About On/Off Valves

More

On/Off Valves with Yor-Lok Fittings

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Valves are standard port, so they slightly restrict flow.

Brass valves have good corrosion resistance. Nickel-plated brass valves are more corrosion resistant than plain brass valves, and have a polished finish.

316 stainless steel valves are more corrosion resistant than plain and nickel-plated brass valves.

Lever handles are easy to open and close—they give you the most leverage of any handle type. Lockable lever handles can be fixed in place using a padlock (not included).

T-handles are our most compact option. They’re great if you want to install valves next to each other or in tight spaces.

NPT connections can be taken apart as needed for maintenance and repair.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: Fluoroelastomer Rubber

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| For Tube OD | Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Yor Lok × Yor Lok | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | __ | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 11/32" | 0000000 | 000000 |

| 3/8" | __ | 2.5 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 11/32" | 0000000 | 00000 |

| 1/2" | __ | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 3/4" | 11/32" | 0000000 | 000000 |

| 3/4" | __ | 12.65 | 2000 psi @ 100° F | -30° to 400° | 4 7/16" | 11/32" | 0000000 | 000000 |

| 1" | __ | 17.35 | 2000 psi @ 100° F | -30° to 400° | 5 1/8" | 11/32" | 0000000 | 000000 |

| 6mm | __ | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 11/32" | 0000000 | 00000 |

| 8mm | __ | 1.35 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 11/32" | 0000000 | 00000 |

| 10mm | __ | 2.6 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 11/32" | 0000000 | 000000 |

| 12mm | __ | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 3/4" | 11/32" | 0000000 | 000000 |

| 15mm | __ | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 3/4" | 11/32" | 0000000 | 000000 |

Yor Lok × NPT Male | ||||||||

| 1/4" | 1/4 | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 1/16" | 11/32" | 00000000 | 00000 |

| 3/8" | 3/8 | 2.5 | 2000 psi @ 100° F | -30° to 400° | 3 1/8" | 11/32" | 00000000 | 00000 |

| 1/2" | 1/2 | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 11/16" | 11/32" | 00000000 | 000000 |

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

Yor Lok × Yor Lok | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 0000000 | 000000 |

| 3/8" | 2.5 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 0000000 | 00000 |

| 1/2" | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 3/4" | 0000000 | 000000 |

| 3/4" | 12.65 | 2000 psi @ 100° F | -30° to 400° | 4 7/16" | 00000000 | 000000 |

| 1" | 17.35 | 2000 psi @ 100° F | -30° to 400° | 5 1/8" | 00000000 | 000000 |

| 6mm | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 00000000 | 00000 |

| 8mm | 1.35 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 00000000 | 000000 |

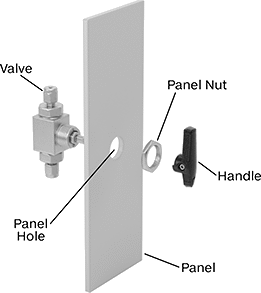

Panel-Mount On/Off Valves with Yor-Lok Fittings

Easily access the handle of these valves while protecting your line behind an instrument panel. Threads and a hex nut below the handle allow you to install these valves in instrument panels. For extra gripping power and a strong seal, they have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Valves are standard port, so they slightly restrict flow.

Valves with lockable handle can be fixed in place using a padlock (not included).

316 stainless steel valves are more corrosion resistant than brass valves.

Fluoroelastomer seals are highly compressible, so they conform to connections to make tight seals, even when surfaces are uneven, misaligned, and dirty.

PTFE seals are the best choice for valves that are opened and closed often. The PTFE material forms a seal while remaining slippery, so you can open and close the valve frequently without the seal wearing down and failing.

PFA seals withstand high pressures and temperature changes. The plastic of the seal is nonporous, so it won’t trap gases or liquids that would weaken these seals.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: See Table

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Panel Cutout Dia. | For Use With | Each | |

Brass Body—Fluoroelastomer Rubber Seal | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | ||||||||||

| 1/8" | 0.22 | 1500 psi @ 70° F | __ | -30° to 300° | 29 | 2 3/8" | 5/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

| 1/4" | 0.88 | 1500 psi @ 70° F | __ | -30° to 300° | 29 | 2 9/16" | 5/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 00000 |

| 3/8" | 1.57 | 1000 psi @ 70° F | __ | -30° to 300° | 29 | 2 5/8" | 5/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 00000 |

| 1/2" | 2.74 | 1000 psi @ 70° F | __ | -30° to 300° | 29 | 3 3/16" | 5/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

