How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Precision Extreme-Pressure Stainless Steel Threaded Pipe Fittings

Made to tighter tolerances than other stainless steel pipe fittings, these are also known as instrumentation fittings. The male threads are rolled for extra strength in extreme-pressure applications. Fittings are commonly used to connect equipment in gas and hydraulic fluid lines. They are 316 stainless steel for excellent corrosion resistance.

Female x male 90° elbow adapters are also known as street elbows.

For technical drawings and 3-D models, click on a part number.

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

316 Stainless Steel | ||||

|---|---|---|---|---|

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | ||||

| 1/16 | 7,000 psi @ 72° F | 7,000 psi @ 300° F | 000000000 | 000000 |

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

316 Stainless Steel | ||||

|---|---|---|---|---|

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female × NPT Male | ||||

| 1/16 | 7,000 psi @ 72° F | 7,000 psi @ 300° F | 000000000 | 000000 |

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met: See table

Pipe Size | Dash Size | 316 Stainless Steel | |||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | Max. Pressure | Max. Steam Pressure | Specifications Met | Each | |

NPT Female × NPT Male | |||||||

| 1/8 | 1/16 | 02 | 6,500 psi @ 72° F | 6,500 psi @ 300° F | ASME B1.20.1, ASME B31.1, ASME B31.3 | 000000000 | 000000 |

Miniature Medium-Pressure Stainless Steel Threaded Pipe Fittings

When space is at a premium choose these compact fittings. Though small in size, they have the strength to handle medium-pressure applications. Fittings are stainless steel for very good corrosion resistance.

Female x male 90° elbow adapters are also known as street elbows.

Metric, BSPP, and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. Made from fluoroelastomer, these gaskets resist chemicals, including benzene, butyl alcohol, and ethylene glycol. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

For technical drawings and 3-D models, click on a part number.

UN/UNF (SAE Straight)

Male Threads with Gasket

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM A314, ASTM A320, ASTM A582

| Pipe Size (A) | Pipe Size (B) | Thread Size (B) | Max. Pressure | Max. Steam Pressure | Gasket Material | Each | |

303 Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

NPT Female × NPT Male | |||||||

| 1/16 | 1/16 | __ | 500 psi @ 72° F | 100 psi @ 350° F | __ | 0000000 | 000000 |

NPT Female × Metric Male | |||||||

| 1/16 | __ | M5 × 0.8 mm | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 00000000 | 00000 |

| 1/16 | __ | M6 × 1 mm | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 00000000 | 00000 |

NPT Female × UN/UNF (SAE Straight) Male | |||||||

| 1/16 | __ | 1/4"-28 | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 00000000 | 00000 |

| 1/16 | __ | 10-32 | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 0000000 | 00000 |

316 Stainless Steel | |||||||

NPT Female × NPT Male | |||||||

| 1/16 | 1/16 | __ | 500 psi @ 72° F | 100 psi @ 350° F | __ | 0000000 | 00000 |

NPT Female × Metric Male | |||||||

| 1/16 | __ | M5 × 0.8 mm | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 0000000 | 00000 |

UN/UNF (SAE Straight)

Male Threads with Gasket

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM A314, ASTM A320, ASTM A582

Pipe Size | ||||||

|---|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Max. Steam Pressure | Gasket Material | Each | |

303 Stainless Steel | ||||||

NPT Female × NPT Male | ||||||

| 1/16 | 1/8 | 500 psi @ 72° F | 100 psi @ 350° F | __ | 0000000 | 000000 |

| 1/8 | 1/16 | 500 psi @ 72° F | 100 psi @ 350° F | __ | 00000000 | 00000 |

| 1/4 | 1/16 | 500 psi @ 72° F | 100 psi @ 350° F | __ | 00000000 | 00000 |

NPT Female × BSPP Male | ||||||

| 1/8 | 1/16 | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 00000000 | 00000 |

316 Stainless Steel | ||||||

NPT Female × NPT Male | ||||||

| 1/8 | 1/16 | 500 psi @ 72° F | 100 psi @ 350° F | __ | 0000000 | 00000 |

| 1/4 | 1/16 | 500 psi @ 72° F | 100 psi @ 350° F | __ | 0000000 | 00000 |

High-Pressure Brass Threaded Pipe Fittings

These fittings have the strength to handle high-pressure applications. They are brass for good corrosion resistance.

