Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 12 1/2" | 15 1/4" | 10 3/4" | 1/8" | 1/2 gal., 2 L | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 000000 |

High-Temperature Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 12 1/4" | 15 1/4" | 10 3/4" | 3/16" | 1/2 gal., 2 L | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

Rectangular Plastic Batch Cans

These batch cans come with loose fitting dust covers to protect contents from dust and debris.

Bottom Inside | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||

| 5 | 18 1/4" | 12 1/4" | 9 1/2" | 15 1/2" | 9 1/2" | 3/16" | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

Rectangular Plastic Batch Cans with Faucet

A built-in faucet allows easy dispensing.

For technical drawings and 3-D models, click on a part number.

Bottom Inside | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||||

| 5 | 13 1/4" | 13 1/4" | 10" | 11" | 11" | 1/4" | White | Semi-Clear | Loose Fitting | Polyethylene Plastic | PTFE Plastic | 175° | Stackable | Seamless | 0000000 | 0000000 |

Food Industry Round Metal Batch Cans

These metal batch cans meet NSF/ANSI 2 standards for food-processing equipment.

| Capacity | Dia. | Ht. | Bottom ID | Gauge | Appearance | Lid Type | Specifications Met | Each | |

300 Series Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 5 gal. | 9 1/4" | 16 3/4" | 9" | 22 | Dull | Loose Fitting | NSF/ANSI 2 | 000000 | 0000000 |

Narrow-Mouth Round Stainless Steel Batch Cans

Also known as milk cans, these have a narrow mouth for controlled pouring. They have a reinforced bottom to minimize wear and tear when sliding cans along the floor. The lid has two 7/16" dia. holes for attaching a tag.

| Capacity, gal. | Dia. | Ht. | Mouth OD | Gauge | Appearance | Lid Type | Each | |

304 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5 | 10 1/2" | 19 3/4" | 7 1/2" | 20 | Dull | Tight Fitting | 000000 | 0000000 |

Round Stainless Steel Batch Cans with Faucet

A built-in faucet allows easy dispensing.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Appearance | Faucet Material | Seal Material | Each | |

304 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 5 | 9 1/2" | 18" | 9 1/2" | 18 | Dull | 316 Stainless Steel | PTFE Plastic | 0000000 | 0000000 |

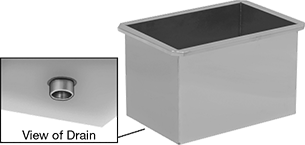

Rectangular Stainless Steel Batch Cans

316 stainless steel is more corrosion resistant than 304 stainless steel.

Batch cans with drain have a drain centered on the bottom of the can.

Rectangular Plastic Tanks

Store large quantities of liquid in these flat-bottomed tanks. They have vented fill caps so air can flow in and out.

For technical drawings and 3-D models, click on a part number.

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Clarity | Max. Temp., °F | UV Protection | Includes | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 22" | 9 1/4" | 7 1/4" | 3/16" | 5" | 1 gal. | White | Semi-Clear | 120° | UV Resistant | Vented Fill Cap | 0000000 | 000000 |

| For Fill Opening Dia. | Features | Each | |

Polypropylene Plastic | |||

|---|---|---|---|

| 5" | Vent | 0000000 | 000000 |

Plastic Easy-Drain Tanks

Optional Stand

with Mixer Mount

The seamless, heavy-wall construction makes these tanks durable and easy to clean. The bottom is sloped to ensure easy drainage.

Stands (sold separately) allow a 14 1/4" minimum clearance from the bottom of drain to the floor.

For technical drawings and 3-D models, click on a part number.

Wall-Mount Plastic Easy-Drain Tanks

These tanks are often used as gravity-fed dispensers.

For technical drawings and 3-D models, click on a part number.

Drain | Mounting Holes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Pipe Size | Gender | Bottom Slope Angle | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | UV Protection | Includes | Each | |

Polyethylene Plastic | ||||||||||||||||||

| 5 | 11" | 11" | 18" | 1/8" | 8" | 1/4 gal. | White | 1 1/4 NPT | Female | 56° | 120° | 6 | 5/16" | No | UV Resistant | Vented Fill Cap | 0000000 | 000000 |

| Replacement Polypropylene Plastic Fill Cap For 8" Fill Opening Dia. | 0000000 | Each | 000000 |

Pressurized Liquid Dispensing Tanks

Attach a compressed air source to pressurize liquids for dispensing and spraying. Tanks have a dip tube that draws liquid from the bottom of the tank. All tanks meet the ASME rating for pressure vessels.

