, pumps, and other machinery. These motors are more compact than base-mount motors and the direct, rigid connection to your equipment keeps them aligned. Rated for continuous duty, they’re often used with equipment that requires constant power, like fans, pumps, and conveyors.

When pairing with a variable frequency drive (AC motor speed control), choose a three-phase motor that’s inverter rated.

Enclosures that are open have vents that let air flow over the motor, which keeps it cool and helps it run efficiently. Use them in clean, dry environments—the enclosure blocks drips and debris that fall from above, but dust and moisture can pass through the vents. Open drip proof (ODP) enclosures have vents. Enclosures that are totally enclosed don’t have vents, so they can be used in damp and dirty environments. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure. Totally enclosed fan cooled (TEFC) enclosures have an external fan that blows air over the outside of the enclosure to keep the motor cool. Optional drip covers are recommended when your motor will be mounted with the shaft facing down. They attach to the back side of the motor to prevent moisture from pooling on top.

For technical drawings and 3-D models, click on a part number.

Motors | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Drip Covers | |||||||||||||

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Insulation Max. Temp., °F | Each | Each | ||

115/230 Volts AC, Single Phase | |||||||||||||||

NEMA 56C | |||||||||||||||

| 1/4 | 1,725 | 2.6/1.3 | No | Open Dripproof (ODP) | 12" | 8 1/4" | 8 1/4" | 5/8" | 1 7/8" | 3" | 266° | 00000000 | 0000000 | 00000000 | 0000000 |

| 1/4 | 1,725 | 5.0/2.5 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 8 1/2" | 7 1/2" | 5/8" | 1 7/8" | 3" | 266° | 00000000 | 000000 | 00000000 | 000000 |

230/460 Volts AC, Three Phase | |||||||||||||||

NEMA 56C | |||||||||||||||

| 1/4 | 1,735 | 1.2/0.6 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 8 1/2" | 6" | 5/8" | 1 7/8" | 3" | 266° | 00000000 | 000000 | 00000000 | 000000 |

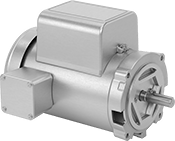

Face-Mount AC Motors

Bolt these motors directly to gearboxes, pumps, and other machinery. They’re more compact than base-mount motors and the direct, rigid connection to your equipment helps keep them aligned. Rated for continuous duty, they are often used with equipment that requires constant power, such as fans and conveyors. These motors are inverter-rated, so you can use them with a variable frequency drive (AC motor speed control).

A totally enclosed fan cooled (TEFC) enclosure means you can use them in damp and dirty environments since they don’t have vents. They have an external fan that blows air over the outside of the enclosure to keep the motor cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

Motors with a NEMA frame size have an oversized shaft and high-quality bearings to stand up to heavy and side loads better than even our domestic motors. Densely packed windings and thin laminations ensure the motor stays cool and runs efficiently.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Insulation Max. Temp., °F | Each | |

230/460 Volts AC, Three Phase | |||||||||||||

NEMA 56C | |||||||||||||

| 1/4 | 1,735 | 0.9/0.4 | Yes | Totally Enclosed Fan Cooled (TEFC) | 10 5/8" | 9 1/8" | 6 5/8" | 5/8" | 1 7/8" | 3 5/16" | 311° | 0000000 | 0000000 |

Hazardous Location Base-Mount AC Motors

These motors are rated for environments where hazardous material is present. They are continuous duty and mount horizontally. You can wire for clockwise or counterclockwise rotation; instructions are included. The base is welded to the enclosure.

Motors with automatic overload protection turn off in overload conditions to prevent motor damage and start automatically after they cool.

