About Wire and Cable

More

About Sleeving

More

High-Temperature Expandable Sleeving

Protect cable, hose, and pipe from abrasion and cuts in high temperature environments—this sleeving withstands temperatures over 450° F. It expands to fit over items for easy installation; sleeving then tightens around its contents for a secure fit. The braided construction permits heat and moisture to dissipate.

PTFE and PEEK sleeving withstand chemicals and salt water, so they can be used in extreme environments where cable and hose need protection from harsh fluids, such as in chemical plants and in oil and gas production. It has better abrasion and tear resistance than fiberglass sleeving. PTFE sleeving also withstands acids and solvents. PEEK is lighter in weight than PTFE, and more cost efficient.

Flame rated VW-1 sleeving meets requirements for preventing the spread of flames based on a timed test with vertically suspended material.

Per Ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Expanded ID | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Length, ft. | 1-49 | 50-Up | |

PEEK Fabric | |||||||||

| 1/4" | 1/2" | 1/32" | -90° to 480° | UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1/2" | 7/8" | 1/32" | -90° to 480° | UL 2556 VW-1 | Black | 0000000 | 00000 | 0000 | |

| 3/4" | 1 1/8" | 1/32" | -90° to 480° | UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1 1/4" | 1 3/4" | 1/32" | -90° to 480° | UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1 3/4" | 2 1/2" | 1/32" | -90° to 480° | UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

Flame-Retardant Expandable Sleeving

Tested to meet MIL-STD-202, this sleeving meets performance standards for flame retardance. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Made of polyester, it resists some wear and chemicals, so it’s best used in indoor environments. It’s expandable, so it stretches to fit over items for easy installation, then tightens around its contents for a secure fit. The braided construction permits heat and moisture to dissipate.

Per Ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Expanded ID | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Lengths, ft. | 1-49 | 50-Up | |

Polyester Fabric | |||||||||

| 1/8" | 1/4" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1/4" | 7/16" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 3/8" | 5/8" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 1/2" | 3/4" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 3/4" | 1 1/4" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 1 1/4" | 1 3/4" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

| 1 1/2" | 2 1/2" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

| 1 3/4" | 2 3/4" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

| 2" | 3 1/2" | 1/32" | -90° to 255° | UL Recognized Component, CSA Certified, MIL-STD-202, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

Duct-Rated Flame-Retardant Expandable Sleeving

Rated UL 2024 and NFPA 262 for use in plenum spaces such as duct work and above a drop ceiling, this sleeving self-extinguishes and emits minimal amounts of smoke and gas during combustion. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Made of ECTFE, it protects contents from corrosive chemicals and organic solvents as the sleeving exits the duct. It’s expandable, so it stretches to fit over items for easy installation, then tightens around its contents for a secure fit. The braided construction permits heat and moisture to dissipate.

Per Ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Expanded ID | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Lengths, ft. | 1-49 | 50-Up | |

ECTFE Fabric | |||||||||

| 1/4" | 1/2" | 1/32" | -90° to 300° | UL 2024, NFPA 262, UL 2556 VW-1 | Black | 000000 | 00000 | 00000 | |

| 1/2" | 3/4" | 1/32" | -90° to 300° | UL 2024, NFPA 262, UL 2556 VW-1 | Black | 000000 | 0000 | 0000 | |

| 3/4" | 1 1/4" | 1/32" | -90° to 300° | UL 2024, NFPA 262, UL 2556 VW-1 | Black | 000000 | 0000 | 0000 | |

| 1 3/4" | 2 1/2" | 1/32" | -90° to 300° | UL 2024, NFPA 262, UL 2556 VW-1 | Black | 000000 | 0000 | 0000 | |

Chemical-Resistant Tube Sleeving

Made of PVC, this sleeving resists chemicals, oil, and acids. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Because this sleeving is non-expandable, it does not stretch, so it’s best for applications where you know the exact diameter of the items you need to protect.

