About Electric Motors

When replacing a motor, use the information on your motor’s nameplate to guide your selection.

More

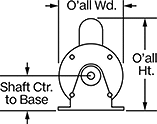

U.S.-Made Base-Mount AC Motors

Wound, wired, and assembled in the U.S. These base-mount motors are manufactured for durability and include high-quality bearings, so they hold up to occasional overload conditions and spikes in torque. Rated for continuous duty, they’re often used with equipment that requires constant power, such as fans, pumps, and conveyors. Bolt the base of these motors to any flat surface and connect the shaft to your load.

When pairing with a variable frequency drive (AC motor speed control), choose a three-phase motor that’s inverter rated.

Enclosures that are totally enclosed don’t have vents, so they can be used in damp and dirty environments. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure. Totally enclosed fan cooled (TEFC) enclosures have an external fan that blows air over the outside of the enclosure to keep the motor cool.

For technical drawings and 3-D models, click on a part number.

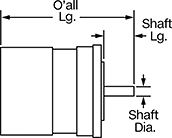

Overall | Shaft | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Insulation Max. Temp., °F | Each | |

230/460 Volts AC, Three Phase | |||||||||||||

NEMA 213T/NEMA 215T—Welded Base | |||||||||||||

| 7 1/2 | 1,770 | 19.0/9.5 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 1/2" | 15 3/8" | 13" | 1 3/8" | 3 3/8" | 5 1/4" | 311° | 00000000 | 000000000 |

| 10 | 1,760 | 24.4/12.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 1/2" | 15 3/8" | 13" | 1 3/8" | 3 3/8" | 5 1/4" | 311° | 00000000 | 00000000 |

Base/Face-Mount AC Motors

Whether you’re switching between jobs or need flexibility during installation, these motors give you a variety of mounting options. Fix the feet to a flat surface or bolt the face directly to a gearbox, pump, or other machinery. You can also do both at once for added stability in applications with high loads or vibration. These motors are rated for continuous duty, so they’re often used for equipment that requires constant power, such as fans, pumps, and conveyors. They're inverter-rated, so you can pair them with a variable frequency drive (AC motor speed control).

All motors have an IEC frame size, which meets international standards for electrical products. They have totally enclosed fan cooled (TEFC) enclosures, which don’t have vents, so you can install them in damp and dirty environments. An external fan blows air over the outside of the enclosure to keep these motors cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

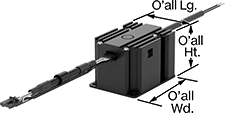

Overall | Shaft | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||

IEC 80M | |||||||||||||||

| 1 | 1,740 | 3.0/1.5 | Yes | Totally Enclosed Fan Cooled (TEFC) | 13 1/4" | 7 1/8" | 6 1/4" | 3/4" | 1 9/16" | 3 1/8" | F | 311° | IP55 | 00000000 | 000000000 |

IEC 90L | |||||||||||||||

| 2 | 1,740 | 5.6/2.8 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 1/2" | 7 3/4" | 6 1/2" | 1" | 2" | 3 1/2" | F | 311° | IP55 | 00000000 | 00000000 |

IEC 90S | |||||||||||||||

| 1 1/2 | 1,745 | 4.2/2.1 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 1/2" | 7 3/4" | 6 1/2" | 1" | 2" | 3 1/2" | F | 311° | IP55 | 00000000 | 00000000 |

IEC 112M | |||||||||||||||

| 4 | 1,760 | 10.6/5.3 | Yes | Totally Enclosed Fan Cooled (TEFC) | 19" | 10" | 8" | 1.11" | 2 3/8" | 4 1/2" | F | 311° | IP55 | 00000000 | 00000000 |

Base-Mount AC Motors

To get equipment moving, bolt the base of these motors to any flat surface and connect the shaft to your load. They’re rated for continuous duty, so they’re often used with equipment that requires constant power, like fans, pumps, and conveyors. They're inverter rated, so you can pair them with a variable frequency drive (AC motor speed control).

Their IEC frame size meets international standards for electrical products. These motors have totally enclosed fan cooled (TEFC) enclosures, which don’t have vents, so they can be used in damp and dirty environments. They have an external fan that blows air over the outside of the enclosure to keep the motor cool. They’re not airtight, but the lack of internal airflow means that motors don’t run as efficiently as they do in open enclosures.

