Compare material, finish, length class, and decimal size equivalents.

About Masonry Drill Bits

More

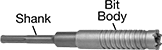

Changeable-Size SDS-Max-Shank Masonry Core Drill Bits for Rotary Hammers

These bits allow you to switch to another size by changing only the bit body. They are hollow and cut with their outside edge for drilling large holes. The SDS-Max shank has three deep slots and two shallow slots for use with SDS-Max-drive rotary hammers. They cannot be used with SDS-Plus-drive rotary hammers.

Drill holes using simultaneous rotary and hammering action to break masonry material into tiny granules. This type of bit drills faster and penetrates material with less pressure than rotary-only bits. Also known as percussion or impact bits. To achieve maximum drilling depth, break up and remove the core every 4” before drilling deeper.

Drill bits include a pilot drill to make starting holes easier.

For technical drawings and 3-D models, click on a part number.

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Shank Type | Point Style | Specifications Met | For Use On | Includes | Each | |

Uncoated Carbide-Tipped Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 1.5" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 0000000 |

| 1 3/4" | 1.75" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 2" | 2" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 2 1/2" | 2.5" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 3" | 3" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 3 1/2" | 3.5" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 4" | 4" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 4 1/2" | 4.5" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 5" | 5" | 17" | 12" | SDS Max | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Material | Specifications Met | Each | |

| 1 1/2" | 1.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 0000000 |

| 1 3/4" | 1.75" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 2" | 2" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 2 1/2" | 2.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 3" | 3" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 3 1/2" | 3.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 4" | 4" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 4 1/2" | 4.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 5" | 5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| For Drill Bit Size | Material | Each | |

| 1 1/2", 1 3/4", 2 1/2", 2", 3 1/2", 3", 4 1/2", 4", 5" | Carbide-Tipped Steel | 0000000 | 000000 |

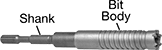

Changeable-Size Spline-Shank Masonry Core Drill Bits for Rotary Hammers

These bits allow you to switch to another size by changing only the bit body. They are hollow and cut with their outside edge for drilling large holes. The shank has 12 splines for use with a spline-drive rotary hammer. Drill holes using simultaneous rotary and hammering action to break masonry material into tiny granules. This type of bit drills faster and penetrates material with less pressure than rotary-only bits. Also called percussion or impact bits.

Drill bits include a pilot drill to make starting holes easier.

For technical drawings and 3-D models, click on a part number.

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Shank Type | Point Style | Specifications Met | For Use On | Includes | Each | |

Uncoated Carbide-Tipped Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 1.5" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 0000000 |

| 1 3/4" | 1.75" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 2" | 2" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 2 1/2" | 2.5" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 3" | 3" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 3 1/2" | 3.5" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 4 1/2" | 4.5" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| 5" | 5" | 17" | 12" | Spline | Standard | ANSI B212.15 | Masonry, Concrete | Pilot Drill | 00000000 | 000000 |

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Material | Specifications Met | Each | |

| 1 1/2" | 1.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 0000000 |

| 1 3/4" | 1.75" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 2" | 2" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 2 1/2" | 2.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 3" | 3" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 3 1/2" | 3.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 4 1/2" | 4.5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| 5" | 5" | 5" | Uncoated Carbide-Tipped Steel | ANSI B212.15 | 0000000 | 000000 |

| For Drill Bit Size | Material | Each | |

| 1 1/2", 1 3/4", 2 1/2", 2", 3 1/2", 3", 4 1/2", 4", 5" | Carbide-Tipped Steel | 0000000 | 000000 |

Carbide Hole-Starting Drill Bits

Harder, stronger, and more wear resistant than cobalt steel, solid-carbide bits maintain their sharp edges longer. They require rigid toolholding to prevent breakage and should not be used in hand-held drilling applications. The short flute and length keep these bits straight for accurate placement when starting holes that will be drilled deeper with a longer bit. Also known as spotting drill bits.

Bits with a 120° point angle are for starting a hole that will be followed by a drill bit with a point angle from 90° to 118°.

For technical drawings and 3-D models, click on a part number.

