About Installing Solid Rivets

More

About Installing Blind Rivets

More

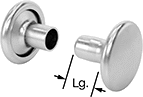

Two-Piece Press-Fit Rivets for Leather and Fabric

Also known as slam rivets, the two heads provide a finished look on both sides of your material. Use a hammer or press to join the mating parts. Access to both sides of the material is required.

Stainless steel rivets are more corrosion resistant than nickel-plated steel and nickel-plated brass rivets.

For technical drawings and 3-D models, click on a part number.

| Dia. | For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Pkg. Qty. | Pkg. | |

Nickel-Plated Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.13" | 0.188"-0.219" | 0.341" | 0.157" | No. 22 | 0.5" | 0.09" | 50 | 000000000 | 00000 |

| 0.134" | 0.177"-0.25" | 0.24" | 0.094" | 3/32" | 0.375" | 0.09" | 100 | 000000000 | 0000 |

Nickel-Plated Brass | |||||||||

| 0.134" | 0.025"-0.25" | 0.297" | 0.15" | 1/8" | 0.275" | 0.06" | 50 | 000000000 | 0000 |

| 0.15" | 0.06"-0.19" | 0.33" | 0.15" | 1/8" | 0.38" | 0.09" | 50 | 000000000 | 0000 |

Stainless Steel | |||||||||

| 0.15" | 0.138"-0.197" | 0.275" | 0.15" | 1/8" | 0.52" | 0.12" | 25 | 000000000 | 0000 |

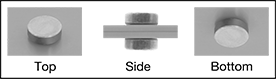

Two-Piece Press-Fit Rivets for Wood

Also known as cutlery rivets, the two heads provide a finished look on both sides of your material. Use a hammer or press to join the mating parts. Access to both sides of the material is required.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Material | Pkg. Qty. | Pkg. | |

0.112" Dia. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.375"-0.563" | 0.375" | 0.125"-0.145" | 1/8" | 0.188" | 0.06" | Brass | 10 | 000000000 | 000000 |

0.149" Dia. | |||||||||

| 0.5"-0.75" | 0.5" | 0.165"-0.185" | No. 19 | 0.313" | 0.045" | Brass | 10 | 000000000 | 0000 |

| 0.625"-0.875" | 0.625" | 0.165"-0.185" | No. 19 | 0.313" | 0.045" | Brass | 10 | 000000000 | 0000 |

Two-Piece Push-In Rivets

Two heads provide a finished look on both sides of your material. They push together and require access to both sides of the material for installation. Pry apart or cut to remove. Made of nylon, these rivets absorb environmental moisture, which can affect dimensions and other properties.

For technical drawings and 3-D models, click on a part number.

Adjustable shank rivets consist of a rivet and a washer. Insert the rivet into the hole and push the washer to the desired length. You can clip off any excess shank.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Temperature Range, °F | Material | Choose a Color | Pkg. Qty. | Pkg. | |

| 0.01"-0.25" | 0.375" | 0.094" | No. 42 | 0.354" | 0.062" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 000000 | |

| 0.01"-0.375" | 0.5" | 0.094" | No. 42 | 0.354" | 0.062" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 0000 | |

| 0.125"-2.188" | 2.312" | 0.125" | 1/8" | 0.5" | 0.062" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 |

Interlocking shank rivets have serrated prongs that lock together.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Temperature Range, °F | Material | Choose a Color | Pkg. Qty. | Pkg. | |

| 0.235"-0.297" | 0.218" | 0.25" | 1/4", E | 0.625" | 0.05" | -40° to 145° | Nylon Plastic | 50 | 000000000 | 000000 | |

| 0.235"-0.297" | 0.226" | 0.281" | K | 0.75" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.346"-0.5" | 0.343" | 0.25" | 1/4", E | 0.625" | 0.05" | -40° to 145° | Nylon Plastic | 50 | 000000000 | 00000 | |

| 0.346"-0.5" | 0.344" | 0.281" | K | 0.75" | 0.093" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.437"-0.75" | 0.437" | 0.437" | 11.0 mm | 1.375" | 0.085" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.5"-0.812" | 0.488" | 0.281" | K | 0.75" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.5"-0.812" | 0.5" | 0.25" | 1/4", E | 0.625" | 0.053" | -40° to 145° | Nylon Plastic | 50 | 000000000 | 00000 | |

| 0.78"-1.375" | 0.75" | 0.25" | 1/4", E | 0.625" | 0.055" | -40° to 145° | Nylon Plastic | 50 | 000000000 | 00000 | |

| 0.78"-1.375" | 0.768" | 0.281" | K | 0.75" | 0.093" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 |

