About Rod Ends

More

About Ball and Roller Bearings

More

Self-Aligning Ball Bearings

With a spherical raceway and two rows of balls, these bearings compensate for shaft misalignment.

Open bearings dissipate heat more efficiently than sealed bearings.

Sealed bearings block out dust and other contaminants better than open bearings, but retain more heat.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Misalignment Capability | Temp. Range, °F | ABEC Rating | Each | |

Open | |||||||||||||

| 108 | 8 | 22 | 7 | Steel | 590 | 120 | 40,000 | Lubricated | 3° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 126 | 6 | 19 | 6 | Steel | 560 | 105 | 30,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1200 | 10 | 30 | 9 | Steel | 1,200 | 260 | 22,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1201 | 12 | 32 | 10 | Steel | 1,250 | 280 | 22,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1202 | 15 | 35 | 11 | Steel | 1,700 | 390 | 18,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1203 | 17 | 40 | 12 | Steel | 1,750 | 450 | 16,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1204 | 20 | 47 | 14 | Steel | 2,850 | 760 | 20,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 00000 |

| 1205 | 25 | 52 | 15 | Steel | 3,200 | 890 | 18,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 00000 |

| 1206 | 30 | 62 | 16 | Steel | 3,550 | 1,000 | 10,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1207 | 35 | 72 | 17 | Steel | 3,550 | 1,100 | 8,500 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1208 | 40 | 80 | 18 | Steel | 4,300 | 1,450 | 7,500 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1302 | 15 | 42 | 13 | Steel | 2,150 | 510 | 16,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1304 | 20 | 52 | 15 | Steel | 2,800 | 750 | 12,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1305 | 25 | 62 | 17 | Steel | 4,050 | 1,100 | 10,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 1307 | 35 | 80 | 21 | Steel | 5,650 | 1,750 | 7,500 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 1308 | 40 | 90 | 23 | Steel | 6,650 | 2,150 | 6,700 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 1310 | 50 | 110 | 27 | Steel | 9,750 | 3,150 | 5,600 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2200 | 10 | 30 | 14 | Steel | 1,800 | 380 | 34,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2201 | 12 | 32 | 14 | Steel | 1,900 | 420 | 30,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2202 | 15 | 35 | 14 | Steel | 1,950 | 450 | 26,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2203 | 17 | 40 | 16 | Steel | 2,350 | 570 | 24,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2204 | 20 | 47 | 18 | Steel | 3,750 | 930 | 20,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2205 | 25 | 52 | 18 | Steel | 3,750 | 980 | 18,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2206 | 30 | 62 | 20 | Steel | 5,350 | 1,500 | 15,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2207 | 35 | 72 | 23 | Steel | 6,750 | 1,950 | 12,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2208 | 40 | 80 | 23 | Steel | 7,150 | 2,200 | 11,000 | Lubricated | 2.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2211 | 55 | 100 | 25 | Steel | 6,000 | 2,200 | 6,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2212 | 60 | 110 | 28 | Steel | 7,600 | 2,800 | 5,300 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2213 | 65 | 120 | 31 | Steel | 9,750 | 3,650 | 4,800 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2300 | 10 | 35 | 17 | Steel | 2,050 | 450 | 18,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 00000 |

| 2302 | 15 | 42 | 17 | Steel | 2,750 | 650 | 14,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2304 | 20 | 52 | 21 | Steel | 4,050 | 1,050 | 19,000 | Lubricated | 3° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2305 | 25 | 62 | 24 | Steel | 6,050 | 1,550 | 16,000 | Lubricated | 3° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2306 | 30 | 72 | 27 | Steel | 7,000 | 1,950 | 13,000 | Lubricated | 3° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2307 | 35 | 80 | 31 | Steel | 8,900 | 2,500 | 12,000 | Lubricated | 3° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2309 | 45 | 100 | 36 | Steel | 12,350 | 3,750 | 5,600 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2310 | 50 | 110 | 40 | Steel | 14,600 | 4,500 | 5,000 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

| 2311 | 55 | 120 | 43 | Steel | 17,150 | 5,350 | 4,800 | Required | 4° | Not Rated | ABEC-1 | 00000000 | 000000 |