304 stainless steel tanks have good corrosion resistance.

316 stainless steel tanks have excellent corrosion resistance.

Tanks that cannot be sold to the listed areas are restricted due to safety regulations.

For technical drawings and 3-D models, click on a part number.

Overall | Opening | Port | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Max. Pressure @ 100°F, psi | Dia. | Ht. | Lg. | Wd. | Pipe Size | Thread Type | Gender | No. of | Temp. Range, °F | Specifications Met | Cannot Be Sold To | Each | |

Tanks without Mounting Plate | ||||||||||||||

304 Stainless Steel | ||||||||||||||

| 5 | 142 | 9" | 23" | 4 7/8" | 5 7/8" | 1/4 | NPT | Female | 4 | -20° to 200° | ASME BPVC.VIII.1 | Canada | 00000000 | 0000000 |

| 5 | 205 | 9" | 22" | 3 1/4" | 3 7/8" | 1/4 | NPT | Female | 4 | -20° to 200° | ASME BPVC.VIII.1 | Canada | 00000000 | 000000 |

316 Stainless Steel | ||||||||||||||

| 5 | 132 | 9" | 22" | 4 7/8" | 5 7/8" | 1/4 | NPT | Female | 4 | -20° to 300° | ASME BPVC.VIII.1 | Canada | 00000000 | 00000000 |

| 5 | 185 | 9" | 22" | 3 1/4" | 3 7/8" | 1/4 | NPT | Female | 4 | -20° to 300° | ASME BPVC.VIII.1 | Canada | 0000000 | 000000 |

Vacuum closure caps are required to use tanks in vacuum applications.

Sanitary Pressurized Liquid Dispensing Tanks

Store and dispense liquids in food, pharmaceutical, and beverage plants—these tanks attach to a compressed air source for use in sanitary environments. A dip tube draws liquid from the bottom of these tanks for dispensing and spraying. They’re made of 316L stainless steel for excellent corrosion resistance, and have an electropolished finish that prevents product buildup and bacterial growth. Connect them to valves, hose, and caps with quick-clamp sanitary tube fittings, which are easier to sanitize than threaded fittings. Tanks comply with ASME BPVC.VIII safety standards for pressure vessels.

Safety regulations restrict sales to the listed jurisdictions/areas.

For technical drawings and 3-D models, click on a part number.

Overall | Gauge Port | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Maximum Pressure @ 100° F, psi | Diameter | Height | Opening Diameter | Flange OD | Gender | Number of | Temperature Range, °F | Specifications Met | Cannot Be Sold To | Each | |

Tanks without Mounting Plate | ||||||||||||

Electropolished 316L Stainless Steel | ||||||||||||

| 5 | 185 | 9" | 23" | 3" | 1 1/2" | Female | 4 | -20° to 100° | ASME BPVC.VIII.1 | Canada | 0000000 | 000000000 |

Pails and Snap-Lock Lids

and Telescoping

Spout

Keep contents secure with these pails and tight-fitting lids.

Lids with tear tab have a tamper-evident sealing ring with tab.

Lids with telescoping spout allow controlled pouring.

Pails | Replacement Lids with Tear Tab | Lids with Tear Tab and Telescoping Spout | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Ht. | Bottom ID | Seal Material | Max. Temp., °F | Specifications Met | Space Saving Features | Choose a Color | Each | Each | Each | |||

Polyethylene Plastic | ||||||||||||||

| 5 | 12" | 14 3/4" | 10 1/8" | EPDM Rubber | 140° | FDA Compliant 21 CFR 177.1520 | Nestable | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |

Pails | Replacement Lids with Tear Tab | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Dia. | Ht. | Bottom ID | Graduation Marks | Seal Material | Max. Temp., °F | Specifications Met | Space Saving Features | Color | Each | Each | ||

Polyethylene Plastic | |||||||||||||

| 5 | 11 3/4" | 14 3/4" | 10 3/8" | 1/2 gal., 1 L | EPDM Rubber | 140° | FDA Compliant 21 CFR 177.1520 | Nestable | Semi-Clear White | 000000 | 000000 | 0000000 | 00000 |

Rectangular UN-Compliant Chemical-Resistant

Shipping Jugs with Tamper-Evident Seal

Prevent the absorption of harsh solvents, cleaning agents, and adhesives to safely ship hazardous liquids. These jugs have a security ring on the lid that separates when the jugs are opened. They’re also known as closed-head pails. All of these jugs are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Jugs with a pouring vent let air escape while you're filling up.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials, and ensure the appropriate method for shipping.