Female x male 90° elbow adapters are also known as street elbows.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Water

- Specifications Met: See table

| Pipe Size | Max. Pressure | Each | |

NPTF Female | |||

|---|---|---|---|

| 1/16 | 1,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Water, Natural Gas, Oil

- Specifications Met: See table

Pipe Size | ||||

|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Each | |

NPT Female × NPT Male | ||||

| 1/16 | 1/16 | 1,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Water, Oil, Natural Gas

Pipe Size | ||||

|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Each | |

NPTF Female × NPTF Male | ||||

| 1/8 | 1/16 | 1,000 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Water

Pipe Size | ||||

|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Each | |

NPTF Female | ||||

| 1/8 | 1/16 | 1,000 psi @ 72° F | 000000000 | 000000 |

Easy-Install High-Pressure Brass Threaded Pipe Fittings

Install and remove these fittings with a socket wrench or hex key (sold separately). They are compact, so they require less clearance than traditional elbows. Use them in high-pressure applications. Fittings are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

| Pipe Size | Drive Size | Max. Pressure | Max. Steam Pressure | Each | |

NPTF Female | |||||

|---|---|---|---|---|---|

| 1/16 | 1/4" | 1,000 psi @ 72° F | 1,000 psi @ 250° F | 0000000 | 00000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPTF Female | ||||

|---|---|---|---|---|

| 1/16 | 1,000 psi @ 72° F | 1,000 psi @ 250° F | 0000000 | 00000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

| Pipe Size | Drive Size | Max. Pressure | Max. Steam Pressure | Each | |

NPTF Male × NPTF Female | |||||

|---|---|---|---|---|---|

| 1/16 | 1/4" | 1,000 psi @ 72° F | 1,000 psi @ 250° F | 0000000 | 00000 |

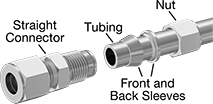

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil - Tubing:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | |||||

|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Temp. Range, °F | Each | |

| 1/4" | 1/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. Also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are 316 stainless steel for excellent corrosion resistance. A molybdenum disulfide coating on the nut acts as a lubricant for easy installation.

For technical drawings and 3-D models, click on a part number.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

| 1/16" | 0.02" | 1/16 | 316 Stainless Steel | 7,500 psi @ 72° F | 0000000 | 000000 |

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | |

| 1/16" | 0.02" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 7,500 psi @ 72° F | 00000000 |

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | |

| 1/16" | 0.02" | 316 Stainless Steel | 7,500 psi @ 72° F | 00000000 |

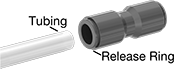

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

Fittings with PTFE thread sealant offer extra protection against leaks.

For technical drawings and 3-D models, click on a part number.

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

| For Tube OD | Pipe Size | Tube Connection Material | Pipe Connection Material | Color | Release Ring Color | Max. Pressure | Features | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/16 | Nylon Plastic | Nickel-Plated Brass | Black | Black | 290 psi @ 72° F | PTFE Thread Sealant | 00000000 | 000000 |

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

| For Tube OD | Pipe Size | Tube Connection Material | Pipe Connection Material | Color | Release Ring Color | Max. Pressure | Features | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/16 | Nylon Plastic | Nickel-Plated Brass | Black | Black | 290 psi @ 72° F | PTFE Thread Sealant | 00000000 | 000000 |

| For Tube OD | Material | Color | Each | |

| 1/8" | Nylon Plastic | Yellow | 00000000 | 00000 |

Brass Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 200° F, except Tube Stem Straight Connectors are 0° to 150° F, and Plugs are 0° to 170° F

- Tubing: See table

These fittings offer good protection against corrosive environments. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting.