Sealed | |||||||||||||

| 2200-2RS | 10 | 30 | 14 | Steel | 1,200 | 260 | 17,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2201-2RS | 12 | 32 | 14 | Steel | 1,400 | 320 | 16,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2202-2RS | 15 | 35 | 14 | Steel | 1,650 | 390 | 14,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2203-2RS | 17 | 40 | 16 | Steel | 1,950 | 490 | 12,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2204-2RS | 20 | 47 | 18 | Steel | 2,850 | 760 | 10,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2205-2RS | 25 | 52 | 18 | Steel | 3,200 | 890 | 9,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2206-2RS | 30 | 62 | 20 | Steel | 3,500 | 1,000 | 7,500 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2207-2RS | 35 | 72 | 23 | Steel | 4,250 | 1,300 | 6,300 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2208-2RS | 40 | 80 | 23 | Steel | 4,450 | 1,550 | 5,600 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2303-2RS | 17 | 47 | 19 | Steel | 2,850 | 760 | 11,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2304-2RS | 20 | 52 | 21 | Steel | 3,200 | 890 | 9,000 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2305-2RS | 25 | 62 | 24 | Steel | 4,250 | 1,200 | 7,500 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2306-2RS | 30 | 72 | 27 | Steel | 5,050 | 1,500 | 6,700 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

| 2307-2RS | 35 | 80 | 31 | Steel | 5,950 | 1,900 | 5,600 | Lubricated | 1.5° | -30° to 210° | ABEC-1 | 0000000 | 000000 |

Tapered Bore Self-Aligning Ball Bearings

For use on tapered shafts and round shafts with adapter sleeves, these ball-bearings have a spherical raceway to compensate for shaft misalignment.

For technical drawings and 3-D models, click on a part number.

Radial Load Capacity | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Diameter, mm | For Housing ID, mm | Width, mm | Ring Material | Dynamic | Static, lbs. | Maximum Speed, rpm | Lubrication | Misalignment Capability | Maximum Temperature, °F | Rate of Taper | ABEC Rating | Each | |

Open | ||||||||||||||

| 1204K | 20 | 47 | 14 | Steel | 2,200 | 580 | 14,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 000000 |

| 1205K | 25 | 52 | 15 | Steel | 2,700 | 740 | 12,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 00000 |

| 1206K | 30 | 62 | 16 | Steel | 3,550 | 1,000 | 10,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 00000 |

| 1207K | 35 | 72 | 17 | Steel | 3,550 | 1,100 | 8,500 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 00000 |

| 1208K | 40 | 80 | 18 | Steel | 4,300 | 1,450 | 7,500 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 00000 |

| 1304K | 20 | 52 | 15 | Steel | 2,800 | 750 | 12,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 00000 |

| 2205K | 25 | 52 | 18 | Steel | 2,750 | 770 | 12,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 00000 |

| 2208K | 40 | 80 | 23 | Steel | 5,000 | 1,650 | 7,500 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 000000 |

| 2209K | 45 | 85 | 23 | Steel | 5,200 | 1,800 | 7,100 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 000000 |

| 2211K | 55 | 100 | 25 | Steel | 6,000 | 2,200 | 6,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 000000 |

| 2306K | 30 | 72 | 27 | Steel | 7,150 | 1,950 | 8,000 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 000000 |

| 2309K | 45 | 100 | 36 | Steel | 12,350 | 3,750 | 5,600 | Required | 4° | 240° | 1:12 | ABEC-1 | 0000000 | 000000 |

High-Load Plastic Ball Bearings

With two rows of balls, these lightweight bearings have greater durability and load capacity—and a wider profile—than single-row plastic bearings. They’re commonly used in bottle-filling machines and other food-processing applications. The acetal body doesn’t absorb water, so it can operate in liquids or be washed down without losing strength. The balls are made of either glass or 316 stainless steel—both materials are corrosion resistant. Since there’s no metal-on-metal contact between the balls and the body, these bearings don’t require lubrication.

For technical drawings and 3-D models, click on a part number.