Per Ft. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | For Wire Gauge | For Wire Size | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Lengths, ft. | 1-99 | 100-Up | |

PVC Plastic | ||||||||||

| 0.022" | 24 | __ | 0.012" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 0.027" | 22 | __ | 0.012" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.034" | 20 | __ | 0.016" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.04" | 18 | __ | 0.016" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.05" | 16 | __ | 0.016" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.07" | 14 | __ | 0.016" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.09" | 12 | __ | 0.016" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.11" | 10 | __ | 0.016" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.13" | 8 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.17" | 6 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.19" | 5 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.21" | 4 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.23" | 3 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.25" | __ | 1/4" | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.26" | 2 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.29" | 1 | __ | 0.02" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.31" | __ | 5/16" | 0.025" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.33" | 1/0 | __ | 0.025" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.38" | __ | 3/8" | 0.025" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.44" | __ | 7/16" | 0.025" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.5" | __ | 1/2" | 0.025" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.56" | __ | 9/16" | 0.03" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.63" | __ | 5/8" | 0.03" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 000 | 000 | |

| 0.75" | __ | 3/4" | 0.035" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 0000 | 000 | |

| 1" | __ | 1" | 0.035" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

| 1.5" | __ | 1 1/2" | 0.045" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

| 2" | __ | 2" | 0.06" | 0° to 220° | UL Listed, UL 2556 VW-1 | Black | 0000000 | 0000 | 0000 | |

High-Temperature Electrical-Insulating Tube Sleeving

This sleeving withstands temperatures up to 390° F and is often used to insulate connections in transformers, relays, and solenoids. It prevents electricity and heat from dissipating from wire and cable. When exposed to flame, it will self-extinguish and produce a nonconductive ash. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Made of silicone-coated fiberglass, it resists chemicals.

| ID | For Wire Gauge | For Wire Size | Wall Thick. | For Max. Voltage | Temperature Range, °F | Specifications Met | Choose a Color | 5 ft. | 10 ft. | 25 ft. | 50 ft. | |

Fiberglass Fabric with Silicone Rubber Coating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black and White | ||||||||||||

| 0.09" | 12 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.11" | 10 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.12" | 9 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.13" | 8 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.17" | 6 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.21" | 4 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.26" | 2 | __ | 0.02" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.33" | 1/0 | __ | 0.03" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.39" | __ | 3/8" | 0.03" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.45" | __ | 7/16" | 0.03" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.51" | __ | 1/2" | 0.03" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.64" | __ | 5/8" | 0.03" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

| 0.77" | __ | 3/4" | 0.03" | 7,000V AC | -65° to 390° | CSA Certified, UL 2556 VW-1, UL Recognized Component | 0000000 | |||||

Electrical-Insulating Tube Sleeving

Add a layer of insulation to prevent electricity and heat from dissipating from wire and cable. This sleeving is often used in motors, transformers, and generators. Made of coated fiberglass, it resists abrasion, acids, alkalies, and chemicals.

Vinyl-coated sleeving resists wax and alcohol. Sleeving is flame-rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material.

| ID | For Wire Gauge | For Wire Size | Wall Thick. | For Max. Voltage | Temperature Range, °F | Specifications Met | Color | 5 ft. | 10 ft. | 25 ft. | 50 ft. | |

Fiberglass Fabric with Vinyl Plastic Coating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.09" | 12 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.11" | 10 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.12" | 9 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.13" | 8 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.17" | 6 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.21" | 4 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.26" | 2 | __ | 0.02" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.33" | 1/0 | __ | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.39" | 1/0 | 3/8" | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.45" | 1/0 | 7/16" | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.51" | 1/0 | 1/2" | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.64" | 1/0 | 5/8" | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 0.77" | 1/0 | 3/4" | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

| 1.02" | 1/0 | 1" | 0.03" | 7,000V AC | 0° to 265° | UL Recognized Component, CSA Certified, UL 2556 VW-1 | Black | 0000000 | ||||

Interference-Shielding Wrap-Around Sleeving

Use this shielded sleeving to protect wire and cable from signal distortion caused by nearby equipment and devices. A sewn-in ground wire dissipates any stored charge. It provides good protection against abrasion. Wrap it around wire and cable without disconnecting them; sleeving has a slit along the entire length. Sleeving with an adhesive strip closure is permanently sealed when the adhesive is applied. Sleeving with foil shielding is for use in stationary applications. Repeated flexing will damage the foil. Polyurethane rubber sleeving provides excellent resistance to solvents, oil, and grease.

