About On/Off Valves

More

About NEMA Plugs, Sockets, and Receptacles

More

About Duct Connections

More

Safe-Break Pin-and-Sleeve Connectors

Connect and disconnect with the power on—spring-loaded contacts open like a switch when separating the connectors, preventing an electrical arc. These connectors are approved as switch-rated connectors for branch circuit and motor circuit disconnect switching. When mated, they form a NEMA 4X rated connection that resists corrosion and protects against washdowns. A ground pin is included in the number of wires.

Receptacles include a junction box with a conduit entry hub.

Finger drawplates (sold separately) create a grip around plugs and sockets or receptacles, making it easier to pull them together tightly when mating.

For technical drawings and 3-D models, click on a part number.

| 2W3P |

3W4P |

Conduit | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Dia. | No. of Poles | No. of Ground Connections | No. of Wires | Industry Designation | Electrical Phase | Current | Wire Connection Type | For Wire Gauge | For Cable OD | Trade Size | Thread Type | Features | Temp. Range, °F | Environmental Rating | Choose a Voltage | Each | |

| 1.3" | 3 | 1 | 2 | 2W3P | Single | 20A | Screw Terminals | 14-12 | __ | 1 | NPT | Internal Shutters | -15° to 140° | IP66, IP67, IP69K, NEMA 4X | 125V AC | 00000000 | 0000000 |

| 1.7" | 4 | 1 | 3 | 3W4P | Three | 20A | Screw Terminals | 14-12 | __ | 1 | NPT | __ | -40° to 140° | IP66, IP67, IP69K, NEMA 4X | 0000000 | 000000 | |

| 1.8" | 3 | 1 | 2 | 2W3P | Single | 30A | Screw Terminals | 14-8 | __ | 1 | NPT | Internal Shutters | -15° to 140° | IP66, IP67, IP69K, NEMA 4X | 125V AC | 00000000 | 000000 |

| 1.9" | 4 | 1 | 3 | 3W4P | Three | 30A | Screw Terminals | 14-8 | 0.2"-0.82" | 1 | NPT | __ | -40° to 140° | IP66, IP67, IP69K, NEMA 4X | 0000000 | 000000 | |

| 2.2" | 4 | 1 | 3 | 3W4P | Three | 60A | Screw Terminals | 12-4 | __ | 1 | NPT | __ | -40° to 140° | IP66, IP67, IP69K, NEMA 4X | 0000000 | 000000 | |

| 2.6" | 4 | 1 | 3 | 3W4P | Three | 100A | Screw Terminals | 10-2 | __ | 1 1/2 | NPT | __ | -40° to 140° | IP66, IP67, IP69K, NEMA 4X | 0000000 | 000000 | |

| For Connector Current | Sleeve Material | Each | |

Ground Sleeves | |||

|---|---|---|---|

| 20 A | Silver-Plated Nickel | 00000000 | 000000 |

| 30 A | Silver-Plated Nickel | 00000000 | 00000 |

| 60 A | Silver-Plated Nickel | 00000000 | 00000 |

| 100 A | Silver-Plated Nickel | 00000000 | 00000 |

Power Sleeves | |||

| 20 A | Silver-Plated Nickel | 00000000 | 00000 |

| 30 A | Silver-Plated Nickel | 00000000 | 00000 |

| 60 A | Silver-Plated Nickel | 00000000 | 00000 |

| 100 A | Silver-Plated Nickel | 00000000 | 00000 |

Hazardous Location Safe-Break Pin-and-Sleeve Connectors

Use connectors where ignitable gas and dust may be present, such as in refineries and silos. They are CSA certified for Class I, Division 2, Groups A, B, C, and D; and Class II, Division 2, Groups F and G. All have a chamber that withstands the pressure of an internal ignition—isolating it from spreading to the surrounding environment. They're rated IP66 and IP67 for protection from washdowns and temporary submersion.

