About Exhaust Fans

More

About Duct Connections

More

About Sound Levels

Measured in decibels (dB), volume ratings indicate how much noise equipment makes. Some common volume levels include a whisper @ 20 dB, a refrigerator @ 40 dB, a conversation @ 60 dB, and a light machine shop @ 90 dB. OSHA recommends hearing protection for exposure to 80 dB and greater.

Direct-Drive Downdraft Roof-Mount Exhaust Fans

Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance. More economical than upblast roof-mount exhaust fans, these draw stagnant and humid air out through your roof and then direct it back toward the roof. All fans have a disconnect switch to turn off the power for servicing.

Fans with a brushless motor are more efficient than fans with a standard motor. They operate at a wide range of speeds for precise speed control and greater energy savings. They’re also quieter and have a longer lifespan because of their advanced electronic controls.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

For technical drawings and 3-D models, click on a part number.

Fans | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting Bases | |||||||||||||||

| Blade Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Base Wd. | Wt., lbs. | Max. Ambient Temp., °F | Housing Material | Specifications Met | Each | Each | |||

Totally Enclosed Motor Enclosure | ||||||||||||||||

120V AC, Single Phase—Hardwire | ||||||||||||||||

| 1 | 10" | 60 cfm @ 1/2 in. of H₂O 500 cfm @ 0 in. of H₂O | Not Rated | 1,500 | 1/30 | 18 5/16" | 11 1/4" | 19" | 21 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 0000000 | 0000000 | 0000000 |

| 1 | 12" | 430 cfm @ 1/2 in. of H₂O 830 cfm @ 0 in. of H₂O | Not Rated | 1,500 | 1/10 | 20 5/16" | 11 3/4" | 19" | 30 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 1 | 14" | 520 cfm @ 1/2 in. of H₂O 1,100 cfm @ 0 in. of H₂O | Not Rated | 1,100 | 1/6 | 27 5/16" | 14 5/8" | 21" | 39 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 1 | 18" | 1,200 cfm @ 1/2 in. of H₂O 2,400 cfm @ 0 in. of H₂O | Not Rated | 1,100 | 1/3 | 33 9/16" | 16 3/8" | 26" | 60 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

Totally Enclosed Motor Enclosure—Brushless Motor | ||||||||||||||||

120V AC, Single Phase—Hardwire | ||||||||||||||||

| 2 | 12" | 1,000 cfm @ 1/2 in. of H₂O 1,300 cfm @ 0 in. of H₂O | 66 dBA @ 5 ft. | 1,575 | 1/3 | 26 1/4" | 19 1/8" | 21" | 54 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 2 | 14" | 1,900 cfm @ 1/2 in. of H₂O 2,300 cfm @ 0 in. of H₂O | 68 dBA @ 5 ft. | 1,525 | 1/2 | 29 3/4" | 21 3/4" | 21" | 61 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 16" | 2,850 cfm @ 1/2 in. of H₂O 3,300 cfm @ 0 in. of H₂O | 71 dBA @ 5 ft. | 1,525 | 1 | 33 1/4" | 23 3/8" | 24" | 74 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

Open Dripproof Motor Enclosure | ||||||||||||||||

120V AC, Single Phase—Hardwire | ||||||||||||||||

| 2 | 9" | 100 cfm @ 1/2 in. of H₂O 400 cfm @ 0 in. of H₂O | 50 dBA @ 5 ft. | 1,250 | 1/32 | 20 3/4" | 14 1/2" | 19" | 40 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 2 | 11" | 600 cfm @ 1/2 in. of H₂O 800 cfm @ 0 in. of H₂O | 57 dBA @ 5 ft. | 1,625 | 3/16 | 23 3/4" | 16 1/4" | 19" | 37 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 2 | 12" | 950 cfm @ 1/2 in. of H₂O 1,250 cfm @ 0 in. of H₂O | 62 dBA @ 5 ft. | 1,625 | 1/4 | 26 1/4" | 19 1/8" | 21" | 53 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 2 | 14" | 1,800 cfm @ 1/2 in. of H₂O 2,100 cfm @ 0 in. of H₂O | 66 dBA @ 5 ft. | 1,625 | 1/2 | 29 3/4" | 21 3/4" | 21" | 56 | Not Rated | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

| 2 | 16" | 2,600 cfm @ 1/2 in. of H₂O 3,100 cfm @ 0 in. of H₂O | 70 dBA @ 5 ft. | 1,450 | 3/4 | 33 1/4" | 23 3/8" | 24" | 77 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 000000 | 0000000 | 000000 |