Radial Load Capacity, lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Diameter | For Housing ID | Width | Ring Material | Dynamic | Static | Maximum Speed, rpm | Lubrication | Temperature Range, °F | ABEC Rating | Each | |

316 Stainless Steel Balls | ||||||||||||

Open | ||||||||||||

| R4 | 1/4" | 5/8" | 3/8" | Acetal Plastic | 50 | 30 | 1,800 | Not Required | -40° to 180° | Not Rated | 00000000 | 000000 |

| R4 | 1/4" | 3/4" | 3/8" | Acetal Plastic | 50 | 30 | 1,800 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R6 | 3/8" | 7/8" | 7/16" | Acetal Plastic | 60 | 40 | 1,200 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R8 | 1/2" | 1 1/8" | 7/16" | Acetal Plastic | 70 | 60 | 900 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R10B | 3/8" | 1 3/8" | 7/16" | Acetal Plastic | 65 | 50 | 1,000 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R10B | 5/8" | 1 3/8" | 7/16" | Acetal Plastic | 85 | 65 | 800 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R12 | 3/4" | 1 5/8" | 5/8" | Acetal Plastic | 100 | 80 | 600 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R16 | 1" | 2" | 3/4" | Acetal Plastic | 125 | 110 | 500 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R16 | 1 1/4" | 2" | 3/4" | Acetal Plastic | 125 | 110 | 500 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R20 | 1 1/4" | 2 1/4" | 3/4" | Acetal Plastic | 125 | 110 | 500 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5200-6 | 10mm | 30mm | 14mm | Acetal Plastic | 75 | 60 | 900 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5201-6 | 12mm | 32mm | 16mm | Acetal Plastic | 75 | 60 | 900 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5202-6 | 15mm | 35mm | 16mm | Acetal Plastic | 85 | 65 | 800 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5203-6 | 17mm | 40mm | 17mm | Acetal Plastic | 85 | 65 | 800 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5204-6 | 20mm | 47mm | 21mm | Acetal Plastic | 100 | 80 | 600 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5205-6 | 25mm | 52mm | 21mm | Acetal Plastic | 125 | 110 | 500 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| A5206-6 | 30mm | 62mm | 23mm | Acetal Plastic | 150 | 130 | 500 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

Glass Balls | ||||||||||||

Open | ||||||||||||

| R4A | 1/4" | 3/4" | 3/8" | Acetal Plastic | 50 | 30 | 1,800 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R8 | 1/2" | 1 1/8" | 7/16" | Acetal Plastic | 75 | 60 | 900 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R8 | 5/8" | 1 3/8" | 7/16" | Acetal Plastic | 65 | 54 | 1,000 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R10B | 1/2" | 1 3/8" | 7/16" | Acetal Plastic | 85 | 65 | 800 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

| R16 | 1" | 2" | 3/4" | Acetal Plastic | 125 | 110 | 500 | Not Required | -40° to 180° | Not Rated | 00000000 | 00000 |

Angular-Contact Thrust Ball Bearings

Double-row bearings handle thrust loads in both directions.

Open bearings dissipate heat more efficiently than shielded and sealed bearings.

Shielded bearings block out dust and other contaminants, but do not dissipate heat as efficiently as open bearings.

Sealed bearings block out dust and other contaminants better than open and shielded bearings, but retain the most heat.

For technical drawings and 3-D models, click on a part number.

Combined Load Cap., lbs. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bearing Trade Number | For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Contact Angle | Temp. Range, °F | ABEC Rating | Each | |

Double Row | |||||||||||||

Open | |||||||||||||

| 3200 | 10 | 30 | 14 | Steel | 1,700 | 960 | 22,000 | Required | 30° | -40° to 250° | ABEC-1 | 00000000 | 000000 |

| 3201 | 12 | 32 | 15.9 | Steel | 2,250 | 1,250 | 20,000 | Required | 30° | -40° to 250° | ABEC-1 | 00000000 | 00000 |

| 3202 | 15 | 35 | 15.9 | Steel | 2,500 | 1,500 | 17,000 | Required | 30° | -40° to 250° | ABEC-1 | 00000000 | 00000 |

| 3203 | 17 | 40 | 17.5 | Steel | 3,200 | 1,950 | 15,000 | Required | 30° | -40° to 250° | ABEC-1 | 00000000 | 00000 |

