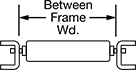

1.9" Diameter Motorized Conveyor Rollers

Add power to a gravity conveyor or build a custom powered conveyor. Rollers can be hardwired to operate in either direction. They have shielded bearings to keep out dust and debris.

For technical drawings and 3-D models, click on a part number.

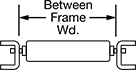

Roller | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Cap., lbs. | O'all Wd. | Wire Lead Lg. | Includes | Choose a Speed, fpm | Each | |

120V AC (Single Phase)—Duty Cycle is Continuous | |||||||||

7/16" Hex Axle—1.9" Dia. Zinc-Plated Steel Roller | |||||||||

| 13" | 12 3/8" | 17 | 140 | 14 1/4" | 2" | Terminal Block | 0000000 | 0000000 | |

| 16" | 15 3/8" | 17 | 140 | 17 1/4" | 2" | Terminal Block | 0000000 | 000000 | |

| 22" | 21 7/16" | 17 | 95 | 23 1/4" | 2" | Terminal Block | 0000000 | 000000 | |

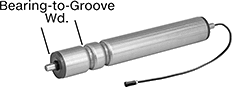

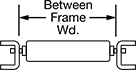

Motorized Round-Groove Conveyor Rollers

Also known as drive rollers, these connect to rollers with two grooves to power conveyors. The bearings are quiet-rolling to reduce conveyor noise and are shielded to keep out dirt and debris.

| For Between Frame Wd. | For Belt Dia. | Roller Wd. | Cap., lbs. | Wire Lead Lg. | Bearing-to-Groove Wd. | Groove Ctr.-to-Ctr. Wd. | O'all Wd. | Includes | Choose a Speed | Each | |

24V DC—Duty Cycle is Continuous with Up to 30 Starts and Stops per Minute | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

7/16" Hex Axle—1.9" Dia. Galvanized Steel Roller | |||||||||||

| 13" | 3/16" | 12.88" | 70 | 19" | 2.50" | 1.3" | 14" | Zone Control Card | 0000000 | 0000000 | |

| 16" | 3/16" | 15.888" | 70 | 19" | 2.50" | 1.3" | 17" | Zone Control Card | 00000000 | 000000 | |

| 21" | 3/16" | 20.88" | 70 | 19" | 2.50" | 1.3" | 22" | Zone Control Card | 00000000 | 000000 | |

| 22" | 3/16" | 21.88" | 70 | 19" | 2.50" | 1.3" | 23" | Zone Control Card | 00000000 | 000000 | |

| 27" | 3/16" | 26.88" | 70 | 19" | 2.50" | 1.3" | 28" | Zone Control Card | 00000000 | 000000 | |

| 31" | 3/16" | 30.88" | 70 | 19" | 2.50" | 1.3" | 32" | Zone Control Card | 00000000 | 000000 | |

120V AC (Single Phase)—Duty Cycle is 3 Seconds On, 2 Seconds Off | |||||||||||

7/16" Hex Axle—1.9" Dia. Zinc-Plated Steel Roller | |||||||||||

| 13" | 3/16" | 12 7/16" | 120 | 2" | 2.17" | 1.3" | 14 1/16" | Terminal Block | 0000000 | 000000 | |

| 21" | 3/16" | 20 7/16" | 75 | 2" | 2.17" | 1.3" | 22 1/16" | Terminal Block | 0000000 | 000000 | |

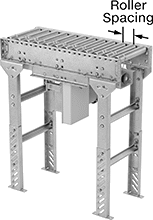

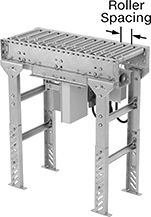

Motorized Roller Conveyors

Also known as line-shaft conveyors, these conveyors are driven by a drive shaft and round belts. Unlike belt conveyors, these have built-in accumulation, so packages can build up without crashing into one another or falling off the conveyor. The rollers are designed to smoothly transfer totes, packages, and other lightweight material. Shipping tubes, drums, and pails are less likely to get stuck in between rollers than between skate wheels.

Mix and match stands and conveyors to form straight lines, curve around obstacles, or create inclines. Only straight conveyor sections contain a motor, but they can power up to 60 ft. of conveyor extensions on either side. The motor can be reversed to send material in either direction.

Fixed-speed conveyors travel at 60 fpm, a common industry rate, to move material. Those with three-phase motors balance power more evenly than single-phase motors, so they can handle heavier loads. While a conveyor with a single-phase motor may lag when a heavy load reaches the conveyor, a conveyor with a three-phase motor will continue smoothly.

