About Backflow-Prevention Valves

More

About Actuated On/Off Valves

More

About Flow-Adjustment Valves

More

About Gradual On/Off Valves

More

About Flanged Flow-Adjustment Valves

More

About Pressure-Relief Valves

More

About On/Off Valves

More

About Gas Regulators

More

How to Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Compact Threaded Flow-Adjustment Valves for Cryogenic Liquid

- Valve Type: Globe

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Nitrogen

- Specifications Met: CGA G-4.1

Often used with portable cryogenic cylinders, these valves are a third of the height of other valves for cryogenic liquid. They are designed to withstand the extreme cold of liquid argon, liquid carbon dioxide, and liquid nitrogen; all are cleaned and bagged to meet CGA G-4.1 standards for oxygen service. These valves gradually open and close with multiple turns of the wheel handle to adjust and regulate flow. They have a nonrising stem that stays in the same position whether the valve is open or closed.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Stem Type | Each | |

Brass Body | |||||||

|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||

| 1/4 | 1 | 600 psi @ 165° F | -320° to 165° | 2 1/2" | Nonrising | 00000000 | 0000000 |

| 3/8 | 1.8 | 600 psi @ 165° F | -320° to 165° | 2 1/2" | Nonrising | 00000000 | 000000 |

| 1/2 | 1.8 | 600 psi @ 165° F | -320° to 165° | 2 1/2" | Nonrising | 00000000 | 000000 |

Threaded Flow-Adjustment Valves for Cryogenic Liquid

- Valve Type: Globe

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Nitrogen

- Seal Material: Glass-Filled PTFE Plastic

- Specifications Met: CGA G-4.1

Designed to withstand the extreme cold of liquid argon, liquid carbon dioxide, and liquid nitrogen, these valves are cleaned and bagged to meet CGA G-4.1 standards for oxygen service. They gradually open and close with multiple turns of the wheel handle to adjust and regulate flow. All have a rising stem that lifts as the valve opens and lowers as the valve closes to provide a visual indication of whether flow is on or off.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Overall Ht. | Stem Type | Each | |

Bronze Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 1/2 | 3.3 | 600 psi @ 150° F | -325° to 150° | 2 5/8" | 8 5/16" | Rising | 00000000 | 0000000 |

| 3/4 | 6.3 | 400 psi @ 150° F | -325° to 150° | 3 3/16" | 10" | Rising | 00000000 | 000000 |

| 1 | 10 | 600 psi @ 150° F | -325° to 150° | 3 3/4" | 11 13/16" | Rising | 00000000 | 000000 |

| 1 1/2 | 26 | 400 psi @ 150° F | -325° to 150° | 4 3/4" | 16 1/2" | Rising | 00000000 | 000000 |

| 2 | 45 | 600 psi @ 150° F | -325° to 150° | 5 3/4" | 16 3/4" | Rising | 00000000 | 00000000 |

Stainless Steel Body | ||||||||

NPT Female × NPT Female | ||||||||

| 1/2 | 5 | 720 psi @ 150° F | -325° to 150° | 3 1/16" | 11 13/16" | Rising | 00000000 | 000000 |

| 1 | 14 | 720 psi @ 150° F | -325° to 150° | 3 15/16" | 12 1/16" | Rising | 00000000 | 000000 |

| 1 1/2 | 53 | 720 psi @ 150° F | -325° to 150° | 5" | 12 5/16" | Rising | 00000000 | 000000 |

| 2 | 28.3 | 720 psi @ 150° F | -325° to 150° | 5 15/16" | 12 5/8" | Rising | 00000000 | 00000000 |

Flanged Flow-Adjustment Valves for Chemicals

With seats that can stand up to aggressive and corrosive solutions, these valves are often used in chemical-processing applications. They bolt to flanges for adjusting and regulating flow in flanged pipelines.

Wafer valves must be sandwiched between two flanges; they have tabs or unthreaded holes to help align the valve between the flanges.

Lug valves can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Lockable lever handles have 10 flow-adjustment positions. The handle can be fixed in place with a padlock (not included).