Lid | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Color | Material | Mouth OD | Features | Max. Temp., °F | Shipping Standard | Color | Each | |

For Shipping Hazardous Liquids | ||||||||||||

HDPE Plastic with EPDM Rubber Seal | ||||||||||||

| 5 | 10 3/8" | 11" | 14 3/4" | Semi-Clear White | HDPE Plastic | 2 3/4" | Pouring Vent with Cap, Security Ring | 130° | UN3H1/Y1.8/100 | Semi-Clear White | 0000000 | 000000 |

| 5 | 11" | 10 1/8" | 14 1/4" | White | HDPE Plastic | 2 3/8" | Security Ring | 170° | UN3H1/Y1.8/100 | White | 00000000 | 00000 |

Rectangular UN-Compliant Shipping Jugs

Also known as closed-head pails, these jugs have a small top opening. Made of HDPE, they resist chemicals and prevent the absorption of harsh solvents, cleaning agents, and adhesives to safely ship hazardous liquids. These jugs are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

Lid | Lid Knockout | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Seal Material | Color | Material | Pipe Size | Gender | Thread Type | Mouth OD | Max. Temp., °F | Shipping Standard | Color | Each | |

For Shipping Hazardous Liquids | |||||||||||||||

HDPE Plastic | |||||||||||||||

| 5 | 11 3/4" | 9 3/4" | 14 5/8" | EPDM | Natural | Polyethylene Plastic | 3/4 | Female | NPT | 2 3/4" | 150° | UN3H1/Y1.8/100 | Semi-Clear Natural | 0000000 | 000000 |

Round UN-Compliant Shipping Jugs

Also known as closed-head pails, these have a small top opening. They are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Steel jugs have an epoxy lining that resists rusting from water and corroding from chemicals.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

Lid | Lid Knockout | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Seal Material | Color | Material | Pipe Size | Gender | Thread Type | Mouth OD | Features | Max. Temp., °F | Shipping Standard | Choose a Color | Each | |

For Shipping Hazardous Liquids | |||||||||||||||

Steel | |||||||||||||||

| 5 | 11" | 13 5/8" | __ | __ | Tin-Plated Steel | __ | __ | __ | 2 1/8" | Telescoping Spout | __ | UN1A1/Y1.8/170 | 0000000 | 00 | |

Polyethylene Plastic | |||||||||||||||

| 5 | 11 1/2" | 14 7/8" | Rubber | Off-White | HDPE Plastic | __ | __ | __ | 2 3/4" | __ | 145° | UN1H1/Y1.8/100 | Blue | 00000000 | 000000 |

| 5 | 11 1/2" | 14 7/8" | Rubber | Off-White | HDPE Plastic | 3/4 | Female | NPT | 2 3/4" | __ | 145° | UN1H1/Y1.8/100 | Semi-Clear White | 00000000 | 00000 |

UN-Compliant Rigid Plastic Shipping Jugs with Packing Kit

These jugs hold their shape as liquid is dispensed. They come with a cardboard box for protection. All are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling. All of these jugs have threads for attaching a spigot.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

Lid | Handle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Jugs | Cap., gal. | Color | Material | Type | Material | Color | Mouth OD | Material | Type | Features | Shipping Standard | Each | |

For Shipping Hazardous Liquids | |||||||||||||

| 1 | 5 | Semi-Clear White | Polyethylene Plastic | Threaded | HDPE Plastic | Semi-Clear White | 2 3/4" | Plastic | Molded | Pouring Vent with Cap | CFR Title 49 for Packing Group II; CFR Title 49 for Packing Group III; UN4G/Y30/S | 00000000 | 000000 |

UN-Compliant Collapsible Plastic Shipping Jugs with Packing Kit

The jug inside these containers collapses as it dispenses for uninterrupted flow. The jug is protected by a cardboard box with an opening to access the jug’s spout. Use them together to ship hazardous liquids. The jug is tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials, and ensure the appropriate method for shipping.

Lid | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Color | Material | Type | Material | Color | Mouth OD | Features | Shipping Standard | Each | |

For Shipping Hazardous Liquids | ||||||||||

| 5 | Clear | Polyethylene Plastic | Threaded | Polypropylene Plastic | White | 1 1/2" | Easy-Access Spout | CFR Title 49 for Packing Group II; CFR Title 49 for Packing Group III; UN4G/Y32/S | 000000 | 000000 |