Filter by

For Wire Gauge

Wire Connection Method

Terminal Type

Insulation Material

Ring Width

Export Control Classification Number (ECCN)

DFARS Specialty Metals

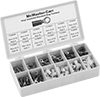

Terminals, Ferrules, and Lugs

Compression Lug

Set Screw Lug

Ring Terminal

Wire Ferrule

Spade Terminal

Lay-In Lug

Quick-Disconnect Terminal

Snap-Plug Terminal

Hook Terminal

Pin Terminal

Other Products