Hazardous location environmental ratings indicate whether manufacturers have included safety features in products to facilitate their safe use in a hazardous environment. Before selecting a product for a hazardous location, ensure it is rated for your environment.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Lg. | Wd. | Ht. | Dia | Lg. | Center to Base | Shaft Type | Overload Protection Type | Class | Max. Temp, °F | Environmental Rating | Each | |

115/208/230 Volts AC, Single Phase | ||||||||||||||||

NEMA 48 | ||||||||||||||||

| 1/4 | 1,800 | 5.0/2.6/2.5 | No | 12 7/8" | 7 1/4" | 8 1/8" | 1/2" | 1 1/2" | 3" | D-Profile | Automatic | B | 104° | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | 0000000 | 0000000 |

Base/Face-Mount AC Motors

Whether you’re switching between jobs or need flexibility during installation, these motors give you a variety of mounting options. Fix the feet to a flat surface or bolt the face directly to a gearbox, pump, or other machinery. You can also do both at once for added stability in applications with high loads or vibration. These motors are rated for continuous duty, so they’re often used for equipment that requires constant power, such as fans, pumps, and conveyors. They’re also inverter-rated, so you can use them with a variable frequency drive (AC motor speed control).

A totally enclosed fan cooled (TEFC) enclosure means you can install them in damp and dirty environments since they don’t have vents. An external fan blows air over the outside of the enclosure to keep these motors cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

These motors have an oversized shaft and high-quality bearings to stand up to heavy and side loads better than even our domestic motors. Densely packed windings and thin laminations ensure the motor stays cool and runs efficiently.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Each | |

230/460 Volts AC, Three Phase | ||||||||||||||

NEMA 56C | ||||||||||||||

| 1/4 | 1,735 | 0.9/0.4 | Yes | Totally Enclosed Fan Cooled (TEFC) | 13 7/8" | 9 5/8" | 7 1/8" | 5/8" | 1 7/8" | 3 1/2" | F | 311° | 00000000 | 0000000 |

Base/Face-Mount DC Motors

With two location options for any-angle mounting, you can put these motors to work in a variety of equipment configurations. Motors are rated for continuous duty and have a keyed shaft that comes with key stock. Wire for clockwise or counterclockwise rotation; instructions are included.

Use a motor speed control (not included) to adjust motor speed. Use an AC to DC transformer (not included) to convert AC power to DC power.

For technical drawings and 3-D models, click on a part number.

Motors | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | Replacement Motor Brushes | ||||||||||||||

| Power, hp | Speed @ Continuous Operating Torque | Max. Speed, rpm | Starting Torque, in.-lbs. | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Base Type | Class | Max. Temp., ° F | Each | Pkg. | ||

90V DC | |||||||||||||||||

NEMA 56C—Totally Enclosed Nonventilated (TENV) | |||||||||||||||||

| 1/4 | 1,750 rpm @ 9 in.-lbs. | 1,863 | 89.33 | 2.5 | 12 1/4" | 6 1/2" | 8 3/4" | 5/8" | 1 7/8" | 3 1/2" | Removable | F | 311° | 0000000 | 0000000 | 00000000 | 000000 |

180V DC | |||||||||||||||||

NEMA 56C—Totally Enclosed Nonventilated (TENV) | |||||||||||||||||

| 1/4 | 1,750 rpm @ 9 in.-lbs. | 1,830 | 103.3 | 1.3 | 12 1/4" | 6 1/2" | 8 3/4" | 5/8" | 1 7/8" | 3 1/2" | Removable | F | 311° | 0000000 | 000000 | 00000000 | 00000 |

AC Gearmotors

Turn speed into torque with these AC-powered gearmotors—they combine a motor and a speed reducer into one. You can wire them for clockwise or counterclockwise rotation; instructions are included. The parallel shaft transmits motion inline with the motor.

Base-mount motors come with a base, so they can be secured to a flat surface. Base/face-mount motors give you the flexibility to mount directly onto equipment or to the included base.

TEFC (totally enclosed fan cooled) motors have an enclosure to protect them from dirt, dust, and moisture. An external fan blows air on the enclosure to keep them cool. 230/460V AC motors are inverter-rated, so you can adjust the speed with a motor speed control (not included).

