Steel Drums

All drums are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 0000000 | 0000000 |

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S | 0000000 | 0000000 |

Openings | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Pipe Size | Gender | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||||

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | 2 NPSM, 3/4 NPSM | Female | Stackable | UN1A2/X120/S | 00000000 | 0000000 |

Openings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Gauge | Weight Cap. | Color | Pipe Size | Gender | Space Saving Features | Shipping Standard | Each | |

Painted Steel | |||||||||||

| 10 | 15" | 19 1/4" | 20 | Not Rated | Black | 2 NPSM, 3/4 NPSM | Female | Stackable | UN1A1/X1.4/250 | 0000000 | 0000000 |

| For Drum Capacity, gal. | Each | |

| 16, 10 | 00000000 | 00000 |

Corrosion-Resistant Steel Drums

The inside of these drums is epoxy coated to resist rust. Drums are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 00000000 | 0000000 |

Leverlock Closing Ring

and Lid with No Openings

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S | 00000000 | 0000000 |

| For Drum Capacity, gal. | Gauge | Each | |

Lid with No Openings | |||

|---|---|---|---|

| 16, 10 | 20 | 00000000 | 000000 |

Stainless Steel Drums

These drums are corrosion resistant and are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

304 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 0000000 | 0000000 |

Openings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Gauge | Weight Cap. | Pipe Size | Gender | Space Saving Features | Shipping Standard | Each | |

304 Stainless Steel | ||||||||||

| 10 | 15" | 19" | 20 | Not Rated | 2 BSPP, 3/4 BSPP | Female | Stackable | UN1A1/X1.4/250 | 0000000 | 0000000 |

304 Stainless Steel | ||||

|---|---|---|---|---|

| For Drum Capacity, gal. | Gauge | Seal Material | Each | |

Lid with No Openings | ||||

| 16, 10, 8 | 20 | EPDM Rubber | 0000000 | 0000000 |

| For Drum Capacity, gal. | Each | |

| 16, 10 | 00000000 | 00000 |

| For Drum Capacity, gal. | Each | |

Nut-and-Bolt Closing Ring | ||

|---|---|---|

| 16, 10 | 00000000 | 000000 |

Food Industry Stainless Steel Drums

In addition to being corrosion resistant, these drums have smooth, welded seams to prevent food and chemicals from collecting in crevices.

Closed-head drums have a lid that’s permanently sealed, so the only way to access the contents inside is through the two lid openings. They’re often used to hold wine and other liquids because they’re less likely to leak or spill than open-head drums. All are UN compliant for shipping.

For technical drawings and 3-D models, click on a part number.

Drums | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Connection | Replacement Drum Plugs for Pipe Size 3/4 | Replacement Drum Plugs for Pipe Size 2 | ||||||||||||||

| Capacity, gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Capacity | Seal Material | Gender | Thread Type | Pipe Size | Shipping Standard | Each | Each | Each | |||

304 Stainless Steel | ||||||||||||||||

| 10 | 14 1/2" | 19 1/2" | 14" | 18 | Not Rated | PTFE Plastic | Female | NPSM | 3/4, 2 | UN1A1/X1.8/550 | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 000000 |

Salvage/Overpack Drums

Use these drums for secondary containment or for temporarily storing and transporting leaking containers. All drums are UN-compliant for shipping.

| For Drum Cap., gal. | Cap., gal. | Weight Cap., lbs. | Dia. | Ht. | Bottom ID | Inside Ht. | Gauge | Color | Lid Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

With Nut-and-Bolt Closing Ring | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 250 | 14 1/4" | 19 1/4" | 14" | 17" | 20 | Yellow | Red | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 0000000 | 0000000 |

With Leverlock Closing Ring | |||||||||||||||

| 5 | 10 | 250 | 14 1/4" | 19" | 14" | 17" | 20 | Yellow | Red | EPDM Rubber | Steel | Stackable | UN1A2/X120/S | 0000000 | 000000 |

Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 14 3/4" | 20 1/2" | 13" | 3/16" | 1 gal. | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

High-Temperature Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 14 3/4" | 20 1/2" | 13" | 3/16" | 1 gal. | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

Rectangular Plastic Batch Cans with Faucet

A built-in faucet allows easy dispensing.

For technical drawings and 3-D models, click on a part number.

Bottom Inside | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||||

| 10 | 19 3/4" | 15" | 10" | 18" | 13" | 1/4" | White | Semi-Clear | Loose Fitting | Polyethylene Plastic | PTFE Plastic | 175° | Stackable | Seamless | 0000000 | 0000000 |

Food Industry Round Metal Batch Cans

These metal batch cans meet NSF/ANSI 2 standards for food-processing equipment.

For technical drawings and 3-D models, click on a part number.

Narrow-Mouth Round Stainless Steel Batch Cans

Also known as milk cans, these have a narrow mouth for controlled pouring. They have a reinforced bottom to minimize wear and tear when sliding cans along the floor. The lid has two 7/16" dia. holes for attaching a tag.

| Capacity, gal. | Dia. | Ht. | Mouth OD | Gauge | Appearance | Lid Type | Each | |

304 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10 | 13 1/4" | 23 3/4" | 7 1/2" | 18 | Dull | Tight Fitting | 000000 | 0000000 |

Round Stainless Steel Batch Cans with Faucet

A built-in faucet allows easy dispensing.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Appearance | Faucet Material | Seal Material | Each | |

304 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10 | 13 1/4" | 19" | 13 1/4" | 18 | Dull | 316 Stainless Steel | PTFE Plastic | 0000000 | 0000000 |

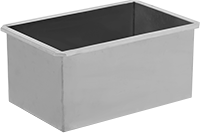

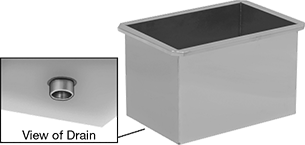

Rectangular Stainless Steel Batch Cans

316 stainless steel is more corrosion resistant than 304 stainless steel.

