Food Industry Plastic Storage Containers

Use these containers in food-processing facilities. All meet either NSF/ANSI standards for sanitary design in food environments or are FDA compliant for direct contact with food.

Containers that cannot be sold to the regions listed are restricted by local chemical regulations.

Pitchers

The open top makes these easier to fill than jugs, while the spout gives more control when pouring.

Styles A and C have a lid and threaded spout cap to reduce spills.

Lid | Spout | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Dia. | Ht. | Opening Dia. | Graduation Marks | Color | Type | Material | Flexibility | OD | Lg. | Max. Temp., °F | Each | |

HDPE Plastic | |||||||||||||

| 1.5 gal. | 8 1/2" | 13" | 3 1/2" | 1 qt., 1 L | Clear | Threaded | HDPE Plastic | Flexible | 1" | 8 1/2" | 120° | 0000000 | 000000 |

Plastic Pans

Style F are also known as photographic trays. A pouring lip makes it easy to pour liquids without making a mess.

Bottom Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Material | Color | Autoclavable | Max. Temp., °F | Space Saving Features | Each | |

| F | 1 1/2 gal. | 15 5/8" | 13 3/8" | 2 1/2" | 13 1/2" | 11 1/4" | Polyethylene Plastic | White | No | 190° | Nestable | 0000000 | 000000 |

Keep-It-Cool Plastic Pans

Freeze these pans prior to use and the internal gel will keep contents below 40° F for eight hours.

Food Industry Stainless Steel Pans

Style E and F have a black nonstick coating for easy cleaning. Do not use with metal utensils, which can scrape off the coating and damage the pans.

Pans cannot be sold to the listed areas due to chemical regulations.

Pans | Loose-Fitting Lids | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity | Lg. | Wd. | Ht. | Bottom Inside Length | Bottom Inside Width | Gauge | Space Saving Features | Specifications Met | Features | Cannot Be Sold To | Each | Each | ||

Dull 300 Series Stainless Steel | |||||||||||||||

| A | 1 1/2 gal. | 12 3/4" | 6 7/8" | 6" | 11" | 5 1/4" | 22 | Nestable | NSF/ANSI 2 | Seamless | __ | 0000000 | 000000 | 0000000 | 000000 |

| A | 1 1/2 gal. | 13 7/8" | 12 3/4" | 2 1/2" | 12 5/8" | 11 1/2" | 22 | Nestable | NSF/ANSI 2 | Seamless | __ | 0000000 | 00000 | 0000000 | 00000 |

| A | 1 1/2 gal. | 20 3/4" | 6 1/2" | 4" | 19" | 4 1/2" | 22 | Nestable | NSF/ANSI 2 | Seamless | __ | 0000000 | 00000 | 0000000 | 00000 |

| E | 1 1/2 gal. | 12 3/4" | 6 7/8" | 6" | 11 3/4" | 6" | 22 | Nestable | NSF/ANSI 2 | Nonstick Surface, Seamless | CT, MN, VT | 0000000 | 00000 | 0000000 | 00000 |

| E | 1 1/2 gal. | 12 3/4" | 10 3/8" | 4" | 11 3/4" | 9 1/2" | 22 | Nestable | NSF/ANSI 2 | Nonstick Surface, Seamless | CT, MN, VT | 0000000 | 00000 | 0000000 | 00000 |

Static-Control Fiberglass Pans

Protect sensitive equipment from electrostatic discharge.

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Autoclavable | Max. Temp., °F | Space Saving Features | Surface Resistivity, ohms/sq. | Each | |

Static Dissipative | ||||||||||||

| 1 1/2 gal. | 22 1/2" | 20" | 1" | 21 1/2" | 19 1/4" | Black | Yes | 250° | Nestable | 105-109 | 00000000 | 000000 |

Antislip Food Industry Fiberglass Pans

To keep items from sliding off, these pans have a molded-in, slip-resistant rubber surface. Often used in cafeterias and food-processing areas, they meet NSF/ANSI 2 standards for food equipment.