| 3204 | 20 | 47 | 20.6 | Steel | 4,450 | 2,650 | 14,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 00000 |

| 3205 | 25 | 52 | 20.6 | Steel | 4,850 | 3,200 | 12,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 00000 |

| 3206 | 30 | 62 | 23.8 | Steel | 6,700 | 4,550 | 10,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

| 3207 | 35 | 72 | 27 | Steel | 8,950 | 6,250 | 9,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

| 3208 | 40 | 80 | 30.2 | Steel | 10,600 | 7,600 | 8,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

| 3210 | 50 | 90 | 30.2 | Steel | 11,400 | 8,750 | 7,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

| 3303 | 17 | 47 | 22.2 | Steel | 4,850 | 2,850 | 14,000 | Required | 30° | -40° to 250° | ABEC-1 | 00000000 | 00000 |

| 3304 | 20 | 52 | 22.2 | Steel | 5,300 | 3,250 | 13,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

| 3305 | 25 | 62 | 25.4 | Steel | 7,150 | 4,550 | 11,000 | Required | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

Shielded | |||||||||||||

| 3200-2Z | 10 | 30 | 14 | Steel | 1,700 | 960 | 24,000 | Lubricated | 30° | -40° to 250° | ABEC-1 | 00000000 | 000000 |

| 3201-2Z | 12 | 32 | 15.9 | Steel | 2,250 | 1,250 | 22,000 | Lubricated | 30° | -40° to 250° | ABEC-1 | 00000000 | 000000 |

| 3202-2Z | 15 | 35 | 15.9 | Steel | 2,500 | 1,500 | 18,000 | Lubricated | 30° | -40° to 250° | ABEC-1 | 00000000 | 000000 |

| 3203-2Z | 17 | 40 | 17.5 | Steel | 3,200 | 1,950 | 16,000 | Lubricated | 30° | -40° to 250° | ABEC-1 | 00000000 | 00000 |

| 3204-2Z | 20 | 47 | 20.6 | Steel | 4,450 | 2,650 | 14,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

| 3205-2Z | 25 | 52 | 20.6 | Steel | 4,850 | 3,200 | 12,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

| 3206-2Z | 30 | 62 | 23.8 | Steel | 6,700 | 4,550 | 10,000 | Lubricated | 30° | -40° to 250° | ABEC-3 | 00000000 | 000000 |

| 3207-2Z | 35 | 72 | 27 | Steel | 8,950 | 6,250 | 9,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

| 3208-2Z | 40 | 80 | 30.2 | Steel | 10,600 | 7,600 | 8,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

| 3210-2Z | 50 | 90 | 30.2 | Steel | 11,400 | 8,750 | 7,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

| 3303-2Z | 17 | 47 | 22.2 | Steel | 4,850 | 2,850 | 14,000 | Lubricated | 30° | -40° to 250° | ABEC-1 | 00000000 | 000000 |

| 3304-2Z | 20 | 52 | 22.2 | Steel | 5,300 | 2,250 | 13,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

| 3305-2Z | 25 | 62 | 25.4 | Steel | 7,150 | 4,550 | 11,000 | Lubricated | 30° | -40° to 300° | ABEC-3 | 00000000 | 000000 |

Sealed | |||||||||||||

| 3200-2RS | 10 | 30 | 14 | Steel | 1,700 | 960 | 17,000 | Lubricated | 30° | -40° to 210° | ABEC-1 | 00000000 | 000000 |

| 3201-2RS | 12 | 32 | 15.9 | Steel | 2,250 | 1,250 | 15,000 | Lubricated | 30° | -40° to 210° | ABEC-1 | 00000000 | 000000 |

| 3202-2RS | 15 | 35 | 15.9 | Steel | 2,500 | 1,500 | 14,000 | Lubricated | 30° | -40° to 210° | ABEC-1 | 00000000 | 000000 |

| 3203-2RS | 17 | 40 | 17.5 | Steel | 3,200 | 1,950 | 12,000 | Lubricated | 30° | -40° to 210° | ABEC-1 | 00000000 | 00000 |