Batch cans with drain have a drain centered on the bottom of the can.

Double-Wall Plastic Tanks

No need for separate spill-control pallets or trays—comply with EPA regulations for storing hazardous liquids with just one tank. These tanks have two walls, so if the primary compartment ruptures, the secondary one will contain the leak. It can hold 110% of the primary tank's volume and will also protect it from damage in case of impact.

Made of polyethylene, these tanks can store a broader range of chemicals than steel double-wall tanks. The plastic contains UV inhibitors so they can be used outside.

These tanks have a flat space on top where you can mount a metering pump. Because these tanks meet NSF/ANSI 61 for drinking water, you can meter chemicals stored in them into your drinking water system.

For technical drawings and 3-D models, click on a part number.

| Cap., gal. | Wd. | Dp. | Ht. | Primary Compartment Opening (No. of) | Secondary Compartment Opening (No. of) | Color | Max. Temp., °F | Specifications Met | Includes | Each | |

Polyethylene Plastic | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 14" | 14" | 22" | 4" Fill Opening Dia. (1) 3/8" Opening Dia. (1) 2 NPT Female Opening (1) | 1 NPT Female Opening (1) | Blue | 130° | EPA 40 CFR 264.175 NSF/ANSI 61 | Vented Fill Cap | 0000000 | 0000000 |

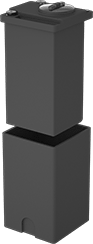

Plastic Easy-Drain Tanks

Optional Stand

with Mixer Mount

The seamless, heavy-wall construction makes these tanks durable and easy to clean. The bottom is sloped to ensure easy drainage.

Stands (sold separately) allow a 14 1/4" minimum clearance from the bottom of drain to the floor.

For technical drawings and 3-D models, click on a part number.

Wall-Mount Plastic Easy-Drain Tanks

These tanks are often used as gravity-fed dispensers.

For technical drawings and 3-D models, click on a part number.

Drain | Mounting Holes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Pipe Size | Gender | Bottom Slope Angle | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | UV Protection | Includes | Each | |

Polyethylene Plastic | ||||||||||||||||||

| 10 | 13" | 13" | 21 1/2" | 1/4" | 8" | 1 gal. | White | 1 1/4 NPT | Female | 54° | 120° | 6 | 5/16" | No | UV Resistant | Vented Fill Cap | 0000000 | 0000000 |

| Replacement Polypropylene Plastic Fill Cap For 8" Fill Opening Dia. | 0000000 | Each | 000000 |

Pressurized Liquid Dispensing Tanks

Attach a compressed air source to pressurize liquids for dispensing and spraying. Tanks have a dip tube that draws liquid from the bottom of the tank. All tanks meet the ASME rating for pressure vessels.

304 stainless steel tanks have good corrosion resistance.

316 stainless steel tanks have excellent corrosion resistance.

Tanks that cannot be sold to the listed areas are restricted due to safety regulations.

For technical drawings and 3-D models, click on a part number.

Overall | Opening | Port | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Max. Pressure @ 100°F, psi | Dia. | Ht. | Lg. | Wd. | Pipe Size | Thread Type | Gender | No. of | Temp. Range, °F | Specifications Met | Cannot Be Sold To | Each | |

Tanks without Mounting Plate | ||||||||||||||

304 Stainless Steel | ||||||||||||||

| 10 | 129 | 12" | 25" | 4 7/8" | 5 7/8" | 1/4 | NPT | Female | 4 | -20° to 200° | ASME BPVC.VIII.1 | Canada | 00000000 | 000000000 |

| 10 | 165 | 12" | 25" | 3 1/4" | 3 7/8" | 1/4 | NPT | Female | 4 | -20° to 200° | ASME BPVC.VIII.1 | Canada | 00000000 | 00000000 |

316 Stainless Steel | ||||||||||||||

| 10 | 115 | 12" | 25" | 4 7/8" | 5 7/8" | 1/4 | NPT | Female | 4 | -20° to 300° | ASME BPVC.VIII.1 | Canada | 00000000 | 00000000 |

| 10 | 190 | 12" | 25" | 3 1/4" | 3 7/8" | 1/4 | NPT | Female | 4 | -20° to 300° | ASME BPVC.VIII.1 | Canada | 0000000 | 00000000 |

Vacuum closure caps are required to use tanks in vacuum applications.

Sanitary Pressurized Liquid Dispensing Tanks

Store and dispense liquids in food, pharmaceutical, and beverage plants—these tanks attach to a compressed air source for use in sanitary environments. A dip tube draws liquid from the bottom of these tanks for dispensing and spraying. They’re made of 316L stainless steel for excellent corrosion resistance, and have an electropolished finish that prevents product buildup and bacterial growth. Connect them to valves, hose, and caps with quick-clamp sanitary tube fittings, which are easier to sanitize than threaded fittings. Tanks comply with ASME BPVC.VIII safety standards for pressure vessels.

Safety regulations restrict sales to the listed jurisdictions/areas.

For technical drawings and 3-D models, click on a part number.

Overall | Gauge Port | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Maximum Pressure @ 100° F, psi | Diameter | Height | Opening Diameter | Flange OD | Gender | Number of | Temperature Range, °F | Specifications Met | Cannot Be Sold To | Each | |

Tanks without Mounting Plate | ||||||||||||

Electropolished 316L Stainless Steel | ||||||||||||

| 10 | 125 | 12" | 25" | 3" | 1 1/2" | Female | 4 | -20° to 100° | ASME BPVC.VIII.1 | Canada | 0000000 | 000000000 |