Wheel handles open and close with multiple turns, providing fully adjustable flow.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—316 Stainless Steel Disc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 1/4" | 150, 125 | 6" | 4 3/4" | 4 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 1 13/16" | 0000000 | 0000000 |

| 2 1/2 | 1/4" | 150, 125 | 7" | 5 1/2" | 4 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 1 15/16" | 0000000 | 000000 |

| 3 | 1/4" | 150, 125 | 7 1/2" | 6" | 4 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 1 15/16" | 0000000 | 000000 |

| 4 | 1/4" | 150, 125 | 9" | 7 1/2" | 8 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 3/16" | 0000000 | 000000 |

| 5 | 1/4" | 150, 125 | 10" | 8 1/2" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 5/16" | 0000000 | 000000 |

| 6 | 1/4" | 150, 125 | 11" | 9 1/2" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 5/16" | 0000000 | 00000000 |

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—316 Stainless Steel Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 150, 125 | 11" | 9 1/2" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 5/16" | 0000000 | 000000000 |

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 1/2" | 0000000 | 00000000 |

- Valve Type: Butterfly

- For Use With: See table

- Seat Material:

Ductile Iron Body: Fluoroelastomer Rubber

Cast Iron Body: PTFE-Lined Buna-N Rubber - Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

Ductile Iron Body—316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | For Use With | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—316 Stainless Steel Disc | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid | 1/4" | 150, 125 | 6" | 4 3/4" | 4 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 1 13/16" | 0000000 | 0000000 |

| 2 1/2 | Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid | 1/4" | 150, 125 | 7" | 5 1/2" | 4 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 1 15/16" | 0000000 | 000000 |

| 3 | Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid | 1/4" | 150, 125 | 7 1/2" | 6" | 4 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 1 15/16" | 0000000 | 000000 |

| 4 | Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid | 1/4" | 150, 125 | 9" | 7 1/2" | 8 | 3/4" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 3/16" | 0000000 | 000000 |

| 5 | Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid | 1/4" | 150, 125 | 10" | 8 1/2" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 5/16" | 0000000 | 00000000 |

| 6 | Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid | 1/4" | 150, 125 | 11" | 9 1/2" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 5/16" | 0000000 | 00000000 |

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—316 Stainless Steel Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 150, 125 | 11" | 9 1/2" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 5/16" | 000000 | 000000000 |

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 1/2" | 000000 | 00000000 |

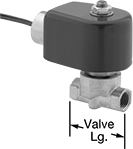

Solenoid On/Off Valves for Cryogenic Liquids

Built to withstand the extreme cold of liquid nitrogen and liquid oxygen, these valves are cleaned and bagged for high-purity applications. They operate on electricity to automatically start and stop flow.

All valves are normally closed unless actuated. The actuator is directly mounted to the valve body to minimize movement and reduce wear.

304 stainless steel valves are more corrosion resistant than brass and bronze valves.

Zero pressure drop valves don’t require a minimum pressure drop between the inlet and outlet for operation. Pressure drop assisted valves require a minimum pressure drop between the inlet and the outlet for operation; the upstream pressure must be greater than the downstream pressure.

NEMA 2 valves resist light splashing water and dust, and their enclosures are rated IP50 for additional protection from dust. Valves rated NEMA 4 and IP65 resist dust, splashing water, and washdowns.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With: Liquid Argon, Liquid Nitrogen, Liquid Oxygen

- Seal Material: PTFE Plastic

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Environmental Rating | Each | |

Normally Closed—120V AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | Female | NPT | 0.7 | 120 psi @ 70° F | Zero Pressure Drop | -320° to 355° | 1 3/4" | 3 1/8" | IP50, NEMA 2 | 00000000 | 0000000 |

| 3/8 | Female | NPT | 3.5 | 125 psi @ 70° F | Pressure Drop Assisted | -320° to 355° | 2 1/2" | 4 7/8" | IP50, NEMA 2 | 00000000 | 000000 |

- For Use With: Liquid Argon, Liquid Nitrogen, Liquid Oxygen

- Seal Material: Glass-Filled PTFE Plastic

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

Normally Closed—24V AC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | NPT | 3.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7" | 0000000 | 0000000 |

| 3/4 | Female | NPT | 7.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/2" | 7 1/8" | 0000000 | 000000 |

| 1 | Female | NPT | 13 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 4 1/8" | 8" | 0000000 | 000000 |

Normally Closed—24V DC | ||||||||||

| 1/2 | Female | NPT | 3.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7" | 0000000 | 000000 |

| 1 | Female | NPT | 13 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 4 1/8" | 8" | 0000000 | 000000 |