Brass Body—PTFE Plastic Seal | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/8" | 0.2 | 3000 psi @ 70° F | __ | -30° to 400° | 29 | 3 1/8" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

| 1/4" | 1.5 | 3000 psi @ 70° F | __ | -30° to 400° | 29 | 3 5/16" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

| 3/8" | 1.5 | 3000 psi @ 70° F | __ | -30° to 400° | 29 | 3 7/16" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

| 1/2" | 12 | 3000 psi @ 70° F | __ | -30° to 400° | 29 | 4 1/16" | 13/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

| 3/4" | 6.5 | 3000 psi @ 70° F | __ | -30° to 400° | 29 | 4 1/16" | 13/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

316 Stainless Steel Body—PFA Plastic Seal | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/16" | 0.03 | 1000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | Not Rated | 1 11/16" | 19/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 000000 |

| 1/8" | 0.2 | 1000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | Not Rated | 2" | 19/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 000000 |

| 1/4" | 0.44 | 1000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | Not Rated | 2 1/4" | 19/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 000000 |

| 3/8" | 1.02 | 1000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | Not Rated | 2 5/8" | 25/32" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 000000 |

| 1/2" | 10.7 | 1000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | Not Rated | 3 7/8" | 1 1/2" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | 0000000 | 000000 |

316 Stainless Steel Body—PTFE Plastic Seal | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/16" | 0.1 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 2 3/4" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 1/8" | 0.2 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 3 1/8" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 1/4" | 1.5 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 3 5/16" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 3/8" | 1.5 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 3 7/16" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 1/2" | 12 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 4 1/16" | 13/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 3/4" | 6.5 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 4 1/16" | 13/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 3mm | 0.2 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 3 1/16" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

| 6mm | 1.5 | 6000 psi @ 125° F | __ | -30° to 280° | 29 | 3 5/16" | 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 00000000 | 000000 |

- Valve Type: Ball

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Max. Shackle Dia. | Panel Cutout Dia. | Each | |

316 Stainless Steel Body—PTFE Plastic Seal | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | |||||||||

| 1/4" | 1.5 | 6000 psi @ 125° F | -30° to 280° | 29 | 3 5/16" | 9/32" | 3/4" | 00000000 | 0000000 |

| 3/8" | 1.5 | 6000 psi @ 125° F | -30° to 280° | 29 | 3 7/16" | 9/32" | 3/4" | 00000000 | 000000 |

| 1/2" | 12 | 6000 psi @ 125° F | -30° to 280° | 29 | 4 1/16" | 9/32" | 13/16" | 00000000 | 000000 |

| 3/4" | 6.5 | 6000 psi @ 125° F | -30° to 280° | 29 | 4 1/16" | 9/32" | 13/16" | 00000000 | 000000 |

- Valve Type: Ball

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

316 Stainless Steel Body—PFA Plastic Seal | ||||||||

|---|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | ||||||||

| 1/4" | 0.34 | 2000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | 1 1/8" | 19/32" | 00000000 | 0000000 |

| 3/8" | 0.7 | 2000 psi @ 300° F | 50 psi @ 300° F | -65° to 300° | 1 5/16" | 25/32" | 00000000 | 000000 |

On/Off Valves with Compression Fittings

A compression sleeve bites into tubing as you tighten the nut, forming a strong seal.

316 stainless steel valves are more corrosion resistant than brass valves.

Full-port valves do not restrict flow.

Standard-port valves slightly restrict flow.

Valves with a Buna-N Rubber seal meet NSF/ANSI Standard 61 for use with drinking water.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type:

Brass Seal: Plug

All Other Valves: Ball - For Use With: See table

| For Tube OD | For Copper Tube Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Environment | For Use With | Specifications Met | Each | |

Brass Body—Buna-N Rubber Seal | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/8" | 1/2 | 16 | 600 psi @ 215° F | 600 psi @ 215° F | -20° to 400° | Full | 3" | Food Industry | Water, Oil, Argon, Helium, Krypton, Neon, Xenon, Steam, Drinking Water | NSF/ANSI 61 | 0000000 | 000000 |

| 7/8" | 3/4 | 30 | 600 psi @ 215° F | 600 psi @ 215° F | -20° to 400° | Full | 3 7/16" | Food Industry | Water, Oil, Argon, Helium, Krypton, Neon, Xenon, Steam, Drinking Water | NSF/ANSI 61 | 0000000 | 00000 |

| 1 1/8" | 1 | 52 | 600 psi @ 215° F | 600 psi @ 215° F | -20° to 400° | Full | 4" | Food Industry | Water, Oil, Argon, Helium, Krypton, Neon, Xenon, Steam, Drinking Water | NSF/ANSI 61 | 0000000 | 00000 |

316 Stainless Steel Body—PTFE Plastic Seal | ||||||||||||

| 3/8" | __ | Not Rated | 500 psi @ 200° F | __ | 40° to 200° | Standard | 3 9/16" | __ | Water, Oil, Argon, Helium, Krypton, Neon, Xenon | __ | 0000000 | 000000 |

Plastic On/Off Valves with Compression Fittings

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Seal Material: Buna-N Rubber

A compression sleeve bites into tubing as you tighten the nut, forming a strong seal. These valves are full port, so they do not restrict flow.