Finger drawplates (sold separately) create a grip around plugs and sockets or receptacles, making it easier to pull them together tightly when mating.

For technical drawings and 3-D models, click on a part number.

| 2W3P |

3W4P |

Conduit | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Dia. | No. of Poles | No. of Ground Connections | No. of Wires | Industry Designation | Electrical Phase | Current | Wire Connection Type | For Wire Gauge | Trade Size | Thread Type | Temp. Range, °F | Choose a Voltage | Each | |

| 1.4" | 3 | 1 | 2 | 2W3P | Single | 20A | Screw Terminals | 16-10 | 3/4 | NPT | -40° to 140° | 125V AC | 0000000 | 0000000 |

| 1.4" | 4 | 1 | 3 | 3W4P | Three | 20A | Screw Terminals | 16-10 | 3/4 | NPT | -40° to 140° | 0000000 | 000000 | |

| 1.9" | 3 | 1 | 2 | 2W3P | Single | 30A | Screw Terminals | 14-6 | 3/4 | NPT | -40° to 140° | 125V AC | 0000000 | 000000 |

| 1.9" | 4 | 1 | 3 | 3W4P | Three | 30A | Screw Terminals | 14-6 | 3/4 | NPT | -40° to 140° | 0000000 | 000000 | |

| 2.1" | 4 | 1 | 3 | 3W4P | Three | 60A | Screw Terminals | 10-4 | 1 | NPT | -40° to 140° | 0000000 | 00000000 | |

Corrosion-Resistant Pin-and-Sleeve Connectors

When used together, connectors maintain a watertight and corrosion-resistant NEMA 4X connection. All meet UL 1686 and are fully interchangeable with other UL 1686 configured and listed devices.

3W4P (three wire four pole) connectors have a ground pin that is included in the number of poles. They are marked 3W4P.

Receptacles include a mounting box with a conduit entry hub.

For technical drawings and 3-D models, click on a part number.

Conduit | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Face Dia. | No. of Poles | No. of Ground Connections | No. of Wires | Industry Designation | Electrical Phase | Current | Voltage | Wire Connection Type | For Wire Gauge | Trade Size | Thread Type | Temp. Range, °F | Each | ||

| A | 1.9" | 3 | 0 | 3 | 3W3P | Three | 30A | 250V DC/600V AC | Screw Terminals | 10-6 | 1 | NPT | -55° to 100° | 0000000 | 0000000 |

| B | 1.9" | 4 | 0 | 4 | 4W4P | Three | 30A | 250V DC/600V AC | Screw Terminals | 10-6 | 1 | NPT | -55° to 100° | 0000000 | 000000 |

| C | 1.9" | 4 | 1 | 3 | 3W4P | Three | 30A | 250V DC/600V AC | Screw Terminals | 10-6 | 1 | NPT | -55° to 100° | 0000000 | 000000 |

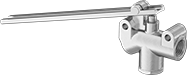

Snap-Shut Threaded On/Off Valves

For applications that require intermittent operation, such as spraying and washing, push or pull the lever on these valves to start flow. They spring closed when the lever is released.

Brass valves are stronger and less brittle than zinc valves for use in higher-pressure applications.Valves with a TFE plastic seat are more durable than those with a Viton® fluoroelastomer rubber seat.

Replace worn components on 30° elbow valves with a repair kit (sold separately).

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Stem

- For Use With: Air, Argon, Helium, Inert Gas, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Buna-N Rubber

- Seat Material: TFE Plastic

Grease Fittings

Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. They’re also known as hydraulic grease fittings.

Zinc-plated steel fittings have mild corrosion resistance. 303 stainless steel fittings are more corrosion resistant than brass fittings and have good chemical resistance. 400 nickel fittings are the most corrosion resistant and can be used in caustic environments, such as those involving salt water, sulfuric acid, and alkalies.