Motors that cannot be sold to the regions listed are restricted due to energy efficiency regulations.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Cannot Be Sold To | Each | |

230/460 Volts AC, Three Phase | ||||||||||||||||

IEC 100L—Welded Base | ||||||||||||||||

| 1 1/2 | 4,000 | 4.4/2.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 9" | 11 1/8" | 28mm | 60mm | 100mm | F | 311° | IP55 | CA | 0000000 | 0000000 |

| 2 | 4,000 | 6.0/3.0 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 9" | 11 1/8" | 28mm | 60mm | 100mm | F | 311° | IP55 | __ | 0000000 | 000000 |

| 3 | 4,000 | 7.8/3.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 9" | 11 1/8" | 28mm | 60mm | 100mm | F | 311° | IP55 | __ | 0000000 | 000000 |

| 4 | 4,000 | 9.8/4.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 9" | 11 1/8" | 28mm | 60mm | 100mm | F | 311° | IP55 | CA | 0000000 | 000000 |

| 4 | 4,000 | 10.4/5.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 9" | 11 1/8" | 28mm | 60mm | 100mm | F | 311° | IP55 | CA | 0000000 | 00000000 |

IEC 112M—Welded Base | ||||||||||||||||

| 3 | 4,000 | 8.8/4.4 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 10" | 12" | 28mm | 60mm | 112mm | F | 311° | IP55 | __ | 0000000 | 00000000 |

| 5 1/2 | 4,000 | 12.4/6.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 10" | 12" | 28mm | 60mm | 112mm | F | 311° | IP55 | CA | 0000000 | 00000000 |

| 5 1/2 | 4,000 | 13.8/6.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 3/4" | 10" | 12" | 28mm | 60mm | 112mm | F | 311° | IP55 | CA | 0000000 | 00000000 |

Face-Mount AC Motors

Bolt these motors directly to gearboxes, pumps, and other machinery. They’re more compact than base-mount motors and the direct, rigid connection to your equipment helps keep them aligned. Rated for continuous duty, they are often used with equipment that requires constant power, such as fans and conveyors. These motors are inverter-rated, so you can use them with a variable frequency drive (AC motor speed control).

All have an IEC frame size to meet international standards for electrical products. A totally enclosed fan cooled (TEFC) enclosure means you can use them in damp and dirty environments since they don’t have vents. They have an external fan that blows air over the outside of the enclosure to keep the motor cool. They’re not airtight, but since air isn’t flowing inside the enclosure, the motor won’t run as efficiently as it would in an open enclosure.

Motors that cannot be sold to the regions listed are restricted due to energy efficiency regulations.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Max. Speed, rpm | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Mounting Flange Type | Dia. | Lg. | Center to Base | Insulation Max. Temp., °F | Environmental Rating | Cannot Be Sold To | Each | |

230/460 Volts AC, Three Phase | ||||||||||||||||

IEC 100L | ||||||||||||||||

| 3 | 1,770 | 7.8/3.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 5/8" | 9 3/4" | 11 5/8" | B5 | 28mm | 60mm | 100mm | 311° | IP55 | __ | 00000000 | 000000000 |

| 4 | 3,500 | 9.8/4.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 5/8" | 8 7/8" | 11 5/8" | B14 | 28mm | 60mm | 100mm | 311° | IP55 | CA | 00000000 | 000000 |

| 4 | 3,500 | 9.8/4.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 5/8" | 9 3/4" | 11 5/8" | B5 | 28mm | 60mm | 100mm | 311° | IP55 | CA | 00000000 | 000000 |

IEC 112M | ||||||||||||||||

| 5 1/2 | 1,760 | 13.8/6.9 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 5/8" | 10" | 12 5/8" | B5 | 28mm | 60mm | 112mm | 311° | IP55 | CA | 00000000 | 00000000 |

| 5 1/2 | 3,520 | 12.4/6.2 | Yes | Totally Enclosed Fan Cooled (TEFC) | 15 5/8" | 10" | 12 5/8" | B5 | 28mm | 60mm | 112mm | 311° | IP55 | CA | 00000000 | 00000000 |

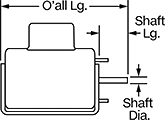

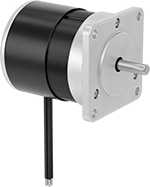

Brushless DC Motors

Since there are no brushes to add weight and friction, these motors can achieve a higher torque-to-weight ratio, faster speeds, and better efficiency than DC motors with brushes. All motors require a driver (sold separately) to operate.