Snap shank rivets have male and female halves that fit together.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Temperature Range, °F | Material | Choose a Color | Pkg. Qty. | Pkg. | |

| 0.032" | 0.125" | 0.13" | 1/8" | 0.5" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 000000 | |

| 0.045" | 0.125" | 0.13" | 1/8" | 0.5" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.062" | 0.188" | 0.13" | 1/8" | 0.5" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.093" | 0.188" | 0.13" | 1/8" | 0.5" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.125" | 0.21" | 0.13" | 1/8" | 0.5" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 | |

| 0.187" | 0.313" | 0.13" | 1/8" | 0.5" | 0.1" | -40° to 145° | Nylon Plastic | 25 | 000000000 | 00000 |

Domed-on-Both-Sides Blind Rivets

Create a finished look on both sides of your material with these two-piece rivets. Made of aluminum, they are lightweight, nonmagnetic, and have good corrosion resistance. To install, you will need access to both sides of your material and a standard blind rivet tool (sold separately) with a nosepiece that matches the rivet cap diameter.

The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking. Joint strength is also affected by rivet spacing and hole size.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | Rivet Cap Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength | Tensile Strength, lbs. | Material | Pkg. Qty. | Pkg. | |

Steel Mandrel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

3/16" Dia. | ||||||||||||

| 0.625"-0.75" | 0.52" | 0.58" | 0.25" | 1/4", E | 0.375" | 0.098" | Not Rated | 230 | 5000 Series Aluminum | 10 | 000000000 | 000000 |

| 0.687"-0.875" | 0.52" | 0.64" | 0.25" | 1/4", E | 0.375" | 0.098" | Not Rated | 230 | 5000 Series Aluminum | 10 | 000000000 | 00000 |

| 0.875"-1.062" | 0.52" | 0.82" | 0.25" | 1/4", E | 0.375" | 0.098" | Not Rated | 230 | 5000 Series Aluminum | 10 | 000000000 | 00000 |

| 1.062"-1.25" | 0.52" | 1.01" | 0.25" | 1/4", E | 0.375" | 0.098" | Not Rated | 230 | 5000 Series Aluminum | 10 | 000000000 | 00000 |

1/4" Dia. | ||||||||||||

| 0.625"-0.75" | 0.454" | 0.58" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 0.75"-0.875" | 0.608" | 0.695" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 0.875"-1.125" | 0.608" | 0.82" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 1.125"-1.375" | 0.608" | 1.07" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 1.375"-1.625" | 0.608" | 1.32" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 1.625"-1.875" | 0.608" | 1.57" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 1.875"-2.125" | 0.608" | 1.82" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

| 2.125"-2.375" | 0.608" | 2.07" | 0.313" | 5/16" | 0.625" | 0.095" | Not Rated | 450 | Aluminum | 10 | 000000000 | 0000 |

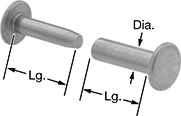

Solid Rivets with Washer for Soft Material

The washer creates a large holding surface on the back of the material. Also known as belt rivets, use for fastening conveyor belts or leather. Install in a countersunk hole and the angled head sits flush with the material's surface. These rivets are made of copper, which is electrically conductive, nonmagnetic, and has good corrosion resistance.

Installation requires access to both sides of the material as well as a tool and a hammer.

For technical drawings and 3-D models, click on a part number.

| For Max. Material Thick. | Lg. | Overall Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Countersink Angle | Washer Thick. | Material | Pkg. Qty. | Pkg. | |

No. 6—0.2" Dia. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.546" | 0.66" | 0.75" | 0.234" | A | 0.688" | 0.09" | 144° | 0.062" | 110 Copper | 10 | 000000000 | 000000 |

No. 6—0.228" Dia. | ||||||||||||

| 0.796" | 0.91" | 1" | 0.234" | A | 0.688" | 0.09" | 144° | 0.062" | 110 Copper | 5 | 000000000 | 0000 |

| 1.296" | 1.41" | 1.5" | 0.234" | A | 0.688" | 0.09" | 144° | 0.062" | 110 Copper | 5 | 000000000 | 0000 |