208/230V AC, Three Phase—Hardwire | ||||||||||||||||

| 3 | 19" | 4,500 cfm @ 1/2 in. of H₂O 5,000 cfm @ 0 in. of H₂O | 75 dBA @ 5 ft. | 1,300 | 2 | 38 15/16" | 32 3/4" | 28" | 189 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 21" | 6,200 cfm @ 1/2 in. of H₂O 6,700 cfm @ 0 in. of H₂O | 82 dBA @ 5 ft. | 1,400 | 5 | 38 15/16" | 32 1/4" | 28" | 201 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 24" | 8,100 cfm @ 1/2 in. of H₂O 9,000 cfm @ 0 in. of H₂O | 73 dBA @ 5 ft. | 925 | 3 | 43 7/16" | 37 1/4" | 33" | 288 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 30" | 10,400 cfm @ 1/2 in. of H₂O 11,500 cfm @ 0 in. of H₂O | 69 dBA @ 5 ft. | 700 | 5 | 52 13/16" | 44" | 40" | 467 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

| 3 | 36" | 11,000 cfm @ 1/2 in. of H₂O 13,500 cfm @ 0 in. of H₂O | 64 dBA @ 5 ft. | 450 | 5 | 63 5/16" | 49 1/2" | 44" | 532 | 120° | Aluminum | AMCA Certified, ETL Listed | 0000000 | 00000000 | 0000000 | 000000 |

Belt-Drive Downdraft Roof-Mount Exhaust Fans

Belt-drive fans are quieter and have a longer life span than direct-drive fans because components can be replaced if worn or damaged. More economical than upblast roof-mount exhaust fans, these draw stagnant and humid air out through your roof and then direct it back toward the roof.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Fans | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting Bases | |||||||||||

| Blade Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Base Wd. | Housing Material | Each | Each | ||

Open Dripproof Motor Enclosure | ||||||||||||

120/208-230V AC, Single Phase—Hardwire | ||||||||||||

| 16" | 2,800 cfm @ 1/2 in. of H₂O 3,200 cfm @ 0 in. of H₂O | 70 dBA @ 5 ft. | 1,145 | 3/4 | 33 11/16" | 29 1/4" | 26" | Aluminum | 0000000 | 000000000 | 0000000 | 0000000 |

| 20" | 4,900 cfm @ 1/2 in. of H₂O 5,400 cfm @ 0 in. of H₂O | 74 dBA @ 5 ft. | 1,080 | 1 1/2 | 38 1/4" | 31 3/4" | 30" | Aluminum | 0000000 | 00000000 | 0000000 | 000000 |

208-230/460V AC, Three Phase—Hardwire | ||||||||||||

| 24" | 6,900 cfm @ 1/2 in. of H₂O 7,750 cfm @ 0 in. of H₂O | 73 dBA @ 5 ft. | 875 | 2 | 44 1/4" | 39 11/16" | 33" | Aluminum | 0000000 | 00000000 | 0000000 | 000000 |

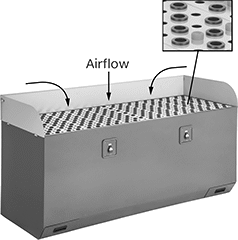

Downdraft Tables for Metalworking

Pull metal particles from grinding, cutting, and finishing workpieces out of the air to avoid breathing them and creating sparks in your work area. Blowers draw particles into these tables through holes in the surface. Once inside, the particles are captured with filters, and clean air is released back into your space. These tables are best for jobs that create large particles. You shouldn’t use them with fine powders, such as dust from sanding aluminum, titanium, and steel. The filters are made of aluminum, which means they won't spark if metal particles hit them.