Fittings with a check valve prevent grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

PTF-SAE and NPTF (Dryseal) threads are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/8 PTF-SAE Threads | ||||||||||

| Zinc-Plated Steel | 29/32" | 1/4" | 19/64" | 7/16" | 10,000 | Ball | 10 | 0000000 | 000000 | 00000 |

| Zinc-Plated Steel | 2 3/32" | 19/64" | 1 1/4" | 7/16" | 10,000 | Ball | 1 | 0000000 | 0000 | 0000 |

| 303 Stainless Steel | 29/32" | 19/64" | 19/64" | 7/16" | 10,000 | Ball | 1 | 0000000 | 0000 | 0000 |

| 400 Nickel | 1 1/4" | 11/32" | 11/32" | 7/16" | 10,000 | Ball | 1 | 0000000 | 00000 | 00000 |

Leakproof Grease Fittings

Keep thin grease from leaking out—the check valve in these fittings has a Buna-N seat that creates a tighter seal than check valves in other grease fittings. The valve stays closed when not in use to keep out dirt and other contaminants. Fittings are zinc-plated steel, which has mild corrosion resistance. They're also known as hydraulic grease fittings. They have PTF-SAE and NPTF (Dryseal) threads, which are compatible with NPT threads.

For technical drawings and 3-D models, click on a part number.

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Shank Lg. | Thread Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/8 NPTF Threads | ||||||||||

| Zinc-Plated Steel | 1 7/32" | 25/64" | 17/64" | 7/16" | 5,000 | Disc | 5 | 0000000 | 000000 | 000000 |

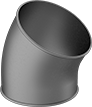

Quick-Disconnect Duct and Fittings

Join duct and fittings with quick-release clamps for faster disassembly and cleanout than other duct systems.

Galvanized steel has good corrosion resistance. 304 stainless steel is the most corrosion resistant.

For technical drawings and 3-D models, click on a part number.

Galvanized Steel | 304 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Duct Size | ID | End Construction | Style | Gauge | Each | Style | Gauge | Each | ||

| 3 | 3 1/16" | Rolled | A | 24 | 00000000 | 000000 | A | 14 | 00000000 | 0000000 |

| 4 | 3 7/8" | Rolled | A | 24 | 00000000 | 00000 | A | 14 | 00000000 | 000000 |

| 5 | 4 7/8" | Rolled | A | 24 | 00000000 | 00000 | A | 14 | 00000000 | 000000 |

| 6 | 5 7/8" | Rolled | A | 24 | 00000000 | 000000 | A | 14 | 00000000 | 000000 |

| 7 | 6 7/8" | Rolled | A | 24 | 00000000 | 000000 | __ | __ | 000000 | 00 |

| 8 | 7 7/8" | Rolled | B | 22 | 00000000 | 000000 | B | 22 | 00000000 | 000000 |

| 9 | 8 7/8" | Rolled | B | 22 | 00000000 | 000000 | __ | __ | 000000 | 00 |

| 10 | 9 7/8" | Rolled | B | 22 | 00000000 | 000000 | B | 22 | 00000000 | 000000 |

| 12 | 12" | Rolled | B | 22 | 00000000 | 000000 | B | 22 | 00000000 | 000000 |

| 14 | 13 15/16" | Rolled | B | 20 | 00000000 | 000000 | B | 20 | 00000000 | 000000 |

| 16 | 16" | Rolled | B | 20 | 00000000 | 000000 | B | 20 | 00000000 | 000000 |

| 18 | 17 15/16" | Rolled | B | 20 | 00000000 | 000000 | B | 20 | 00000000 | 000000 |

| 20 | 19 15/16" | Rolled | B | 20 | 00000000 | 000000 | B | 20 | 00000000 | 000000 |

| 22 | 22" | Rolled | B | 20 | 00000000 | 000000 | __ | __ | 000000 | 00 |

| 24 | 23 15/16" | Rolled | B | 20 | 00000000 | 000000 | __ | __ | 000000 | 00 |