About Shaft Couplings

More

About Shaft Collars

Shaft collars are useful for holding and positioning components on a shaft. They can also serve as mechanical stops and stroke limiters.

More

Clamping Precision Flexible Shaft Couplings

Designed to grip evenly around your shaft, these couplings provide more holding power than set screw couplings without marring the shaft. Tighten the clamping screws to secure.

Spiral couplings have long cuts in their body for flexibility to handle parallel, axial, and angular misalignment better than parallel couplings. However, they’re not as rigid. Often used for light duty encoder and stepper drive applications, they allow zero backlash (no play) and never need lubrication. They’re also known as helical beam couplings.

Parallel couplings have short, intermittent cuts that make them more rigid and able to handle more torque and speed than spiral couplings, but they’re worse at correcting misalignment. Use them in high-torque applications, such as linear test systems and scientific instruments. They’re sometimes called slit couplings.

Aluminum couplings are lightweight with good corrosion resistance. Stainless steel couplings offer excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

Spiral Cut | ||||||||||

7075 Aluminum | ||||||||||

| 9mm × 1/4" | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 9mm × 3/8" | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 00000 |

| 9mm × 3/8" | 38mm | 30mm | 6,000 | 58 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 9mm × 1/2" | 38mm | 30mm | 6,000 | 58 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 9mm × 5/8" | 38mm | 30mm | 6,000 | 58 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 9mm × 6mm | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 00000 |

| 9mm × 7mm | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 00000 |

| 9mm × 8mm | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 00000 |

| 9mm × 8mm | 38mm | 30mm | 6,000 | 58 | 0.381mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 9mm × 9mm | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 00000 |

| 9mm × 9mm | 38mm | 30mm | 6,000 | 58 | 0.381mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 10mm × 9mm | 30mm | 25mm | 6,000 | 27 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 00000 |

| 10mm × 9mm | 38mm | 30mm | 6,000 | 58 | 0.381mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 12mm × 9mm | 38mm | 30mm | 6,000 | 58 | 0.381mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

303 Stainless Steel | ||||||||||

| 6mm × 9mm | 30mm | 25mm | 6,000 | 40 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 8mm × 9mm | 30mm | 25mm | 6,000 | 40 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 9mm | 30mm | 25mm | 6,000 | 40 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 10mm | 30mm | 25mm | 6,000 | 40 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 10mm | 38mm | 30mm | 6,000 | 88 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 12mm | 38mm | 30mm | 6,000 | 88 | 0.38mm | 3° | 0.25mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

Parallel Cut | ||||||||||

7075 Aluminum | ||||||||||

| 9mm × 5mm | 21.5mm | 20mm | 7,500 | 21.7 | 0.12mm | 3° | 0.5mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

| 9mm × 9mm | 26mm | 20mm | 7,500 | 21.7 | 0.25mm | 3° | 0.5mm | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 12mm × 9mm | 34mm | 25mm | 5,000 | 34.5 | 0.4mm | 3° | 0.7mm | Forward/Reverse, Start/Stop | 0000000 | 000000 |

Clamping Vibration-Damping Precision Flexible Shaft Couplings

Designed to grip evenly around your shaft, these couplings provide more holding power than set screw couplings without marring the shaft. Tighten the clamping screws to secure. Good for precision motor and pump applications, the spider-shaped cushion reduces shock and compensates for minor shaft misalignment. Couplings allow zero backlash (no play).

A complete coupling consists of two hubs and one spider (each component sold separately). Hubs are lightweight, corrosion-resistant aluminum. Spiders are polyurethane for fair vibration damping and good chemical resistance.

For technical drawings and 3-D models, click on a part number.

Durometer 98A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 1 13/32" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 8,000 | 150 | 0.003" | 0.8° | 0° to 180° | 0000000 | 000000 |

| 1 13/16" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 00000 | 8,000 | 170 | 0.003" | 0.8° | 0° to 180° | 0000000 | 00000 |

| 35.3mm | 25.4mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 150 | 0.003" | 0.8° | 0° to 180° | 0000000 | 00000 |

| 44.5mm | 33.3mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 170 | 0.003" | 0.8° | 0° to 180° | 0000000 | 00000 |

Durometer 92A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 1 13/32" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 8,000 | 58 | 0.005" | 0.9° | 0° to 180° | 0000000 | 000000 |

| 1 13/16" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 000000 | 00000 | 8,000 | 70 | 0.005" | 0.9° | 0° to 180° | 0000000 | 00000 | |

| 35.3mm | 25.4mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 58 | 0.005" | 0.9° | 0° to 180° | 0000000 | 00000 |

| 44.5mm | 33.3mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 70 | 0.005" | 0.9° | 0° to 180° | 0000000 | 00000 |