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed @ Continuous Operating Torque | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Gear Type | Bearing Type | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

115/230 Volts AC, Single Phase | |||||||||||||||||

| 1/4 | 12 rpm @ 1,030 in.-lbs. | 5.4/2.7 | No | Totally Enclosed Fan Cooled (TEFC) | 13 1/2" | 8 1/4" | 7 3/4" | Helical and Spur | Ball | 3/4" | 1 1/2" | 3" | B | 266° | IP43 | 0000000 | 000000000 |

| 1/4 | 26 rpm @ 569 in.-lbs. | 5.4/2.7 | No | Totally Enclosed Fan Cooled (TEFC) | 13 1/2" | 8 1/4" | 7 3/4" | Helical and Spur | Ball | 3/4" | 1 1/2" | 3" | B | 266° | IP43 | 0000000 | 00000000 |

230/460 Volts AC, Three Phase | |||||||||||||||||

| 1/4 | 10 rpm @ 1,460 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 17" | 7" | 7 3/4" | Helical | Roller | 1 1/4" | 2 3/8" | 4.53" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 20 rpm @ 760 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 1/2" | 6" | 7 1/4" | Helical | Roller | 1" | 2" | 3.54" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 30 rpm @ 515 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 1/2" | 6" | 7 1/4" | Helical | Roller | 1" | 2" | 3.54" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 38 rpm @ 400 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | Helical | Roller | 3/4" | 1 1/2" | 2.95" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 53 rpm @ 285 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | Helical | Roller | 3/4" | 1 1/2" | 2.95" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 73 rpm @ 205 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | Helical | Roller | 3/4" | 1 1/2" | 2.95" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 100 rpm @ 150 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | Helical | Roller | 3/4" | 1 1/2" | 2.95" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 148 rpm @ 106 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | Helical | Roller | 3/4" | 1 1/2" | 2.95" | F | 311° | IP54 | 0000000 | 000000 |

| 1/4 | 294 rpm @ 44 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | Helical | Roller | 3/4" | 1 1/2" | 2.95" | F | 311° | IP54 | 0000000 | 000000 |

Overall | Shaft | Insulation | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed @ Continuous Operating Torque | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Gear Type | Bearing Type | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

115/230 Volts AC, Single Phase | |||||||||||||||||

| 1/4 | 47 rpm @ 294 in.-lbs. | 2.35/1.25 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 7" | 5 1/4" | Helical and Spur | Ball and Roller | 3/4" | 1 1/2" | 3.56" | B | 266° | IP44 | 0000000 | 0000000 |

| 1/4 | 88 rpm @ 163 in.-lbs. | 2.35/1.25 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 7" | 5 1/4" | Helical and Spur | Ball and Roller | 3/4" | 1 1/2" | 3.56" | B | 266° | IP44 | 0000000 | 000000 |

| 1/4 | 113 rpm @ 128 in.-lbs. | 2.35/1.25 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 7" | 5 1/4" | Helical and Spur | Ball and Roller | 3/4" | 1 1/2" | 3.56" | B | 266° | IP44 | 0000000 | 000000 |

| 1/4 | 159 rpm @ 91 in.-lbs. | 2.35/1.25 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 7" | 5 1/4" | Helical and Spur | Ball and Roller | 3/4" | 1 1/2" | 3.56" | B | 266° | IP44 | 0000000 | 000000 |

| 1/4 | 338 rpm @ 41 in.-lbs. | 2.35/1.25 | No | Totally Enclosed Fan Cooled (TEFC) | 11 1/2" | 7" | 5 1/4" | Helical and Spur | Ball and Roller | 3/4" | 1 1/2" | 3.56" | B | 266° | IP44 | 0000000 | 000000 |

Washdown AC Gearmotors

IP rated, these gearmotors stand up to high-pressure washdowns. They combine a motor with a speed reducer to lower speed while increasing torque. Their parallel shaft transmits motion inline with the motor.

Since they’re inverter-rated, you can adjust the speed with a motor speed control (not included). Wire these motors for clockwise or counterclockwise rotation; instructions are included.