| 3204-2RS | 20 | 47 | 20.6 | Steel | 4,450 | 2,650 | 10,000 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3205-2RS | 25 | 52 | 20.6 | Steel | 4,850 | 3,200 | 8,500 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3206-2RS | 30 | 62 | 23.8 | Steel | 6,700 | 4,550 | 7,500 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3207-2RS | 35 | 72 | 27 | Steel | 8,950 | 6,250 | 6,300 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3208-2RS | 40 | 80 | 30.2 | Steel | 10,600 | 7,600 | 5,600 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3210-2RS | 50 | 90 | 30.2 | Steel | 11,400 | 8,750 | 4,800 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3303-2RS | 17 | 47 | 22.2 | Steel | 4,850 | 2,850 | 11,000 | Lubricated | 30° | -40° to 210° | ABEC-1 | 00000000 | 000000 |

| 3304-2RS | 20 | 52 | 22.2 | Steel | 5,300 | 2,250 | 9,000 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

| 3305-2RS | 25 | 62 | 25.4 | Steel | 7,150 | 4,550 | 7,500 | Lubricated | 30° | -40° to 210° | ABEC-3 | 00000000 | 000000 |

Spherical-Roller Bearings

Two rows of rollers give these bearings dynamic radial load capacities over five times higher than comparably sized tapered-roller bearings. Also known as rock crusher bearings, they handle heavy shock loads and are used for metal milling machinery, mining and oil field equipment, and in paper mills.

For technical drawings and 3-D models, click on a part number.

Combined Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | For Housing ID, mm | Wd., mm | Bearing Trade Number | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | Max. Temp. Range, °F | Each | |

Open | |||||||||||

| 25 | 52 | 18 | 22205 | Steel | 8,400 | 8,300 | 7,100 | Required | 390 | 000000 | 0000000 |

| 30 | 62 | 20 | 22206 | Steel | 11,200 | 11,200 | 6,000 | Required | 390 | 000000 | 000000 |

| 35 | 72 | 23 | 22207 | Steel | 15,500 | 15,900 | 5,300 | Required | 390 | 000000 | 000000 |

| 40 | 80 | 23 | 22208 | Steel | 25,400 | 22,300 | 6,700 | Required | 390 | 000000 | 000000 |

| 40 | 90 | 33 | 22308 | Steel | 35,000 | 33,400 | 7,600 | Required | 212 | 0000000 | 000000 |

| 45 | 85 | 23 | 22209 | Steel | 26,500 | 24,900 | 6,000 | Required | 390 | 000000 | 000000 |

| 45 | 100 | 36 | 22309 | Steel | 42,000 | 41,000 | 6,800 | Required | 212 | 0000000 | 000000 |

| 50 | 90 | 23 | 22210 | Steel | 24,500 | 24,000 | 9,800 | Required | 212 | 0000000 | 000000 |

| 50 | 110 | 40 | 22310 | Steel | 51,250 | 50,000 | 6,300 | Required | 212 | 0000000 | 000000 |

| 55 | 100 | 25 | 22211 | Steel | 33,400 | 32,300 | 5,300 | Required | 390 | 000000 | 000000 |

| 60 | 110 | 28 | 22212 | Steel | 40,000 | 39,100 | 4,800 | Required | 390 | 000000 | 000000 |

| 65 | 120 | 31 | 22213 | Steel | 49,500 | 51,500 | 4,300 | Required | 390 | 000000 | 000000 |

| 65 | 140 | 48 | 22313 | Steel | 78,500 | 82,000 | 5,000 | Required | 212 | 0000000 | 000000 |

| 70 | 125 | 31 | 22214 | Steel | 50,500 | 52,000 | 4,000 | Required | 390 | 0000000 | 000000 |

| 70 | 150 | 51 | 22314 | Steel | 87,500 | 87,500 | 4,800 | Required | 212 | 0000000 | 000000 |

| 75 | 130 | 31 | 22215 | Steel | 53,500 | 54,750 | 4,000 | Required | 390 | 0000000 | 000000 |

| 80 | 140 | 33 | 22216 | Steel | 59,250 | 61,750 | 3,600 | Required | 390 | 0000000 | 000000 |

| 85 | 150 | 36 | 22217 | Steel | 69,500 | 73,000 | 3,400 | Required | 390 | 0000000 | 000000 |

| 90 | 160 | 40 | 22218 | Steel | 80,750 | 88,750 | 3,200 | Required | 390 | 0000000 | 000000 |

| 95 | 170 | 43 | 22219 | Steel | 93,250 | 101,000 | 3,000 | Required | 390 | 0000000 | 000000 |

| 100 | 180 | 46 | 22220 | Steel | 102,000 | 110,000 | 2,800 | Required | 390 | 0000000 | 000000 |

| 110 | 200 | 53 | 22222 | Steel | 136,000 | 145,000 | 2,600 | Required | 390 | 0000000 | 000000 |