Durometer 85A Polyurethane Spiders | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | ||||||||||||

| Overall Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Temp. Range, °F | Each | ||

| 1 13/32" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 8,000 | 30 | 0.006" | 1° | 0° to 180° | 0000000 | 000000 |

| 1 13/16" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 000000 | 00000 | 8,000 | 36 | 0.006" | 1° | 0° to 180° | 0000000 | 00000 | |

| 35.3mm | 25.4mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 30 | 0.006" | 1° | 0° to 180° | 0000000 | 00000 |

| 44.5mm | 33.3mm | Keyed | Forward/Reverse, Start/Stop | 9mm | 0000000 | 00000 | 8,000 | 36 | 0.006" | 1° | 0° to 180° | 0000000 | 00000 |

Servomotor Precision Flexible Shaft Couplings

Able to handle high twisting forces as well as misalignment, these couplings are good for high-performance servomotor applications. Couplings are aluminum and stainless steel for corrosion resistance and allow zero backlash (no play). They grip evenly around your shaft for a strong hold without marring the shaft. Tighten the clamping screws to secure.

For technical drawings and 3-D models, click on a part number.

Misalignment Capability | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Lg. | OD | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | For Motion Type | Each | |

2017 Aluminum and 304 Stainless Steel | ||||||||||

| 3/16" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 1/4" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 5/16" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 3/8" × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 3/8" × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 1/2" × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 5/8" × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 5mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 6mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 8mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 9mm × 9mm | 1 9/32" | 1 1/64" | 10,000 | 18 | 0.006" | 1° | 0.013" | Forward/Reverse, Start/Stop | 00000000 | 00000 |

| 9mm × 9mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 10mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 14mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 15mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

| 9mm × 16mm | 1 57/64" | 1 35/64" | 10,000 | 89 | 0.009" | 1° | 0.02" | Forward/Reverse, Start/Stop | 00000000 | 000000 |

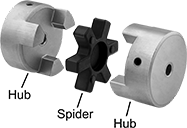

Set Screw Flexible Shaft Couplings

Each hub includes a set screw (unless noted), which bites into your shaft to hold the coupling in place. Also known as Lovejoy® couplings, these three-piece couplings have a spider-shaped cushion between two hubs to reduce shock and handle minor shaft misalignment.

Buna-N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance.

For technical drawings and 3-D models, click on a part number.

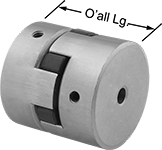

Clamping High-Parallel-Misalignment Flexible Shaft Couplings

Designed to grip evenly around your shaft, these couplings provide more holding power than set screw couplings without marring the shaft. Tighten the clamping screws to secure. Also known as Oldham couplings, they have a slotted disc that allows hubs to slide independently—good for applications with parallel shaft misalignment. They also allow zero backlash (no play) and never need lubrication.

A complete coupling consists of two hubs and one disc (each component sold separately).

Aluminum hubs are lightweight and have good corrosion resistance.

Acetal discs stand up to high twisting forces. Nylon discs have excellent vibration and shock absorption. PEEK discs have excellent impact resistance and the chemical resistance to withstand a variety of acids and other harsh substances.

For technical drawings and 3-D models, click on a part number.

Acetal Plastic Discs | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | |||||||||||||

| O'all Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | Temp. Range, °F | Each | ||

| 1 1/4" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 4,500 | 165 | 0.008" | 0.5° | 0.004" | -10° to 150° | 00000000 | 000000 |

| 1 7/8" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 00000 | 4,500 | 350 | 0.008" | 0.5° | 0.006" | -10° to 150° | 00000000 | 00000 |

Nylon Plastic Discs | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | |||||||||||||

| O'all Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | Temp. Range, °F | Each | ||

| 1 1/4" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 4,500 | 140 | 0.008" | 0.5° | 0.004" | -10° to 130° | 00000000 | 000000 |

| 1 7/8" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 00000 | 4,500 | 300 | 0.008" | 0.5° | 0.006" | -10° to 130° | 00000000 | 00000 |