Variable-speed conveyors adjust from standard conveyor speeds down to 25 fpm, so they’re often used to slow material flow for quality checks.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

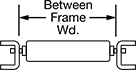

Wd. | Roller | Ht. | No. of Stands | 3 ft. Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Power, hp | Speed, fpm | Cap., lbs./ft. | Required | Included | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||||||

120V AC—Single Phase (Plug In) | |||||||||||||

| 16" | 13" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 000000000 |

| 17" | 14" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 19" | 16" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 21" | 18" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 25" | 22" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 29" | 26" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 31" | 28" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 35" | 32" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 00000000 | 00000000 |

240/460V AC—Three Phase (Hardwire) | |||||||||||||

| 16" | 13" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 0000000 | 00000000 |

| 17" | 14" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 00000000 | 00000000 |

| 19" | 16" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 0000000 | 00000000 |

| 21" | 18" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 00000000 | 00000000 |

| 25" | 22" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 0000000 | 00000000 |

| 29" | 26" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 00000000 | 00000000 |

| 31" | 28" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 00000000 | 00000000 |

| 35" | 32" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 0000000 | 00000000 |

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 60 | 40 | 2 | 2 | Connecting Plates | 00000000 | 00000000 |

Wd. | Roller | Ht. | No. of Stands | 3 ft. Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Spacing | Projection | Frame | O'all | Power, hp | Speed, fpm | Cap., lbs./ft. | Required | Included | Features | Each | |

1.9" Dia. Galvanized Steel Rollers—7/16" Hex Axle | |||||||||||||

120V AC—Single Phase (Plug In) | |||||||||||||

| 16" | 13" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 000000000 |

| 17" | 14" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 19" | 16" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 21" | 18" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 25" | 22" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 29" | 26" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 31" | 28" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 35" | 32" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

| 41" | 38" | 3" | 1/4" | 5 1/2" | 36"-48" | 1/2 | 25-60 | 40 | 2 | 2 | Connecting Plates, On/Off Switch | 0000000 | 00000000 |

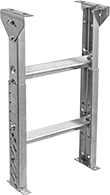

Conveyor Mount. Slot | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Conveyor Mount. Fasteners Included | No. of Conveyor Mount. Holes | Lg. | Wd. | Mount. Hole Ctr.-to-Ctr. | Floor Mount. Fasteners Included | No. of Floor Mount. Holes | Floor Mount. Hole Dia. | Each | |

For 16" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 0000000 |

For 17" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 19" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 21" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 25" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 29" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 31" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 35" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

For 41" Overall Wd. | ||||||||||

| 30 1/4" to 42 1/4" | Yes | 4 | 1" | 7/16" | 4" | No | 4 | 9/16" | 00000000 | 000000 |

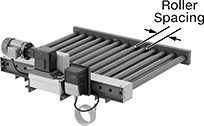

Heavy Duty Motorized Roller Conveyors

Move pallets, drums, racks, and other heavy items around your facility with these conveyors. Also known as chain-driven live roller conveyors, they have sprocketed rollers connected to a drive chain to move heavy loads. The sprockets minimize slipping, so these conveyors can smoothly move loads that are four times heavier than what you can move with our standard motorized roller conveyors. All have an adjustable speed range that goes as slow as 15 fpm, so you can slow material down to perform quality checks.

For technical drawings and 3-D models, click on a part number.

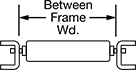

Wd. | No. of Stands | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg., ft. | ANSI Chain Number | Frame Ht. | Voltage | Motor Phase | Power, hp | Speed Range, fpm | Cap., lbs./ft. | Required | Included | Features | Each | |

4 1/2" Roller Spacing | ||||||||||||||

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||||||||

| 60 1/4" | 43" | 5 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 2 | None | Chain Guard, On/Off Switch | 0000000 | 000000000 |

| 60 1/4" | 43" | 10 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 3 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

| 68 1/4" | 51" | 5 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 2 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

| 68 1/4" | 51" | 10 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 3 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

6" Roller Spacing | ||||||||||||||

2 1/2" Dia. Steel Rollers—11/16" Hex Axle | ||||||||||||||

| 60 1/4" | 43" | 5 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 2 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

| 60 1/4" | 43" | 10 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 3 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

| 68 1/4" | 51" | 5 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 2 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

| 68 1/4" | 51" | 10 | 60 | 6" | 120V AC | Three | 1 1/2 | 15-60 | 290 | 3 | None | Chain Guard, On/Off Switch | 0000000 | 00000000 |

| Motor Enclosure Type | Power, hp | Voltage | Each | |

Three Phase | ||||

|---|---|---|---|---|

| Totally Enclosed Fan Cooled (TEFC) | 1 1/2 | 240V AC, 460V AC | 00000000 | 000000000 |

| Features | Each | |

| On/Off Switch | 00000000 | 000000000 |

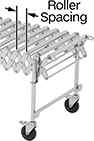

Ready-to-Run Flexible Roller Conveyors

Expand, retract, and curve these conveyors wherever you need them—they’re ready to run once you plug them in. These conveyors are ideal in situations where you need flexibility, such as loading and unloading trucks, connecting two trailers, or extending an existing line that you've outgrown. They have rollers to convey objects of different shapes and sizes in assembly, packaging, and shipping applications. To save space, these conveyors compress down to 8 1/2 ft. when they are not in use. They’re sometimes kept in storage as a backup line, so you can pull them out if other conveyors unexpectedly shut down.