Fittings with acrylic thread sealant offer extra protection against leaks.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

Release Ring | For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Material | Color | Max. Pressure | Material | Hardness Rating | Features | Each | |

NPTF Threads | ||||||||||

| 1/8" | 1/16 | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | Hard | Acrylic Thread Sealant | 000000000 | 000000 |

| 5/32" | 1/16 | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | Hard | Acrylic Thread Sealant | 000000000 | 00000 |

Moisture-Resistant Push-to-Connect Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water,

except Manifolds with Swivel: Air, Water - Temperature Range: 32° to 100° F

- Tubing: Use with firm (Durometer 90A-95A) nylon plastic or polyurethane rubber

These fittings won’t absorb moisture, so they’re good for water and high-humidity air applications. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. They have good corrosion resistance.

Nickel-plated brass fittings have better corrosion resistance than unfinished brass fittings.

Fittings with thread sealant offer extra protection against leaks.

For technical drawings and 3-D models, click on a part number.

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

| For Tube OD | Pipe Size | Tube Connection Material | Color | Release Ring Color | Max. Pressure | Features | Choose a Pipe Connection Material | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/16 | Polybutylene Plastic | Gray | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 00000 | |

| 5/32" | 1/16 | Polybutylene Plastic | Gray | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

| 1/4" | 1/16 | Polybutylene Plastic | Gray | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

Fittings with intermittent swivel rotate 360° before and after installation as needed to allow movement in the system and to prevent kinking.

| For Tube OD | Pipe Size | Tube Material | Color | Release Ring Color | Max. Pressure | Features | Choose a Pipe Connection Material | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/16 | Polybutylene Plastic | Gray | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 00000 | |

| 5/32" | 1/16 | Polybutylene Plastic | Gray | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

| 1/4" | 1/16 | Polybutylene Plastic | Gray | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 0000 | |

Low-Temperature/High-Pressure D.O.T. Push-to-Connect Tube Fittings for Air

- Temperature Range: -40° to 200° F

- Tubing: Use with hard (Durometer 65D) nylon plastic

- Specifications Met:

Cartridges: D.O.T. FMVSS 571, SAE J2494-4, SAE J1131

All other fittings: D.O.T. FMVSS 571

Connect high-pressure brake lines with fittings that won’t crack in frigid temperatures. Often used on commercial trucks and trailers, these fittings meet Department of Transportation FMVSS 571 safety standards. Also known as instant fittings, they connect to tubing with a simple push, and an internal gripping ring and O-ring will hold the tubing tight. A built-in tube support slips inside the tubing to prevent it from collapsing. To disconnect, push on the release ring and pull the tubing out of the fitting. All have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 5/32" | 1/16 | Brass | 250 psi @ 72° F | 00000000 | 000000 |

Brass Low-Pressure Barbed Tube Fittings for Air and Water

A brass body provides protection against corrosive environments. Fittings have barbs that grip onto tubing.

NPTF (Dryseal) fittings are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -65° to 75° F

- Tubing: Use with firm (Durometer 95A) polyurethane rubber

| For Tube ID | Pipe Size | Number of Barbs | Material | Max. Pressure | Each | |

NPTF Threads | ||||||

|---|---|---|---|---|---|---|

| 0.17" | 1/16 | Multiple | Brass | 100 psi @ 72° F | 000000000 | 00000 |

Quick-Assembly Brass Compression Tube Fittings for Air and Water

- Temperature Range: 0° to 150° F

- Tubing: Fittings with acetal plastic sleeves: Use with (firm or hard) polyethylene plastic or polypropylene plastic

Fittings with brass sleeves: Use with (firm or hard) nylon plastic, polyethylene plastic or polypropylene plastic

These fittings include a nut with a built-in sleeve (ferrule), so there’s no need to remove the nut for assembly. The sleeve compresses the tubing as you tighten the nut, creating a strong seal. Fittings are also known as flareless fittings. They are brass for good corrosion resistance.

Tube supports are recommended if you want to use the fittings with soft polypropylene and polyethylene tubing to prevent the tube from collapsing.

NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.