Drivers control the speed and direction the motor spins. To program the driver, connect it to your computer with a mini USB cord (sold separately) and use the free downloadable software to enter your speed and acceleration parameters. No coding is necessary.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed @ Continuous Operating Torque | Max. Speed, rpm | Starting Torque, in.-oz. | Full Load Current, A | Lg. | Wd. | Ht. | Shaft Type | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Each | |

30V DC | ||||||||||||||

NEMA 17 | ||||||||||||||

| 5,530 rpm @ 8.2 in.-oz. | 6,400 | 0.2 | 1.4 | 2 15/16" | 1 5/8" | 1 5/8" | Solid | 1/4" | 3/4" | 0.83" | A | 221° | 0000000 | 0000000 |

| 5,850 rpm @ 16 in.-oz. | 6,470 | 0.4 | 2.7 | 3 3/4" | 1 5/8" | 1 5/8" | Solid | 1/4" | 3/4" | 0.83" | A | 221° | 0000000 | 000000 |

| 6,210 rpm @ 21 in.-oz. | 6,730 | 0.6 | 3.8 | 4 1/2" | 1 5/8" | 1 5/8" | Solid | 1/4" | 3/4" | 0.83" | A | 221° | 0000000 | 000000 |

76V DC | ||||||||||||||

NEMA 23 | ||||||||||||||

| 5,770 rpm @ 74 in.-oz. | 6,000 | 2.1 | 4.9 | 5 3/4" | 2 1/4" | 2 1/4" | D-Profile | 1/4" | 13/16" | 1.135" | B | 266° | 0000000 | 000000 |

| 6,000 rpm @ 19 in.-oz. | 6,000 | 0.69 | 2.4 | 3 3/8" | 2 1/4" | 2 1/4" | D-Profile | 1/4" | 13/16" | 1.135" | B | 266° | 0000000 | 000000 |

| 6,000 rpm @ 39 in.-oz. | 6,000 | 1.2 | 3.7 | 4 1/8" | 2 1/4" | 2 1/4" | D-Profile | 1/4" | 13/16" | 1.135" | B | 266° | 0000000 | 000000 |

| 6,000 rpm @ 49 in.-oz. | 6,000 | 1.6 | 4.5 | 5" | 2 1/4" | 2 1/4" | D-Profile | 1/4" | 13/16" | 1.135" | B | 266° | 0000000 | 000000 |

USB | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Full Load Current, A | Current, A | Input Voltage Range | Connection Gender | Connection Type | Standard | Wire Connection Type | Lg. | Wd. | Ht. | Each | |

| 1.4-4.9 | 7 | 12-60V DC | Female | Mini B | 2.0 | Wire Leads | 2.28" | 2.99" | 1.96" | 0000000 | 0000000 |

| Connections | USB Standard | Color | Lg., ft. | Each | |

| USB A Male Plug × USB Mini-B Male Plug | 2.0 | Black | 6 | 0000000 | 00000 |

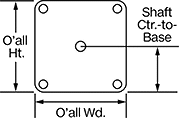

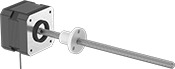

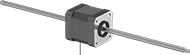

Stepper Motors with Linear Actuation

Instead of a shaft, these stepper motors have a lead screw that converts rotational motion to linear motion. Moving in increments smaller than the thickness of a sheet of paper, they're ideal for applications that require fine motion control, such as positioning electrical components on a circuit board. They move in equal steps and hold their position when stationary, so they do not require encoders, sensors, or other position feedback devices. The lead screw is built into the motor, so there are fewer points of failure than systems that use a shaft coupling to connect the lead screw. All are bipolar hybrid stepper motors, which deliver greater torque, precision, and efficiency than other types of stepper motors.

External lead screw stepper motors work similar to a traditional linear motion system; attach the load to the flanged nut, which travels back and forth along the lead screw.