Normally Closed—120V AC | ||||||||||

| 1/2 | Female | NPT | 3.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7 1/16" | 0000000 | 000000 |

| 1/2 | Female | NPT | 3.5 | 200 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/4" | 7 1/16" | 0000000 | 000000 |

| 3/4 | Female | NPT | 7.5 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 3 1/2" | 7 3/8" | 0000000 | 000000 |

| 1 | Female | NPT | 13 | 110 psi @ -350° F | Zero Pressure Drop | -350° to 400° | 4 1/8" | 8 1/8" | 0000000 | 000000 |

- For Use With: Liquid Nitrogen, Liquid Oxygen

- Seal Material: PTFE Plastic

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Dia. | O'all Ht. | Environmental Rating | Each | |

Normally Closed—120V AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4 | Female | NPT | 0.9 | 225 psi @ 120° F | Pressure Drop Assisted | -320° to 120° | 1 11/16" | 4 13/16" | IP65, NEMA 4 | 0000000 | 0000000 |

| 3/8 | Female | NPT | 1.9 | 225 psi @ 120° F | Pressure Drop Assisted | -320° to 120° | 1 11/16" | 4 13/16" | IP65, NEMA 4 | 0000000 | 000000 |

| 1/2 | Female | NPT | 2.8 | 225 psi @ 120° F | Pressure Drop Assisted | -320° to 120° | 1 11/16" | 5 1/4" | IP65, NEMA 4 | 0000000 | 000000 |

Threaded Gradual On/Off Valves for Cryogenic Liquid

- Valve Type: Gate

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Natural Gas, Liquid Methane, Liquid Nitrogen, Liquid Oxygen

- Packing Material: PTFE Plastic

- Specifications Met: ASME B31.3, CGA G-4.1, MSS-SP-80

Built to handle the extreme cold of liquid gases, these bronze valves are ideal for liquid carbon dioxide carbonation systems, liquid nitrogen coolant systems, and other cryogenic applications. They’ll also work with liquified natural gas and liquid oxygen. They’re cleaned and bagged to meet CGA G-4.1 for oxygen service. Also known as gate valves, they open and close gradually with multiple turns of the wheel handle to prevent sudden starts and stops.

The handle raises as these valves open and lowers as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. They have a threaded union stem housing, so you can separate the stem from the housing while the valve is inline. That means you can complete maintenance tasks, such as packing the stem, without taking apart your whole setup.

For technical drawings and 3-D models, click on a part number.

O'all | Stem | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Type | Housing Connection Style | Each | |

NPT Female | ||||||||||

Wheel Handle—Bronze Body and Brass Gate | ||||||||||

| 1/2 | 19.8 | 600 psi @ 72° F | -320° to 150° | 2 5/16" | 10 3/16" | 2 5/16" | Rising | Threaded Union | 0000000 | 0000000 |

| 3/4 | 36 | 600 psi @ 72° F | -320° to 150° | 2 1/2" | 11 5/16" | 2 1/2" | Rising | Threaded Union | 0000000 | 000000 |

| 1 | 60 | 600 psi @ 72° F | -320° to 150° | 2 7/8" | 13 1/2" | 2 7/8" | Rising | Threaded Union | 0000000 | 000000 |

| 1 1/2 | 152 | 600 psi @ 72° F | -320° to 150° | 3 7/16" | 18 3/8" | 3 7/16" | Rising | Threaded Union | 0000000 | 00000000 |

| 2 | 245 | 600 psi @ 72° F | -320° to 150° | 3 13/16" | 21 5/16" | 3 13/16" | Rising | Threaded Union | 0000000 | 00000000 |

Compact Threaded On/Off Valves for Chemicals

For chemical-processing applications in confined areas, these valves have a low-profile handle to fit in tight spots. A rubber seal and a plastic body stand up to aggressive, corrosive solutions.

CPVC valves resist heat up to 195° F, so they’re the best choice if your system connects to a heater.

Full-port valves do not restrict flow. Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Stop Cock

- For Use With: Ammonia, Carbon Dioxide, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Liquid Carbon Dioxide, Phosphoric Acid, Sodium Hydroxide, Water

- Seal Material: EPDM Rubber

| Pipe Size | Flow Coefficient (Cv) | Port Type | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

NPT Female × NPT Female | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 1.6 | Standard | 150 psi @ 70° F | 35° to 120° | 2 13/16" | 00000000 | 000000 |

NPT Female × NPT Male | |||||||

| 1/4 | 1.6 | Standard | 150 psi @ 70° F | 35° to 120° | 2 3/4" | 00000000 | 00000 |