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Autoclavable | Max. Temp., °F | Space Saving Features | Specifications Met | Each | |

| 1 1/2 gal. | 20 1/4" | 15" | 1 1/4" | 19 3/4" | 13 1/2" | Black | No | 200° | Nestable | NSF/ANSI 2 | 0000000 | 000000 |

Conductive Plastic Compartmented Pans

Protect sensitive parts from electrostatic discharge. The dividers are removable, allowing you to create the size and number of compartments that you need.

Compartment | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Compartments | Compartment Cap., oz. | Cap., gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Color | Autoclavable | Max. Temp., °F | Space Saving Features | Surface Resistivity, ohms/sq. | Includes | Each | |

Polypropylene Plastic | ||||||||||||||||

| 56 | 3 1/4 | 1 1/2 | 2 1/2" | 1 1/4" | 1 7/8" | 16 1/2" | 10 7/8" | 2 1/2" | Black | No | 120° | Stackable | 105 | 13 Dividers | 00000000 | 000000 |

Vented Food Industry Stainless Steel Pans

These pans have ¼” dia. perforations on the sides and bottom to allow drainage and air flow. They meet NSF/ANSI 2 sanitary design standards for food equipment.

Food Industry Round Metal Batch Cans

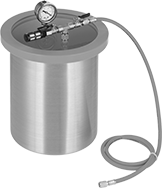

Vacuum Containers

Also known as vacuum degassing chambers, these remove trapped air from mixtures such as paint and mold resins. The fittings on the hose contain a gasket that allows you to connect the hose to flared fittings.

304 stainless steel containers have excellent corrosion resistance and are commonly used in laboratories.

Containers with a side-mount gauge allow you to see the material inside of them when looking from the top.

Glass lids resist corrosion. They’re primarily used to eliminate air bubbles in woodworking projects that use harsh chemicals, which would deteriorate plastic lids. Glass lids are less durable than acrylic lids.

Acrylic lids are more durable than glass lids. They’re commonly used to eliminate air bubbles in hard setting materials, such as silicone and polyurethane.

Replacement lids do not include hardware or seal.

Replacement manifold assemblies include a manifold, vacuum gauge, washer, O-ring, and hex nut.

Containers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gauge | Hose | Replacement Lids | |||||||||||||||||

| Cap. | Dia. | Ht. | Bottom ID | Vacuum Range, in. of Hg | Accuracy | Grad. Marks, in. of Hg | Lg. | Thread Size | Gender | For Connection Style | For Flared Angle | For Tube OD | Max. Temp., °F | Removes Particle Size Down To | Includes | Each | Each | ||

304 Stainless Steel with Top-Mount Gauge | |||||||||||||||||||

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 1/2 gal. | 8 1/4" | 9 1/4" | 7 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 0000000 | 0000000 | 0000000 |

304 Stainless Steel with Side-Mount Gauge | |||||||||||||||||||

Glass Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 1/2 gal. | 8 1/4" | 9 1/4" | 7 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| Gauge Mounting Location | Each | |

| Side | 0000000 | 000000 |

| Removes Particle Size Down To | Each | |

| 50 microns | 0000000 | 00000 |

Electric Sprayers

To save time and effort when disinfecting bathrooms, worksites, and other large spaces, these sprayers are electric powered, so you don’t need to pump them by hand. They have a nonsparking motor, which means they work with flammable chemicals. But, they won’t work with oil-based disinfectants. The nozzle produces a flat, thin spray pattern for an even coating and comes in three sizes. The smaller the nozzle, the finer the spray. Adjust the flow rate to avoid wasting chemicals.

The wand is light enough to hold with one hand and has a trigger that’s easy to squeeze, reducing hand fatigue. Use the spray extension wand to access hard-to-reach areas and spray from a distance when working with hazardous chemicals. These sprayers also have two hose lengths—the shorter length is more flexible and gives you more control when spraying high flow rates, while the longer length lets you reach more places without having to move the sprayer.

Note: The material of the parts can affect a sprayer’s compatibility with a chemical or solution. Make sure all parts of the sprayer are suitable to your application.