Flame rated VW-1 sleeving meets requirements for preventing the spread of flames based on a timed test with vertically suspended material.

Per Ft. | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Lengths, ft. | 1-24 | 25-Up | |

Polyurethane Rubber with Foil Shielding | ||||||||

| 3/8" | 1/32" | -65° to 225° | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 000000 | 000000 | |

| 1/2" | 1/32" | -65° to 225° | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1" | 1/32" | -65° to 225° | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1 1/2" | 1/32" | -65° to 225° | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 2" | 1/32" | -65° to 225° | UL Recognized Component, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

Chemical-Resistant Wrap-Around Sleeving

Coated with PVC, this polyester sleeving resists chemicals and solvents. It’s flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material. Sleeving meets MIL-C-43006 for material quality. Wrap it around wire, cable, and hose without disconnecting them. It has a slit along the entire length that permanently seals with the adhesive strip.

Per Ft. | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | Wall Thick. | Temperature Range, °F | Specifications Met | Color | Lengths, ft. | 1-24 | 25-Up | |

Polyester Plastic with PVC Plastic Coating | ||||||||

| 3/8" | 1/32" | -40° to 180° | UL Recognized Component, MIL-C-43006 Type II Class 1, UL 2556 VW-1 | Black | 0000000 | 000000 | 000000 | |

| 1/2" | 1/32" | -40° to 180° | UL Recognized Component, MIL-C-43006 Type II Class 1, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1" | 1/32" | -40° to 180° | UL Recognized Component, MIL-C-43006 Type II Class 1, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 1 1/2" | 1/32" | -40° to 180° | UL Recognized Component, MIL-C-43006 Type II Class 1, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

| 2" | 1/32" | -40° to 180° | UL Recognized Component, MIL-C-43006 Type II Class 1, UL 2556 VW-1 | Black | 0000000 | 00000 | 00000 | |

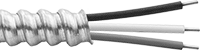

Armored Building Cable

- Use For: Buildings

- Flexible

- Temperature Range:

MC, THHN: 15° to 190° F

MC, XHHW-2: -40° to 190° F - Outer Insulation:

MC, THHN: Aluminum Armor

MC, XHHW-2: Aluminum Armor, PVC Plastic - Inner Insulation:

MC, THHN: PVC Plastic

MC, XHHW-2: Cross-Linked Polyethylene (XLPE)

Also known as metal clad (MC) cable, this cable has metal armor that acts as conduit to protect the building wires. It's often used along the exterior of walls to carry power to outlet boxes. It has a ground wire that is not counted in the number of wires.

Hazardous location environmental ratings indicate whether manufacturers have included safety features in products to facilitate their safe use in a hazardous environment. Before selecting a product for a hazardous location, ensure it is rated for your environment.

Cable with THHN wire stands up to condensation and moisture in basements and other damp environments.

For technical drawings and 3-D models, click on a part number.

| Wire Ga. | No. of Wires | Cable AWG | Current | OD | Inner Insulation Color | Features | Environmental Rating | Specifications Met | 10 ft. | 25 ft. | 50 ft. | 100 ft. | 250 ft. | |

MC, THHN Solid Wire | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

600V AC | ||||||||||||||

| 14 | 2 | 14/2 | 15 A @ 86° F | 0.44" | Black, Green, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 14 | 3 | 14/3 | 15 A @ 86° F | 0.46" | Black, Green, Red, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 14 | 4 | 14/4 | 15 A @ 86° F | 0.49" | Black, Blue, Green, Red, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 12 | 2 | 12/2 | 20 A @ 86° F | 0.48" | Black, Green, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 12 | 3 | 12/3 | 20 A @ 86° F | 0.51" | Black, Green, Red, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 12 | 4 | 12/4 | 20 A @ 86° F | 0.54" | Black, Blue, Green, Red, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 10 | 2 | 10/2 | 30 A @ 86° F | 0.54" | Black, Green, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 10 | 3 | 10/3 | 30 A @ 86° F | 0.58" | Black, Green, Red, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

| 10 | 4 | 10/4 | 30 A @ 86° F | 0.62" | Black, Blue, Green, Red, White | Insulated Ground Wire | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Divisions 1, 2 | UL 1569, UL 2556 VW-1 | 0000000 | |||||