High-Load Tapered-Roller Bearings

Double rows of tapered bearings support large shafts with heavy loads. They also handle thrust loads in either direction as well as radial loads. All come assembled and ready to use.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | Thrust Load Cap., lbs. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | For Housing ID | Wd. | Bearing Trade No. | Taper Direction | Dynamic | Static | Dynamic | Static | Thrust Clearance | For Thrust Load Type | Max. Speed, rpm | Lubrication | Temp. Range, °F | Includes | Each | |

Steel Ring | ||||||||||||||||

Open | ||||||||||||||||

| 1 1/4" | 2 5/16" | 31/32" | 08125/08231D | Out | 12,400 | 7,850 | 5,750 | 10,900 | 0.008" | Two Direction | 12,000 | Required | -65° to 250° | One Spacer | 0000000 | 0000000 |

| 2 1/4" | 4 1/4" | 2 1/8" | 462/452D | Out | 62,900 | 37,200 | 20,700 | 36,400 | 0.012" | Two Direction | 6,700 | Required | -65° to 250° | One Spacer | 0000000 | 000000 |

| 4" | 7 1/2" | 4" | 861/854D | Out | 179,000 | 142,000 | 59,000 | 138,000 | 0.012" | Two Direction | 3,800 | Required | -65° to 250° | One Spacer | 0000000 | 00000000 |

Needle-Roller Bearings

Also known as drawn-cup roller bearings, these are our thinnest roller bearings. The outer ring is drawn out to form a lip that holds the bearing together. Bearings take on the shape of their housing and may be oblong prior to installation.

Open bearings dissipate heat more efficiently than sealed bearings.

For technical drawings and 3-D models, click on a part number.

Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | For Housing ID | Wd. | Ring Material | Dynamic | Static | Max. Speed, rpm | Lubrication | For Shaft Surface Smoothness (Ra), microinch | Temp. Range, °F | Specifications Met | Each | |

Open | ||||||||||||

| 15mm | 21mm | 22mm | Steel | 3,000 | 4,350 | 16,500 | Required | 8 | -20° to 280° | DIN 618, ISO 3245 | 00000000 | 000000 |

| 16mm | 22mm | 22mm | Steel | 2,900 | 4,350 | 15,600 | Required | 8 | -20° to 280° | DIN 618, ISO 3245 | 00000000 | 00000 |

| 20mm | 26mm | 30mm | Steel | 4,900 | 8,950 | 12,700 | Required | 8 | -20° to 280° | DIN 618, ISO 3245 | 00000000 | 00000 |

| 25mm | 32mm | 38mm | Steel | 7,600 | 14,800 | 10,200 | Required | 8 | -20° to 280° | DIN 618, ISO 3245 | 00000000 | 00000 |

| 30mm | 37mm | 38mm | Steel | 8,400 | 17,750 | 8,600 | Required | 8 | -20° to 280° | DIN 618, ISO 3245 | 00000000 | 00000 |

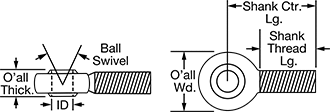

Internally Threaded High-Speed Ball Bearing Rod Ends

A double row of precision ball bearings allows high speeds and smooth operation. Seals keep lubricant in and dirt out.

Carbon steel rod ends meet DIN dimensional and material standards. They come lubricated, so you won't need to lubricate them at installation. They will require ongoing lubrication.