No. 7—0.191" Dia. | ||||||||||||

| 0.335" | 0.43" | 0.5" | 0.194" | No. 10 | 0.563" | 0.07" | 144° | 0.056" | 110 Copper | 10 | 000000000 | 0000 |

| 0.46" | 0.555" | 0.625" | 0.194" | No. 10 | 0.563" | 0.07" | 144° | 0.056" | 110 Copper | 10 | 000000000 | 0000 |

| 0.585" | 0.68" | 0.75" | 0.194" | No. 10 | 0.563" | 0.07" | 144° | 0.056" | 110 Copper | 10 | 000000000 | 0000 |

| 0.835" | 0.93" | 1" | 0.194" | No. 10 | 0.563" | 0.07" | 144° | 0.056" | 110 Copper | 10 | 000000000 | 00000 |

| 1.085" | 1.18" | 1.25" | 0.194" | No. 10 | 0.563" | 0.07" | 144° | 0.056" | 110 Copper | 10 | 000000000 | 00000 |

| 1.335" | 1.43" | 1.5" | 0.194" | No. 10 | 0.563" | 0.07" | 144° | 0.056" | 110 Copper | 10 | 000000000 | 00000 |

No. 8—0.181" Dia. | ||||||||||||

| 0.222" | 0.312" | 0.375" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 25 | 000000000 | 00000 |

| 0.347" | 0.437" | 0.5" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 25 | 000000000 | 00000 |

| 0.472" | 0.562" | 0.625" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 25 | 000000000 | 00000 |

| 0.597" | 0.687" | 0.75" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 25 | 000000000 | 00000 |

| 0.722" | 0.812" | 0.875" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 10 | 000000000 | 0000 |

| 0.847" | 0.937" | 1" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 10 | 000000000 | 00000 |

| 1.097" | 1.187" | 1.25" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 10 | 000000000 | 00000 |

| 1.347" | 1.437" | 1.5" | 0.182" | No. 14 | 0.5" | 0.063" | 144° | 0.05" | 110 Copper | 10 | 000000000 | 0000 |

No. 9—0.161" Dia. | ||||||||||||

| 0.237" | 0.317" | 0.375" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 50 | 000000000 | 00000 |

| 0.362" | 0.442" | 0.5" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 50 | 000000000 | 00000 |

| 0.487" | 0.567" | 0.625" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 25 | 000000000 | 00000 |

| 0.612" | 0.692" | 0.75" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 25 | 000000000 | 00000 |

| 0.737" | 0.817" | 0.875" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 25 | 000000000 | 00000 |

| 0.862" | 0.942" | 1" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 25 | 000000000 | 00000 |

| 1.112" | 1.192" | 1.25" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 25 | 000000000 | 00000 |

| 1.362" | 1.442" | 1.5" | 0.166" | No. 19 | 0.469" | 0.058" | 144° | 0.045" | 110 Copper | 25 | 000000000 | 00000 |

No. 10—0.151" Dia. | ||||||||||||

| 0.245" | 0.32" | 0.375" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 25 | 000000000 | 00000 |

| 0.37" | 0.445" | 0.5" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 25 | 000000000 | 00000 |

| 0.495" | 0.57" | 0.625" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 25 | 000000000 | 00000 |

| 0.62" | 0.695" | 0.75" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 25 | 000000000 | 00000 |

| 0.745" | 0.82" | 0.875" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 10 | 000000000 | 0000 |

| 0.87" | 0.945" | 1" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 10 | 000000000 | 0000 |

| 1.12" | 1.195" | 1.25" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 10 | 000000000 | 0000 |

| 1.37" | 1.445" | 1.5" | 0.152" | No. 24 | 0.438" | 0.055" | 144° | 0.041" | 110 Copper | 10 | 000000000 | 0000 |

No. 12—0.137" Dia. | ||||||||||||

| 0.262" | 0.33" | 0.375" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 50 | 000000000 | 00000 |

| 0.387" | 0.455" | 0.5" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 25 | 000000000 | 0000 |

| 0.512" | 0.58" | 0.625" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 25 | 000000000 | 0000 |

| 0.637" | 0.705" | 0.75" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 25 | 000000000 | 00000 |

| 0.887" | 0.955" | 1" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 25 | 000000000 | 00000 |

| 1.137" | 1.205" | 1.25" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 25 | 000000000 | 00000 |

| 1.387" | 1.455" | 1.5" | 0.138" | 3.5 mm | 0.375" | 0.045" | 144° | 0.033" | 110 Copper | 10 | 000000000 | 0000 |