NPT Male × NPT Male | |||||||

| 1/4 | 1.2 | Full | 150 psi @ 70° F | 35° to 120° | 2 5/8" | 000000000 | 00000 |

- Valve Type: Ball

- For Use With: Ammonia, Carbon Dioxide, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Liquid Carbon Dioxide, Phosphoric Acid, Sodium Hydroxide, Water

- Seal Material: EPDM Rubber

| Pipe Size | Flow Coefficient (Cv) | Port Type | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

NPT Female × NPT Female | |||||||

|---|---|---|---|---|---|---|---|

| 3/8 | 7.7 | Full | 150 psi @ 70° F | 30° to 120° | 2 3/4" | 00000000 | 000000 |

| 1/2 | 14 | Full | 150 psi @ 70° F | 30° to 120° | 3 1/8" | 00000000 | 00000 |

| 3/4 | 29 | Full | 150 psi @ 70° F | 30° to 120° | 3 3/4" | 000000000 | 00000 |

| 1 | 47 | Full | 150 psi @ 70° F | 30° to 120° | 4 1/2" | 000000000 | 00000 |

- Valve Type: Stop Cock

- For Use With: Ammonia, Carbon Dioxide, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Liquid Carbon Dioxide, Phosphoric Acid, Sodium Hydroxide, Water

- Seal Material: EPDM Rubber

| For Tube ID | Pipe Size | Flow Coefficient (Cv) | Port Type | Max. Pressure | Temperature Range, °F | Port-to-Port Lg. | Each | |

Barbed × NPT Male | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5/8" | 1/4 | 1.2 | Full | 150 psi @ 70° F | 35° to 120° | 3 11/16" | 000000000 | 000000 |

- Valve Type: Ball

- For Use With: Carbon Dioxide, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Liquid Carbon Dioxide, Phosphoric Acid, Water

- Seal Material: EPDM Rubber

| Pipe Size | Flow Coefficient (Cv) | Port Type | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

NPT Female × NPT Female | |||||||

|---|---|---|---|---|---|---|---|

| 3/8 | 7.7 | Full | 150 psi @ 70° F | 30° to 195° | 2 3/4" | 0000000 | 000000 |

| 1/2 | 14 | Full | 150 psi @ 70° F | 30° to 195° | 3 1/8" | 0000000 | 00000 |

| 3/4 | 29 | Full | 150 psi @ 70° F | 30° to 195° | 3 3/4" | 000000000 | 00000 |

| 1 | 47 | Full | 150 psi @ 70° F | 30° to 195° | 4 1/2" | 000000000 | 00000 |

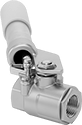

Threaded On/Off Valves for Refrigerant

- Valve Type: Ball

- For Use With: Refrigerant

- Seal Material: PTFE Plastic

- Specifications Met: NACE (National Association of Corrosion Engineers) MR0103, NACE (National Association of Corrosion Engineers) MR0175

Often used in HVAC or refrigeration systems, these valves are designed to control the flow of ammonia, nitrogen, and other harsh chemicals. To prevent accidental spills, a spring on the handle will automatically close the valve if you lose your grip. It’s also known as a deadman’s handle. The ball has a vent to relieve gas buildup when the valve is closed. Made from 316 stainless steel, these valves have excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Refrigerant Number | Features | Each | |

316 Stainless Steel Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||||

| 1/4 | 8.4 | 2,000 psi @ 100° F | -20° to 500° | 29 | 2 1/16" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 0000000 |

| 3/8 | 7.2 | 2,000 psi @ 100° F | -20° to 500° | 29 | 2 1/16" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

| 1/2 | 15 | 2,000 psi @ 100° F | -20° to 500° | 29 | 2 1/4" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

| 3/4 | 30 | 2,000 psi @ 100° F | -20° to 500° | 29 | 3" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

| 1 | 43 | 2,000 psi @ 100° F | -20° to 500° | 29 | 3 3/8" | R-134A, R-717, R-728, R-744 | Vented Ball | 0000000 | 000000 |

Vacuum-Breaking Valves for Chemicals

A plastic body withstands pH neutralizing, cleaning, and plating solutions containing sodium hydroxide, methyl ethyl ketone, and other harsh chemicals. Also known as vacuum breakers, these valves have vents that open when pressure drops to relieve vacuum conditions and prevent backward suction from drawing liquid into upstream piping.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Ammonia, Argon, Beverage, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Food, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Water, Xenon