Vertical shields on the sides of these tables help protect you from flying debris. They’re removable, so you can make space for large workpieces. The removable trays at the bottom of these tables catch large chips and scraps, making them easy to clean up.

Tables | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Opening | Replacement Filters | ||||||||||||||

| Airflow, cfm | Horsepower, hp | Current, A | Volume, dBA | Removes Particle Size Down To, microns | Ht. | Wd. | Dp. | Lg. | Wd. | O'all Cap., lbs. | Features | Includes | Each | Each | ||

Powder-Coated Steel Frame with Stainless Steel Top | ||||||||||||||||

120V AC, 60Hz—Hardwire | ||||||||||||||||

| 1,790 | 1/2 | 6 | 78 | 250 | 34 3/4" | 65 3/4" | 24 3/4" | 2" | 7/8" | 440 | Removable Side Shields, Removable Tray | Four 250 Micron Fireproof Filters | 00000000 | 000000000 | 00000000 | 0000000 |

Downdraft Tables for Woodworking

Keep large particles out of the air while cutting and routing wood products. Air blowers pull particles into the table through holes in the surface, making sure you don't breathe them. Tables have a blower on each side for even suction across the table surface. Inside the table, filters remove the particles, and exhaust vents release clean air back into your shop.

These tables should only be used with wood, plastic composites, and other non-combustible materials. Do not use them to filter materials that may create sparks, such as metallic dust. They are not designed to filter liquids, exhaust fumes, or smoke.

Rubber grommets built into the surface help keep your workpiece from slipping. The removable tray catches large chips and scraps that fall to the bottom of the table, making them easy to clean up. These tables have side shields to protect you from flying debris, which fold down if you need to make space for large workpieces. When doing precision work, use the removable plugs to block holes in the tabletop so small parts don't fall through.

Tables | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Replacement 0.3 Micron Filters | Replacement 1 Micron Filters | ||||||||||||||

| Airflow, cfm | Horsepower, hp | Current, A | Volume, dBA | Ht. | Wd. | Dp. | Opening Dia. | O'all Cap., lbs. | Features | Includes | Each | Each | Each | |||

Powder-Coated Steel Frame and Top | ||||||||||||||||

110V AC, 60Hz—Hardwire | ||||||||||||||||

| 2,874 | 1 | 12 | 68 | 39 3/4" | 78 3/4" | 27 3/4" | 3/4", 1 1/8" | 880 | Antislip Rubber Grommets, Removable Side Shields, Removable Tray | Removable Plugs, Two 0.3 Micron Filters, Two 1 Micron Filters | 00000000 | 000000000 | 00000000 | 000000 | 00000000 | 000000 |

Standard Duct and Fittings

No need for clamps or connectors—duct and fittings press-fit together. Male ends are crimped or tapered, making them slightly smaller than a female end for simple assembly.

Galvanized steel has good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Downdraft diverters have an internal cone that prevents drafts from extinguishing pilot lights.

Galvanized Steel | ||||||

|---|---|---|---|---|---|---|

| Duct Size | Female ID | Male OD | Gauge | End Construction | Each | |

| 3 | 3" | 2 7/8" | 26 | Crimped | 0000000 | 000000 |

| 4 | 4" | 3 7/8" | 26 | Crimped | 0000000 | 00000 |

| 5 | 5" | 4 7/8" | 26 | Crimped | 0000000 | 00000 |

| 6 | 6" | 5 7/8" | 26 | Crimped | 0000000 | 00000 |

| 7 | 7" | 6 7/8" | 26 | Crimped | 0000000 | 00000 |

| 8 | 8" | 7 7/8" | 26 | Crimped | 0000000 | 000000 |

| 10 | 10" | 9 7/8" | 24 | Crimped | 0000000 | 000000 |

| 12 | 12" | 11 7/8" | 24 | Crimped | 0000000 | 000000 |