1.9" Diameter Motorized Conveyor Rollers

Add power to a gravity conveyor or build a custom powered conveyor. Rollers can be hardwired to operate in either direction. They have shielded bearings to keep out dust and debris.

For technical drawings and 3-D models, click on a part number.

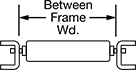

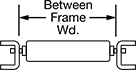

Roller | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | O'all Wd. | Wire Lead Lg. | Includes | Choose a Speed, fpm | Each | |

120V AC (Single Phase)—Duty Cycle is Continuous | |||||||||

7/16" Hex Axle—1.9" Dia. Zinc-Plated Steel Roller | |||||||||

| 13" | 12 3/8" | 17 | 140 | 14 1/4" | 2" | Terminal Block | 0000000 | 0000000 | |

| 16" | 15 3/8" | 17 | 140 | 17 1/4" | 2" | Terminal Block | 0000000 | 000000 | |

| 22" | 21 7/16" | 17 | 95 | 23 1/4" | 2" | Terminal Block | 0000000 | 000000 | |

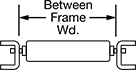

Motorized Round-Groove Conveyor Rollers

Also known as drive rollers, these connect to rollers with two grooves to power conveyors. The bearings are quiet-rolling to reduce conveyor noise and are shielded to keep out dirt and debris.

For technical drawings and 3-D models, click on a part number.

| For Between Frame Wd. | For Belt Dia. | Roller Wd. | Cap., lbs. | Wire Lead Lg. | Bearing-to-Groove Wd. | Groove Ctr.-to-Ctr. Wd. | O'all Wd. | Includes | Choose a Speed | Each | |

120V AC (Single Phase)—Duty Cycle is 3 Seconds On, 2 Seconds Off | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

7/16" Hex Axle—1.9" Dia. Zinc-Plated Steel Roller | |||||||||||

| 13" | 3/16" | 12 7/16" | 120 | 2" | 2.17" | 1.3" | 14 1/16" | Terminal Block | 0000000 | 0000000 | |

| 21" | 3/16" | 20 7/16" | 75 | 2" | 2.17" | 1.3" | 22 1/16" | Terminal Block | 0000000 | 000000 | |

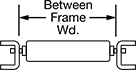

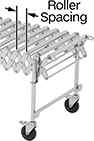

Flexible Roller Conveyors

Expand, curve, and retract the accordion-style frame to position these conveyors wherever you need them. Snake them around obstacles in cramped areas, bend them into a horseshoe to connect two trailers, or stretch them out to extend an existing line. When they’re not in use, retract these conveyors down to a fraction of their length. Their rollers are designed to smoothly transfer flat objects or ones with uneven bottoms. Shipping tubes, drums, and pails are less likely to get stuck in between rollers than between skate wheels.

Note: Capacities are based on an evenly distributed load. The length of the material you're conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | |||||||

|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | O'all Ht. | Cap., lbs./ft. | Features | Each | |

3'5" to 12'10" Lg. | ||||||||

1 3/8" Dia. Zinc-Plated Steel Rollers—5/16" Round Axle | ||||||||

| 21" | 18" | 5 1/4" | 1/4" | 28"-44" | 200 | Connecting Hooks, Handle, Package Stop | 0000000 | 000000000 |

| 27" | 24" | 5 1/4" | 1/4" | 28"-44" | 200 | Connecting Hooks, Handle, Package Stop | 0000000 | 00000000 |

| 33" | 30" | 5 1/4" | 1/4" | 28"-44" | 200 | Connecting Hooks, Handle, Package Stop | 0000000 | 00000000 |

6'7" to 24'8" Lg. | ||||||||

1 3/8" Dia. Zinc-Plated Steel Rollers—5/16" Round Axle | ||||||||

| 21" | 18" | 5 1/4" | 1/4" | 28"-44" | 200 | Connecting Hooks, Handle, Package Stop | 0000000 | 00000000 |

| 27" | 24" | 5 1/4" | 1/4" | 28"-44" | 200 | Connecting Hooks, Handle, Package Stop | 0000000 | 00000000 |

| 33" | 30" | 5 1/4" | 1/4" | 28"-44" | 200 | Connecting Hooks, Handle, Package Stop | 0000000 | 00000000 |

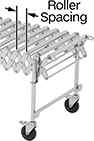

Ready-to-Run Flexible Roller Conveyors

Expand, retract, and curve these conveyors wherever you need them—they’re ready to run once you plug them in. These conveyors are ideal in situations where you need flexibility, such as loading and unloading trucks, connecting two trailers, or extending an existing line that you've outgrown. They have rollers to convey objects of different shapes and sizes in assembly, packaging, and shipping applications. To save space, these conveyors compress down to 8 1/2 ft. when they are not in use. They’re sometimes kept in storage as a backup line, so you can pull them out if other conveyors unexpectedly shut down.

Grab the handles at each end to move these conveyors into place. The legs adjust to your desired height. Connecting hooks on each end can fasten them to other conveyors. Lock the casters to keep them in place. A knob on the controller face lets you adjust the speed. To prevent damage, sensors at the end of the conveyor will stop the rollers if a package is nearing the edge.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg. | Spacing | Projection | O'all Ht. | Cap., lbs./ft. | Voltage | Power, hp | Speed, fpm | Features | Each | |

1 1/2" Dia. Zinc-Plated Steel Rollers—1/2" Round Axle | ||||||||||||

| 34" | 30" | 8'6"-24' | 5" | 1/4" | 30"-42" | 145 | 120V AC | 1/8 | 0-120 | Connecting Hooks, Emergency Stop, Handles, On/Off Switch, Package Stop, Sensor | 0000000 | 0000000000 |

Roller | ||||

|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Each | |

1 1/2" Dia. Zinc-Plated Steel Roller—1/2" Round Axle | ||||

| 30" | 28 15/32" | 16 | 0000000 | 000000 |

| Motor Enclosure Type | Power, hp | Each | |

| Totally Enclosed Nonventilated (TENV) | 1/8 | 0000000 | 0000000 |

| Features | Each | |

| On/Off Switch | 0000000 | 0000000 |

| Features | Each | |

| Emergency Stop | 0000000 | 0000000 |

| Max. Sensing Distance | Each | |

| 2" | 0000000 | 0000000 |