- Diaphragm Material: Fluoroelastomer Rubber

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Max. Pressure | Min. Opening Pressure, psi | End-to-End Lg. | Color | Temperature Range, °F | Each | |

PVC Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 1/2 | 80 | 100 psi @ 75° F | 1 | 4 5/16" | Gray | 40° to 140° | 000000 | 0000000 |

| 3/4 | 80 | 100 psi @ 75° F | 1 | 4 5/8" | Gray | 40° to 140° | 0000000 | 000000 |

| 1 | 80 | 100 psi @ 75° F | 1 | 5 1/8" | Gray | 40° to 140° | 0000000 | 000000 |

CPVC Plastic Body | ||||||||

NPT Female × NPT Female | ||||||||

| 1/2 | 80 | 100 psi @ 75° F | 1 | 4 5/16" | Light Gray | 40° to 180° | 0000000 | 000000 |

| 3/4 | 80 | 100 psi @ 75° F | 1 | 4 5/8" | Light Gray | 40° to 180° | 0000000 | 000000 |

| 1 | 80 | 100 psi @ 75° F | 1 | 5 1/8" | Light Gray | 40° to 180° | 0000000 | 000000 |

- For Use With: Air, Ammonia, Argon, Beverage, Carbon Dioxide, Chlorinated Water, Diesel Fuel, Drinking Water, Ethylene Glycol, Food, Helium, Hydrochloric Acid, Kerosene, Krypton, Liquid Carbon Dioxide, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Water, Xenon

- Piston Material:

PVC Plastic Body: PVC Plastic

CPVC Plastic Body: CPVC Plastic - Spring Material: Plastic Polymer

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Max. Pressure | Min. Opening Pressure, psi | End-to-End Lg. | Color | Temperature Range, °F | Each | |

PVC Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | ||||||||

| 2 | 80 | 100 psi @ 75° F | 1 | 8 1/2" | Gray | 40° to 140° | 0000000 | 0000000 |

CPVC Plastic Body | ||||||||

NPT Female × NPT Female | ||||||||

| 1 1/2 | 80 | 100 psi @ 75° F | 1 | 7 15/16" | Light Gray | 40° to 180° | 0000000 | 000000 |

Easy-to-Install Threaded Check Valves for Harsh Chemicals

To reduce installation time and allow for maintenance without detaching pipe connections, these valves have union fittings. The plastic body and fluoroelastomer seal provide excellent chemical resistance. Valves open to allow flow in one direction and close when flow stops or reverses.

PVC and CPVC valves come with unthreaded socket-connect female fittings in addition to the threaded NPT female fittings.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- For Use With:

BSPP thread type:

Butane, Kerosene, Liquid Carbon Dioxide, Natural Gas, Nitric Acid, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Water

NPT thread type:

Citric Acid, Diesel Fuel, Drinking Water, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Sodium Hypochlorite, Water - Ball Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

Flow-Control Orifices for Chemicals

- For Use With: Air, Ammonia, Sodium Hydroxide, Beverage, Carbon Dioxide, Diesel Fuel, Water, Oil, Ethylene Glycol, Food, Hydrochloric Acid, Kerosene, Liquid Carbon Dioxide, Methanol, Soap Solutions, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Oxygen, Nitric Acid

- Max. Pressure: 120 psi @ 75° F

- Temperature Range: 40° to 140° F

Made of PVC, these orifices have excellent resistance to a wide range of corrosive chemicals. Also known as flow restrictors and precision orifice valves, they are used to throttle, vent, bleed, or regulate the flow of liquids and gases. They automatically adjust to changing inlet pressure to maintain consistent outlet flow.

For technical drawings and 3-D models, click on a part number.

Pressure-Relief Valves for Cryogenic Applications

- For Use With: Liquid Carbon Dioxide, Liquid Nitrogen, Liquid Oxygen

- Temperature Range: -320° to 165° F

Cleaned and bagged to meet CGA G-4.1 for oxygen service and other high-purity applications, these valves are built to withstand the extreme cold of liquid carbon dioxide, liquid nitrogen, and liquid oxygen. They begin opening at the set pressure and fully open at about 10% over the set pressure. Valves begin closing as pressure drops and fully close when the system pressure is restored below the set pressure. Set pressure is not adjustable.

Valves are not intended for direct contact with cryogenic liquids. Risers (sold separately) are required to convert cryogenic liquids into gases before they contact the valve. 3/8 NPT valve requires a 1/2 NPT × 3/8 NPT bushing when using a riser.