Base-mount motors come with a base, so they can be secured to a flat surface. TEFC (totally enclosed fan cooled) enclosures protect against dirt, dust, and moisture. An external fan blows air on the enclosure to keep it cool. Motors rated IP66 have a labyrinth drain plug that keeps water out while letting condensation escape.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed @ Continuous Operating Torque | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max Temp., °F | Environmental Rating | Each | |

230/460 Volts AC—Base Mount | ||||||||||||||

| 1/4 | 30 rpm @ 515 in.-lbs. | 1.04/0.52 | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | 3/4" | 1 5/8" | 2.95" | F | 311° | IP66 | 0000000 | 0000000 |

| 1/4 | 38 rpm @ 400 in.-lbs. | 1.04/0.52 | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | 3/4" | 1 5/8" | 2.95" | F | 311° | IP66 | 0000000 | 000000 |

| 1/4 | 53 rpm @ 285 in.-lbs. | 1.04/0.52 | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | 3/4" | 1 5/8" | 2.95" | F | 311° | IP66 | 0000000 | 000000 |

| 1/4 | 73 rpm @ 205 in.-lbs. | 1.04/0.52 | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | 3/4" | 1 5/8" | 2.95" | F | 311° | IP66 | 0000000 | 000000 |

| 1/4 | 100 rpm @ 150 in.-lbs. | 1.04/0.52 | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | 3/4" | 1 5/8" | 2.95" | F | 311° | IP66 | 0000000 | 000000 |

| 1/4 | 148 rpm @ 106 in.-lbs. | 1.04/0.52 | Totally Enclosed Fan Cooled (TEFC) | 14 1/2" | 5 1/2" | 6 3/4" | 3/4" | 1 5/8" | 2.95" | F | 311° | IP66 | 0000000 | 000000 |

Right-Angle AC Gearmotors

A motor and speed reducer in one, these gearmotors have hypoid gears for energy-efficient operation. You can use them to turn a shaft on your equipment or add a keyed shaft (sold separately). Wire for clockwise or counterclockwise rotation; instructions are included. Gearmotors meet IP54 for protection from dust and splashed water. They're inverter rated so you can use them with a motor speed control (not included) to adjust the motor speed.

For technical drawings and 3-D models, click on a part number.

Gearmotors | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Output | Optional Keyed Shafts with Key Stock | |||||||||||

| Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lbs. | Full Load Current, A | Lg. | Wd. | Ht. | For Shaft Dia. | Shaft Center to Base | Environmental Rating | Each | Each | ||

230/400-460 Volts AC, Three Phase | |||||||||||||

| 1/4 | 7 rpm @ 1,730 in.-lbs. | 1,120 | 1.25/0.9-1 | 16" | 5 1/2" | 7 3/4" | 1 1/4" | 2.28" | IP54 | 0000000 | 000000000 | 0000000 | 000000 |

| 1/4 | 14 rpm @ 871 in.-lbs. | 965 | 1.25/0.9-1 | 16" | 5 1/2" | 7 3/4" | 1 1/4" | 2.28" | IP54 | 0000000 | 00000000 | 0000000 | 00000 |

DC Gearmotors

Convert speed to torque to get the power you need—gearmotors are a motor and speed reducer in one. You can wire for clockwise or counterclockwise rotation; instructions are included. Gearmotors transmit motion inline with the motor.

To control motor speed, motor controls are also available. To convert AC power to DC power, see AC to DC transformers.

For technical drawings and 3-D models, click on a part number.

Gearmotors | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | Replacement Motor Brushes | ||||||||||||||

| Power, hp | Speed @ Continuous Operating Torque | Radial Load Capacity, lbs. | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., ° F | Each | Pkg. Qty. | Each | ||

90 Volts DC | |||||||||||||||||

| 1/4 | 42 rpm @ 280 in.-lbs. | 327 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311° | 0000000 | 0000000 | __ | 000000000 | 000000 |

| 1/4 | 62 rpm @ 220 in.-lbs. | 303 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311° | 0000000 | 000000 | __ | 000000000 | 00000 |

| 1/4 | 83 rpm @ 155 in.-lbs. | 267 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311° | 0000000 | 000000 | __ | 000000000 | 00000 |

| 1/4 | 110 rpm @ 100 in.-lbs. | 256 | 2 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311° | 0000000 | 000000 | __ | 000000000 | 00000 |

| 1/4 | 165 rpm @ 70 in.-lbs. | 232 | 2 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311° | 0000000 | 000000 | __ | 000000000 | 00000 |

| Each | Pkg. | ||||||||||||||||

| 1/4 | 360 rpm @ 40 in.-lbs. | 170 | 2.51 | Totally Enclosed Nonventilated (TENV) | 14 1/4" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311° | 0000000 | 000000 | 2 | 000000000 | 00000 |