For technical drawings and 3-D models, click on a part number.

On/Off Valves with Yor-Lok Fittings for Chemicals

- Valve Type: Ball

- For Use With: Acetone, Air, Ammonia, Carbon Dioxide, Diesel Fuel, Gasoline, Kerosene

- Ball Material: Monel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Specifications Met: ASME B16.34, ASME B31.3

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. These valves have a PTFE seal and a corrosion-resistant Monel ball and body that can stand up to aggressive and corrosive chemicals such as acetone. All are standard port, so they slightly restrict flow. A red handle makes them easy to identify.

For technical drawings and 3-D models, click on a part number.

On/Off Valves with Yor-Lok Fittings for Fuel

- Valve Type: Ball

- For Use With: Diesel Fuel, Fuel Oil, Gasoline, Kerosene

- Seal Material: PTFE Plastic

- Specifications Met: ASME B16.34

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Designed for transferring diesel fuel, fuel oil, gasoline, and kerosene, these valves have a 316 stainless steel body for excellent corrosion resistance. All are standard port, so they slightly restrict flow.

Diverting Valves with Yor-Lok Fittings

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: See table

For extra gripping power and a strong seal, these valves have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Valves divert flow between ports. Turn the handle to direct flow from the bottom-port inlet to either side-port outlet. Valves are standard port, so they slightly restrict flow. All have threads and a hex nut below the handle for panel mounting.

Valves with flow shut-off can stop flow completely in addition to diverting flow between outlet ports.

316 stainless steel valves are more corrosion resistant than brass valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Flow Pattern | Flow Shut-Off | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | Seal Material | End-to-End Lg. | Each | |

Brass Body | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok × Yor Lok | ||||||||||

| 1/8" | L-Pattern | No | 0.15 | 3000 psi @ 70° F | -30° to 400° | 29 | PTFE Plastic | 3 1/8" | 0000000 | 0000000 |

| 1/8" | L-Pattern | Yes | 0.22 | 1500 psi @ 70° F | -30° to 300° | 29 | Buna-N Rubber, Fluoroelastomer Rubber | 2 3/8" | 0000000 | 000000 |

| 1/4" | L-Pattern | No | 0.9 | 3000 psi @ 70° F | -30° to 400° | 29 | PTFE Plastic | 3 5/16" | 0000000 | 000000 |

| 1/4" | L-Pattern | Yes | 0.88 | 1500 psi @ 70° F | -30° to 300° | 29 | Buna-N Rubber, Fluoroelastomer Rubber | 2 9/16" | 0000000 | 00000 |

| 3/8" | L-Pattern | No | 0.6 | 3000 psi @ 70° F | -30° to 400° | 29 | PTFE Plastic | 3 7/16" | 0000000 | 000000 |

| 3/8" | L-Pattern | Yes | 1.57 | 1000 psi @ 70° F | -30° to 300° | 29 | Buna-N Rubber, Fluoroelastomer Rubber | 2 5/8" | 0000000 | 00000 |

| 1/2" | L-Pattern | No | 4.6 | 3000 psi @ 70° F | -30° to 400° | 29 | PTFE Plastic | 4" | 0000000 | 000000 |

| 1/2" | L-Pattern | Yes | 2.74 | 1000 psi @ 70° F | -30° to 300° | 29 | Buna-N Rubber, Fluoroelastomer Rubber | 3 1/8" | 0000000 | 000000 |

316 Stainless Steel Body | ||||||||||

Yor Lok × Yor Lok × Yor Lok | ||||||||||

| 1/16" | L-Pattern | No | 0.08 | 6000 psi @ 125° F | -30° to 280° | 29 | PTFE Plastic | 2 3/4" | 00000000 | 000000 |

| 1/8" | L-Pattern | No | 0.15 | 6000 psi @ 125° F | -30° to 280° | 29 | PTFE Plastic | 3 1/8" | 00000000 | 000000 |

| 1/4" | L-Pattern | No | 0.9 | 6000 psi @ 125° F | -30° to 280° | 29 | PTFE Plastic | 3 5/16" | 00000000 | 000000 |

| 3/8" | L-Pattern | No | 0.6 | 6000 psi @ 125° F | -30° to 280° | 29 | PTFE Plastic | 3 7/16" | 00000000 | 000000 |

| 1/2" | L-Pattern | No | 4.6 | 6000 psi @ 125° F | -30° to 280° | 29 | PTFE Plastic | 4 1/16" | 00000000 | 000000 |