Pass-through lead screw stepper motors give you the most design versatility because there are two ways to move your load: on the motor body or on the ends of the lead screw. The motor moves when the lead screw is fixed or the lead screw moves when the motor body is fixed.

Travel distance per full step determines the control you have over the motor’s positioning. The smaller the measurement, the finer positioning control you have, but the more steps it will take to go the same distance.

Dynamic load capacity is the maximum load a motor can move. If you increase the speed, the dynamic load capacity decreases. Click on a part number and select "Product Detail" to view the load-speed chart and confirm the motor will work for your application.

All motors require a driver and controller (not included).

For technical drawings and 3-D models, click on a part number.

O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Travel Distance per Full Step | Travel Lg. | Dynamic Load Capacity, lbs. | Max. Speed, in./sec. | Max. Current per Phase | Full Step Increment | Polarity | No. of Wire Leads | Lg. | Wd. | Ht. | Lead Screw Lg. | Thread Size | Temp. Range, °F | Each | |

External Lead Screw | |||||||||||||||

NEMA 17 | |||||||||||||||

| 0.000625" | 5.2" | 50 | 1.2 | 1.5A | 1.8° | Bipolar | 4 | 7.3" | 1.7" | 1.7" | 6" | 1/4"-16 | 35° to 130° | 0000000 | 0000000 |

| 0.000625" | 5.2" | 75 | 1.1 | 2.6A | 1.8° | Bipolar | 4 | 7.9" | 1.7" | 1.7" | 6" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.000625" | 11.2" | 50 | 1.2 | 1.5A | 1.8° | Bipolar | 4 | 13.3" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.000625" | 11.2" | 75 | 1.1 | 2.6A | 1.8° | Bipolar | 4 | 13.9" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.00125" | 5.2" | 25 | 2 | 1.5A | 1.8° | Bipolar | 4 | 7.3" | 1.7" | 1.7" | 6" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.00125" | 5.2" | 60 | 2.1 | 2.6A | 1.8° | Bipolar | 4 | 7.9" | 1.7" | 1.7" | 6" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.00125" | 11.2" | 25 | 2 | 1.5A | 1.8° | Bipolar | 4 | 13.3" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.00125" | 11.2" | 60 | 2.1 | 2.6A | 1.8° | Bipolar | 4 | 13.9" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

NEMA 23 | |||||||||||||||

| 0.0003125" | 11" | 200 | 0.5 | 2A | 1.8° | Bipolar | 4 | 13.8" | 2.3" | 2.3" | 12" | 3/8"-16 | 35° to 130° | 0000000 | 000000 |

| 0.0005" | 11" | 200 | 0.8 | 2A | 1.8° | Bipolar | 4 | 13.8" | 2.3" | 2.3" | 12" | 3/8"-10 | 35° to 130° | 0000000 | 000000 |

| 0.002" | 11" | 75 | 3 | 2A | 1.8° | Bipolar | 4 | 13.8" | 2.3" | 2.3" | 12" | 3/8"-10 | 35° to 130° | 0000000 | 000000 |

Pass-Through Lead Screw | |||||||||||||||

NEMA 17 | |||||||||||||||

| 0.000625" | 10.1" | 75 | 1.1 | 2.6A | 1.8° | Bipolar | 4 | 12.3" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.000625" | 10.6" | 50 | 1.2 | 1.5A | 1.8° | Bipolar | 4 | 12.3" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.00125" | 10.1" | 60 | 2.1 | 2.6A | 1.8° | Bipolar | 4 | 12.3" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

| 0.00125" | 10.6" | 25 | 2 | 1.5A | 1.8° | Bipolar | 4 | 12.3" | 1.7" | 1.7" | 12" | 1/4"-16 | 35° to 130° | 0000000 | 000000 |

NEMA 23 | |||||||||||||||

| 0.0003125" | 10.2" | 200 | 0.5 | 2A | 1.8° | Bipolar | 4 | 12.5" | 2.3" | 2.3" | 12" | 3/8"-16 | 35° to 130° | 0000000 | 000000 |

| 0.0005" | 10.2" | 200 | 0.8 | 2A | 1.8° | Bipolar | 4 | 12.5" | 2.3" | 2.3" | 12" | 3/8"-10 | 35° to 130° | 0000000 | 000000 |

| 0.002" | 10.2" | 75 | 3 | 2A | 1.8° | Bipolar | 4 | 12.5" | 2.3" | 2.3" | 12" | 3/8"-10 | 35° to 130° | 0000000 | 000000 |

AC Gearmotors

Turn speed into torque with these AC-powered gearmotors—they combine a motor and a speed reducer into one. You can wire them for clockwise or counterclockwise rotation; instructions are included. The parallel shaft transmits motion inline with the motor.