Shank | 120° Point Angle | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | For Use On | Each | |

Inch | |||||||||

Titanium Aluminum Nitride (TiAlN) Coated Carbide | |||||||||

| 1/8" | 0.125" | 2" | 1/8" | Round | 1/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Brass, Bronze, Fiberglass, Plastic | 00000000 | 000000 |

| 3/16" | 0.1875" | 2" | 3/16" | Round | 3/16" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 1/4" | 0.25" | 2 1/2" | 1/4" | Round | 1/4" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 5/16" | 0.3125" | 2 1/2" | 5/16" | Round | 5/16" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 3/8" | 0.375" | 2 1/2" | 3/8" | Round | 3/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 1/2" | 0.5" | 3" | 1/2" | Round | 1/2" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

Titanium Nitride (TiN) Coated Carbide | |||||||||

| 1/8" | 0.125" | 2" | 1/8" | Round | 1/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 3/16" | 0.1875" | 2" | 3/16" | Round | 3/16" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 1/4" | 0.25" | 2 1/2" | 1/4" | Round | 1/4" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 5/16" | 0.3125" | 2 1/2" | 5/16" | Round | 5/16" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 3/8" | 0.375" | 2 1/2" | 3/8" | Round | 3/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

| 1/2" | 0.5" | 3" | 1/2" | Round | 1/2" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 00000000 | 00000 |

Uncoated Carbide | |||||||||

| 1/8" | 0.125" | 2" | 1/8" | Round | 1/8" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

| 3/16" | 0.1875" | 2" | 3/16" | Round | 3/16" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

| 1/4" | 0.25" | 2 1/2" | 1/4" | Round | 1/4" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 0000000 | 00000 |

| 5/16" | 0.3125" | 2 1/2" | 5/16" | Round | 5/16" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

| 3/8" | 0.375" | 2 1/2" | 0.38" | Round | 3/8" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 0000000 | 00000 |

| 1/2" | 0.5" | 3" | 1/2" | Round | 1/2" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 0000000 | 00000 |

| 5/8" | 0.625" | 3 1/2" | 0.63" | Round | 5/8" | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 0000000 | 000000 |

Metric | |||||||||

Titanium Nitride (TiN) Coated Carbide | |||||||||

| 8 mm | 0.315" | 63mm | 8mm | Round | 8mm | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Aluminum, Brass, Bronze, Fiberglass, Plastic | 0000000 | 00000 |

Uncoated Carbide | |||||||||

| 3 mm | 0.1181" | 57mm | 3mm | Round | 3mm | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

| 5 mm | 0.1968" | 63mm | 5mm | Round | 5mm | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

| 6 mm | 0.2362" | 63mm | 6mm | Round | 6mm | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

| 10 mm | 0.3937" | 70mm | 10mm | Round | 10mm | Standard | Steel, Iron, Stainless Steel, Aluminum, Brass, Bronze, Plastic | 00000000 | 00000 |

Cobalt Steel Hole-Starting Drill Bits

The short flute and length keep these bits straight for accurate placement when starting holes that will be drilled deeper with a longer bit. Also known as spotting drill bits. Cobalt steel bits are heat resistant and maintain their sharp edges when drilling hard material. They are for use in both hand-held drilling and machine-tool applications.

Titanium-aluminum-nitride (TiAlN) coated drill bits resist wear and temperature better than uncoated drill bits, so they last longer and can drill at higher speeds.

Bits with a 120° point angle are for starting a hole that will be followed by a drill bit with a point angle from 90° to 118°.

For technical drawings and 3-D models, click on a part number.

Shank | 120° Point Angle | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Drill Bit Size | Decimal Size Equivalent | Overall Lg. | Max. Drilling Dp. | Type | Size | Point Style | For Use On | Each | |

Inch | |||||||||

Uncoated Cobalt Steel | |||||||||

| 1/4" | 0.25" | 2 5/8" | 0.89" | Round | 1/4" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 000000 |

| 3/8" | 0.375" | 3 1/2" | 1" | Round | 3/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |

| 1/2" | 0.5" | 4" | 1.38" | Round | 1/2" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |

| 5/8" | 0.625" | 4 1/2" | 1.38" | Round | 5/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |

| 3/4" | 0.75" | 5 1/8" | 1.63" | Round | 3/4" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |

Titanium Aluminum Nitride (TiAlN) Coated Cobalt Steel | |||||||||

| 1/4" | 0.25" | 2 5/8" | 1.38" | Round | 1/4" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 000000000 | 00000 |

| 3/8" | 0.375" | 3 1/2" | 1" | Round | 3/8" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 000000000 | 00000 |

| 1/2" | 0.5" | 4" | 1.38" | Round | 1/2" | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel, Titanium, Fiberglass | 000000000 | 00000 |

Metric | |||||||||

Uncoated Cobalt Steel | |||||||||

| 4.0 mm | 0.1575" | 52mm | 12.7mm | Round | 4mm | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |

| 5.0 mm | 0.1968" | 60mm | 15mm | Round | 5mm | Standard | Steel, Hardened Steel, Tool Steel, Iron, Stainless Steel, Nickel | 00000000 | 00000 |