Right-Angle DC Gearmotors

A good solution for tight spaces, these gearmotors transmit motion at a 90° angle from the motor, so they’re positioned alongside your application when mounted. Gearmotors combine a motor and speed reducer to lower speed and increase torque.

To control motor speed, motor controls are also available. To convert AC power to DC power, see AC to DC transformers.

Gearmotors with a hollow body/removable shaft come assembled with a single-sided shaft for right-hand output. You can remove the shaft and turn it around for left-hand output, or you can replace it with a dual shaft (sold separately) to drive two processes at the same time. To monitor shaft rotation, you can pair this shaft with an encoder (not included).

For technical drawings and 3-D models, click on a part number.

Gearmotors | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | Optional Conduit Boxes | Replacement Motor Brushes | |||||||||||||

| Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lbs. | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Each | Each | Each | |||

90 Volts DC | |||||||||||||||||

| 1/4 | 60 rpm @ 135 in.-lbs. | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356° | 00000000 | 0000000 | 00000000 | 000000 | 000000000 | 000000 |

| 1/4 | 79 rpm @ 125 in.-lbs. | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356° | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 |

| 1/4 | 120 rpm @ 90 in.-lbs. | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356° | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 |

| 1/4 | 233 rpm @ 50 in.-lbs. | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356° | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 |

| 1/4 | 465 rpm @ 30 in.-lbs. | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356° | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 |

Gearmotors | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | Optional Conduit Boxes | Replacement Motor Brushes | |||||||||||||

| Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lbs. | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Each | Each | Pkg. | |||

90 Volts DC | |||||||||||||||||

| 1/4 | 60 rpm @ 120 in.-lbs. | 300 | 2.33 | 12 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311° | 00000000 | 0000000 | 00000000 | 000000 | 000000000 | 000000 |

| 1/4 | 90 rpm @ 100 in.-lbs. | 300 | 2.33 | 12 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311° | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 |

Shaft | Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Type | Number of | Key Included | Lg. | Wd. | Dp. | Direction of Operation | Includes | Each | |

| 5/8" | 1.6" | Keyed | 2 | Yes | 1.22" | 0.188" | 0.108" | Clockwise or Counterclockwise | Retaining Rings | 00000000 | 0000000 |

Washdown DC Gearmotors

Rated IP55 with an epoxy-coated enclosure, these gearmotors drive low-speed, high-torque applications in areas that are subject to low-pressure washdowns. They combine a motor with a speed reducer to lower speeds while increasing torque. Since their shaft is parallel to the motor, they transmit motion inline with the motor. They have a TENV (totally enclosed nonventilated) enclosure that is similar to a TEFC (totally enclosed fan cooled) enclosure, except it doesn't have a fan. It relies on cooling from the air circulation created by the motor's motion instead.

You can wire the shaft to rotate clockwise or counterclockwise; instructions are included.

For technical drawings and 3-D models, click on a part number.

Gearmotors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | Replacement Motor Brushes | |||||||||||||

| Power | Speed @ Continuous Operating Torque | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | Each | ||

90 Volts DC | ||||||||||||||||

| 1/4 hp | 42 rpm @ 280 in.-lbs. | 2.6 | Totally Enclosed Nonventilated (TENV) | 13 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311° | IP55 | 0000000 | 000000000 | 000000000 | 000000 |

| 1/4 hp | 500 rpm @ 25 in.-lbs. | 2.4 | Totally Enclosed Nonventilated (TENV) | 13 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311° | IP55 | 00000000 | 00000000 | 000000000 | 00000 |