Grab the handles at each end to move these conveyors into place. The legs adjust to your desired height. Connecting hooks on each end can fasten them to other conveyors. Lock the casters to keep them in place. A knob on the controller face lets you adjust the speed. To prevent damage, sensors at the end of the conveyor will stop the rollers if a package is nearing the edge.

Note: Capacities are based on an evenly distributed load. The length of the material you’re conveying should be at least three times the roller spacing.

For technical drawings and 3-D models, click on a part number.

Wd. | Roller | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all | Between Frame | Lg. | Spacing | Projection | O'all Ht. | Cap., lbs./ft. | Voltage | Power, hp | Speed, fpm | Features | Each | |

1 1/2" Dia. Zinc-Plated Steel Rollers—1/2" Round Axle | ||||||||||||

| 34" | 30" | 8'6"-24' | 5" | 1/4" | 30"-42" | 145 | 120V AC | 1/8 | 0-120 | Connecting Hooks, Emergency Stop, Handles, On/Off Switch, Package Stop, Sensor | 0000000 | 0000000000 |

Roller | ||||

|---|---|---|---|---|

| For Between Frame Wd. | Wd. | Gauge | Each | |

1 1/2" Dia. Zinc-Plated Steel Roller—1/2" Round Axle | ||||

| 30" | 28 15/32" | 16 | 0000000 | 000000 |

| Motor Enclosure Type | Power, hp | Each | |

| Totally Enclosed Nonventilated (TENV) | 1/8 | 0000000 | 0000000 |

| Features | Each | |

| On/Off Switch | 0000000 | 0000000 |

| Features | Each | |

| Emergency Stop | 0000000 | 0000000 |

| Max. Sensing Distance | Each | |

| 2" | 0000000 | 0000000 |

Modular Mini Chain Belt Conveyors

Build a mini conveyor in any shape you need. These conveyors have curved, straight, incline, and decline runs that you can quickly join together with the included brackets. They're often used in areas with limited floor space and applications that require frequent layout changes. To customize your conveyor, add on components, such as package stops and merge guides, with the built-in T-slots on the side. T-slot bolts are sold separately. These conveyors come with guides installed.

You'll need a drive assembly, an idler assembly, and a belt to complete your conveyor. To determine the belt length you need, multiply your conveyor’s length by 2.1. If you need a belt longer than what’s available, you can connect multiple together. Use a belt installation tool (sold separately) to pull out the pin, then line up two ends and push the pin in with the tool to connect them. You can also shorten a belt using the same tool.

Maximum run length is 70 ft. with two 90° curves. Adding more curved conveyors will reduce the run length.

For technical drawings and 3-D models, click on a part number.

Install drive assemblies at the start of your conveyor. They include a gearmotor that powers the belt. Use the controller to start, stop, and change the conveyor’s speed. A stand is included.

Choose an assembly with the motor and controller mounted on the left side or the right side, depending on your space constraints.

Wd. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Belt | Overall | Conveyor Bed Lg., ft. | Overall Ht. | Speed Range, fpm | Number of Stands Included | Voltage | Reversible | Features | Each | |

Left Side Motor | ||||||||||

| 3 1/4" | 15 1/4" | 2 | 38" | 30-110 | 1 | 120V AC | No | On/Off Switch, Pre-Installed Guides | 0000000 | 000000000 |

| 6" | 18" | 2 | 38" | 30-110 | 1 | 120V AC | No | On/Off Switch, Pre-Installed Guides | 0000000 | 00000000 |

| 10 1/4" | 22 1/4" | 2 | 38" | 30-110 | 1 | 120V AC | No | On/Off Switch, Pre-Installed Guides | 0000000 | 00000000 |

Right Side Motor | ||||||||||

| 3 1/4" | 15 1/4" | 2 | 38" | 30-110 | 1 | 120V AC | No | On/Off Switch, Pre-Installed Guides | 0000000 | 00000000 |

| 6" | 18" | 2 | 38" | 30-110 | 1 | 120V AC | No | On/Off Switch, Pre-Installed Guides | 0000000 | 00000000 |

| 10 1/4" | 22 1/4" | 2 | 38" | 30-110 | 1 | 120V AC | No | On/Off Switch, Pre-Installed Guides | 0000000 | 00000000 |

| Voltage | Features | Each | |

| 120V AC | On/Off Switch | 00000000 | 0000000 |