Base-mount motors come with a base, so they can be secured to a flat surface. TEFC (totally enclosed fan cooled) motors have an enclosure to protect them from dirt, dust, and moisture. An external fan blows air on the enclosure to keep them cool. 230/460V AC motors are inverter-rated, so you can adjust the speed with a motor speed control (not included).

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | Insulation | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed @ Continuous Operating Torque | Full Load Current, A | Inverter Rated | Motor Enclosure Type | Lg. | Wd. | Ht. | Gear Type | Bearing Type | Dia. | Lg. | Center to Base | Class | Max. Temp., °F | Environmental Rating | Each | |

230/460 Volts AC, Three Phase | |||||||||||||||||

| 1/4 | 10 rpm @ 1,460 in.-lbs. | 1.04/0.52 | Yes | Totally Enclosed Fan Cooled (TEFC) | 17" | 7" | 7 3/4" | Helical | Roller | 1 1/4" | 2 3/8" | 4.53" | F | 311° | IP54 | 0000000 | 0000000 |

| 1/2 | 10 rpm @ 3,100 in.-lbs. | 1.83/0.91 | Yes | Totally Enclosed Fan Cooled (TEFC) | 18 3/4" | 8" | 8 3/4" | Helical | Roller | 1 3/8" | 2 3/4" | 4.53" | F | 311° | IP54 | 0000000 | 00000000 |

| 1/2 | 20 rpm @ 1,530 in.-lbs. | 1.83/0.91 | Yes | Totally Enclosed Fan Cooled (TEFC) | 17 3/4" | 7" | 8 1/2" | Helical | Roller | 1 1/4" | 2 3/8" | 4.53" | F | 311° | IP54 | 0000000 | 000000 |

| 1/2 | 31 rpm @ 1,010 in.-lbs. | 1.83/0.91 | Yes | Totally Enclosed Fan Cooled (TEFC) | 16 3/4" | 6 1/4" | 7 3/4" | Helical | Roller | 1" | 2" | 3.54" | F | 311° | IP54 | 0000000 | 000000 |

| 1 | 20 rpm @ 3,230 in.-lbs. | 3.1/1.56 | Yes | Totally Enclosed Fan Cooled (TEFC) | 21" | 8" | 9 1/4" | Helical | Roller | 1 3/8" | 2 3/4" | 4.53" | F | 311° | IP54 | 0000000 | 00000000 |

| 1 | 41 rpm @ 1,550 in.-lbs. | 3.1/1.56 | Yes | Totally Enclosed Fan Cooled (TEFC) | 20" | 7" | 9" | Helical | Roller | 1 1/4" | 2 3/8" | 4.53" | F | 311° | IP54 | 0000000 | 00000000 |

| 2 | 31 rpm @ 4,070 in.-lbs. | 6/3 | Yes | Totally Enclosed Fan Cooled (TEFC) | 23 1/4" | 8 1/2" | 9 3/4" | Helical | Roller | 1 3/8" | 2 3/4" | 5.12" | F | 311° | IP54 | 0000000 | 00000000 |

| 2 | 75 rpm @ 1,690 in.-lbs. | 6/3 | Yes | Totally Enclosed Fan Cooled (TEFC) | 21 1/2" | 7" | 9 1/2" | Helical | Roller | 1 1/4" | 2 3/8" | 4.53" | F | 311° | IP54 | 0000000 | 00000000 |