Washdown Right-Angle DC Gearmotors

Drive low-speed, high-torque applications in tight areas that are washed down. These gearmotors have an epoxy-coated enclosure and are rated IP55 to protect against water from low-pressure washdowns. They combine both a motor and speed reducer to lower speeds and increase torque. Since their shaft is at a 90° angle from their motor, they transmit motion alongside your application, so they take up less space than gearmotors with a shaft that's inline with their motor. They have a TENV (totally enclosed nonventilated) enclosure that is similar to a TEFC (totally enclosed fan cooled) enclosure, except it doesn't have a fan. It relies on cooling from the air circulation created by the motor's motion instead.

You can wire the shaft to rotate clockwise or counterclockwise; instructions are included. You can also switch the shaft's right-hand orientation to a left-hand orientation by removing the retaining covers, reversing the orientation, and then reassembling.

For technical drawings and 3-D models, click on a part number.

Gearmotors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | Replacement Motor Brushes | |||||||||||||

| Power, hp | Speed @ Continuous Operating Torque | Full Load Current, A | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | Each | ||

90 Volts DC | ||||||||||||||||

| 1/4 | 62 rpm @ 135 in.-lbs. | 3.7 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311° | IP55 | 0000000 | 000000000 | 000000000 | 000000 |

| 1/4 | 125 rpm @ 90 in.-lbs. | 3.8 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311° | IP55 | 0000000 | 00000000 | 000000000 | 00000 |

| 1/4 | 250 rpm @ 50 in.-lbs. | 3.7 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311° | IP55 | 0000000 | 00000000 | 000000000 | 00000 |

Direct-Drive Fan Motors

Since they have fewer moving parts, you can use these direct-drive motors to build fans that require less maintenance than fans with belt-drive motors. Mount them directly to a fan column.

For technical drawings and 3-D models, click on a part number.

Shaft | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Speed, rpm | Power, hp | Dia. | Lg. | Direction of Operation | Current, A | Voltage | Lg. | Wd. | Ht. | Insulation Class | Overload Protection Type | Each | |

NEMA 48Z—Welded (D-Profile Shaft) | |||||||||||||

Single Phase—Hardwire | |||||||||||||

| 1,100 | 1/4 | 1/2" | 3 1/4" | Clockwise or Counterclockwise | 4.0 2.0 | 120V AC 240V AC | 9 3/4" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 0000000 |

| 1,700 | 1/4 | 1/2" | 3 1/8" | Clockwise or Counterclockwise | 3.4 1.7 | 120V AC 240V AC | 10 1/8" | 5 5/8" | 8 1/8" | B | Automatic | 0000000 | 000000 |

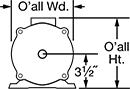

Pedestal Fan Motors

Build your own fan or replace a fan motor. Mount one of these motors directly to a fan column. Four 8-32 threaded mounting studs extend 1" for mounting a fan guard.

View information about motors.

Note: When selecting a fan blade, be sure the rpm and hp are compatible and the shaft diameter of the blade matches the shaft diameter of the motor.

For technical drawings and 3-D models, click on a part number.

Shaft | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Speed, rpm | Power, hp | Dia. | Lg. | Current, A | Lg. | Ht. | Wd. | Direction of Operation | Service Factor | Mount. Fasteners Included | Mount. Hole Dia. | Features | Specifications Met | Each | |

NEMA 48YZ | |||||||||||||||

120V AC, Single Phase—Hardwire | |||||||||||||||

| 1,075 | 1/4 | 1/2" | 2 3/8" | 2.9 | 10 11/16" | 10 3/8" | 5 11/16" | Clockwise or Counterclockwise | 1.0 | No | 7/16" | Thermal Overload Protection | UL Recognized Component, CSA Certified | 0000000 | 0000000 |

| 1,625 | 1/4 | 1/2" | 2 3/8" | 2.6 | 10 11/16" | 10 3/8" | 5 11/16" | Clockwise or Counterclockwise | 1.0 | No | 7/16" | Thermal Overload Protection | UL Recognized Component, CSA Certified | 0000000 | 000000 |