About Threaded Studs and Rods

More

Made-to-Order Pins

Choose a material, head type, end type, and size to create a custom pin.

Steel pins have good strength.

Stainless steel pins are more corrosion resistant than steel pins. 18-8 stainless steel pins offer a balance of strength and corrosion resistance. They may be mildly magnetic. 416 stainless steel pins are more wear-resistant than other stainless pins. They have some corrosion resistance and are magnetic.

Each | ||||||||

|---|---|---|---|---|---|---|---|---|

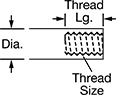

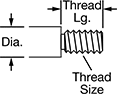

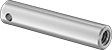

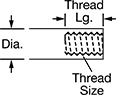

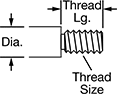

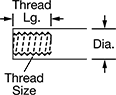

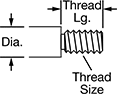

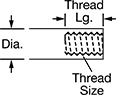

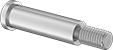

| Dia. | Choose a Material | Choose a Lg. | Choose a Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 1/2" | 00000000 | 0000000 | 000000 | 000000 | ||

Length refers to the unthreaded portion of the pin.

Each | ||||||||

|---|---|---|---|---|---|---|---|---|

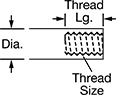

| Dia. | Choose a Material | Choose a Lg. | Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 5/8"-11 | 7/8" | 00000000 | 0000000 | 000000 | 000000 | |

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

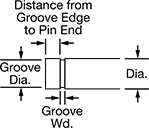

| Dia. | Choose a Material | Choose a Lg. | Choose a Groove Wd. | Choose a Groove Dia. | Choose a Distance from Groove Edge to Pin End | Choose a Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | Min. of 0.03" | 0.69"-0.749" | Min. of 0.25" | 1/2" | 00000000 | 0000000 | 000000 | 000000 | ||

Length refers to the unthreaded portion of the pin.

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

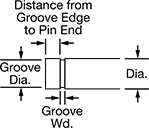

| Dia. | Choose a Material | Choose a Lg. | Choose a Groove Wd. | Choose a Groove Dia. | Choose a Distance from Groove Edge to Pin End | Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | Min. of 0.03" | 0.69"-0.749" | Min. of 0.25" | 5/8"-11 | 7/8" | 00000000 | 0000000 | 000000 | 000000 | |

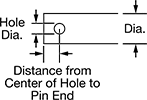

Each | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

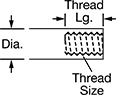

| Dia. | Choose a Material | Choose a Lg. | Choose a Through Hole Dia., in. | Choose a Distance from Center of Hole to Pin End | Choose a Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | Min. of 0.25" | 1/2" | 00000000 | 0000000 | 000000 | 000000 | |||

Length refers to the unthreaded portion of the pin.

Each | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Choose a Material | Choose a Lg. | Choose a Through Hole Dia., in. | Choose a Distance from Center of Hole to Pin End | Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | Min. of 0.25" | 5/8"-11 | 7/8" | 00000000 | 0000000 | 000000 | 000000 | ||

Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Choose a Material | Choose a Lg. | Choose a Thread Size for First Pin End | Choose a Thread Size for Second Pin End | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 1/2" | 00000000 | 0000000 | 000000 | 000000 | |||

Length refers to the unthreaded portion of the pin.

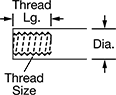

Each | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

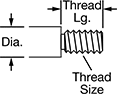

| Dia. | Choose a Material | Choose a Lg. | Choose a Tapped End Thread Size | Tapped End Thread Lg. | Threaded End Thread Size | Threaded End Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 1/2" | 5/8"-11 | 7/8" | 00000000 | 0000000 | 000000 | 000000 | ||

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

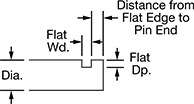

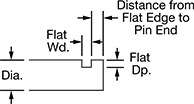

| Dia. | Choose a Material | Choose a Lg. | Choose a Thread Size | Thread Lg. | Flat Dp. | Choose a Distance from Flat Edge to Pin End | Choose a Flat Wd. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 1/2" | 0.062" | Min. of 0.25" | Min. of 1/8" | 00000000 | 0000000 | 000000 | 000000 | ||

Length refers to the unthreaded portion of the pin.

