Filter by

System of Measurement

Overall Length

Shank Type

For Use On

Length Class

Machine Taper Number

Drill Bit Point Type

Material

Finish

Number of Flutes

Flute Direction

Export Control Classification Number (ECCN)

Length

For Drilling Type

DFARS Specialty Metals

Bit Style

Flute Type

Sold As

Morse Taper Diameter

About Drill Bits

Compare material, finish, length class, and decimal size equivalents.

Cobalt Steel Drill Bits

Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Drill Bit Size | Decimal Size Equiv. | Overall Lg. | Max. Drilling Dp. | Type | Size | Drill Bit Point Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Jobbers' Length | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | 1.0625" | 12 1/4" | 6.63" | Morse Taper | Morse 4 | Split | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide-Tipped Drill Bits for Masonry and Concrete

SDS-Plus Shank for Hammer and Rotary Drilling

| |

SDS-Plus Shank |

Drill Bit Size | Decimal Size Equiv. | Overall Lg. | Max. Drilling Dp. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.25" | 12 1/4" | 9.63" | ANSI B212.15 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

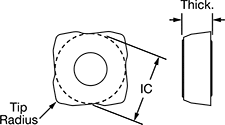

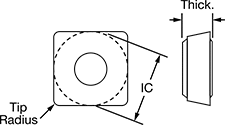

Carbide-Insert Drill Bits

Drill Bits | Replacement Insert Screws | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Shank | For Insert | |||||||||||||

Drill Bit Size | Decimal Size Equiv. | Overall Lg. | Max. Drilling Dp. | Type | Size | Drill Bit Point Type | Inner Inscribed Circle Dia. | Outer Inscribed Circle Dia. | Each | Each | ||||

| 1 5/8" | 1.625" | 12 1/4" | 8.13" | Round | 1 1/2" | Carbide Insert | 0.486" | 0.498" | 0000000 | 000000000 | 0000000 | 00000 | ||

| 2 1/2" | 2.5" | 12 1/4" | 7 1/2" | Round | 1 1/2" | Carbide Insert | 0.705" | 0.732" | 0000000 | 00000000 | 0000000 | 0000 | ||

DeWalt Electric Drills

Style | For Max. Bit Shank Size | Max. No-Load Rotational Speed, rpm | Chuck Type | Chuck Key Included | Current, amp | Gear Housing Material | Overall Lg. | Wt., lb. | Mfr. Model No. | Certification | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pistol Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/2" | 1,250 | Keyed | Yes | 10 | Metal | 12 1/4" | 5 | DWD210G | CSA Certified, UL Listed | 360° Adjustable Side Handle | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||