PEEK Plastic Discs | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2024 Aluminum Hubs | Misalignment Capability | |||||||||||||

| O'all Lg. | OD | For Shaft Type | For Motion Type | For Shaft Dia. | Each | Max. Speed, rpm | Max. Torque, in.-lbs. | Parallel | Angular | Axial | Temp. Range, °F | Each | ||

| 1 1/4" | 1" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 000000 | 4,500 | 42 | 0.008" | 0.5° | 0.004" | -10° to 300° | 000000000 | 000000 |

| 1 7/8" | 1 5/16" | Round | Forward/Reverse, Start/Stop | 9mm | 000000 | 00000 | 4,500 | 70 | 0.008" | 0.5° | 0.006" | -10° to 300° | 000000000 | 00000 |

Set Screw High-Parallel-Misalignment Flexible Shaft Couplings

Each hub includes a set screw, which bites into your shaft to hold the coupling in place. Also known as Oldham couplings, these couplings have a slotted disc that allows hubs to slide independently—good for applications with parallel shaft misalignment. They also allow zero backlash (no play) and never need lubrication.

A complete coupling consists of two hubs and one disc (each component sold separately). Hubs are made of aluminum, so they’re lightweight and have good corrosion resistance.

Acetal discs stand up to high twisting forces. Nylon discs have excellent vibration and shock absorption. PEEK discs have excellent impact resistance and the chemical resistance to withstand a variety of acids and other harsh substances.

For technical drawings and 3-D models, click on a part number.

Clamping Shaft Collars

These metal collars are stronger than plastic shaft collars. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Black-oxide steel collars have some corrosion resistance. Zinc-plated steel collars have moderate corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Washdown Clamping Shaft Collars

Suitable for use in washdown applications, these plastic collars also offer good chemical resistance. They clamp evenly around the shaft to create a strong, mar-free hold. To use, slide onto your shaft and tighten the clamping screw to secure.

Acetal collars have a naturally slippery surface and resist swelling when exposed to moisture.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | White Acetal Plastic | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

| 9 | 24 | 9 | Socket Head Screw | 1 | 00000000 | 000000 |

Set Screw Shaft Collars

Keep these shaft collars in place by tightening their set screw into the shaft. The tip of the screw digs in for a secure hold, but will mar the shaft’s surface. For maximum holding power, make sure the set screw material is harder than your shaft material. Use these shaft collars to position and retain power transmission components such as sprockets, pulleys, and bearings. You can also use them to limit the movement of a shaft.

Carbon steel collars are strong and wear resistant. Collars with a black-oxide finish have some corrosion resistance, but only in dry environments. Their dark color can be useful for matching other parts in your system. Collars that are blue make it easy to identify metric collars at a glance. They’re tinted to match other blue metric fasteners.

303 stainless steel collars are corrosion resistant and highly machinable.

DIN 705 collars meet an international standard for shaft collar dimensions.

For technical drawings and 3-D models, click on a part number.

Set Screw | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Specifications Met | Each | |

Carbon Steel | |||||||

| 9 | 18 | 10 | Hex Socket | 1 | DIN 705 | 0000000 | 00000 |

Black-Oxide 1215 Carbon Steel | |||||||

| 9 | 16 | 8 | Hex Socket | 1 | __ | 00000000 | 0000 |

Blue Passivated Carbon Steel | |||||||

| 9 | 18 | 10 | Hex Socket | 1 | DIN 705 | 0000000 | 0000 |

303 Stainless Steel | |||||||

| 9 | 16 | 8 | Hex Socket | 1 | __ | 00000000 | 00000 |

| 9 | 18 | 10 | Hex Socket | 1 | DIN 705 | 0000000 | 0000 |

Clamping Two-Piece Shaft Collars

These metal collars are stronger than plastic shaft collars. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Black-oxide steel collars have some corrosion resistance. Aluminum collars are lightweight and have good corrosion resistance. 303 stainless steel collars have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Washdown Clamping Two-Piece Shaft Collars

Suitable for use in washdown applications, these plastic collars also offer good chemical resistance. The two-piece design allows you to install them anywhere on a shaft without removing components or having access to the ends of the shaft. Collars clamp evenly around the shaft to create a strong, mar-free hold. Tighten the clamping screws to secure.

Acetal collars have a naturally slippery surface and resist swelling when exposed to moisture.

For technical drawings and 3-D models, click on a part number.

Clamping Screw | White Acetal Plastic | |||||

|---|---|---|---|---|---|---|

| For Shaft Dia., mm | OD, mm | Wd., mm | Type | No. Included | Each | |

| 9 | 24 | 9 | Socket Head Screw | 2 | 0000000 | 000000 |