Speed-Control AC Gearmotors

Start, stop, reverse direction, and control the speed of these gearmotors from the mounted keypad. Because you can fine tune output speed and direction, these gearmotors are often used in material processing and handling applications, such as controlling the speed of a mixer or conveyor. These gearmotors are both a motor and speed reducer in one to lower speed while increasing torque. All transmit motion inline with the motor. Secure them to flat surfaces with the base mount. These gearmotors have a TEFC (totally enclosed fan cooled) enclosure that protects better than ODP (open drip proof) enclosures. They are not airtight but can be used in dirty, dusty, and damp environments. To keep the motor cool, they have an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed Range @ Continuous Operating Torque | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Environmental Rating | Each | |

240 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.6 rpm to 9.9 rpm @ 3,190 in.-lbs. | 1.9 | 19 1/4" | 9 1/4" | 11 1/2" | 1 3/8" | 2 3/4" | 4 1/2" | IP54 | 0000000 | 000000000 |

| 1/2 | 5 rpm to 30 rpm @ 1,030 in.-lbs. | 1.9 | 17 1/4" | 8 1/2" | 10 1/2" | 1" | 2" | 3 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,440 in.-lbs. | 3.5 | 22 1/2" | 9 3/4" | 12 1/2" | 1 1/2" | 3 1/8" | 5 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 4.9 rpm to 30 rpm @ 2,120 in.-lbs. | 3.5 | 20 1/4" | 8 3/4" | 11 1/2" | 1 1/8" | 2 3/8" | 4 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 8.6 rpm to 52 rpm @ 1,210 in.-lbs. | 3.5 | 19 1/4" | 8 1/2" | 10 3/4" | 1" | 2" | 3 1/2" | IP54 | 0000000 | 00000000 |

460 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.6 rpm to 9.9 rpm @ 3,190 in.-lbs. | 1.1 | 19 1/4" | 9 1/4" | 11 1/2" | 1 3/8" | 2 3/4" | 4 1/2" | IP54 | 0000000 | 00000000 |

| 1/2 | 5 rpm to 30 rpm @ 1,030 in.-lbs. | 1.1 | 17 1/4" | 8 1/2" | 10 1/2" | 1" | 2" | 3 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,440 in.-lbs. | 1.7 | 22 1/2" | 9 3/4" | 12 1/2" | 1 1/2" | 3 1/8" | 5 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 4.9 rpm to 30 rpm @ 2,120 in.-lbs. | 1.7 | 20 1/4" | 8 3/4" | 11 1/2" | 1 1/8" | 2 3/8" | 4 1/2" | IP54 | 0000000 | 00000000 |

| 1 | 8.6 rpm to 52 rpm @ 1,210 in.-lbs. | 1.7 | 19 1/4" | 8 1/2" | 10 3/4" | 1" | 2" | 3 1/2" | IP54 | 0000000 | 00000000 |

Speed-Control Right-Angle AC Gearmotors

A good solution for tight spaces, these gearmotors let you control the start, stop, rotation direction, and speed while transmitting motion at a 90° angle from the motor, so you can mount them alongside your application. They combine a motor with a speed reducer to lower speed while increasing torque. All have a mounted keypad to make changes to the integrated speed control. Mount them to flat surfaces using their base. These gearmotors have a TEFC (totally enclosed fan cooled) enclosure that protects better than an ODP (open dripproof) enclosure. They aren’t airtight, but they can be used in dirty, dusty, and damp environments. To keep the motor cool, the enclosure has an external fan that blows air over the outside of the motor.

For technical drawings and 3-D models, click on a part number.

Overall | Shaft | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Speed Range @ Continuous Operating Torque | Full Load Current, A | Lg. | Wd. | Ht. | Dia. | Lg. | Center to Base | Environmental Rating | Each | |

Left-Hand Output Shaft | |||||||||||

240 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.9 rpm to 12 rpm @ 2,660 in.-lbs. | 1.9 | 19" | 11 1/4" | 12" | 2 7/8" | 2 7/8" | 5.2" | IP54 | 0000000 | 000000000 |

| 1/2 | 4.8 rpm to 29 rpm @ 1,080 in.-lbs. | 1.9 | 17 1/4" | 9 1/2" | 11" | 1" | 2 1/8" | 3.94" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,750 in.-lbs. | 3.5 | 23 1/4" | 13 1/2" | 13 1/2" | 2" | 4 1/8" | 7.09" | IP54 | 0000000 | 00000000 |

| 1 | 4.8 rpm to 29 rpm @ 2,120 in.-lbs. | 3.5 | 20 1/2" | 11" | 11 3/4" | 1 3/8" | 2 7/8" | 4.41" | IP54 | 0000000 | 00000000 |

| 1 | 7.6 rpm to 46 rpm @ 1,350 in.-lbs. | 3.5 | 21" | 10 1/2" | 12 1/2" | 1 1/4" | 2 1/2" | 3.15" | IP54 | 0000000 | 00000000 |