Armored Building Cable with Uninsulated Ground Wire

- Use For: Buildings

- Flexible

- Temperature Range: 15° to 190° F

- Insulation:

Outer: Aluminum Armor

Inner: PVC Plastic

Also known as AC cable, this cable has an uninsulated aluminum ground wire that's in constant contact with the aluminum armor, so it can be used for bonding and grounding. The uninsulated ground wire is not counted in the number of wires. The armor acts as conduit to protect the THHN building wires. It's often used along the exterior of walls to carry power to outlet boxes. All are flame rated VW-1 to meet requirements for preventing the spread of flames based on a timed test with vertically suspended material.

| Wire Ga. | No. of Wires | Cable AWG | Current | OD | Inner Insulation Color | Features | Industry Designation | Specifications Met | 10 ft. | 25 ft. | 50 ft. | 100 ft. | 250 ft. | |

Solid Wire | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

600V AC | ||||||||||||||

| 14 | 2 | 14/2 | 15 A @ 86° F | 0.46" | Black, White | Uninsulated Ground Wire | AC, THHN | UL Listed, UL 2556 VW-1 | 0000000 | |||||

| 14 | 3 | 14/3 | 15 A @ 86° F | 0.48" | Black, Red, White | Uninsulated Ground Wire | AC, THHN | UL Listed, UL 2556 VW-1 | 0000000 | |||||

| 12 | 2 | 12/2 | 20 A @ 86° F | 0.5" | Black, White | Uninsulated Ground Wire | AC, THHN | UL Listed, UL 2556 VW-1 | 0000000 | |||||

| 12 | 3 | 12/3 | 20 A @ 86° F | 0.52" | Black, Red, White | Uninsulated Ground Wire | AC, THHN | UL Listed, UL 2556 VW-1 | 0000000 | |||||

| 10 | 2 | 10/2 | 30 A @ 86° F | 0.56" | Black, White | Uninsulated Ground Wire | AC, THHN | UL Listed, UL 2556 VW-1 | 0000000 | |||||

| 10 | 3 | 10/3 | 30 A @ 86° F | 0.59" | Black, Red, White | Uninsulated Ground Wire | AC, THHN | UL Listed, UL 2556 VW-1 | 0000000 | |||||

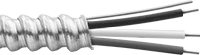

Armored Fire Alarm Cable

- Use For: Buildings

- Flexible

- Temperature Range: -10° to 190° F

- Insulation:

Outer: Aluminum Armor

Inner: Nylon Plastic, PVC Plastic

Prevent damage to wires for fire alarm systems, smoke detectors, and other critical circuits with this armored cable. Also known as metal clad (MC) cable, the metal armor acts as a conduit to protect the wires inside. The PVC inner insulation resists flames. Its nylon jacket is low smoke, so it can be used without conduit in duct work, under raised floors, and above a drop ceiling. This cable has a ground wire that is not counted in the number of wires.

Hazardous location environmental ratings indicate whether manufacturers have included safety features in products to facilitate their safe use in a hazardous environment. Before selecting a product for a hazardous location, ensure it’s rated for your environment.

Shielded cable has a layer of foil that blocks signal interference from nearby equipment and devices.

For technical drawings and 3-D models, click on a part number.

| Wire Ga. | No. of Wires | Cable AWG | OD | Outer Insulation Color | Inner Insulation Color | Features | Industry Designation | Environmental Rating | Specifications Met | 10 ft. | 25 ft. | 50 ft. | 100 ft. | 250 ft. | |

Unshielded Solid Wire | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

300V AC/300V DC | |||||||||||||||

| 18 | 4 | 18/4 | 0.43" | Red | Black, Blue, Green, Red, White | Insulated Ground Wire | MC-FPLP | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Division 2 | UL Listed, UL 2556 VW-1 | 0000000 | |||||

Shielded Solid Wire | |||||||||||||||

300V AC/300V DC | |||||||||||||||

| 18 | 2 | 18/2 | 0.39" | Red | Black, White | Uninsulated Ground Wire | MC-FPLP | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G NEC Class III Division 2 | UL Listed, UL 2556 VW-1 | 0000000 | |||||