Fill Opening | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Ht. | Wd. | Dp. | Max. Flow Rate, gpm | Operating Pressure, psi | Tank Material | Color | Hose Lg. | Wd. | Dp. | Cord Lg., ft. | Includes | Each | |

Flat Dispensing | ||||||||||||||

120V AC—Three-Prong Plug | ||||||||||||||

| 1 1/2 | 19 5/8" | 13 1/2" | 20 1/4" | 0.5 | 0 - 1,000 | Polyethylene Plastic | Black | 4.5 ft., 50 ft. | 8" | 9" | 6 1/2 | 0.015" Dia. Nozzle, 0.017" Dia. Nozzle, 0.019" Dia. Nozzle, 15" Spray Extension Wand | 0000000 | 000000000 |

Heated Ultrasonic Cleaners

Heat cleaning solutions to increase their effectiveness. These ultrasonic cleaners use sound waves moving through the solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

Cleaning pans act as a second cleaning tank when placed inside the tank of an ultrasonic cleaner. They have ledges that rest on top of the cleaner, leaving the bottom submerged in the tank’s solution. Ultrasonic waves from the tank transfer through the solid bottom of the basket to the solution inside.

For technical drawings and 3-D models, click on a part number.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

| 6 | 11 3/4" | 6" | 6" | 12 3/4" | 7" | 11" | 43 | 335 | 120V AC | 60 | Timer, Heater, Drain | ABS Plastic Cover | 0000000 | 000000000 |

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 6 | 5 | 10 5/8" | 5 1/4" | 9" | 4" | 5" | 0.222" | 0.028" | 0000000 | 0000000 |

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 6 | 10 | 10 5/8" | 4 7/8" | 10 5/8" | 4 7/8" | 5" | 0.156" | 0000000 | 0000000 |

Top | Bottom | ||||||

|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Lg. | Wd. | Lg. | Wd. | Ht. | Each | |

304 Stainless Steel | |||||||

| 6 | 11 3/4" | 6" | 11" | 5 1/2" | 6" | 0000000 | 0000000 |

Programmable Heated Ultrasonic Cleaners

Precisely control the cleaning process by setting the temperature and time. Heating cleaning solutions and using the degas function to remove dissolved gases increases their effectiveness. These cleaners use sound waves moving through the solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

| 6 | 11 1/2" | 6" | 6" | 15 5/8" | 12 1/2" | 14 3/4" | 40 | 335 | 120V AC | 90 | Timer, Heater, Automatic Shut-Off, Degas Function, Sleep Mode, Drain | Cover | 0000000 | 000000000 |

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 6 | 5 | 10 5/8" | 5 1/4" | 9" | 4" | 5" | 0.222" | 0.028" | 0000000 | 0000000 |

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 6 | 10 | 10 5/8" | 4 7/8" | 10 5/8" | 4 7/8" | 5" | 0.156" | 0000000 | 0000000 |

Ultrasonic Cleaners

Sound waves move through the cleaning solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

Cleaning pans act as a second cleaning tank when placed inside the tank of an ultrasonic cleaner. They have ledges that rest on top of the cleaner, leaving the bottom submerged in the tank’s solution. Ultrasonic waves from the tank transfer through the solid bottom of the basket to the solution inside.

For technical drawings and 3-D models, click on a part number.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

Timed Cleaning | ||||||||||||||

| 6 | 11 3/4" | 6" | 6" | 12 3/4" | 7" | 11" | 43 | 135 | 120V AC | 60 | Timer, Drain | ABS Plastic Cover | 0000000 | 000000000 |

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 6 | 5 | 10 5/8" | 5 1/4" | 9" | 4" | 5" | 0.222" | 0.028" | 0000000 | 0000000 |

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 6 | 10 | 10 5/8" | 4 7/8" | 10 5/8" | 4 7/8" | 5" | 0.156" | 0000000 | 0000000 |

Top | Bottom | ||||||

|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Lg. | Wd. | Lg. | Wd. | Ht. | Each | |

304 Stainless Steel | |||||||

| 6 | 11 3/4" | 6" | 11" | 5 1/2" | 6" | 0000000 | 0000000 |