460 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.9 rpm to 12 rpm @ 2,660 in.-lbs. | 1.1 | 19" | 11 1/4" | 12" | 2 7/8" | 2 7/8" | 5.2" | IP54 | 0000000 | 00000000 |

| 1/2 | 4.8 rpm to 29 rpm @ 1,080 in.-lbs. | 1.1 | 17 1/4" | 9 1/2" | 11" | 1" | 2 1/8" | 3.94" | IP54 | 0000000 | 00000000 |

| 1 | 1.8 rpm to 11 rpm @ 5,750 in.-lbs. | 1.7 | 23 1/4" | 13 1/2" | 13 1/2" | 2" | 4 1/8" | 7.09" | IP54 | 0000000 | 00000000 |

| 1 | 4.9 rpm to 30 rpm @ 2,120 in.-lbs. | 1.7 | 20 1/2" | 11" | 11 3/4" | 1 3/8" | 2 7/8" | 4.41" | IP54 | 0000000 | 00000000 |

| 1 | 6.4 rpm to 39 rpm @ 1,620 in.-lbs. | 1.7 | 21" | 10 1/2" | 12 1/2" | 1 1/4" | 2 1/2" | 3.15" | IP54 | 0000000 | 00000000 |

Right-Hand Output Shaft | |||||||||||

240 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.9 rpm to 12 rpm @ 2,660 in.-lbs. | 1.9 | 19" | 12" | 12" | 1 3/8" | 2 7/8" | 5.2" | IP54 | 0000000 | 00000000 |

| 1/2 | 4.8 rpm to 29 rpm @ 1,080 in.-lbs. | 1.9 | 17 1/4" | 8 1/2" | 11" | 1" | 2 1/8" | 3.94" | IP54 | 0000000 | 00000000 |

| 1 | 1.9 rpm to 12 rpm @ 5,750 in.-lbs. | 3.5 | 23 1/4" | 12" | 13 1/2" | 2" | 4 1/8" | 7.09" | IP54 | 0000000 | 00000000 |

| 1 | 4.8 rpm to 29 rpm @ 2,120 in.-lbs. | 3.5 | 20 1/2" | 9" | 11 3/4" | 1 3/8" | 2 7/8" | 4.41" | IP54 | 0000000 | 00000000 |

| 1 | 7.6 rpm to 46 rpm @ 1,350 in.-lbs. | 3.5 | 21" | 8 1/2" | 12 1/2" | 1 1/4" | 2 1/2" | 3.15" | IP54 | 0000000 | 00000000 |

460 Volts AC, Three Phase | |||||||||||

| 1/2 | 1.9 rpm to 12 rpm @ 2,660 in.-lbs. | 1.1 | 19" | 12" | 12" | 1 3/8" | 2 7/8" | 5.2" | IP54 | 0000000 | 00000000 |

| 1/2 | 4.8 rpm to 29 rpm @ 1,080 in.-lbs. | 1.1 | 17 1/4" | 8 1/2" | 11" | 1" | 2 1/8" | 3.94" | IP54 | 0000000 | 00000000 |

| 1 | 1.8 rpm to 11 rpm @ 5,750 in.-lbs. | 1.7 | 23 1/4" | 12" | 13 1/2" | 2" | 4 1/8" | 7.09" | IP54 | 0000000 | 00000000 |

| 1 | 4.9 rpm to 30 rpm @ 2,120 in.-lbs. | 1.7 | 20 1/2" | 9" | 11 3/4" | 1 3/8" | 2 7/8" | 4.41" | IP54 | 0000000 | 00000000 |

| 1 | 6.4 rpm to 39 rpm @ 1,620 in.-lbs. | 1.7 | 21" | 8 1/2" | 12 1/2" | 1 1/4" | 2 1/2" | 3.15" | IP54 | 0000000 | 00000000 |