Cadmium-plated alloy steel rod ends offer moderate corrosion resistance. They have an oversized shank, which is one size larger than the ID, to handle greater stress. Their lubricant meets MIL-PRF-81322. These rod ends won't require ongoing lubrication.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Choose a Shank Thread Direction | Each | |

Ball Joints | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel | |||||||||||

| M6 | 6mm | 8° | 20mm | 11mm | 30mm | 12mm | 100 | DIN 648 | Right Hand | 00000000 | 000000 |

| M10 | 10mm | 8° | 28mm | 17mm | 43mm | 20mm | 300 | DIN 648 | 0000000 | 00000 | |

| M12 | 12mm | 7.5° | 32mm | 19mm | 50mm | 22mm | 400 | DIN 648 | 0000000 | 00000 | |

| M16 | 16mm | 8° | 42mm | 22mm | 64mm | 28mm | 500 | DIN 648 | Right Hand | 00000000 | 000000 |

| M20 | 20mm | 7° | 50mm | 30mm | 77mm | 33mm | 750 | DIN 648 | 0000000 | 000000 | |

| M22 | 22mm | 8° | 54mm | 32mm | 84mm | 37mm | 850 | DIN 648 | Right Hand | 00000000 | 000000 |

Ball Joints with Oversized Shank | |||||||||||

Cadmium-Plated Alloy Steel | |||||||||||

| 1/4"-28 | 3/16" | 20° | 3/4" | 1/2" | 1 3/8" | 3/4" | 1,000 | MIL-PRF-81322, MS21153 | Right Hand | 0000000 | 000000 |

| 5/16"-24 | 1/4" | 20° | 15/16" | 9/16" | 1 7/16" | 3/4" | 1,700 | MIL-PRF-81322, MS21153 | Right Hand | 0000000 | 000000 |

High-Speed Ball Bearing Rod Ends

A double row of precision ball bearings allows high speeds and smooth operation. Rod ends are made of cadmium- or zinc-plated steel, which both offer moderate corrosion resistance. Seals keep lubricant in and dirt out.

Cadmium-plated steel rod ends have lubricant that meets MIL-PRF-81322. They won’t require ongoing lubrication. Those with an oversized shank have a shank that is one size larger than the ID to handle greater stress.

Zinc-plated steel rod ends meet DIN dimensional standards. They come lubricated, so you won’t need to lubricate them at installation. They will require ongoing lubrication.

For technical drawings and 3-D models, click on a part number.

| Shank Thread Size | ID | Max. Ball Swivel | O'all Wd. | O'all Thick. | Shank Center Lg. | Shank Thread Lg. | Static Radial Load Cap., lbs. | Specifications Met | Shank Thread Direction | Each | |

Ball Joints | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Cadmium-Plated Alloy Steel | |||||||||||

| 10-32 | 3/16" | 20° | 25/32" | 7/16" | 1 3/8" | 3/4" | 1,000 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 0000000 |

Zinc-Plated Carbon Steel | |||||||||||

| M6 | 6mm | 8° | 20mm | 9mm | 36mm | 22mm | 140 | DIN 648 | Right Hand | 00000000 | 00000 |

| M8 | 8mm | 8.5° | 24mm | 12mm | 42mm | 25mm | 220 | DIN 648 | Right Hand | 00000000 | 00000 |

| M10 | 10mm | 8° | 28mm | 14mm | 48mm | 29mm | 320 | DIN 648 | Right Hand | 00000000 | 00000 |

| M12 | 12mm | 7.5° | 32mm | 16mm | 54mm | 33mm | 400 | DIN 648 | Right Hand | 00000000 | 00000 |

Ball Joints with Oversized Shank | |||||||||||

Cadmium-Plated Alloy Steel | |||||||||||

| 1/4"-28 | 3/16" | 20° | 3/4" | 7/16" | 1 9/16" | 1" | 1,000 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

| 3/8"-24 | 1/4" | 20° | 15/16" | 9/16" | 1 7/8" | 1 1/8" | 1,700 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

| 3/8"-24 | 5/16" | 20° | 1 1/4" | 7/8" | 2 7/16" | 1 9/16" | 2,900 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |

| 7/16"-20 | 5/16" | 20° | 1 1/4" | 7/8" | 2 7/16" | 1 9/16" | 2,900 | MIL-PRF-81322, MS21151 | Right Hand | 0000000 | 000000 |