Adapters (sold separately) convert the valve relief-port connection from UNEF female threads to NPT female threads.

For technical drawings and 3-D models, click on a part number.

Valves | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Relief Port | Risers | Adapters | |||||||||

| Pipe Size | Location | Maximum Pressure, psi | Thread Size | Location | Overall Ht. | Choose a Set Pressure, psi | Each | Each | Each | |||

NPT Male Inlet and UNEF Female Relief Port | ||||||||||||

Brass Body | ||||||||||||

| 1/4 | Bottom | 600 | 3/4"-20 | Top | 2 5/8" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | |

| 3/8 | Bottom | 600 | 3/4"-20 | Top | 2 5/8" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 1/2 | Bottom | 600 | 3/4"-20 | Top | 2 13/16" | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

ASME-Code Fast-Acting Pressure-Relief Valves for Cryogenic Fluids

- For Use With: Argon, Carbon Dioxide, Helium, Hydrogen, Methane, Nitrogen, Oxygen

- Specifications Met: ASME BPVC.VIII

- Temperature Range: -320° to 150° F

These valves meet ASME Code Section VIII for use with cryogenic pressure vessels. Rated for use with argon, carbon dioxide, helium, hydrogen, methane, nitrogen, and oxygen, they are cleaned and bagged for oxygen service and other high-purity applications. All spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. Attach a drain line to the threaded relief port for remote discharge.

For technical drawings and 3-D models, click on a part number.

Fast-Acting Pressure-Relief Valves for Cryogenic Liquids

- For Use With: Liquid Argon, Liquid Nitrogen, Liquid Oxygen

- Temperature Range: -320° to 350° F

Cleaned and bagged for oxygen service and other high-purity applications, these valves can withstand the extreme cold of liquid argon, liquid nitrogen, and liquid oxygen. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All have a vented relief port to exhaust discharge directly.

For technical drawings and 3-D models, click on a part number.

Pressure-Regulating Valves for Cryogenic Liquids

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Nitrogen, Liquid Oxygen

- Temperature Range: -320° to 150° F

These valves can withstand the extreme cold of liquid argon, liquid carbon dioxide, liquid nitrogen, and liquid oxygen. All are cleaned and bagged for oxygen service and other high-purity applications. They automatically reduce a high, variable inlet pressure to a lower, stable outlet pressure. Adjust the outlet pressure within the range.

For technical drawings and 3-D models, click on a part number.

Extended-Life Pressure-Regulating Valves for Cryogenic Liquids

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Nitrogen, Liquid Oxygen

- Temperature Range: -320° to 150° F

For a longer service life than standard valves for cryogenic liquids, these have a durable bronze body. All are cleaned and bagged for oxygen service and other high-purity applications. They automatically reduce a high, variable inlet pressure to a lower, stable outlet pressure. Adjust the outlet pressure within the range. Valves are designed to withstand the extreme cold of liquid argon, liquid carbon dioxide, liquid nitrogen, and liquid oxygen. They have an internal strainer to trap debris.

For technical drawings and 3-D models, click on a part number.

Tank-Mount Pressure-Regulating Valves for Cryogenic Cylinders

- For Use With: See Table

- Temperature Range: -20° to 120° F

Automatically reduce a high inlet pressure from compressed gas tanks to a lower, stable outlet pressure. These valves can remove gases from liquid cryogenic cylinders. They have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. Valves come with a gauge to monitor outlet pressure. They are single stage and reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use With | CGA Number | Location | Thread Direction | Stage | Thread Size | Location | Thread Direction | Pressure Range, psi | Pressure Adjustment Method | Each | |

UNF Male Outlet × NGO Female Inlet | |||||||||||

Brass Body—Stainless Steel Diaphragm and PTFE Seal | |||||||||||

| Carbon Dioxide | CGA 320 | Side | Right Hand | Single | 9/16"-18 | Bottom | Right Hand | 0 to 350 | T-Handle | 0000000 | 0000000 |

| Oxygen | CGA 540 | Side | Right Hand | Single | 9/16"-18 | Bottom | Right Hand | 0 to 125 | T-Handle | 0000000 | 000000 |

UNF Male Outlet × NGO Male Inlet | |||||||||||

Brass Body—Stainless Steel Diaphragm and PTFE Seal | |||||||||||

| Argon, Nitrogen | CGA 580 | Side | Right Hand | Single | 9/16"-18 | Bottom | Right Hand | 0 to 350 | T-Handle | 0000000 | 000000 |