Filter by

Reach Length

Clamping Surface Type

Mount Type

Vise Type

Thread Size

Body Height

Material

Clamping Surface Texture

Holding Capacity

Pipe Size

Length

Jaw Width

DFARS Specialty Metals

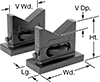

Fabricating and Machining

Fluid Handling

Material Handling

Measuring and Inspecting

Building and Machinery Hardware

Fastening and Joining

Power Transmission