Each | ||||||||

|---|---|---|---|---|---|---|---|---|

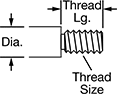

| Dia. | Choose a Material | Choose a Lg. | Thread Size | Thread Lg. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 5/8"-11 | 7/8" | 00000000 | 0000000 | 000000 | 000000 | |

Length refers to the unthreaded portion of the pin.

Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Choose a Material | Choose a Lg. | Thread Size | Thread Lg. | Flat Dp. | Choose a Distance from Flat Edge to Pin End | Choose a Flat Wd. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 1/4"-5" | 5/8"-11 | 7/8" | 0.062" | Min. of 0.25" | Min. of 1/8" | 00000000 | 0000000 | 000000 | 000000 | |

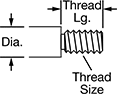

Flat-Head Made-to-Order Pins

Create a custom headed pin with your choice of material, dimensions, and end type.

Steel pins have good strength.

Stainless steel pins are more corrosion resistant than steel pins. 18-8 stainless steel pins offer a balance of strength and corrosion resistance. They may be mildly magnetic. 416 stainless steel pins are more wear-resistant than other stainless pins. They have some corrosion resistance and are magnetic.

Head | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

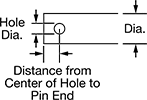

| Dia. | Choose a Material | Choose a Lg. | Choose a Thread Size | Thread Lg. | Ht. | Dia. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 5/16"-5" | 1/2" | 1/4" | 15/16" | 00000000 | 0000000 | 000000 | 000000 | ||

Head | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Choose a Material | Choose a Lg. | Thread Size | Thread Lg. | Ht. | Dia. | 1-4 | 5-9 | 10-Up | |

| 3/4" | 5/16"-5" | 5/8"-11 | 7/8" | 1/4" | 15/16" | 00000000 | 0000000 | 000000 | 000000 | |

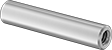

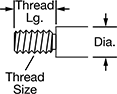

Threaded on One End Studs

Use the unthreaded end as a pivot point, hinge, shaft, or locator pin. Made from 18-8 stainless steel, these studs are chemical resistant and may be mildly magnetic.

For technical drawings and 3-D models, click on a part number.

Shaft | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lg. | Thread Lg. | Lg. | Dia. | Dia. Tolerance | Tensile Strength, psi | Hardness | Each | |

18-8 Stainless Steel | ||||||||

5/8"-11 | ||||||||

| 1 1/2" | 5/8" | 3/4" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 2" | 3/4" | 1 1/4" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 0000 |

| 2 1/2" | 3/4" | 1 3/4" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 3" | 3/4" | 2 1/4" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 3 1/2" | 3/4" | 2 3/4" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 4" | 1" | 3" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 4 1/2" | 1 1/2" | 3" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 5" | 1 1/2" | 3 1/2" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 5 1/2" | 1 1/2" | 4" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

| 6" | 1 1/2" | 4 1/2" | 5/8" | -0.03" to 0.03" | 70,000 | Not Rated | 000000000 | 00000 |

Threaded Locating and Support Buttons

Use these buttons to support and position workpieces and fixtures from the bottom or side. Their hex shape lets you screw them into a threaded hole with a wrench or socket. Threading makes these buttons easier to replace than press-fit, so they are a good choice for high-wear applications. They’re also known as rest buttons.

For technical drawings and 3-D models, click on a part number.

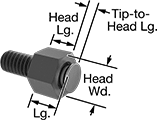

Swiveling Locating and Support Buttons

The swiveling tip supports uneven and angled surfaces on workpieces and fixtures. These buttons screw into a threaded hole. Also known as rest buttons.

For technical drawings and 3-D models, click on a part number.

Head | Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tip Dia. | Lg. | Wd. | Tip-to-Head Lg. | Lg. | Size | Lg. | Range of Motion | Head Lg. Tolerance | Load Capacity, lbs. | Tip Material | Each | |

Steel | ||||||||||||

| 13/16" | 11/16" | 15/16" | 1/8" | 13/16" | 5/8"-11 | 1" | 32° | -0.002" to 0.002" | 9,900 | Stainless Steel | 0000000 | 000000 |